设计简介

摘要

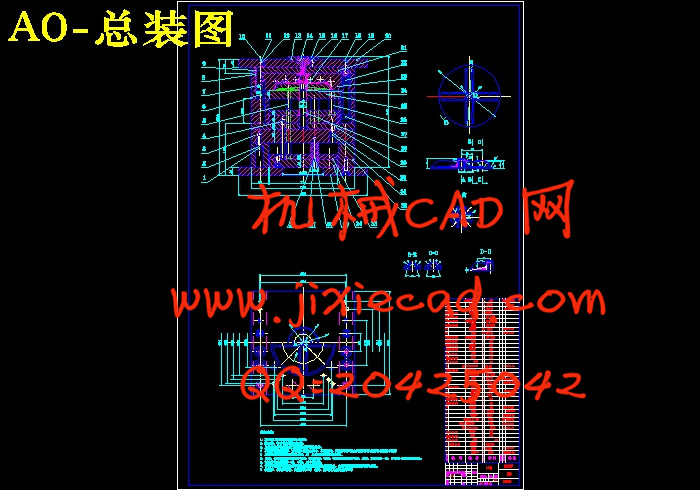

本模具为波轮注射模,结构形状分布均匀,以整体式的零件进行浇注,叶片不规则,表面为洗衣工作面,加工有一定困难~波轮精度较高,选用单腔;以推杆为主推管为辅的联合脱模方式;采用点浇口浇注系统。采用最简单的外连接直通式冷却水道,冷却剂用水。

进行脱模力计算以及成型零部件工作尺寸计算。

关键词:注射机,脱模力,推杆

目 录

第一章 对塑件进行工艺分析·························1

1.1分析塑件使用材料的种类及其工艺性··········································1

1.2分析塑件结构工艺性························································1

第二章选择注射机确定型腔数························2

2.1根据塑件的形状估算其体积和重··············································2

2.2选择设备型号规格,确定型腔数················································2

2.2.1注射机额定注射量·····················································2

2.2.2根据塑件精度确定型腔数···············································3

2.2.3根据生产批量确定型腔数···············································3

第三章确定成型方案································5

3.1确定成型位置······························································5

3.2确定分型面································································5

3.3脱模方式··································································5

3.4浇注系统形成······························································5

3.5冷却系统和加热系统考虑····················································5

3.6确定成形零部件的结构形式··················································5

第四章绘制结构方案草图····························7

4.1注射量的校核······························································7

4.2锁模力与型腔内平均压力、注射压力的校核····································7

4.3模具厚度与注射机闭合高度校核··············································9

4.4注射机开模行程····························································9

第五章计算与说明·································10

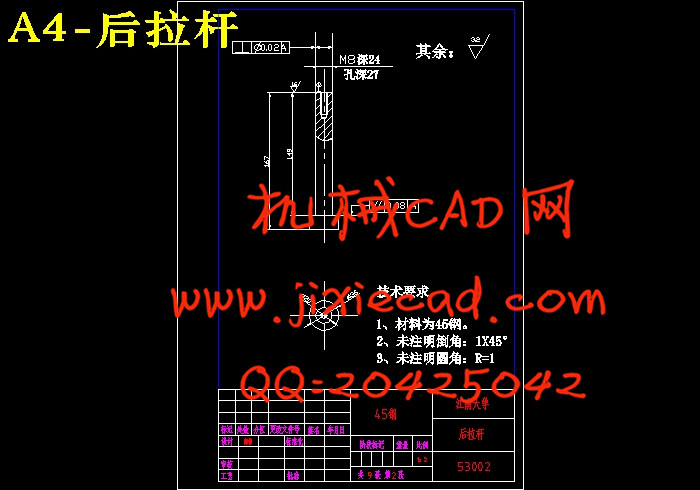

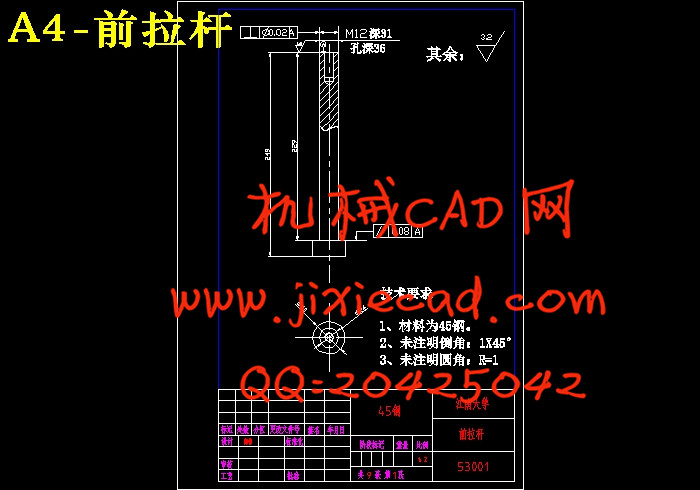

5.1脱模力计算·······························································10

5.1.1计算公式································································10

5.2成型零部件工作尺寸计算···················································10

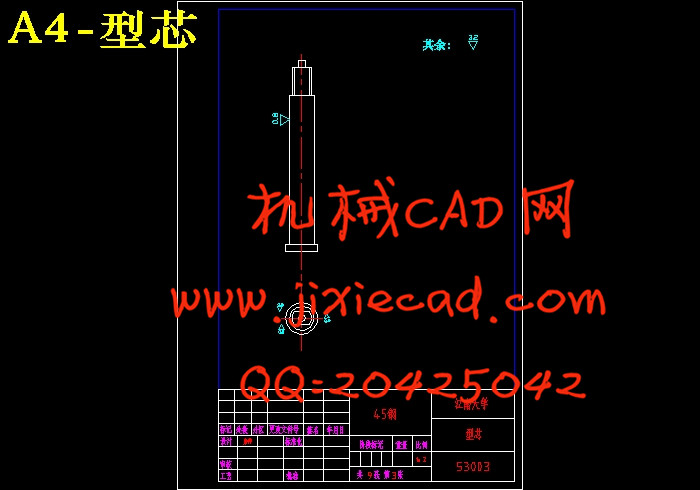

5.2.1定模、动模(型腔、型芯)选用材料··········································10

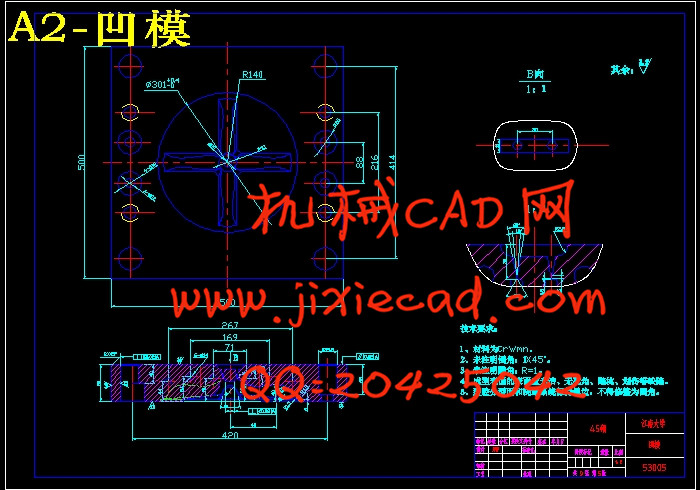

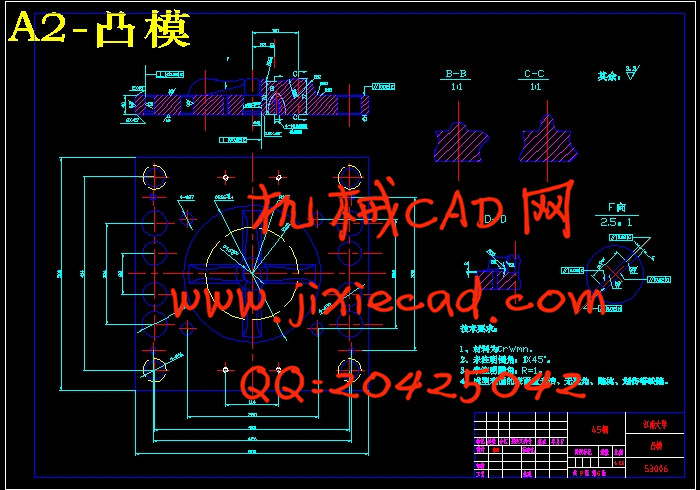

5.2.2型腔侧壁厚度和底版厚度确定··············································11

5.2.3型腔、型芯工作尺寸确定··················································12

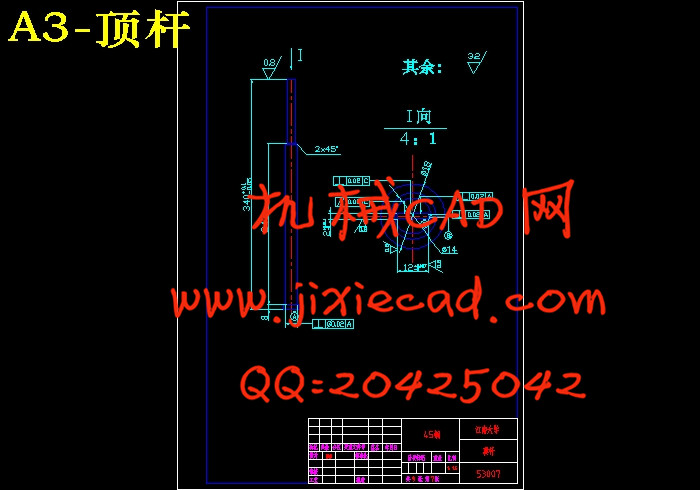

5.3推杆计算·································································17

5.3.1推杆选用材料····························································17

5.3.2计算推杆长度····························································17

5.4进行关键零件的强度和刚度校核··············································18

5.4.1推杆的强度和刚度的校核·················································18

5.4.2型腔型腔壁厚和底板厚度校核·············································20

总结········································································21

致谢········································································22

参考文献····································································23

本模具为波轮注射模,结构形状分布均匀,以整体式的零件进行浇注,叶片不规则,表面为洗衣工作面,加工有一定困难~波轮精度较高,选用单腔;以推杆为主推管为辅的联合脱模方式;采用点浇口浇注系统。采用最简单的外连接直通式冷却水道,冷却剂用水。

进行脱模力计算以及成型零部件工作尺寸计算。

关键词:注射机,脱模力,推杆

目 录

第一章 对塑件进行工艺分析·························1

1.1分析塑件使用材料的种类及其工艺性··········································1

1.2分析塑件结构工艺性························································1

第二章选择注射机确定型腔数························2

2.1根据塑件的形状估算其体积和重··············································2

2.2选择设备型号规格,确定型腔数················································2

2.2.1注射机额定注射量·····················································2

2.2.2根据塑件精度确定型腔数···············································3

2.2.3根据生产批量确定型腔数···············································3

第三章确定成型方案································5

3.1确定成型位置······························································5

3.2确定分型面································································5

3.3脱模方式··································································5

3.4浇注系统形成······························································5

3.5冷却系统和加热系统考虑····················································5

3.6确定成形零部件的结构形式··················································5

第四章绘制结构方案草图····························7

4.1注射量的校核······························································7

4.2锁模力与型腔内平均压力、注射压力的校核····································7

4.3模具厚度与注射机闭合高度校核··············································9

4.4注射机开模行程····························································9

第五章计算与说明·································10

5.1脱模力计算·······························································10

5.1.1计算公式································································10

5.2成型零部件工作尺寸计算···················································10

5.2.1定模、动模(型腔、型芯)选用材料··········································10

5.2.2型腔侧壁厚度和底版厚度确定··············································11

5.2.3型腔、型芯工作尺寸确定··················································12

5.3推杆计算·································································17

5.3.1推杆选用材料····························································17

5.3.2计算推杆长度····························································17

5.4进行关键零件的强度和刚度校核··············································18

5.4.1推杆的强度和刚度的校核·················································18

5.4.2型腔型腔壁厚和底板厚度校核·············································20

总结········································································21

致谢········································································22

参考文献····································································23