设计简介

摘 要

注射成型是在整个的制造业生产中都一直占有十分重要的位置。根据数据分析,注射成型的制品大约可以占到所有模具塑料制品总产量的三分之一,而注射模大约可以占塑料成型模具总数量的二分之一以上。注塑模具在其模具工业中的重要性可见一斑。并且现在,注塑模具的设计和制造中的传统方法早已经满足不了现代生产发展的需求。人们为了赢得竞争、占有市场、达到可持续发展,模具生产就必须变革传统的生产方法,从而引进新技术、新思维。

看计算机技术日新月异的今天,将计算机运用到注塑模具和制造业当中己经是迫在眉睫。此文的主要研究工作及成果如下:

l)此文具体地阐述了模具CAD的技术特点还有先进的制造模式在模具行业中的具体应用,在分析了国内、国际模具CAD的研究现状和发展趋势的基础上,提出了以计算机应用技术为手段的辅助型模具设计的新方法。

2)主要针对注塑模具中常见的成型方式进行了分析和研究,以求达到将注塑模设计过程智能化的目的。

3)在熟悉注塑模具设计基本知识的基础上,对于系统进行具体的分析并且得到具体系统的总体框架,了解到系统需要实现的功能,选择好设计工具。分析论述了模块设计注塑模具的关键技术。

4)通过对系统体系结构还有功能模块的具体分析,对于系统进行了功能的设计,划分了系统功能模块。分析了设计过程中所涉及到的具体内容以及系统的设计框架模型。

5)运用注塑模设计模块,例如成型零部件设计、脱模机构的设计、温度调节系统的设计、排气系统的设计等;

6) 运用自动分型、修补开口以及孔洞还有自动生成型芯跟型腔的方法。把握好镶块、抽芯以及脱模方向等几个关键问题 , 就可以实现比较复杂的塑料模具的快速设计。

7)用户利用本系统进行注塑模设计的时候,能够快速、方便、准确地查询和计算出所需设计参数。在模具设计过程中还可以修改或增减需要的内容来完善参数表中的内容,使软件更具有成长性,极大限度的利用已有的知识和以往的设计经验,避免重复的劳动,可以进一步的加快了对新模具的设计。它是模具设计快速化、智能化的重要技术手段。

关键词: CAD;模块; 快速准确; 塑料模具

注射成型是在整个的制造业生产中都一直占有十分重要的位置。根据数据分析,注射成型的制品大约可以占到所有模具塑料制品总产量的三分之一,而注射模大约可以占塑料成型模具总数量的二分之一以上。注塑模具在其模具工业中的重要性可见一斑。并且现在,注塑模具的设计和制造中的传统方法早已经满足不了现代生产发展的需求。人们为了赢得竞争、占有市场、达到可持续发展,模具生产就必须变革传统的生产方法,从而引进新技术、新思维。

看计算机技术日新月异的今天,将计算机运用到注塑模具和制造业当中己经是迫在眉睫。此文的主要研究工作及成果如下:

l)此文具体地阐述了模具CAD的技术特点还有先进的制造模式在模具行业中的具体应用,在分析了国内、国际模具CAD的研究现状和发展趋势的基础上,提出了以计算机应用技术为手段的辅助型模具设计的新方法。

2)主要针对注塑模具中常见的成型方式进行了分析和研究,以求达到将注塑模设计过程智能化的目的。

3)在熟悉注塑模具设计基本知识的基础上,对于系统进行具体的分析并且得到具体系统的总体框架,了解到系统需要实现的功能,选择好设计工具。分析论述了模块设计注塑模具的关键技术。

4)通过对系统体系结构还有功能模块的具体分析,对于系统进行了功能的设计,划分了系统功能模块。分析了设计过程中所涉及到的具体内容以及系统的设计框架模型。

5)运用注塑模设计模块,例如成型零部件设计、脱模机构的设计、温度调节系统的设计、排气系统的设计等;

6) 运用自动分型、修补开口以及孔洞还有自动生成型芯跟型腔的方法。把握好镶块、抽芯以及脱模方向等几个关键问题 , 就可以实现比较复杂的塑料模具的快速设计。

7)用户利用本系统进行注塑模设计的时候,能够快速、方便、准确地查询和计算出所需设计参数。在模具设计过程中还可以修改或增减需要的内容来完善参数表中的内容,使软件更具有成长性,极大限度的利用已有的知识和以往的设计经验,避免重复的劳动,可以进一步的加快了对新模具的设计。它是模具设计快速化、智能化的重要技术手段。

关键词: CAD;模块; 快速准确; 塑料模具

Abstract

Injection molding is a very important position in the whole manufacturing industry. According to the data analysis, injection molding products can be accounted for about 1/3 of the total production of all mold plastic products, and injection mold can be accounted for about 1/2 of the total number of plastic molding die. The importance of injection mold in the mold industry is evident. And now, the traditional method of the design and manufacture of injection mold can not meet the needs of the development of modern production. In order to win the competition, the market, the sustainable development, the mold production must change the traditional production method, thus the introduction of new technology, new thinking.

Look at today's computer technology with each passing day, the computer is applied to the injection mold and manufacturing industry which has been imminent. The main research work and results are as follows:

1) this article specifically describes the mold CAD technology characteristics and advanced manufacturing mode in the mold industry, the specific application, on the analysis of the research status and development trend of domestic and international mold CAD based, and puts forward the new method based on computer application technology assisted model is a means of fixture design.

2) mainly for common injection mold and molding method were analysis and research, in order to achieve the design of injection mould for the purpose of intelligent process.

3) familiar with the basic knowledge of injection mold design, based on the specific analysis of the system and get the overall framework of the specific system, to understand the system needs to achieve the function, choose a good design tools. The key technology of module design of injection mold is analyzed and discussed.

4) through the system architecture and functional modules of the specific analysis, the system for the design of the function, the division of the system function module. The specific content of the design process and the design framework of the system are analyzed.

5) based on the injection mold design module, such as design of molding parts, demoulding mechanism design, the temperature control system design, exhaust system design;

6) using automatic parting, repair openings and holes, as well as automatic generation of core and cavity. The rapid design of complex plastic mould can be realized by grasping the key problems such as insert block, core pulling and ejection direction.

7) users to use the system of injection mold design, can fast, easy and accurate to search and calculate the required design parameters. In the process of mould design can also modify or increase or decrease in the content to improve the parameters in the table of content, to make the software more growth, which greatly limits the use existing knowledge and previous experience in the design, to avoid duplication of work, can further speed up the new mold design. It is an important technical means for the rapid and intelligent mold design.

Key words:CAD; Module; Fast and Accurate; Plastics Mold

目 录

引言 1

第一章塑件工艺分析 1

1.1 材料分析 1

1.2 塑件的结构分析 1

1.3 制件的精度分析 2

1.4 粗糙度分析 3

1.5 脱模斜度 3

1.6 表面质量分析 4

第二章计算制件的体积和质量

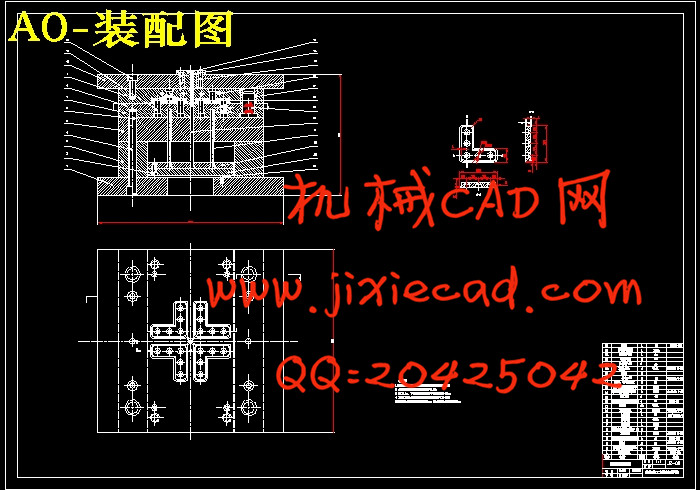

2.1 模具结构 5

2.2 初选注射机的型号 5

第三章确定塑件的工艺参数 7

第四章注射模的结构设计 8

4.1 型腔排列方式和它的数目的确定 8

4.2 分型面的选择 8

4.3 确定浇注系统 9

4.3.1 主注道的设计 10

4.3.2 分流道设计 11

4.3.3 分流道的尺寸和它的形状 11

4.3.4 浇口的设计 12

4.3.5 确定型腔型芯的固定形式和型腔型芯的结构 12

4.3.6 此次模具选取的是推杆一次推出机构 13

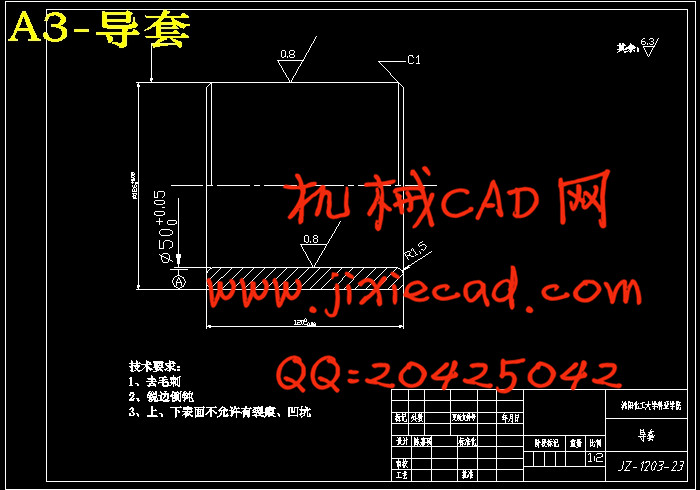

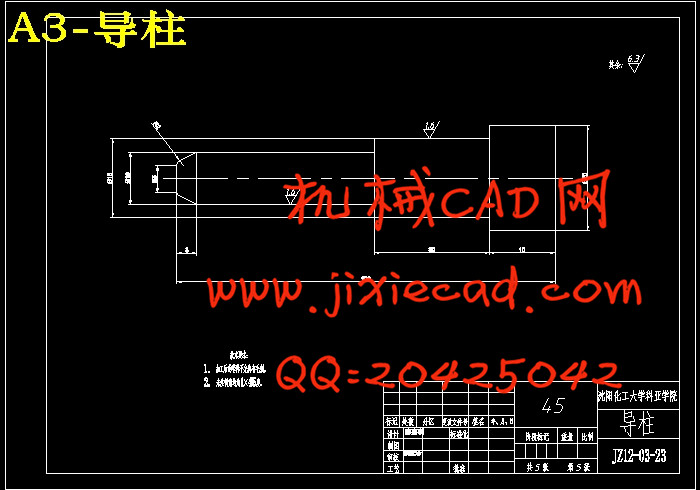

4.3.7 合模导向机构的设计 13

4.3.8 排气机构的设计 13

4.3.9 温度调节系统的设计 13

第五章有关模具的计算 14

5.1 模具工作尺寸的计算 14

5.1.1 计算型腔的经向尺寸 14

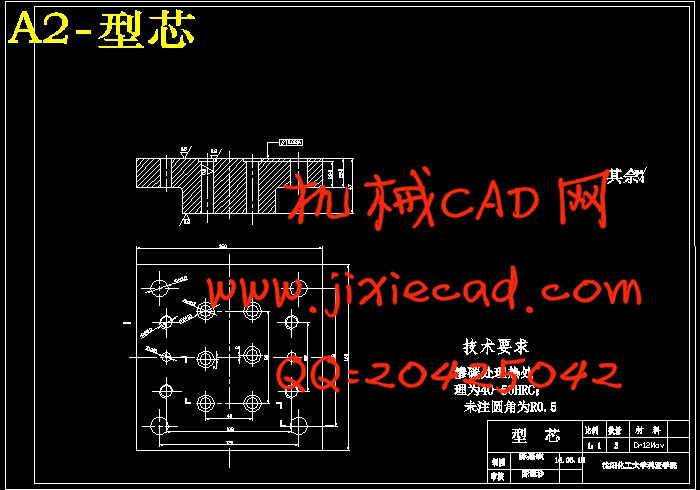

5.1.2 型芯经向尺寸的计算 15

5.1.3 型腔深度及型芯高度的计算 16

5.1.4 孔距的计算 16

5.1.5 型腔固定板周界尺寸的计算 17

第六章 注射机有关参数的校核 18

6.1 选用注射机 18

6.2 锁模力的校核 19

6.3 开模距离校核 19

6.4 模具外形尺寸的验查 20

6.5 开模行程的验查 20

第七章结束语 21

参考文献 23

4.3.5 确定型腔型芯的固定形式和型腔型芯的结构 12

4.3.6 此次模具选取的是推杆一次推出机构 13

4.3.7 合模导向机构的设计 13

4.3.8 排气机构的设计 13

4.3.9 温度调节系统的设计 13

第五章有关模具的计算 14

5.1 模具工作尺寸的计算 14

5.1.1 计算型腔的经向尺寸 14

5.1.2 型芯经向尺寸的计算 15

5.1.3 型腔深度及型芯高度的计算 16

5.1.4 孔距的计算 16

5.1.5 型腔固定板周界尺寸的计算 17

第六章 注射机有关参数的校核 18

6.1 选用注射机 18

6.2 锁模力的校核 19

6.3 开模距离校核 19

6.4 模具外形尺寸的验查 20

6.5 开模行程的验查 20

第七章结束语 21

参考文献 23

致谢 24