设计简介

摘要

随着我国家工业的高速稳定的发展,对模具工业,尤其是注塑模具带来了巨大的发展,带动了我国注塑模具的发展。2004年,注塑模具在在模具行业占到30%左右,据有关专家预测,在未来几年中,随着经济的快速发展,中国注塑模具工业还将以年均增长速度10%以上的速度快速发展。在国内注塑模具市场,工程注塑模具需求量最大。注射成型是塑料成型的一种常用的方法,适用于热塑性塑料的快速成型,可以一次成型形状复杂塑件。本设计题目为底板模具设计,主要涉及模具设计的相关知识以及和模具设计相关的CAD软件等相关专业得应用。通过对该模具的设计,进一步加强了对注塑模具设计的基础知识掌握,为设计更复杂的注塑模具做好铺垫和吸取了更深刻的经验。

在设计之前,要具备机械制图,公差与技术测量,模具制造工艺,塑料成型工艺及模具设计等方面必要的基础知识和专业知识,初步了解塑件的成型工艺和生产过程,熟习各种注塑模具的结构。综合运用注塑模具设计,机械制图,互换性与技术测量673A械原理及零件,模具材料及热处理,模具制造工艺,塑料成型工艺及模具设计等方面必要的基础知识和专业知识,分析和解决注塑模具设计问题,进一步巩固加深和开拓所学的知识。通过设计实践,逐步树立正确的设计思想,增强创新意识和竞争意识,基本掌握注塑模具的一般规律,培养分析问题和解决问题的能力。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算塑料的体积,便于选取注塑机及确定型腔数量;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的选取。

关键词:注塑模具;注射成型; 模具设计

Abstract

In recent years, the rapid development of our country's industry, the mold industry, especially plastic mold put forward more and more high requirements. In 2004, plastic mold in in mold industry accounted for about 30%, according to the relevant experts predict, in the next few years, with the rapid development of economy, China plastic mold industry will also with an average annual growth rate of more than 10% of the speed of rapid development. In the domestic plastic mold market, engineering plastic mold demand is the largest. Injection molding is an important method of plastic molding, it is mainly applicable to thermoplastic plastic molding, can be a complex shape of precision plastic parts. This design topic for the bottom plate mold design, mainly related to the design of the mold related knowledge and mold design and related to the application of CAD software and other related professional. Through the design of the mold, to further strengthen the injection mold design of the basic knowledge to master, for the design of more sophisticated injection mold to pave the way and draw a more profound experience.

Before the design, it is necessary to have a mechanical drawing, tolerance and technical measurement, mold manufacturing process, plastic molding process and mold design and other aspects the necessary basic knowledge and professional knowledge, a preliminary understanding of plastic forming technology and production process, familiar with all kinds of plastic mold structure.

The integrated use of plastic mold design, mechanical drawing, swap and technical measurement 673A mechanical principle of parts and components, material and heat treatment of die and mold, mold manufacturing process, plastic molding process and mold design and other aspects the necessary basic knowledge and professional knowledge, analysis and to solve the problem of plastic mold design, to further consolidate and deepen and develop the theory of knowledge.

Through the design practice, gradually establish the correct design ideas, enhance the sense of innovation and competition, the basic grasp of the general law of plastic mold, the ability to analyze and solve problems.

The design using the basic knowledge of plastic molding process and mold design, the first analysis of plastic parts of the composition and performance requirements, prepare for the selection of the type of the gate; and then estimate the plastic volume, easy selection of injection molding machines and determine the number of cavity is analysed. Finally, the plastic parts, determine the characteristics of mold design parameters, design points and launch device selection.

Key words: plastic mold ;injection ;mold design

目录

绪论 1

第一章 模具的设计背景 2

1.1模具设计背景 2

第二章 塑件的工艺性分析 4

2.1塑件的成型工艺性分析 4

2.1.1原料:低密度聚乙烯(LDPE) 4

2.1.2塑件的结构分析 4

2.1.3制件的精度分析 5

2.1.4脱模斜度 5

2.1.5结论 5

2.2塑料成型工艺参数 5

2.3塑件的结构、尺寸精度及表面质量分析 6

2.3.1结构分析 6

2.3.2 尺寸精度分析 6

2.3.3 表面质量分析 6

2.4计算塑件的体积和质量 6

第三章 注塑模的结构设计 8

3.1分型面的选择 8

3.2确定型腔数目及布置 8

3.3浇注系统的设计 9

3.3.1浇注系统的组成 9

3.3.2主流道的设计 9

3.3.3浇口套的设计 10

3.3.4分流道的设计 11

3.3.5浇口的设计 11

3.3.6冷料穴 11

3.3.7调温系统 11

3.3.8功能特性 12

3.3.9排气方式 13

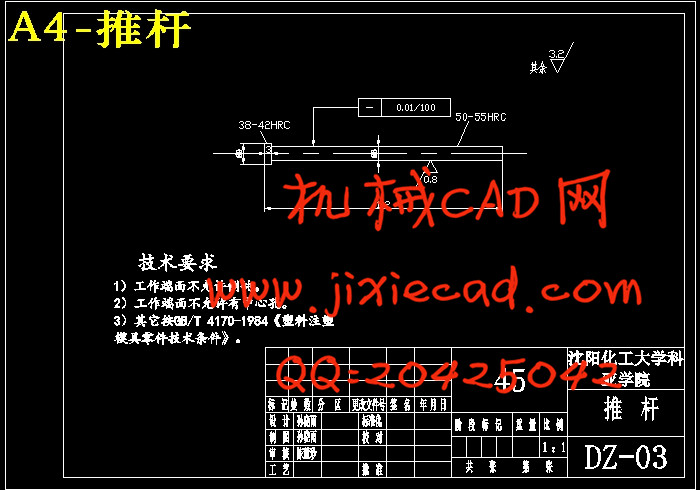

3.4推出机构设计 13

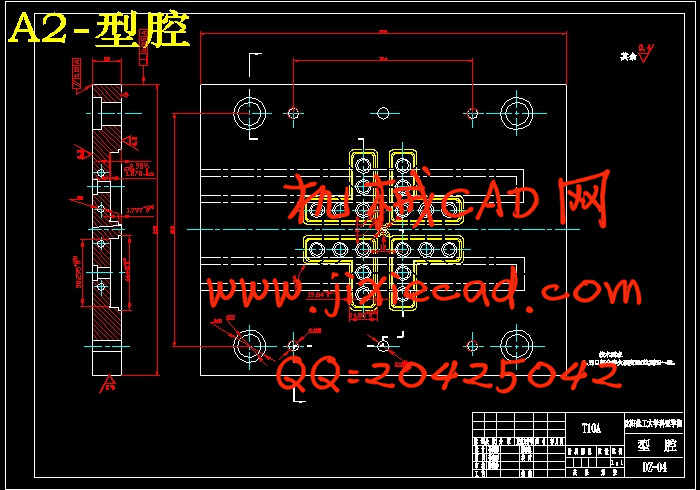

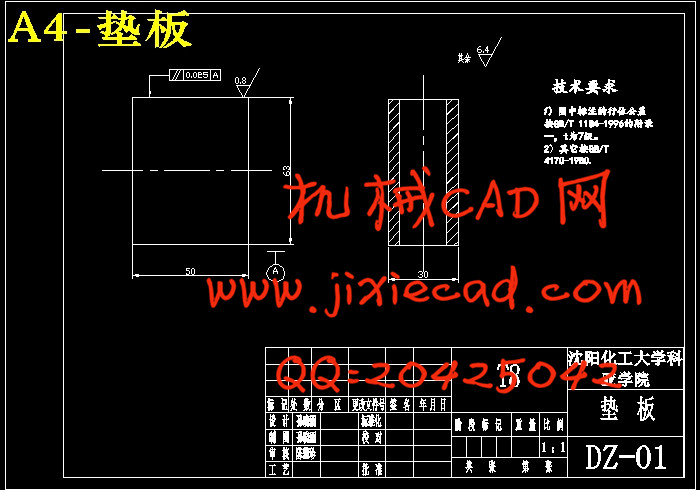

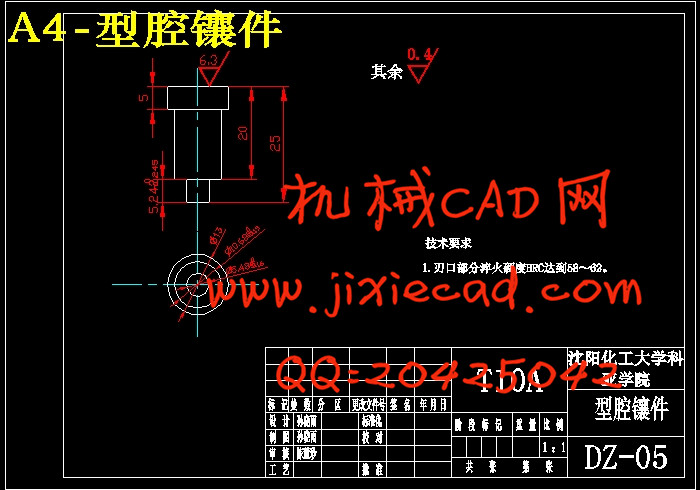

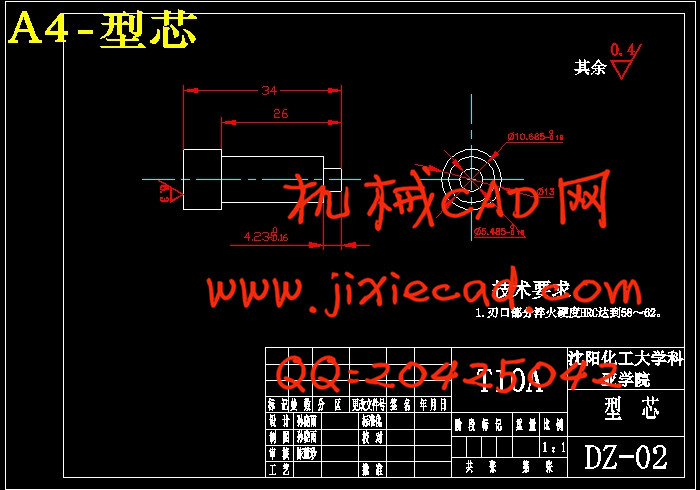

3.5成型零部件的设计 14

3.6模架的选择 15

第四章 成型设备的选择及有关参数的计算 17

4.1注射机的选择 17

4.2锁模力的计算 18

第五章模具成型零件工作尺寸的计算 20

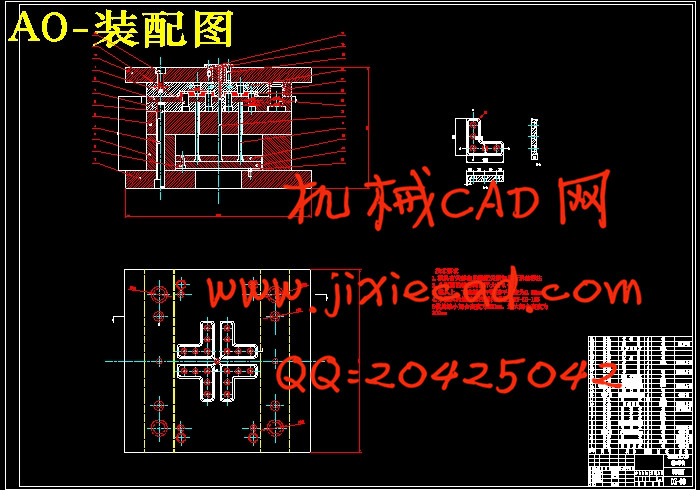

第六章 绘制模具总装图 22

总结 23

致谢 24

参考文献 25

随着我国家工业的高速稳定的发展,对模具工业,尤其是注塑模具带来了巨大的发展,带动了我国注塑模具的发展。2004年,注塑模具在在模具行业占到30%左右,据有关专家预测,在未来几年中,随着经济的快速发展,中国注塑模具工业还将以年均增长速度10%以上的速度快速发展。在国内注塑模具市场,工程注塑模具需求量最大。注射成型是塑料成型的一种常用的方法,适用于热塑性塑料的快速成型,可以一次成型形状复杂塑件。本设计题目为底板模具设计,主要涉及模具设计的相关知识以及和模具设计相关的CAD软件等相关专业得应用。通过对该模具的设计,进一步加强了对注塑模具设计的基础知识掌握,为设计更复杂的注塑模具做好铺垫和吸取了更深刻的经验。

在设计之前,要具备机械制图,公差与技术测量,模具制造工艺,塑料成型工艺及模具设计等方面必要的基础知识和专业知识,初步了解塑件的成型工艺和生产过程,熟习各种注塑模具的结构。综合运用注塑模具设计,机械制图,互换性与技术测量673A械原理及零件,模具材料及热处理,模具制造工艺,塑料成型工艺及模具设计等方面必要的基础知识和专业知识,分析和解决注塑模具设计问题,进一步巩固加深和开拓所学的知识。通过设计实践,逐步树立正确的设计思想,增强创新意识和竞争意识,基本掌握注塑模具的一般规律,培养分析问题和解决问题的能力。

本设计运用塑料成型工艺及模具设计的基础知识,首先分析塑件的成分及性能要求,为选取浇口的类型做好了准备;然后估算塑料的体积,便于选取注塑机及确定型腔数量;最后分析了塑件的特征,确定模具的设计参数、设计要点及推出装置的选取。

关键词:注塑模具;注射成型; 模具设计

Abstract

In recent years, the rapid development of our country's industry, the mold industry, especially plastic mold put forward more and more high requirements. In 2004, plastic mold in in mold industry accounted for about 30%, according to the relevant experts predict, in the next few years, with the rapid development of economy, China plastic mold industry will also with an average annual growth rate of more than 10% of the speed of rapid development. In the domestic plastic mold market, engineering plastic mold demand is the largest. Injection molding is an important method of plastic molding, it is mainly applicable to thermoplastic plastic molding, can be a complex shape of precision plastic parts. This design topic for the bottom plate mold design, mainly related to the design of the mold related knowledge and mold design and related to the application of CAD software and other related professional. Through the design of the mold, to further strengthen the injection mold design of the basic knowledge to master, for the design of more sophisticated injection mold to pave the way and draw a more profound experience.

Before the design, it is necessary to have a mechanical drawing, tolerance and technical measurement, mold manufacturing process, plastic molding process and mold design and other aspects the necessary basic knowledge and professional knowledge, a preliminary understanding of plastic forming technology and production process, familiar with all kinds of plastic mold structure.

The integrated use of plastic mold design, mechanical drawing, swap and technical measurement 673A mechanical principle of parts and components, material and heat treatment of die and mold, mold manufacturing process, plastic molding process and mold design and other aspects the necessary basic knowledge and professional knowledge, analysis and to solve the problem of plastic mold design, to further consolidate and deepen and develop the theory of knowledge.

Through the design practice, gradually establish the correct design ideas, enhance the sense of innovation and competition, the basic grasp of the general law of plastic mold, the ability to analyze and solve problems.

The design using the basic knowledge of plastic molding process and mold design, the first analysis of plastic parts of the composition and performance requirements, prepare for the selection of the type of the gate; and then estimate the plastic volume, easy selection of injection molding machines and determine the number of cavity is analysed. Finally, the plastic parts, determine the characteristics of mold design parameters, design points and launch device selection.

Key words: plastic mold ;injection ;mold design

目录

绪论 1

第一章 模具的设计背景 2

1.1模具设计背景 2

第二章 塑件的工艺性分析 4

2.1塑件的成型工艺性分析 4

2.1.1原料:低密度聚乙烯(LDPE) 4

2.1.2塑件的结构分析 4

2.1.3制件的精度分析 5

2.1.4脱模斜度 5

2.1.5结论 5

2.2塑料成型工艺参数 5

2.3塑件的结构、尺寸精度及表面质量分析 6

2.3.1结构分析 6

2.3.2 尺寸精度分析 6

2.3.3 表面质量分析 6

2.4计算塑件的体积和质量 6

第三章 注塑模的结构设计 8

3.1分型面的选择 8

3.2确定型腔数目及布置 8

3.3浇注系统的设计 9

3.3.1浇注系统的组成 9

3.3.2主流道的设计 9

3.3.3浇口套的设计 10

3.3.4分流道的设计 11

3.3.5浇口的设计 11

3.3.6冷料穴 11

3.3.7调温系统 11

3.3.8功能特性 12

3.3.9排气方式 13

3.4推出机构设计 13

3.5成型零部件的设计 14

3.6模架的选择 15

第四章 成型设备的选择及有关参数的计算 17

4.1注射机的选择 17

4.2锁模力的计算 18

第五章模具成型零件工作尺寸的计算 20

第六章 绘制模具总装图 22

总结 23

致谢 24

参考文献 25