设计简介

摘 要

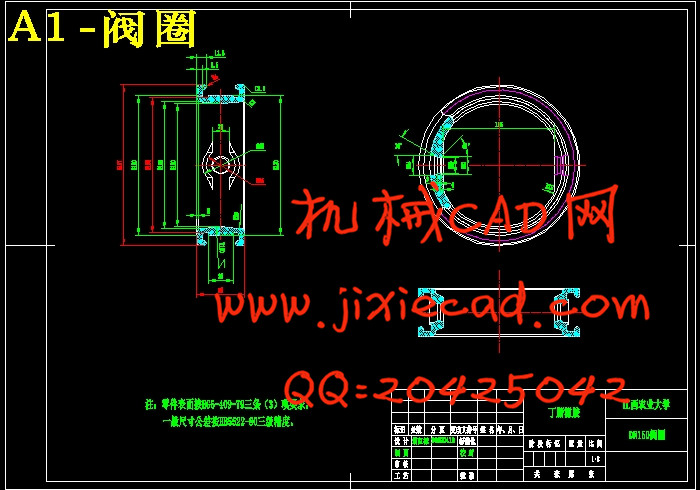

DN150阀圈作为一种常见的中心型蝶阀的组成部分,其主要作用表现在阀圈的密封性方面,属于橡胶产品,该类产品的成形需要经过的一个重要的过程是橡胶的硫化,硫化是塑性状态的生胶在压力、温度、时间三要素的作用下形成有弹性状态的橡胶制品的过程,而该过程就是在模具中完成,该类模具称为橡胶模具,橡胶模具的分类有四大类:橡胶压模,橡胶传递模,橡胶注压模和橡胶挤出模。根据该设计的产品形状结构分析可知该产品模具适合选用橡胶压模。

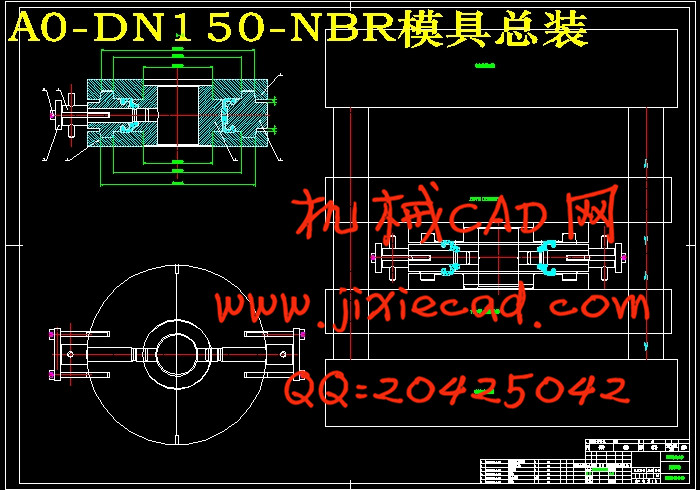

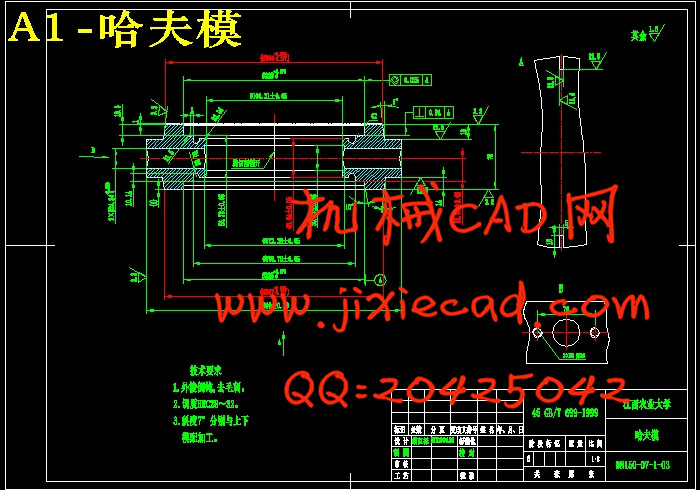

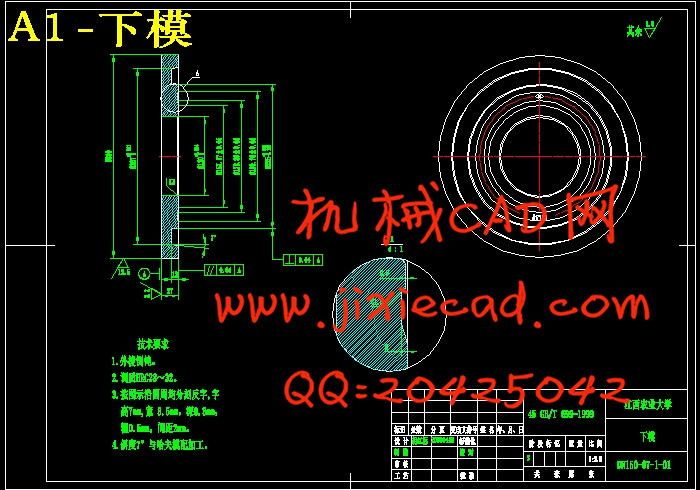

本设计就是为了DN150产品进行的模具设计过程,其主要包括模具结构的确定,分型面的选择,以及模具的其他结构的设计。

模具设计是一种经验性很强的设计,是在长期积累的经验和知识对模具设计起着重要的影响。积累一些关于模具设计的经验和知识。增强感性认识。

关键词: 橡胶 DN150阀圈 硫化的三要素 橡胶模具 橡胶压模

The design of DN150 Valve laps mould

Abstract:

DN150 Valve laps as a common Marine center part of the valve, the main function of sealing performance in valve laps, rubber product, this product belongs to the forming of an important process through the rubber vulcanization, plastic state is born of vulcanized rubber in pressure, temperature, time, three elements formed under the condition of elastic rubber process, and the process is completed in mold, the mould called rubber mold, rubber mold is classified into four categories: rubber, rubber mold transfer molding, rubber injection mould and rubber extrusion dies. According to the design of the product, the product shape structure analysis for select rubber mold pressing dies。

This product is designed for DN150 Valve laps for mould design process, it mainly includes the mould structure, the choice of the mold, and the structural design of the other。

Mould design is a kind of strong design, is critical in long-term accumulate experience and knowledge for mould design plays an important influence. Some of the mould design accumulate experience and knowledge. Enhance perceptual knowledge。

Key words:

Rubber DN150 valve laps Three key element of vulcanization

rubber mold Rubber molding

目 录

序言 ·······························································1

设计任务和设计要求·············································2

第一部分 橡胶模具的分类及最优方案选择·······························5

一、 模具的类型及特点·············································5

二、 模具设计的最优方案分析·······································6

三、 几种典型的压模结构与分析·····································6

四、 模腔数的确定·················································7

五、 分型面的选择··················································8

六、 余料槽的选择·················································11

(1)余料槽是否与大气沟通的几条原则·····························11

(2)无须设置余料槽的情况·······································11

七、启模口的设计···················································12

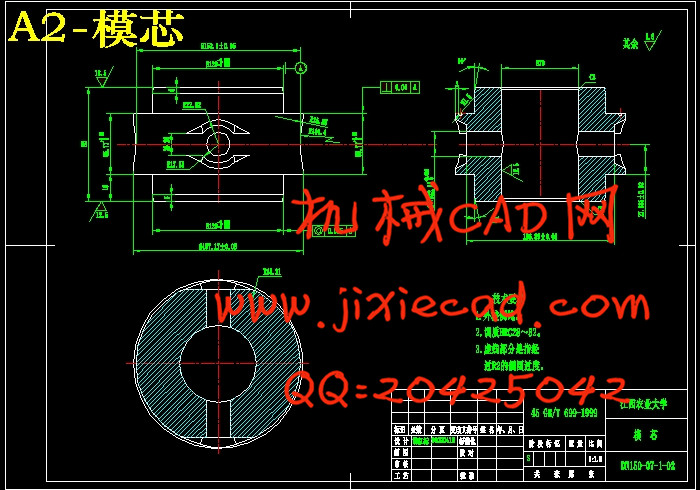

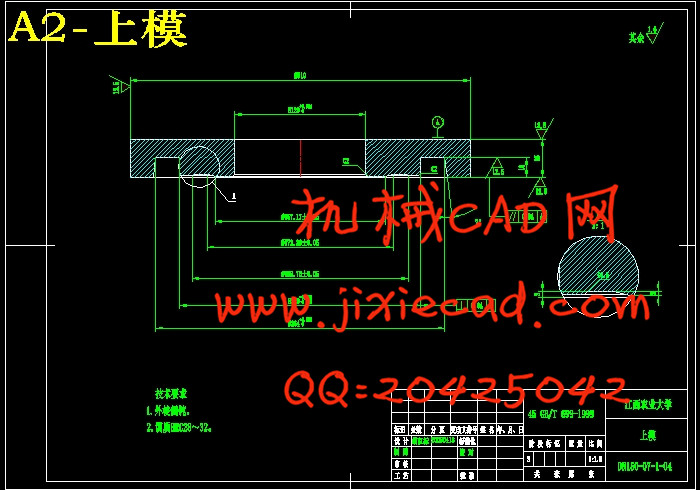

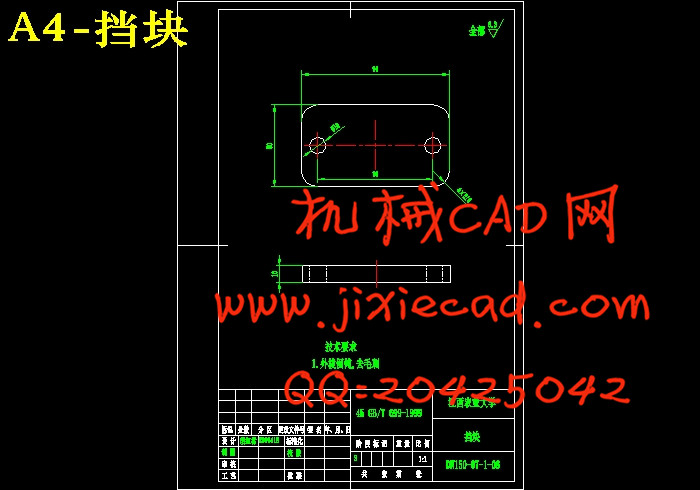

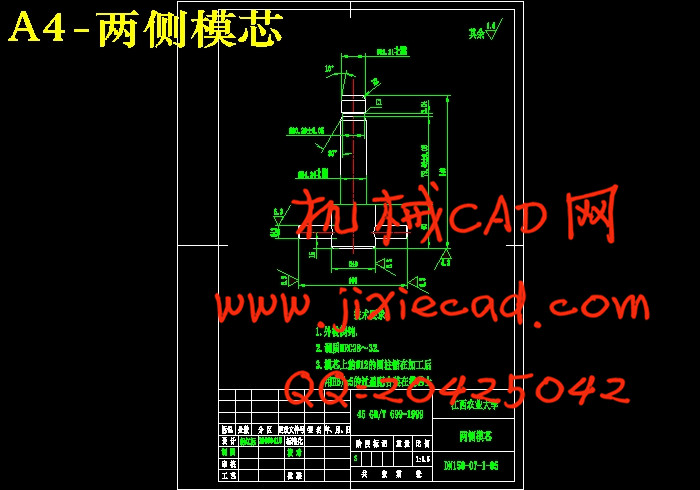

第二部分 模具设计················································13

模腔尺寸的确定及计算·········································14

模具外形尺寸的确定··········································15

三、 模具零件的精度选择··········································16

四、 模具粗糙度选择···············································17

第三部分 模具的选材与校核·········································18

毕业设计总结······················································21

参考文献··························································22

DN150阀圈作为一种常见的中心型蝶阀的组成部分,其主要作用表现在阀圈的密封性方面,属于橡胶产品,该类产品的成形需要经过的一个重要的过程是橡胶的硫化,硫化是塑性状态的生胶在压力、温度、时间三要素的作用下形成有弹性状态的橡胶制品的过程,而该过程就是在模具中完成,该类模具称为橡胶模具,橡胶模具的分类有四大类:橡胶压模,橡胶传递模,橡胶注压模和橡胶挤出模。根据该设计的产品形状结构分析可知该产品模具适合选用橡胶压模。

本设计就是为了DN150产品进行的模具设计过程,其主要包括模具结构的确定,分型面的选择,以及模具的其他结构的设计。

模具设计是一种经验性很强的设计,是在长期积累的经验和知识对模具设计起着重要的影响。积累一些关于模具设计的经验和知识。增强感性认识。

关键词: 橡胶 DN150阀圈 硫化的三要素 橡胶模具 橡胶压模

The design of DN150 Valve laps mould

Abstract:

DN150 Valve laps as a common Marine center part of the valve, the main function of sealing performance in valve laps, rubber product, this product belongs to the forming of an important process through the rubber vulcanization, plastic state is born of vulcanized rubber in pressure, temperature, time, three elements formed under the condition of elastic rubber process, and the process is completed in mold, the mould called rubber mold, rubber mold is classified into four categories: rubber, rubber mold transfer molding, rubber injection mould and rubber extrusion dies. According to the design of the product, the product shape structure analysis for select rubber mold pressing dies。

This product is designed for DN150 Valve laps for mould design process, it mainly includes the mould structure, the choice of the mold, and the structural design of the other。

Mould design is a kind of strong design, is critical in long-term accumulate experience and knowledge for mould design plays an important influence. Some of the mould design accumulate experience and knowledge. Enhance perceptual knowledge。

Key words:

Rubber DN150 valve laps Three key element of vulcanization

rubber mold Rubber molding

目 录

序言 ·······························································1

设计任务和设计要求·············································2

第一部分 橡胶模具的分类及最优方案选择·······························5

一、 模具的类型及特点·············································5

二、 模具设计的最优方案分析·······································6

三、 几种典型的压模结构与分析·····································6

四、 模腔数的确定·················································7

五、 分型面的选择··················································8

六、 余料槽的选择·················································11

(1)余料槽是否与大气沟通的几条原则·····························11

(2)无须设置余料槽的情况·······································11

七、启模口的设计···················································12

第二部分 模具设计················································13

模腔尺寸的确定及计算·········································14

模具外形尺寸的确定··········································15

三、 模具零件的精度选择··········································16

四、 模具粗糙度选择···············································17

第三部分 模具的选材与校核·········································18

毕业设计总结······················································21

参考文献··························································22