设计简介

摘 要

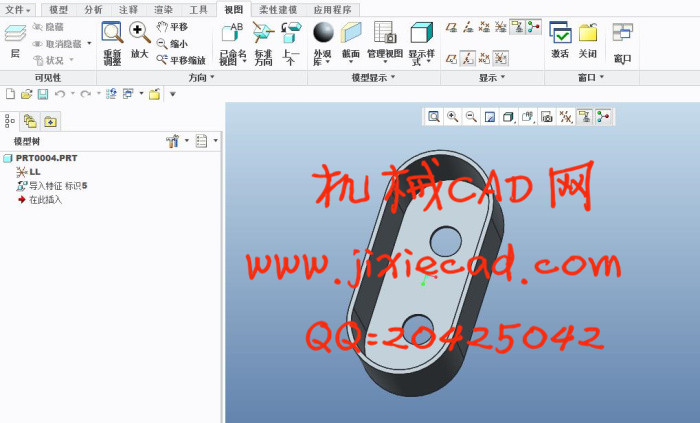

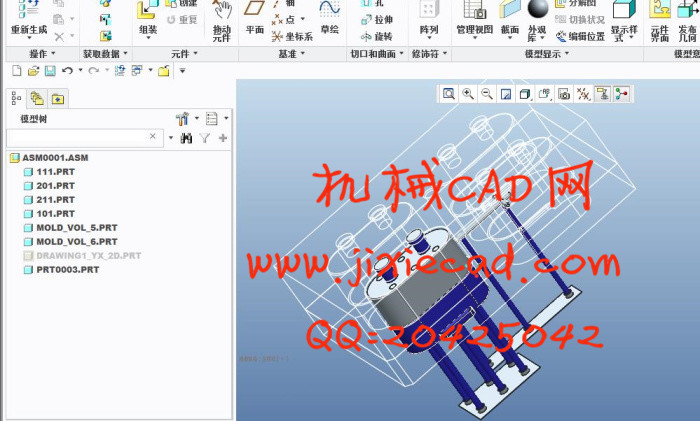

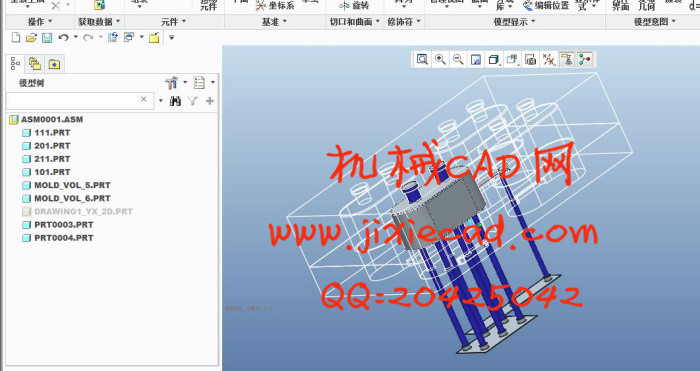

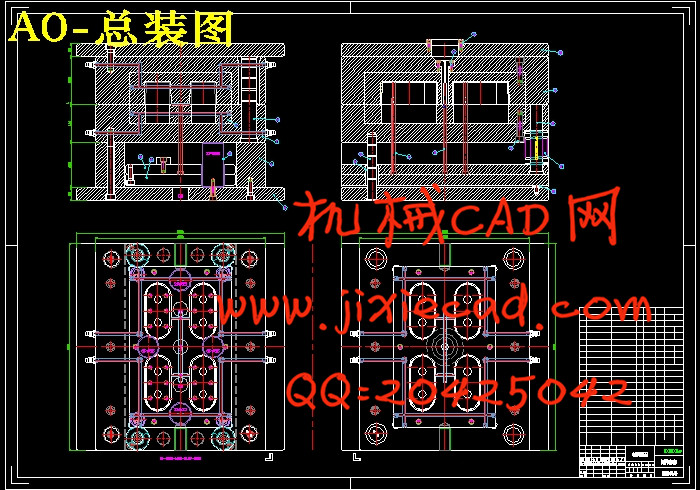

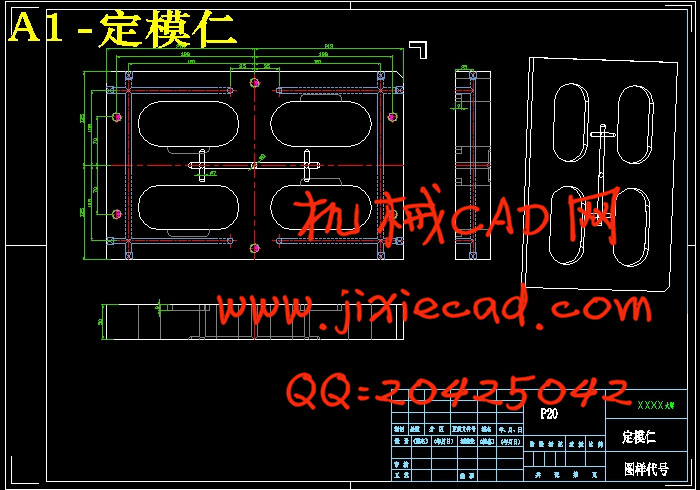

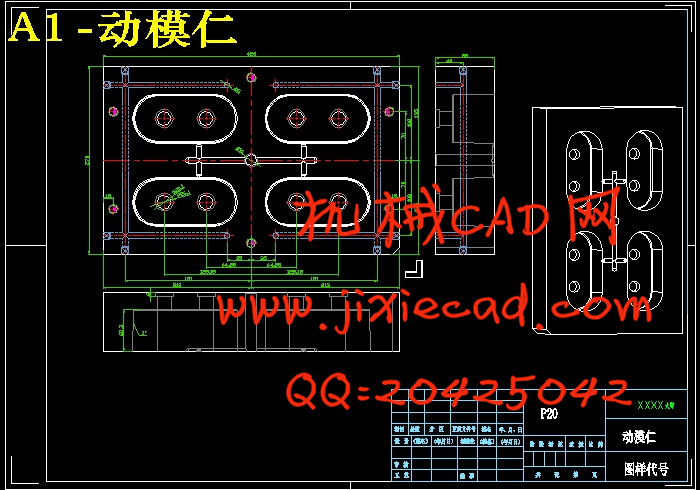

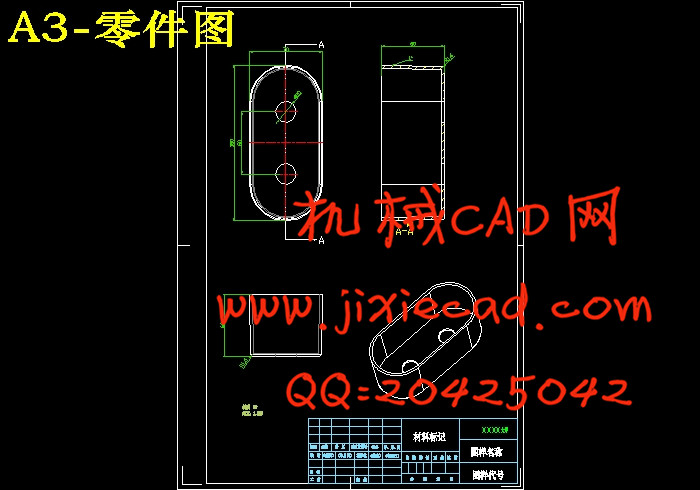

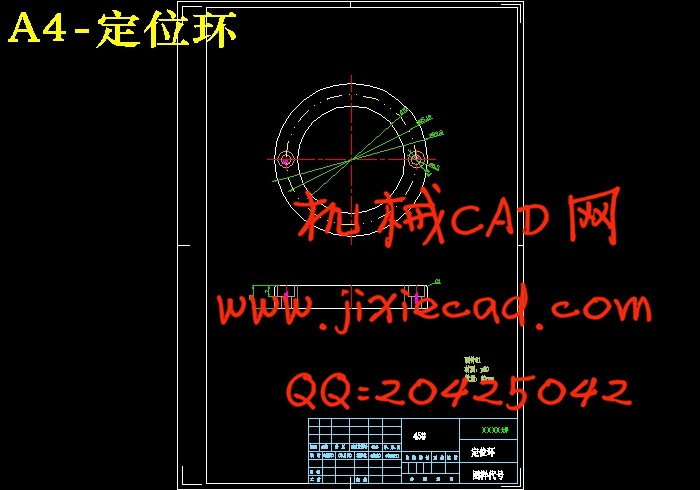

塑料是一种可塑性的合成高分子材料,具有重量轻且坚固,耐化学腐蚀, 电绝缘性好,价格便宜,可塑性好等特点,广泛应用于电脑、手机、汽车、电机、 电器、家电和通讯产品制造中。 注塑成形是成形塑件的主要方法之一, 是指使用注塑机将热塑性塑料熔体在 高压下注入到模具内经冷却固化获得产品的方法。注塑的优点是生产速度快,效 率高,操作可自动化,能成型形状复杂的零件,特别适合大量生产。 本次课程设计的产品为电源按键,具有重量轻,强度高,耐腐蚀,易清洁等 特点,为大批量生产产品。本次设计在针对产品进行工艺性分析后,确定模具分 型面、 型腔数目、 浇口形式、 位置大小; 其中最重要的是确定型芯和型腔的结构, 以及它们的定位和紧固方式。此外还进行了脱模机构的设计,合模导向机构的设 计,冷却系统的设计等。最后绘制完整的模具装配总图和主要的模具零件图及编 制成型零部件的制造加工工艺过程卡片。实践证明:该模具结构合理、可靠,并 能保证产品质量,对此类注塑产品的模具设计有参考价值。

关键词:塑料 , 注塑成形 , 模具设计

Abstract

Plastic is a synthetic polymer material , with the characteristics of plasticity, light weight, sturdiness, electrical insulation, and which is resistance to chemical corrosion and cheap. It is widely used in computers, mobile phones, cars, motors, electrical, home appliances and communication products manufacturing. Injection molding is one of the main methods of forming plastic parts, it refers to the use of plastic injection machine to inject the thermoplastic melts into the mold under high pressure , after cooled to obtain the products . It has the advantage of fast production speed , high production efficiency , and automated operations , it can form the shape of complex parts, particularly suitable for mass production. The production of graduation project is power button , which has a light weight , high strength , corrosion resistance and easy cleaning features for mass production . After analysis the process of the product , the mold parting line , cavity number , gate form , gate location can be determined , one of the most important is to identify core and cavity structures , as well as their positioning and fastening methods. In addition, it also carries out the design of stripping agencies , mold-oriented organizations and the cooling system .At last, draw a complete mold assembly drawing , major parts diagram , and draw up cards of parts manufacturing and processing process . It is proved that the mold structure is reasonable , reliable and can guarantee product quality , and is valuable for the injection mold design of such products .

Key Words: Plastic , Injection molding , Mold design

目 录

1、工艺性分析………………………………………………………(1)

2、确定型腔数目…………………………………………………… (1)

3、型腔、型芯工作部位尺寸的确定………………………………(1)

4、浇注系统的设计………………………………………………… (3)

5、选用模架………………………………………………………… (4)

6、校核注射机 ………………………………………………………(5)

7、推出结构设计 ……………………………………………………(5)

8、冷却系统的设计 …………………………………………………(6)

9、排气系统的设计 …………………………………………………(6)

10、总 结 ……………………………………………………………(9)

11、参考文献 ………………………………………………………(10)