设计简介

防尘塑料帽的模具设计与制造

中文摘要

随着现代工业发展的需要,塑料制品在工业、农业和日常生活等各个领域的应用越来越广泛,质量要求也越来越高。在塑料制品的生产中,高质量的模具设计、先进的模具制造设备、合理的加工工艺、优质的模具材料和现代化的成形设备等都是成形优质塑料的重要条件。

特别是近年来,随着塑料工业的飞速发展和通用与工程塑料在强度和精度等方面的不断提高,塑料制品的应用范围也在不断扩大,如:家用电器、仪器仪表,建筑器材,汽车工业、日用五金等众多领域,塑料制品所占的比例正迅猛增加。一个设计合理的塑料件往往能代替多个传统金属件。工业产品和日用产品塑料化的趋势不断上升。在工业生产中,用各种压力机和装在压力机上的专用工具,通过压力把金属或非金属材料制出所需要形状的零件或制品,这种专用工具统称模具。

模具在国民经济中所占据的地位日益显著,可以说人类的衣、食、住、行,没有拿一方面离得开模具。模具是机械、汽车、电子、通讯、家电等工业产品的基础工艺装备,属于高新技术产品。作为基础工业,模具的质量、精度、寿命对其他工业的发展起着十分重要的作用,在国际上称为“工业之母”。随着我国国民经济的迅速发展,作为工业品基础的模具工业,也得到了蓬勃发展,已成为国民经济建设中的重要产业。模具工业不但在国民经济中占据重要地位,在世界市场上也是独树一帜。世界模具市场总体上供不应求,市场需求在600到650亿美元。如今,模具工业的发展甚至已经超过了新兴的电子工业。

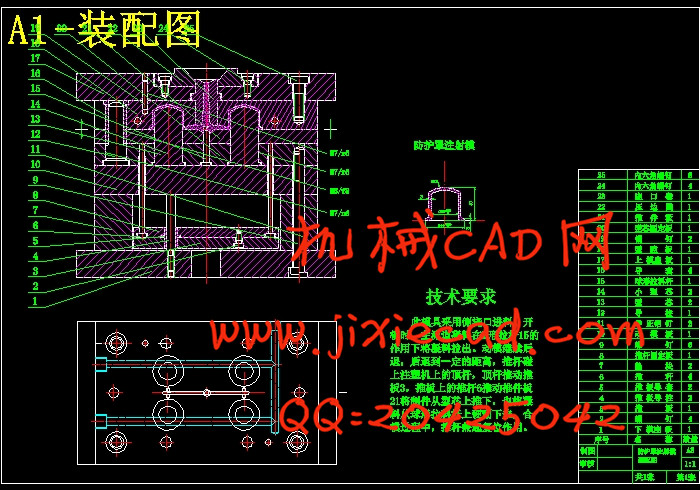

模具按制造的产品分类,可以分为塑料模具(又分为注塑模具、铸压模具和吹塑模具)、冲压模具、铸造模具、橡胶模具和玻璃模具等。其中,尤以注塑模具和冲压模具用途广、技术成熟、占据的比重大。本文以防尘塑料帽的模具设计为例,详细论述塑料的工艺特性、ABS塑料的工艺参数、型腔和型芯的结构形式、模具的机构设计、模架的选择原则,力求做到理论联系实际和反映国内外先进水平。

关键词:塑料特性、型芯和型腔结构、模具结构、标准模架

Shields mold design and manufacture

English Abstract

With modern industrial development needs in the plastics industry, agriculture and daily life, and other fields of application become wider, and more high-quality requirements. Plastic products in the production of high-quality die design, advanced mold manufacturing equipment and reasonable processing, high-quality materials and modern mould forming equipment are forming an important condition for high quality plastics.

Especially in recent years, with the rapid development of the plastics industry, and GM and engineering plastics in areas such as strength and accuracy of the continuous enhancement of the scope of the application of plastic products is growing, such as: household appliances, instrumentation, construction equipment, automotive industry , the daily hardware, and many other fields, the proportion of plastic products is rapidly increasing. A rational design of plastic parts can often replace more than traditional metal pieces. Industrial products and plastic products daily and the trend is rising. In the industrial production and various press installed in the press and on the special instruments, through pressure on the metal or non-metallic materials produced by the need to shape parts or products, such special instruments collectively die.

Die in the national economy in the occupied status is increasingly significant, it can be said of human clothing, food, housing, transportation, not with one hand Chideikai die. Die those in the machinery, automotive, electronics, telecommunications, household appliances, and other industrial products based process equipment, high-tech products are. As basic industries, the quality of molds, precision, life on other industrial development plays an important role in the international community as "the mother of industry." With the rapid development of China's national economy, as the basis of industrial tooling industry, has also been vigorous development of the national economy has become an important industry in the building. Tooling industry in the national economy not only occupy an important position in the world market is also unique. World Die overall market demand, the market demand in the 600 to 65 billion US dollars. Today, the development of mould industry has exceeded even the emerging electronics industry.

Die by manufacturing the product category, can be divided into plastic molds (also divided into injection mold, pressure die casting and blow mould

), stamping dies, die casting, rubber molds and mold, and other glass. Among them, especially injection molds and stamping die-use, technological maturity, which hold the majority. This paper shields to prevent the mold design for example, discussed in detail the process of plastic, ABS plastics processing parameters, cavity and core structural forms Die Design, mode-choice principles, and strive to do with reality and theory reflect the advanced level both at home and abroad.

Key words: plastic characteristics of core and cavity structure, die structure, the standard mold base

目 录中文摘要

随着现代工业发展的需要,塑料制品在工业、农业和日常生活等各个领域的应用越来越广泛,质量要求也越来越高。在塑料制品的生产中,高质量的模具设计、先进的模具制造设备、合理的加工工艺、优质的模具材料和现代化的成形设备等都是成形优质塑料的重要条件。

特别是近年来,随着塑料工业的飞速发展和通用与工程塑料在强度和精度等方面的不断提高,塑料制品的应用范围也在不断扩大,如:家用电器、仪器仪表,建筑器材,汽车工业、日用五金等众多领域,塑料制品所占的比例正迅猛增加。一个设计合理的塑料件往往能代替多个传统金属件。工业产品和日用产品塑料化的趋势不断上升。在工业生产中,用各种压力机和装在压力机上的专用工具,通过压力把金属或非金属材料制出所需要形状的零件或制品,这种专用工具统称模具。

模具在国民经济中所占据的地位日益显著,可以说人类的衣、食、住、行,没有拿一方面离得开模具。模具是机械、汽车、电子、通讯、家电等工业产品的基础工艺装备,属于高新技术产品。作为基础工业,模具的质量、精度、寿命对其他工业的发展起着十分重要的作用,在国际上称为“工业之母”。随着我国国民经济的迅速发展,作为工业品基础的模具工业,也得到了蓬勃发展,已成为国民经济建设中的重要产业。模具工业不但在国民经济中占据重要地位,在世界市场上也是独树一帜。世界模具市场总体上供不应求,市场需求在600到650亿美元。如今,模具工业的发展甚至已经超过了新兴的电子工业。

模具按制造的产品分类,可以分为塑料模具(又分为注塑模具、铸压模具和吹塑模具)、冲压模具、铸造模具、橡胶模具和玻璃模具等。其中,尤以注塑模具和冲压模具用途广、技术成熟、占据的比重大。本文以防尘塑料帽的模具设计为例,详细论述塑料的工艺特性、ABS塑料的工艺参数、型腔和型芯的结构形式、模具的机构设计、模架的选择原则,力求做到理论联系实际和反映国内外先进水平。

关键词:塑料特性、型芯和型腔结构、模具结构、标准模架

Shields mold design and manufacture

English Abstract

With modern industrial development needs in the plastics industry, agriculture and daily life, and other fields of application become wider, and more high-quality requirements. Plastic products in the production of high-quality die design, advanced mold manufacturing equipment and reasonable processing, high-quality materials and modern mould forming equipment are forming an important condition for high quality plastics.

Especially in recent years, with the rapid development of the plastics industry, and GM and engineering plastics in areas such as strength and accuracy of the continuous enhancement of the scope of the application of plastic products is growing, such as: household appliances, instrumentation, construction equipment, automotive industry , the daily hardware, and many other fields, the proportion of plastic products is rapidly increasing. A rational design of plastic parts can often replace more than traditional metal pieces. Industrial products and plastic products daily and the trend is rising. In the industrial production and various press installed in the press and on the special instruments, through pressure on the metal or non-metallic materials produced by the need to shape parts or products, such special instruments collectively die.

Die in the national economy in the occupied status is increasingly significant, it can be said of human clothing, food, housing, transportation, not with one hand Chideikai die. Die those in the machinery, automotive, electronics, telecommunications, household appliances, and other industrial products based process equipment, high-tech products are. As basic industries, the quality of molds, precision, life on other industrial development plays an important role in the international community as "the mother of industry." With the rapid development of China's national economy, as the basis of industrial tooling industry, has also been vigorous development of the national economy has become an important industry in the building. Tooling industry in the national economy not only occupy an important position in the world market is also unique. World Die overall market demand, the market demand in the 600 to 65 billion US dollars. Today, the development of mould industry has exceeded even the emerging electronics industry.

Die by manufacturing the product category, can be divided into plastic molds (also divided into injection mold, pressure die casting and blow mould

), stamping dies, die casting, rubber molds and mold, and other glass. Among them, especially injection molds and stamping die-use, technological maturity, which hold the majority. This paper shields to prevent the mold design for example, discussed in detail the process of plastic, ABS plastics processing parameters, cavity and core structural forms Die Design, mode-choice principles, and strive to do with reality and theory reflect the advanced level both at home and abroad.

Key words: plastic characteristics of core and cavity structure, die structure, the standard mold base

前言----------------------------------------------------------------------1

第一章 塑料成型工艺--------------------------------------------------4

1. 1 塑件的成型工艺分析------------------------------------------------4

1. 2 ABS塑料的材料特性-------------------------------------------------4

1. 3 ABS塑料的成型特性-------------------------------------------------5

1. 4 ABS塑料的成型工艺参数---------------------------------------------5

第二章 设计方案及参数的确定----------------------------------------7

2. 1 注射机的选用------------------------------------------------------7

2. 2 型腔数目和分布----------------------------------------------------8

2. 3 选择分型面--------------------------------------------------------9

第三章 模具的结构设计-----------------------------------------------10

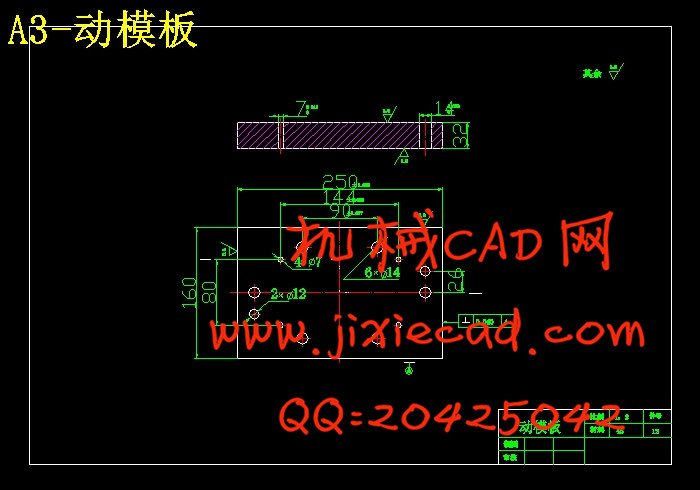

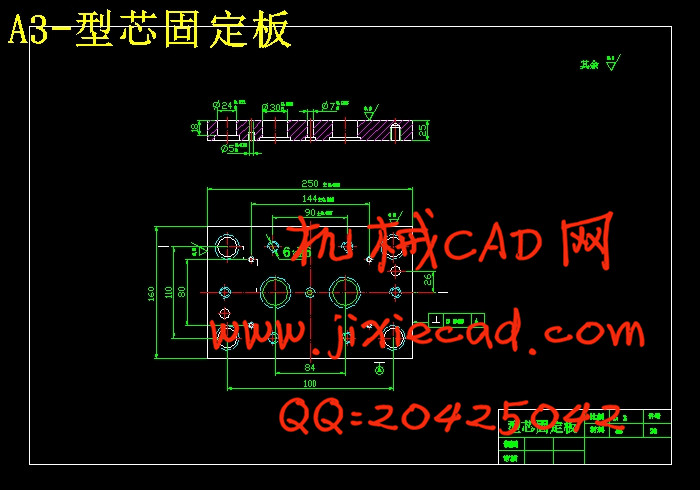

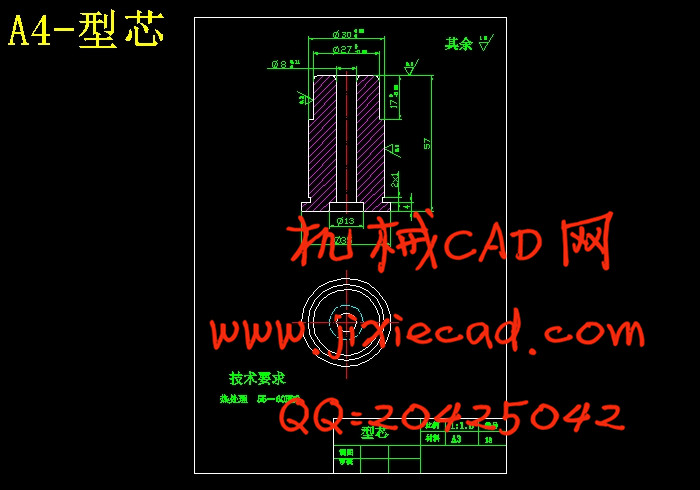

3. 1 确定型腔和型芯的结构形式-----------------------------------------10

3. 2 浇注系统设计-----------------------------------------------------12

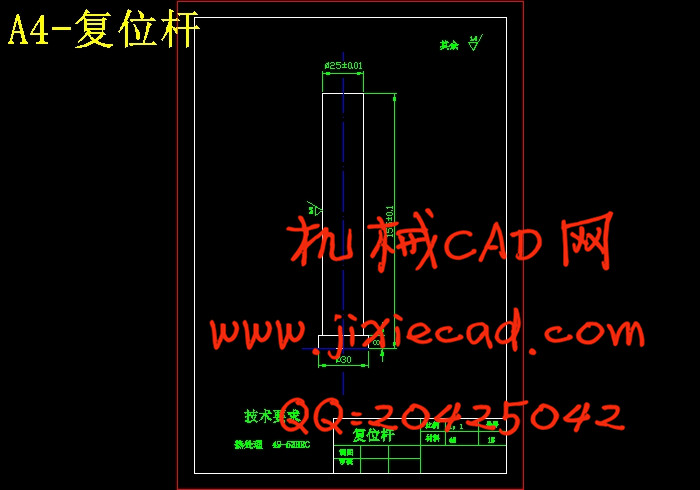

3. 3 机构的设计-------------------------------------------------------16

3. 4 注射模标准模架的设计---------------------------------------------21

3. 5 注射模排气系统的设计---------------------------------------------25

第四章 注射模的设计结果参数---------------------------------------27

小结和致谢--------------------------------------------------------------33

参考文献----------------------------------------------------------------35