设计简介

摘要

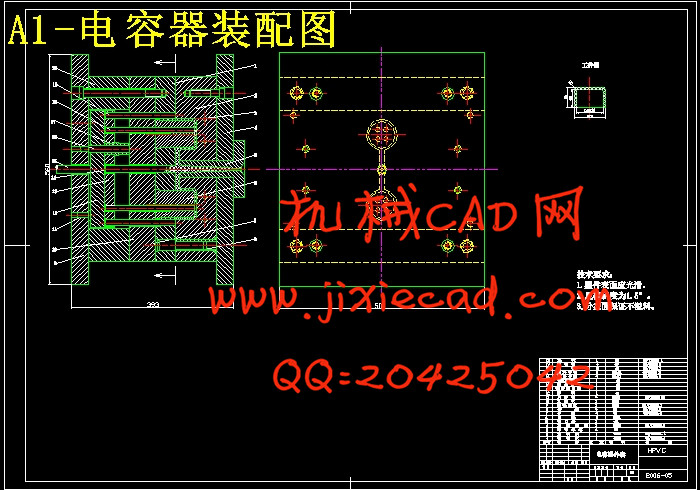

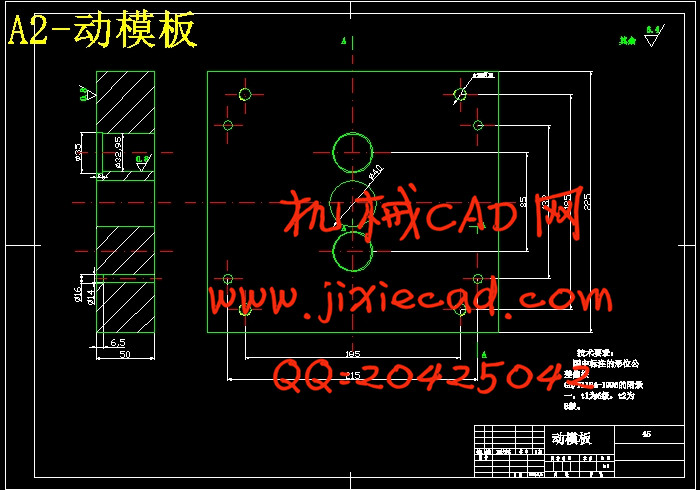

模具是工业生产中的重要工艺装备,模具工业是国民经济各部门发展的重要基础之一。随着机械工业、电子工业、航空工业、仪器仪表工业和日常用品工业的发展,塑料成型制件的需求量越来越多,质量要求也越来越高,这就要求成型塑料件的模具的开发、设计与制造的水平也必须越来越高。注射成型是热塑性塑料成型的一种重要方法,它具有成型周期短、能一次成型形状复杂、尺寸精确、带有金属或非金属嵌件的塑料制件。注射成型的生产率高,易实现自动化生产。定模安装在注射机的固定模板上,动模安装在注射机的移动模板上,并可随移动模板的移动实现模具的启闭。模具闭合后,动模和定模一起构成模具型腔和浇注系统,注塑机即可向模具凹模注入熔融塑料,经冷却待凹模内塑件定型后动模和定模分离,由推出机构将塑件推出,即完成一个生产周期。一般塑料模组成的组成部分:成型零部件、浇注系统、导向机构、脱模机构、侧向分型与抽芯机构、加热和冷却系统、排气系统、其他零部件。

关键词:型芯,型腔,装配图,电容器

Keyword:Convex mold, cave mold, the assemble diagram, capacitor

目录

绪论 2

1. 零件的工艺分析 4

1.1 塑件的原材料分析 4

1.2 塑件结构,尺寸精度,壁厚,表面质量分析 4

2.确定型腔数 5

2.1 确定塑件质量 5

2.2 选择设备型号、规格、确定型腔数 5

2.3 计算型腔数 5

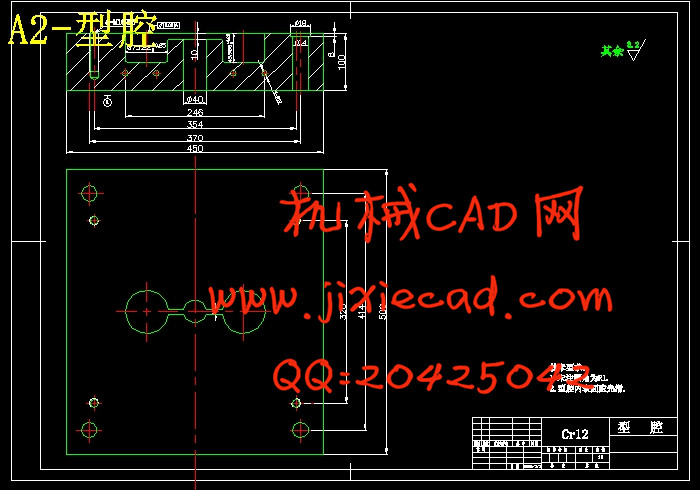

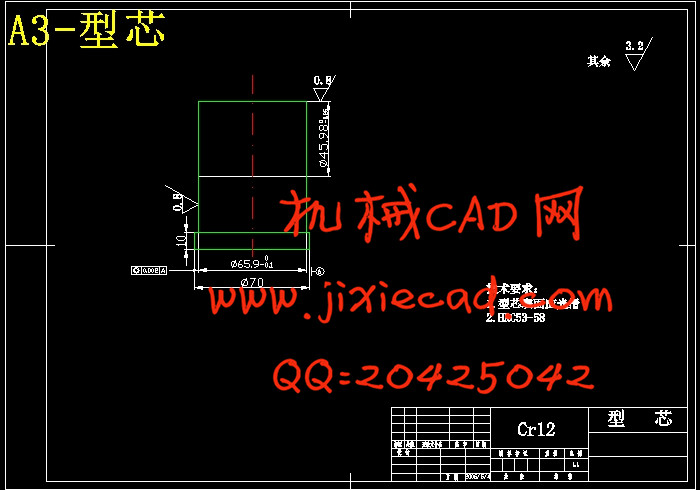

3.型腔,型芯工作部分尺寸的确定 6

3.1 收缩率的计算 6

3.2 型腔内径计算 6

3.3 型芯计算 6

4.浇注系统的设计 7

4.1 注射模分型面的选择 7

4.2 主流道的设计 7

4.3 分流道的设计 8

4.4 浇口设计 8

4.5 型腔位置的排布 9

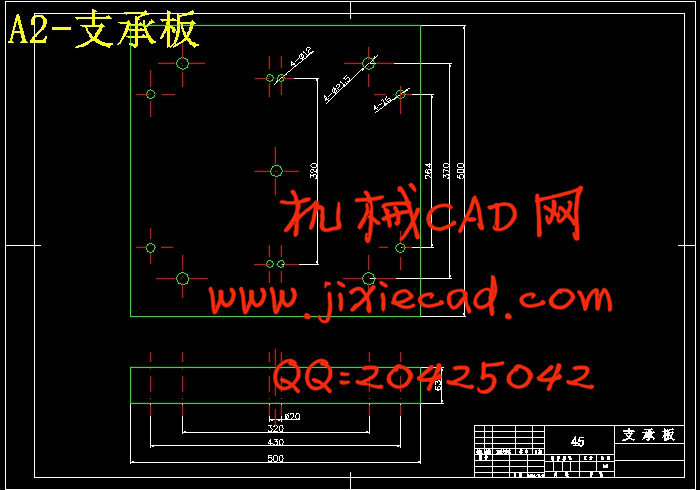

5.选用模架 10

5.1型腔强度和刚度的计算 10

5.2 初选注射机 10

5.3 选标准模架 10

6.校核注射机 11

6.1 注射量,锁模力,注射压力,模架厚度的校核 11

6.2 开模行程的校核 11

6.3 模具在注射机上的安装 11

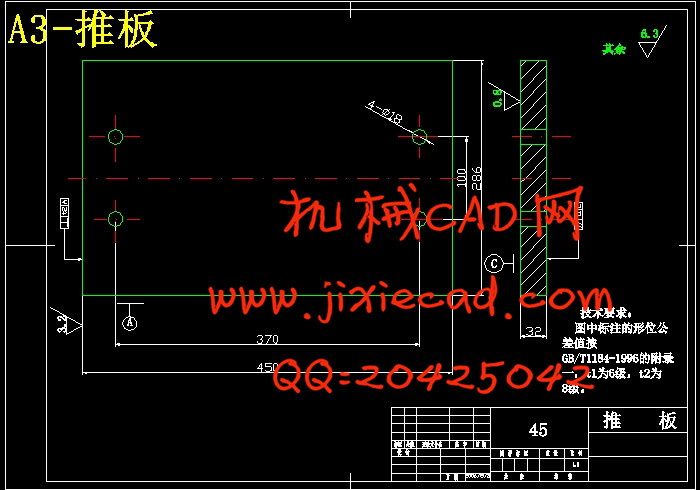

7.推出结构的设计 12

7.1 推件力的计算 12

7.2 确定顶出方式及顶件位置 12

8.冷却系统的设计 13

9.排气系统的设计 13

总结 13

参考文献 14

模具是工业生产中的重要工艺装备,模具工业是国民经济各部门发展的重要基础之一。随着机械工业、电子工业、航空工业、仪器仪表工业和日常用品工业的发展,塑料成型制件的需求量越来越多,质量要求也越来越高,这就要求成型塑料件的模具的开发、设计与制造的水平也必须越来越高。注射成型是热塑性塑料成型的一种重要方法,它具有成型周期短、能一次成型形状复杂、尺寸精确、带有金属或非金属嵌件的塑料制件。注射成型的生产率高,易实现自动化生产。定模安装在注射机的固定模板上,动模安装在注射机的移动模板上,并可随移动模板的移动实现模具的启闭。模具闭合后,动模和定模一起构成模具型腔和浇注系统,注塑机即可向模具凹模注入熔融塑料,经冷却待凹模内塑件定型后动模和定模分离,由推出机构将塑件推出,即完成一个生产周期。一般塑料模组成的组成部分:成型零部件、浇注系统、导向机构、脱模机构、侧向分型与抽芯机构、加热和冷却系统、排气系统、其他零部件。

Summary

Molding tool is the industry produce medium of the important craft material, the molding tool industry is one of the important foundations of each section of national economy development.Along with the machine industry, electronics industry, aviation industry, the instrument appearance industry and usually the development of the thing industry, the plastics models the demand of make the piece more and more, the quantity request is also more and more high, this development, design of the molding tool and the level of the manufacturings that will beg to model the plastics piece also must be more and more high.It is a kind of important method that the hot sex plastics model to inject to model, it has the period of model short, can model the shape complications, the size precision and take the plastics system piece of have the metals or nonmetal piece once.The rate of production that inject to model is high, easy realization the automation produce.Settle the mold gearing in injecting the fixed template of the machine, move the mold gearing in injecting the ambulation template of the machine, and can with move the ambulation of the template to carry out the molding tool to open and close.The molding tool moves the mold and settles the mold after shut match to constitute the cave mold of molding tool and sprinkle to note the system together, injecting the machine then to the molding tool cave mold infusion meltdown plastics, move the mold and settle the mold separation after need an already set of plastics inside the cave mold through the cooling, from release the organization to release the plastics piece, then complete a production period.The general plastics module become of constitute the part:Model zero partses and sprinkle to note the system, lead to the organization, take off the mold organization, side toward an organization of the cent, heat and cooling system, line up to annoy the system, other zero partses.关键词:型芯,型腔,装配图,电容器

Keyword:Convex mold, cave mold, the assemble diagram, capacitor

目录

绪论 2

1. 零件的工艺分析 4

1.1 塑件的原材料分析 4

1.2 塑件结构,尺寸精度,壁厚,表面质量分析 4

2.确定型腔数 5

2.1 确定塑件质量 5

2.2 选择设备型号、规格、确定型腔数 5

2.3 计算型腔数 5

3.型腔,型芯工作部分尺寸的确定 6

3.1 收缩率的计算 6

3.2 型腔内径计算 6

3.3 型芯计算 6

4.浇注系统的设计 7

4.1 注射模分型面的选择 7

4.2 主流道的设计 7

4.3 分流道的设计 8

4.4 浇口设计 8

4.5 型腔位置的排布 9

5.选用模架 10

5.1型腔强度和刚度的计算 10

5.2 初选注射机 10

5.3 选标准模架 10

6.校核注射机 11

6.1 注射量,锁模力,注射压力,模架厚度的校核 11

6.2 开模行程的校核 11

6.3 模具在注射机上的安装 11

7.推出结构的设计 12

7.1 推件力的计算 12

7.2 确定顶出方式及顶件位置 12

8.冷却系统的设计 13

9.排气系统的设计 13

总结 13

参考文献 14