设计简介

摘要

在机械产品中,单件与小批量产品占到70%~80%,这类产品一般都采用通用机床加工,当产品改变时机床与工艺装备均需作相应的变换与调整,而且通用机床的自动化程度不高,基本上由人工操作,难以保证生产效率与产品质量。特别是一些曲线、曲面轮廓组成的复杂零件,只能借助靠模和仿形机床,或者借助划线或样板用手工操作的方法来加工,加工精度和生产效率受到很大的限制。

由于数控机床综合应用了电子计算机、自动控制、伺服驱动、精密监测与新型机械结构等方面的技术成果,具有高柔性、高精度、与高自动化的特点,因此,采用数控加工手段,解决了机械加工中常规技术难以解决甚至无法解决的单件、小批量、特别是复杂型面零件的加工。应用数控加工技术是机械制造业的一次技术革命,使机械制造业的发展进入了一个新的阶段,提高了机械制造业的制造水平,为社会提供了高质量、多品种及高可靠性的机械产品。目前应用数控技术的领域已从当初的航空工业部门逐步扩大到汽车、造船、机床、建筑等民用机械制造,并取得了巨大的经济效益。

随着计算机技术的高速发展,传统的制造业开始了根本性变革,各工业发达国家投入巨资,对现代制造技术进行研究开发,提出了全新的制造模式。在现代制造系统中,数控技术是关键技术,它集微电子、计算机、信息处理、自动检测、自动控制等高新技术于一体,具有高精度、高效率、柔性自动化等特点,对制造业实现柔性自动化、集成化、智能化起着举足轻重的作用。

关键字:数控、发展途径、加工工艺、铣削

Abstract

In the mechanical products, a single piece and small batch products accounted for 70%~80%, this kind of products are generally used when machining, machine tools and process equipment product changes are required to transform and adjust accordingly, and the automation level of the universal machine is not high, basically by manual operation, it is difficult to guarantee the production efficiency and product quality. Especially for complex parts, consisting of some curve surface, can have the aid of copying and copying machine, or by means of marking or model with a manual method to machining, the machining precision and the production efficiency has been greatly restricted.

Because the technology of CNC machine tool of comprehensive application of computer, automatic control, servo drive, precise monitoring and new mechanical structure and so on, has the advantages of high flexibility, high precision, and high automation features, therefore, the CNC machining method, solves the problem of mechanical processing in conventional technology is difficult to solve or even can not solve the single, small batch in particular, the processing of complex surface parts. A revolution of technology application of NC machining technology is the machinery manufacturing industry, the development of the machinery manufacturing industry has entered a new stage, to improve the manufacturing level of the machinery manufacturing industry, provides high quality, variety and high reliability of mechanical products for the society. At present, the application of numerical control technology has been from the beginning of the aviation industry and gradually expand to the automobile, shipbuilding, machine tools, building and other civil machinery manufacturing, and has made great economic benefits.

With the rapid development of computer technology, the traditional manufacturing industry began a fundamental change, the industrial developed countries invested heavily, for modern manufacturing technology research and development, put forward a new manufacturing model. In modern manufacturing systems, the numerical control technology is the key technology, which integrates microelectronics, computer, information processing, automatic detection, automatic control and other high-tech in one, with high precision, high efficiency, flexibility and automation features, the manufacturing industry flexible automation, integrated, intelligent play a decisive role.

Key words: numerical control, development, processing, milling

Because the technology of CNC machine tool of comprehensive application of computer, automatic control, servo drive, precise monitoring and new mechanical structure and so on, has the advantages of high flexibility, high precision, and high automation features, therefore, the CNC machining method, solves the problem of mechanical processing in conventional technology is difficult to solve or even can not solve the single, small batch in particular, the processing of complex surface parts. A revolution of technology application of NC machining technology is the machinery manufacturing industry, the development of the machinery manufacturing industry has entered a new stage, to improve the manufacturing level of the machinery manufacturing industry, provides high quality, variety and high reliability of mechanical products for the society. At present, the application of numerical control technology has been from the beginning of the aviation industry and gradually expand to the automobile, shipbuilding, machine tools, building and other civil machinery manufacturing, and has made great economic benefits.

With the rapid development of computer technology, the traditional manufacturing industry began a fundamental change, the industrial developed countries invested heavily, for modern manufacturing technology research and development, put forward a new manufacturing model. In modern manufacturing systems, the numerical control technology is the key technology, which integrates microelectronics, computer, information processing, automatic detection, automatic control and other high-tech in one, with high precision, high efficiency, flexibility and automation features, the manufacturing industry flexible automation, integrated, intelligent play a decisive role.

Key words: numerical control, development, processing, milling

目 录

摘 要 1

Abstract 1

1绪 论 2

1.1 数控机床的发展过程 2

1.2 本论文的研究内容 3

1.3选题意义 4

1.4 论文结构 4

2 零件的图样分析 5

2.1 零件的结构特点分析 5

2.2 零件的技术要求分析 6

3 零件的工艺规程设计 8

3.1 毛坯的选择 8

3.2 定位基准的选择 8

3.3 装夹方式的选择 8

3.4 加工顺序的安排 8

4 设备及其工艺装备的确定 10

4.1 机床的选择 10

4.2 刀具的选择 10

5 切削用量的选取 12

6 工艺卡片 14

6.1 工艺过程卡 14

6.2 数控加工工序卡 14

7 数控加工程序的编制 15

7.1 CAM编程的一般步骤 15

7.2 编程坐标系的确定 15

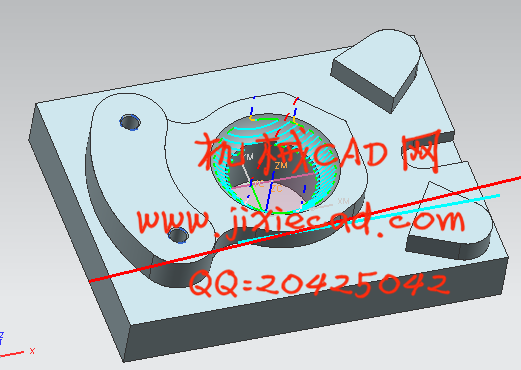

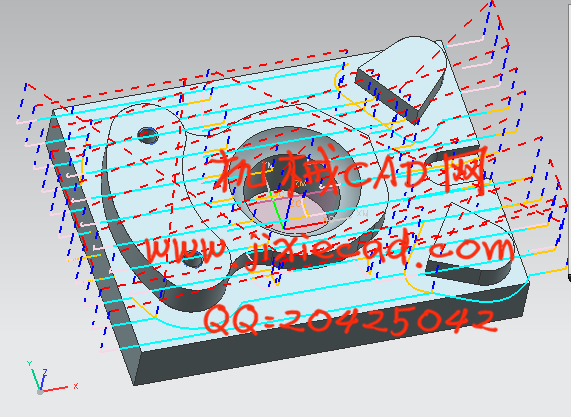

7.3 走刀路线的生成 16

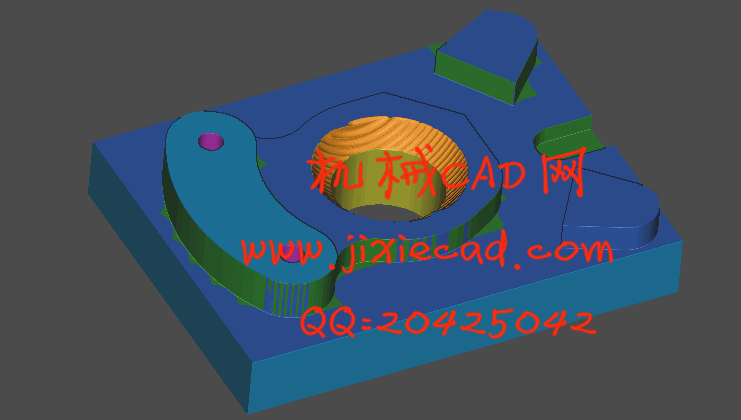

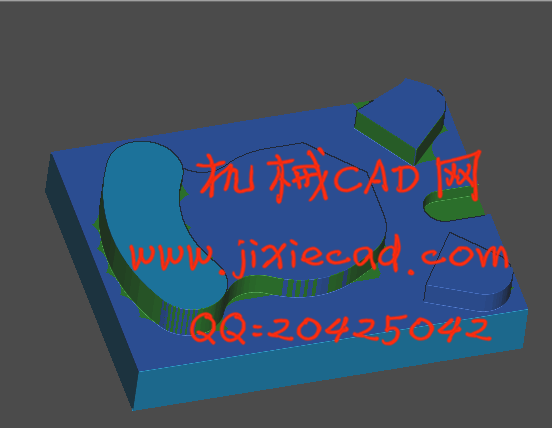

7.4仿真加工 18

设计总结 30

致谢 31

参考文献 32