设计简介

摘要

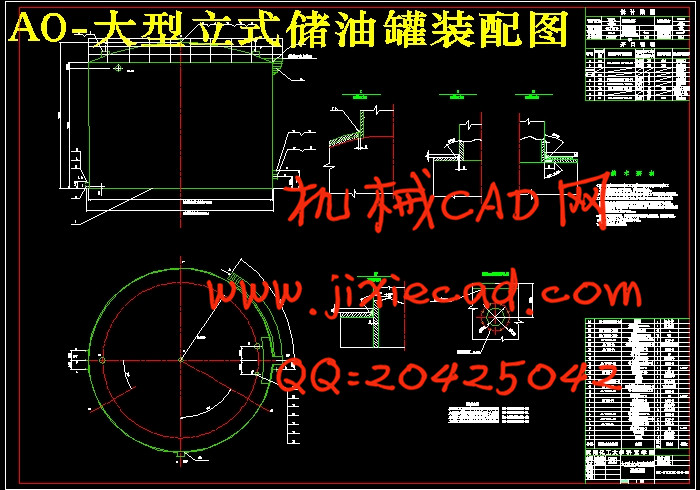

本设计的题目是大型立式储油罐的机构设计。顾名思义,大型立式储油罐的作用便是用来大规模储藏油类原材料的封闭容器。本设计的尺寸大小为直径15m,长度10.5m,材质16Mn,壁厚10mm的大型立式储罐。

本文的目的是对大型储油罐依据国内以及国际的现状和发展趋势对大型立式储油罐进行的结构设计。使我国的大型立式储油罐的结构设计方案更符合我国的国情和满足国内的对于大型储罐的需求。

液化油体等具有易燃易爆的特点,大型立式储油罐属于具有较大危险的储存容器。针对液化石油气储罐的危险特性,结合本专业《过程设备与压力容器设计》所学的知识,在设计上充分考虑液大型立式储油罐各项参数,确保大型立式储油罐能安全运行,对化工行业具有重要的现实意义。

目前,全世界公认的储罐大型话的优点有:占地总面积相对较小;节省建造罐体的总体资金(包括管网和配件等);节省钢材的消耗量和工程中的材料等;使储藏和运输过程变得更加便捷。但是储罐大型化发展而产生的新问题也有很多,例如:对管板壁材料的要求提高了。在储罐大型化的同时,对焊接的技术也变得具有更高的要求;事故产生危险的可能性大大增加,消防安全措施也要随之增强[3]。

本次设计有以下过程:1.写出该结构的几种设计方案。2.强度计算及尺寸选择。3.绘制结构设计图。4.撰写主要工艺过程。5.撰写设计说明书。

本设计的题目是大型立式储油罐的机构设计。顾名思义,大型立式储油罐的作用便是用来大规模储藏油类原材料的封闭容器。本设计的尺寸大小为直径15m,长度10.5m,材质16Mn,壁厚10mm的大型立式储罐。

本文的目的是对大型储油罐依据国内以及国际的现状和发展趋势对大型立式储油罐进行的结构设计。使我国的大型立式储油罐的结构设计方案更符合我国的国情和满足国内的对于大型储罐的需求。

液化油体等具有易燃易爆的特点,大型立式储油罐属于具有较大危险的储存容器。针对液化石油气储罐的危险特性,结合本专业《过程设备与压力容器设计》所学的知识,在设计上充分考虑液大型立式储油罐各项参数,确保大型立式储油罐能安全运行,对化工行业具有重要的现实意义。

目前,全世界公认的储罐大型话的优点有:占地总面积相对较小;节省建造罐体的总体资金(包括管网和配件等);节省钢材的消耗量和工程中的材料等;使储藏和运输过程变得更加便捷。但是储罐大型化发展而产生的新问题也有很多,例如:对管板壁材料的要求提高了。在储罐大型化的同时,对焊接的技术也变得具有更高的要求;事故产生危险的可能性大大增加,消防安全措施也要随之增强[3]。

本次设计有以下过程:1.写出该结构的几种设计方案。2.强度计算及尺寸选择。3.绘制结构设计图。4.撰写主要工艺过程。5.撰写设计说明书。

本次设计的有以下设计任务: 1.罐体经济尺寸的选择;2.罐壁的设计;包括罐壁的强度计算,罐体风力的稳定计算,罐体的抗震设计,罐壁的结构设计等。3.储罐罐底的设计;4.储罐罐顶的设计;5.贮罐附件的设计及选用;6。焊接工艺等内容。

经过设计后的大型立式储油罐具有建造时间段,施工方式简单,储油量大,抗腐蚀能力强,保养维护便捷,降低了安全事故发生的概率,使用时间更长等优点。

关键词: 结构设计;强度计算; 设计优点

Abstract

经过设计后的大型立式储油罐具有建造时间段,施工方式简单,储油量大,抗腐蚀能力强,保养维护便捷,降低了安全事故发生的概率,使用时间更长等优点。

关键词: 结构设计;强度计算; 设计优点

Abstract

The topic of this design is a large vertical storage tanks of mechanism design. As the name implies, large vertical storage tanks is to form large-scale storage oil closed container of raw materials. The design of the size for 15 m in diameter, length is 10.5 m, 16 Mn, material thickness of 10 mm large vertical storage tanks.

The purpose of this article is to large oil tanks on the basis of the status quo and development trend of domestic and international for the structure design of large vertical storage tanks. The structure design scheme of large vertical storage tanks in China conforms to China's national conditions and meet the domestic demand for large storage tank.

Liquefied oil body has the characteristics of flammable and explosive, such as large vertical storage tanks with larger danger belongs to storage containers. Based on the dangerous characteristics of liquefied petroleum gas storage tank, and combined with the professional process equipment and pressure vessel design knowledge, on the design fully consider fluid large vertical storage tanks of various parameters, ensure the safe operation of large vertical storage tanks, the chemical industry has important practical significance.

At present, the world recognized the advantages of large storage tank words are: covering a total area of relatively small; Save to build tanks total capital (including pipe and fittings, etc.); Save the consumption of steel and engineering of materials, etc.; The storage and transportation become more convenient. However, the development of large-scale storage tank, and also has a lot of new problems, such as: the requirement of pipe wall materials increased. In large-scale storage tank at the same time, the technology has become a higher requirements for welding; Accidents have greatly increases the possibility of danger, fire safety measures will also grow.

This design has the following process: 1. To write the structure of several kinds of design scheme. 2. The strength calculation and size selection. 3. Draw the structure design. 4. Write the main technological process. 5. Write the design specification.

This design has the following design task: 1. The economy of tank size choice; 2. The design of the tank wall; Including the tank wall strength calculation, wind stability calculation of tank, seismic design of the tanks, tank wall structure design, etc. 3. The design of the tank bottom; 4. The design of the tank roof; 5. The design of tank accessories and selection; 6. Welding technology and so on.

After the design of large vertical storage tanks with construction period,

The purpose of this article is to large oil tanks on the basis of the status quo and development trend of domestic and international for the structure design of large vertical storage tanks. The structure design scheme of large vertical storage tanks in China conforms to China's national conditions and meet the domestic demand for large storage tank.

Liquefied oil body has the characteristics of flammable and explosive, such as large vertical storage tanks with larger danger belongs to storage containers. Based on the dangerous characteristics of liquefied petroleum gas storage tank, and combined with the professional process equipment and pressure vessel design knowledge, on the design fully consider fluid large vertical storage tanks of various parameters, ensure the safe operation of large vertical storage tanks, the chemical industry has important practical significance.

At present, the world recognized the advantages of large storage tank words are: covering a total area of relatively small; Save to build tanks total capital (including pipe and fittings, etc.); Save the consumption of steel and engineering of materials, etc.; The storage and transportation become more convenient. However, the development of large-scale storage tank, and also has a lot of new problems, such as: the requirement of pipe wall materials increased. In large-scale storage tank at the same time, the technology has become a higher requirements for welding; Accidents have greatly increases the possibility of danger, fire safety measures will also grow.

This design has the following process: 1. To write the structure of several kinds of design scheme. 2. The strength calculation and size selection. 3. Draw the structure design. 4. Write the main technological process. 5. Write the design specification.

This design has the following design task: 1. The economy of tank size choice; 2. The design of the tank wall; Including the tank wall strength calculation, wind stability calculation of tank, seismic design of the tanks, tank wall structure design, etc. 3. The design of the tank bottom; 4. The design of the tank roof; 5. The design of tank accessories and selection; 6. Welding technology and so on.

After the design of large vertical storage tanks with construction period,

construction simple, big oil, corrosion resistance is strong, the maintenance is convenient, reduce the probability of safety accidents, advantages of using time is longer.

keywords: The structure design; Strength calculation; Design advantages

目 录

第一章 绪论 1

1.1 储罐的发展概况 1

第二章 设计方案 2

2.1 各种设计方法 2

2.1.1 正装法 2

2.1.2 倒装法 2

2.2 各种方法优缺点比较 5

2.2.1 正装法 5

2.2.2 倒装法 6

2.3 油罐的基础 6

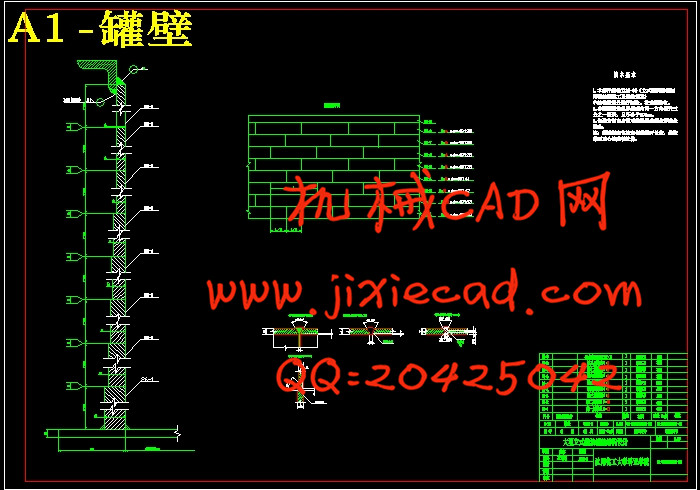

第三章 罐壁设计 8

3.1 罐壁的强度计算 8

3.1.1 罐壁厚的计算 8

3.1.2 罐壁的应力校核 10

3.2 储罐的风力稳定计算 11

3.2.1 抗风圈 11

3.2.2 抗风圈所需要的最小截面系数WZ 11

3.2.3 加强圈计算 13

3.3 储罐的抗震计算 15

3.3.1 地震载荷的计算 15

3.3.2 抗震验算 17

3.3.3 液面晃动波高计算 19

3.3.4 地震对储罐的破坏 20

3.3.5 储罐抗震加固措施 20

3.4 罐壁结构 21

3.4.1 截面与连接形式 21

3.4.2 罐壁的开孔补强 23

3.4.3 罐壁保温结构 23

第四章 罐底设计 24

4.1 罐底结构设计 24

4.1.1 罐底的结构形式和特点 24

4.1.2 罐底的排板形式与节点 24

4.2.1 中幅板的薄膜力 26

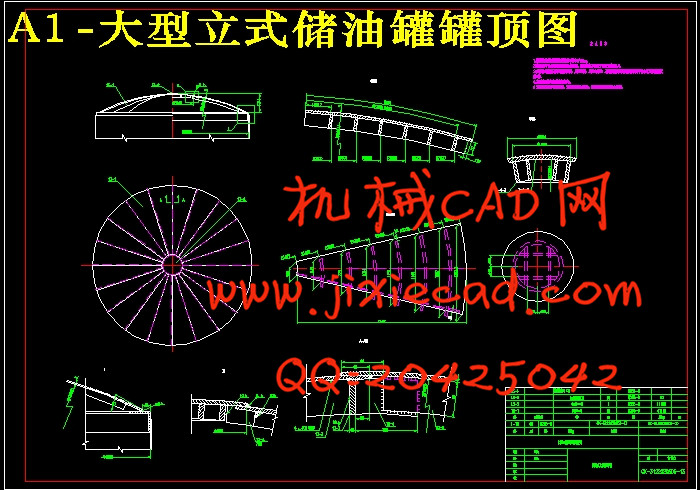

第五章 罐顶设计 30

5.1 拱顶结构及主要的几何尺寸 30

5.2 扇形顶板尺寸 31

5.3 包边角钢 32

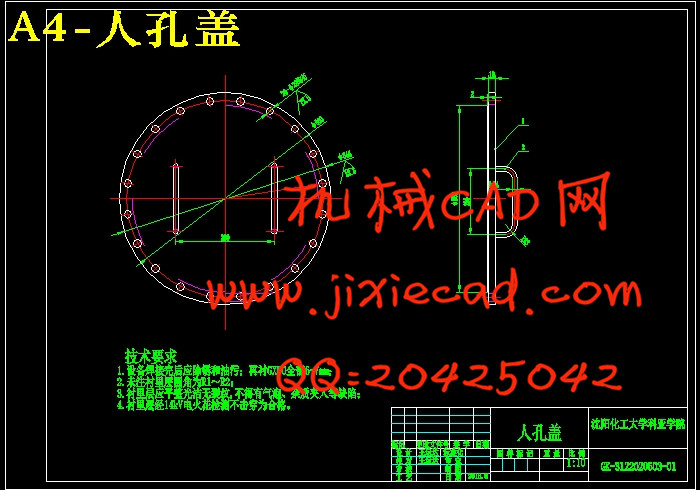

第六章 贮罐附件及其选用 35

6.1 人孔 35

6.2 通气孔 36

6.3 量液孔 37

6.4 贮罐进出液口 37

6.5 法兰和垫片 37

第七章 焊接工艺 38

7.1 板材检验 38

7.2 钢材的矫形:净化与板加工 38

7.3 焊接材料的选用 38

7.4 贮罐底板、壁板、顶板制造、组装与焊接 39

7.5 壁板的制造与安装 40

7.6 顶盖的组装与焊接 40

7.7 焊缝的检验和总体试验 41

参考文献 42

致谢 43