设计简介

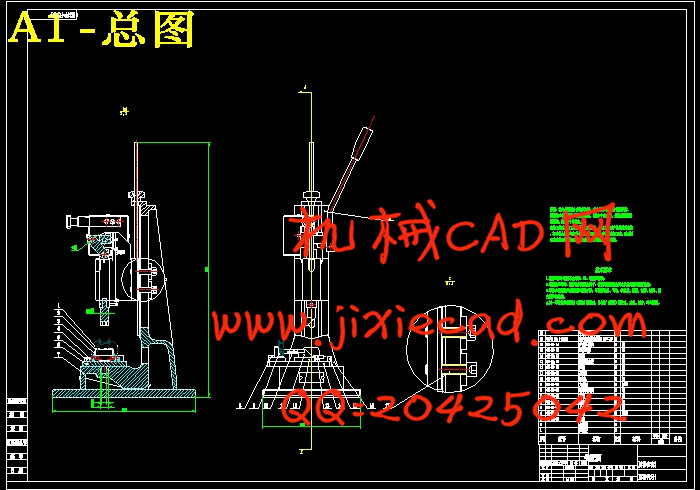

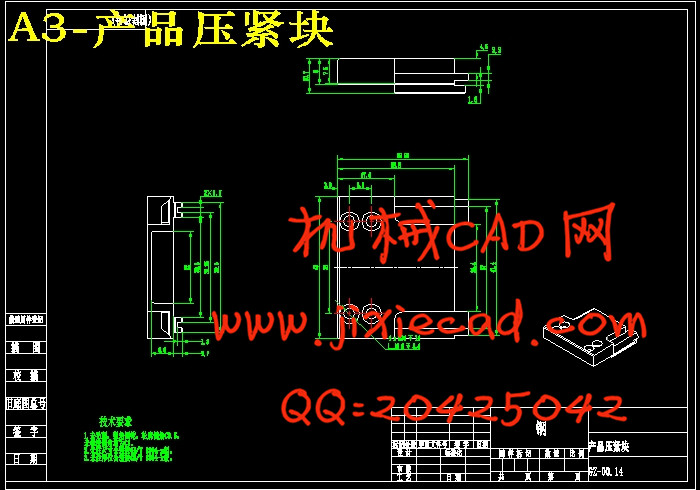

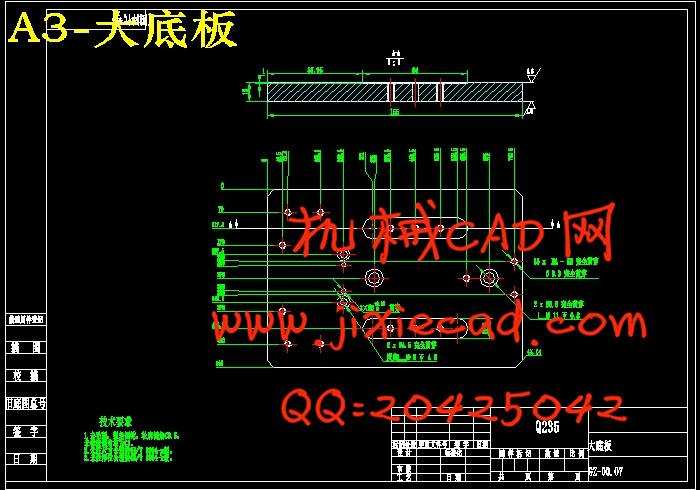

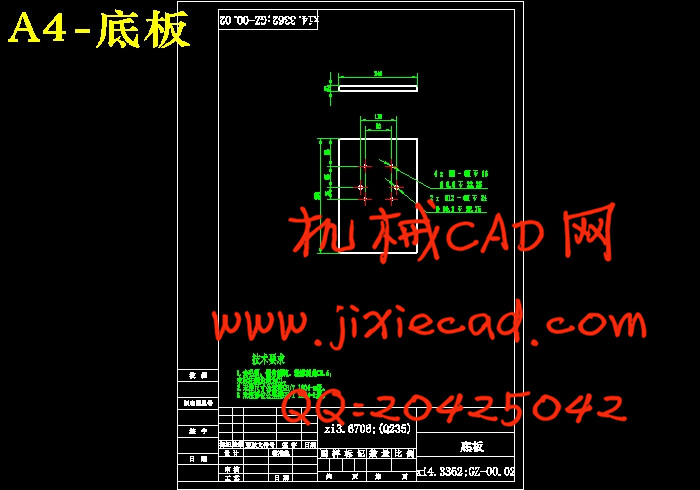

金属件与塑料件装配工装

摘要

随着科技水平的进步与发展,出现了许多新的机械设计的方法,为设备的研发以及制造奠定了坚实的基础。为了能够开发更先进的金属件与塑料件装配工装,对金属件与塑料件装配工装的选型设计有着重要的研究意义。当今的时代,手板压机对于机械装配行业是重要的设备,因此它们也促进了金属件与塑料件装配工装机械的发展。当前我国的金属件与塑料件装配工装机械行业的内在潜在价值还有待强有力的挖掘,金属件与塑料件装配工装机械的进一步研究将会给个人乃至集体和社会带来重要的积极意义,在研究的同时还可以让学生的综合能力得到开发与锻炼,最为重要的是总体设计就体现了这一点。第一,我们要让现在毕业的学生打好专业知识的基础并从而提升所学的知识,从而在以后工作中能够游刃有余。第二,可以让他们在课题中能够用发展性的眼光看待问题,充分发挥创新能力,攻破现实难题。对于金属件与塑料件装配工装设计这一课题,它的涵知识面较广,具有极强的综合性,学生则必须要凭借过硬的专业能力和海量的知识,加上要有一定的在计算机上绘制图表的能力。因此,学生可以积极主动的思考和钻研这个设计课题,这样学生便可以在问题的分析解决上得到能力的提升,从而也能够积累对未来有帮助的工作经验。这篇论文会对国内金属件与塑料件装配工装的历来的情况进行一个简要的概述,而且加上了金属件与塑料件装配工装工作的理念简述,综述国内外金属件与塑料件装配工装的现在的发展情况后,也综合了它的装置构造是如何设计概念。论文中,做好了金属件与塑料件装配工装构造与设计的方案,对该装置的参考数据进行定位,校对其强度,分析其运动,金属件与塑料件装配工装的每个机械构造和尺寸分别得到确定和定位。

关键词:弹簧,压力机,曲柄

Assembly and assembly of metal parts and plastic parts

Abstract

With the progress and development of science and technology, many new methods of mechanical design have emerged, laying a solid foundation for the R & D and manufacture of equipment. In order to develop more advanced metal parts and plastic parts assembly tooling, it has important research significance for the selection and design of metal parts and plastic parts assembly tooling. In today's times, the hand press is an important equipment for the mechanical assembly industry, so they also promote the development of metal parts and plastic parts assembly machinery. At present, the inherent potential value of the metal parts and plastic parts assembly machinery industry in our country still needs to be excavated. Further research on the assembly and assembly machinery of metal parts and plastic parts will bring important positive significance to the individual and the community and the society. At the same time, the comprehensive ability of the students can be developed. And the most important thing is the overall design. First, we should let the graduates now lay the foundation of professional knowledge and enhance their knowledge so as to be able to work well in the future. Second, they can make them look at problems in a developmental perspective, give full play to their ability to innovate and break through practical problems. For the design of the assembly and assembly of metal parts and plastic parts, it has a wide range of knowledge and strong comprehensiveness. The students must rely on the excellent professional ability and mass knowledge, plus the ability to draw a graph on the computer. Therefore, students can actively think and study the design topic, so that students can improve the ability to solve the problem in the analysis, and thus can also accumulate useful work experience for the future.This paper will give a brief overview of the history of the assembly and assembly of metal parts and plastic parts, and a brief introduction to the concept of the work of the assembly and assembly of the metal parts and the plastic parts, and a summary of the development of the metal and plastic assembly tooling at home and abroad, and the synthesis of how its structure is set up. Concept. In this paper, the structure and design of the assembly and design of the assembly of metal and plastic parts are done. The reference data of the device is located, the strength of the assembly is checked, its movement is analyzed, and each mechanical structure and size of the assembly and assembly of the metal parts and the plastic parts are determined and located respectively.

Key words: Spring, press, crank

目录

目 录 I第1章 绪论 5

1.1选课的依据及课题的意义: 5

1.2国内外研究现状 5

1.3产品用途及其适用范围 7

1.4本次毕业设计主要完成的任务 7

1.5实现方法及预期目标 7

第2章 金属件与塑料件装配工装的设计方案 8

2.1 设计思想 8

2.2 金属件与塑料件装配工装的工作原理及组成 8

2.3 金属件与塑料件装配工装的驱动方案设计 9

第3章 曲柄滑块机构的设计计算 10

3.1曲柄压力机的结构 10

3.2曲轴的设计 10

3.3曲轴的材料选择 11

3.4曲轴设计计算 12

3.4.1预选曲轴有关尺寸 12

3.4.2核验轴颈尺寸 12

3.4.3计算及绘制许用负荷图 13

3.5连杆组件的设计 15

3.5.1压力机的连杆组 15

3.5.2连杆的设计 16

3.5.3连杆材料 16

3.5.4连杆长度和杆身设计 16

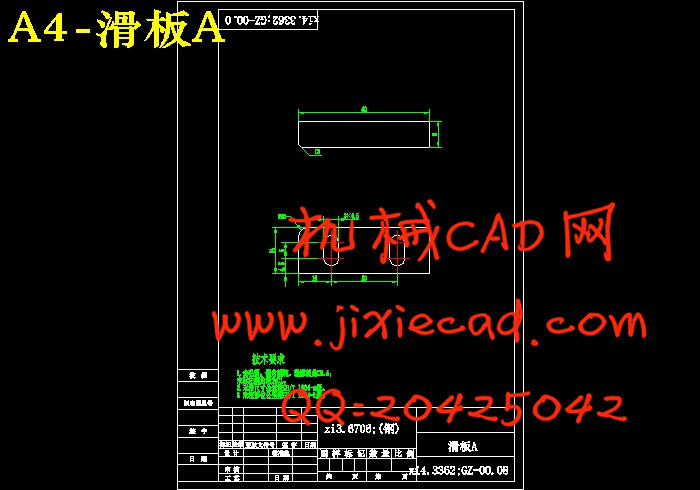

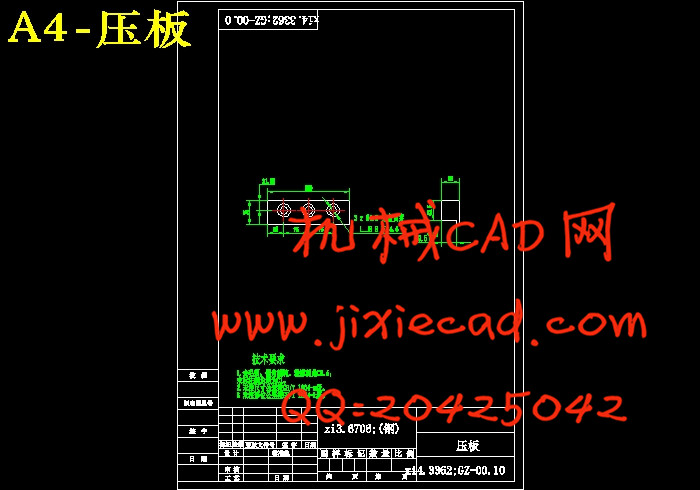

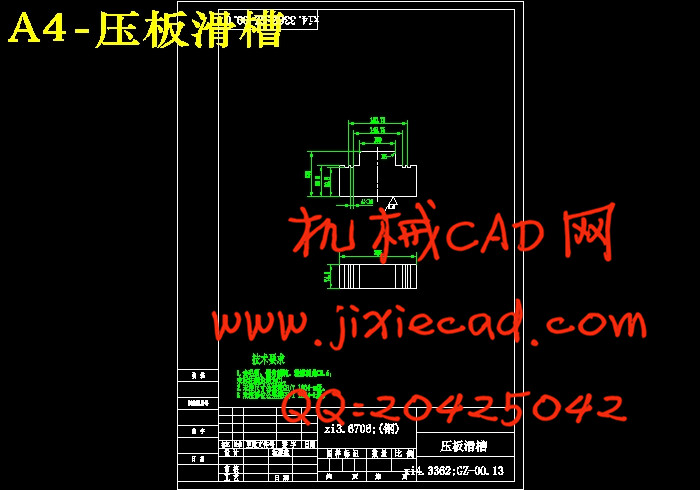

3.6导轨的选择 17

3.6.1导轨的基本要求 17

3.6.2导轨的材料及热处理 17

3.7轴的选择 18

3.7.1轴瓦的特殊性 18

3.7.2轴瓦材料的性能要求 18

3.7.3轴瓦的形式及定义 18

3.8弹簧的选择 18

结论 22

参考文献 23

致谢 24