设计简介

摘 要

三维打印(3D printing),即快速成形技术的一种,它是一种数字模型文件为基础,运用粉末状金属或塑料等可粘合材料,通过逐层打印的方式来构造物体的技术。过去其常在模具制造、工业设计等领域被用于制造模型,现正逐渐用于一些产品的直接制造。特别是一些高价值应用(比如髋关节或牙齿,或一些飞机零部件)已经有使用这种技术打印而成的零部件。“三维打印”意味着这项技术的普及。三维打印通常是采用数字技术材料打印机来实现。这种打印机的产量以及销量在二十一世纪以来就已经得到了极大的增长,其价格也正逐年下降。三维打印技术以及由此带来的新的产业模式成为学术界、产业界、投资人及政策制定者共同关注的焦点和科技角逐的新方向,它的应用领域也非常广泛。三维打印技术提供了复杂的艺术品制作可能性,比传统的模具工艺更容易实现制造。此外,大尺寸艺术品,传统方法大多是设计者制作小比例的作品,然后再由数名工匠根据模型一同制作大比例的作品,工匠水平高低不一,最终作品失真度大,但是通过三维打印技术,目标模型可在计算机内调节比例,通过高精度高效率的打印制作,可以获得高精度的艺术作品。

本文的设计内容为调研3D打印机工作原理以及发展现状,根据调研结果,针对当前应用较为广泛的3D打印机进行分析比较,综合各个结构的特点,设计3D打印机的构型方案。根据设计方案,对电机、轴承、带轮及其附属机构进行选型计算,并进行应力校核;最后根据设计方案,采用三维软件solidworks软件对3D打印机进行三维建模。

关键词: 3D打印机、结构设计、三维建模、复杂性

In this paper, the design content of working principle and development present situation of the research on 3 d printer, according to the survey results, which has been widely applied for the current is analyzed by 3 d printers, characteristic of each structure, design of a 3 d printer configuration scheme.According to the design scheme of bearing, pulley, selection of gear and its affiliates, and stress checking.According to the design scheme of using 3 d software solidworks software for 3 d modeling 3 d printers.

Keywords: 3 D printer,the structure design, 3 D modeling ,complexity

Abstract V

第1章 绪论 6

1.1论文概述 6

1.2 3D打印机国内外发展现状 6

1.3本文研究内容 7

1.4研究意义 7

第2章 3D打印机方案设计 9

2.1 3D打印机应用 9

2.2 3D打印机结构原理 9

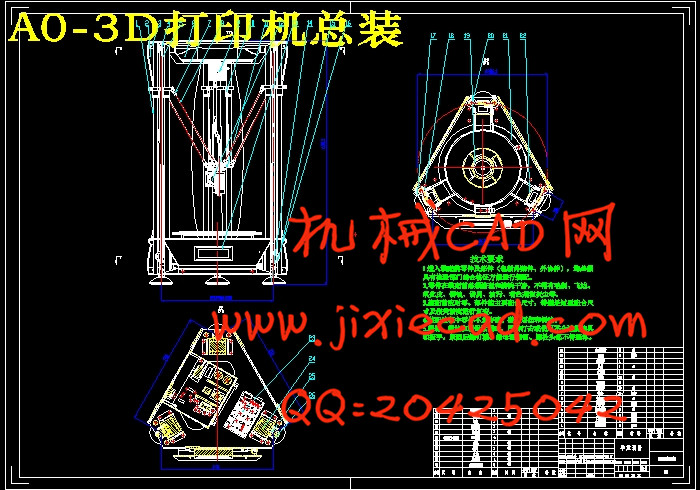

2.3 3D打印机总体方案 10

2.4本章小结 10

第3章 3D打印机设计计算 11

3.1设计参数 11

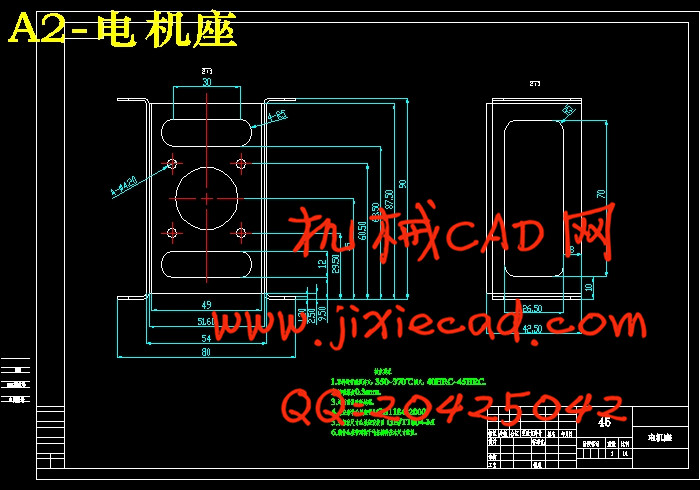

3.2电机选型设计 11

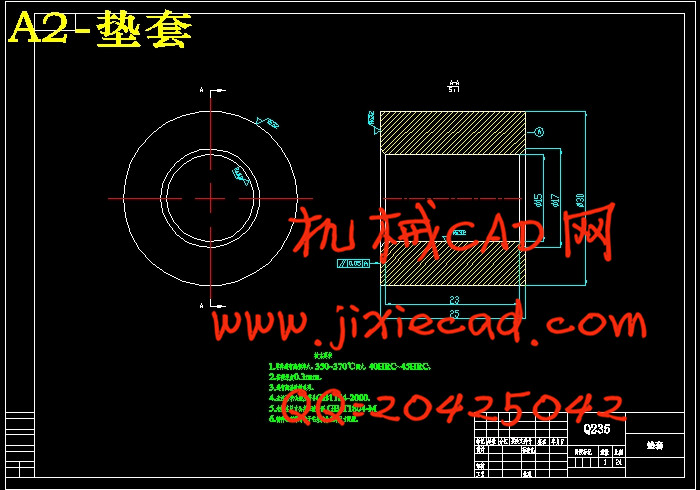

3.3联轴器的选用原则 13

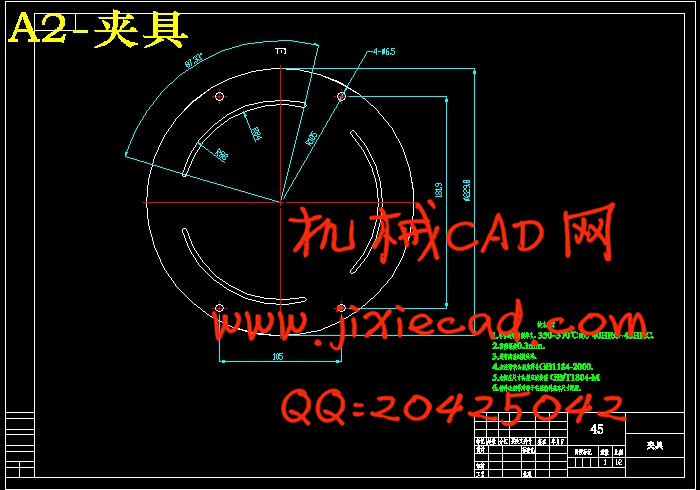

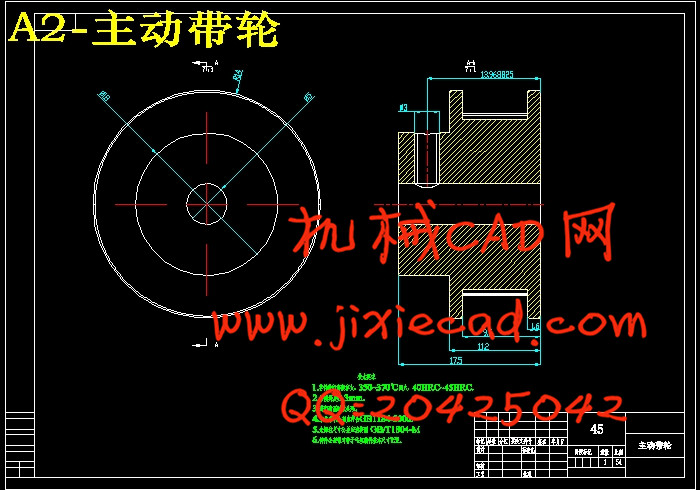

3.4带传动的设计 15

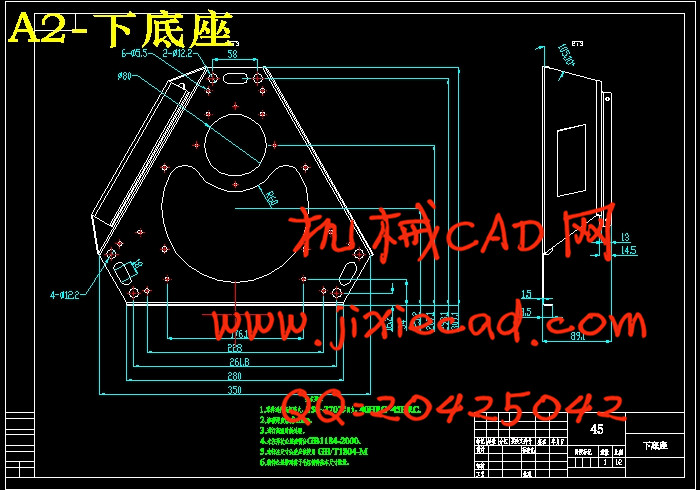

3.5螺栓校核计算 17

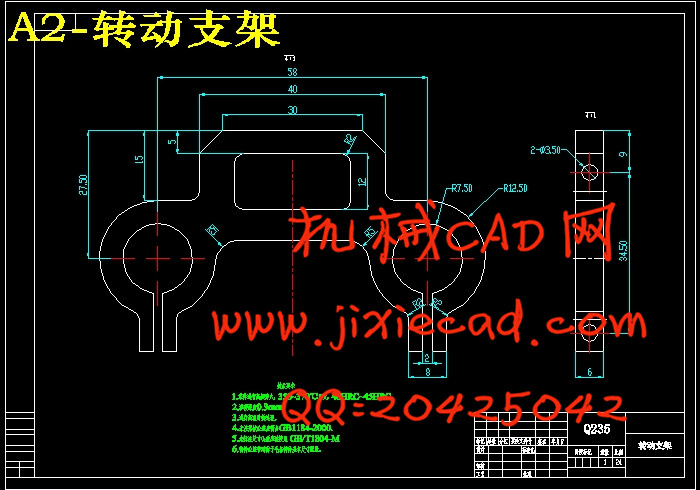

3.6轴承设计计算 19

3.7齿轮参数设计校核 21

3.8本章小结 23

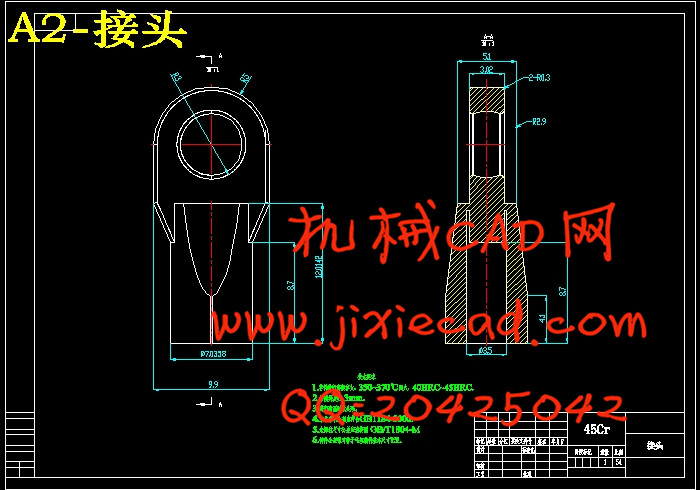

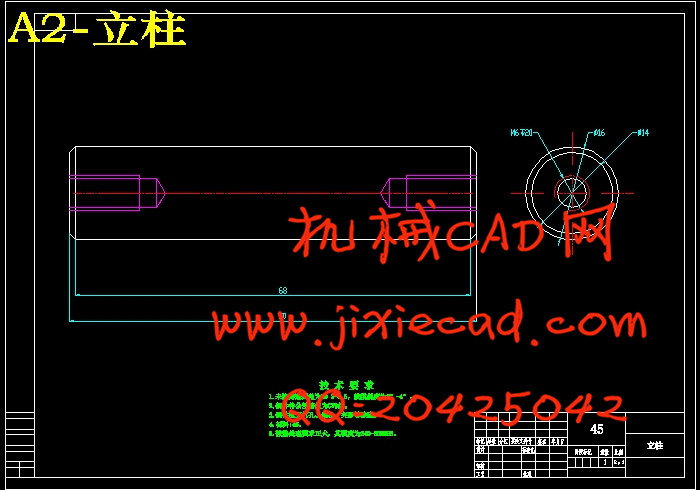

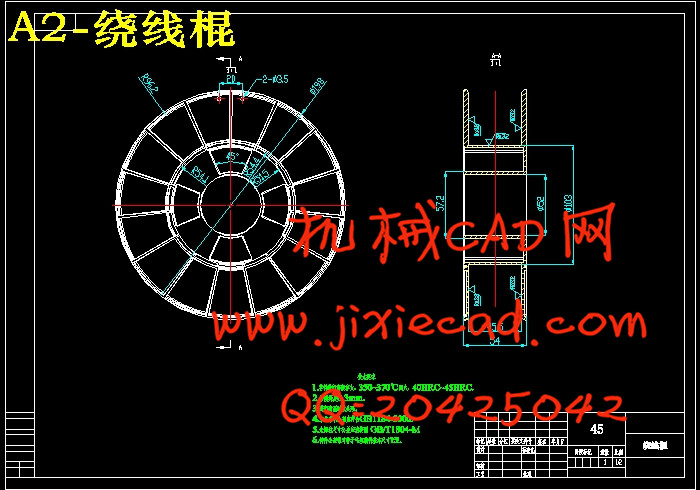

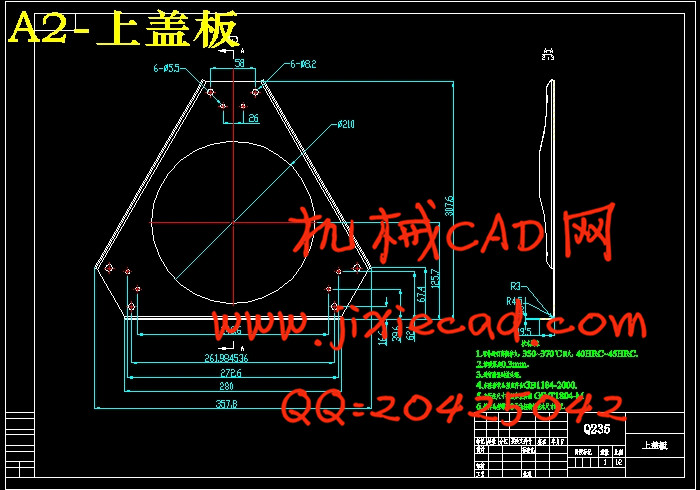

第4章 3D打印机三维建模 24

4.1 Solidworks三维建模技术 24

4.2 3D打印机三维建模 24

4.3 3D打印机装配 35

4.4 本章小结 37

参考文献 39

致谢 40

三维打印(3D printing),即快速成形技术的一种,它是一种数字模型文件为基础,运用粉末状金属或塑料等可粘合材料,通过逐层打印的方式来构造物体的技术。过去其常在模具制造、工业设计等领域被用于制造模型,现正逐渐用于一些产品的直接制造。特别是一些高价值应用(比如髋关节或牙齿,或一些飞机零部件)已经有使用这种技术打印而成的零部件。“三维打印”意味着这项技术的普及。三维打印通常是采用数字技术材料打印机来实现。这种打印机的产量以及销量在二十一世纪以来就已经得到了极大的增长,其价格也正逐年下降。三维打印技术以及由此带来的新的产业模式成为学术界、产业界、投资人及政策制定者共同关注的焦点和科技角逐的新方向,它的应用领域也非常广泛。三维打印技术提供了复杂的艺术品制作可能性,比传统的模具工艺更容易实现制造。此外,大尺寸艺术品,传统方法大多是设计者制作小比例的作品,然后再由数名工匠根据模型一同制作大比例的作品,工匠水平高低不一,最终作品失真度大,但是通过三维打印技术,目标模型可在计算机内调节比例,通过高精度高效率的打印制作,可以获得高精度的艺术作品。

本文的设计内容为调研3D打印机工作原理以及发展现状,根据调研结果,针对当前应用较为广泛的3D打印机进行分析比较,综合各个结构的特点,设计3D打印机的构型方案。根据设计方案,对电机、轴承、带轮及其附属机构进行选型计算,并进行应力校核;最后根据设计方案,采用三维软件solidworks软件对3D打印机进行三维建模。

关键词: 3D打印机、结构设计、三维建模、复杂性

Abstract

Three dimensional printing (3 d printing), namely a kind of rapid prototyping technology, it is a model of digital document as the foundation, using the adhesive materials, such as powder metal or plastic to construct objects by means of step by step a printing technology.It used in the mold manufacturing, industrial design, and other fields has been used in the manufacture of the model, is now gradually used for direct manufacturing of some products.In particular, some high value applications (such as hip or teeth, or some parts of the plane) has been using the technology of printing components."3 d printing" means that the popularization of the technology.3 d printing is usually adopt digital printer.Production and sales for the printer in the 21st century has got tremendous growth, its price is also gradually decreased.3 d printing technology, and the resulting new industry pattern become academia, industry, investors and policy makers to focus and compete for the new direction of science and technology, its application field is very broad.3 d printing technology provides a complex art production possibilities, it is easier to implement than traditional mould process manufacturing.In addition, the large size artwork, traditional methods are mostly designers make small proportion of the work, and then made large scale according to the model with the number of craftsmen, artisans have different level of high and low, eventually work distortion degree is big, but by three dimensional printing technology, the target model can adjust the proportion within the computer, by using print production with high efficiency, high precision can achieve high precision work of art.In this paper, the design content of working principle and development present situation of the research on 3 d printer, according to the survey results, which has been widely applied for the current is analyzed by 3 d printers, characteristic of each structure, design of a 3 d printer configuration scheme.According to the design scheme of bearing, pulley, selection of gear and its affiliates, and stress checking.According to the design scheme of using 3 d software solidworks software for 3 d modeling 3 d printers.

Keywords: 3 D printer,the structure design, 3 D modeling ,complexity

目录

摘 要 IVAbstract V

第1章 绪论 6

1.1论文概述 6

1.2 3D打印机国内外发展现状 6

1.3本文研究内容 7

1.4研究意义 7

第2章 3D打印机方案设计 9

2.1 3D打印机应用 9

2.2 3D打印机结构原理 9

2.3 3D打印机总体方案 10

2.4本章小结 10

第3章 3D打印机设计计算 11

3.1设计参数 11

3.2电机选型设计 11

3.3联轴器的选用原则 13

3.4带传动的设计 15

3.5螺栓校核计算 17

3.6轴承设计计算 19

3.7齿轮参数设计校核 21

3.8本章小结 23

第4章 3D打印机三维建模 24

4.1 Solidworks三维建模技术 24

4.2 3D打印机三维建模 24

4.3 3D打印机装配 35

4.4 本章小结 37

参考文献 39

致谢 40