设计简介

摘 要

在爆炸危险区域的自控系统设计中,人们在实践中积累了各种防爆方法,如本质安全型、正压通风型、隔爆型、增安型、充沙型、充油型、浇封型等各种防爆方法。本文以济源市科灵电器有限责任公司的产品为背景,针对目前国内隔爆开关在特殊工作场所中的防爆要求,在公司原有产品技术和设备的基础上,提出了一种较为理想的隔爆兼本质安全型双速真空电磁起动器的设计方案,将隔爆兼本质安全防爆技术与交流双速电机启动技术有机结合开发完成了本次设计产品。

本文第一章首先介绍了煤矿井下防爆技术的发展概况以及电动机防爆起动技术的现状与发展趋势。进一步提出矿用隔爆装置的防爆技术要求,点明本课题主要解决的问题。

本文第二章针对本质安全电路的原理、特点及国家标准的要求,阐述了本质安全电路设计的基本原则及方法。分析了目前矿井电动机控制系统先导电路的工作原理,按照本安电路设计规范要求对煤矿井下防爆隔爆开关的本安电路结构及元件的选型进行了设计计算。对矿用隔爆开关整体设计进行了概述,说明了矿用隔爆开关的工作原理、主电路设计,根据元件的额定值选型从而对隔爆开关设备中所使用的电气元件(真空接触器)进行选型,以及隔爆开关内部电器与整体布局结构设计。

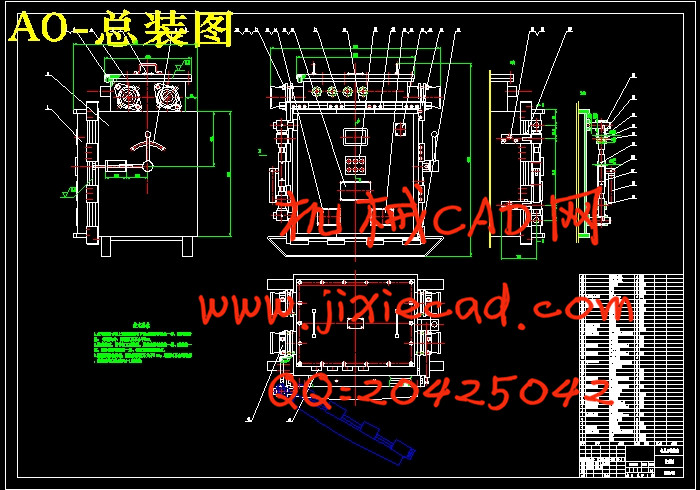

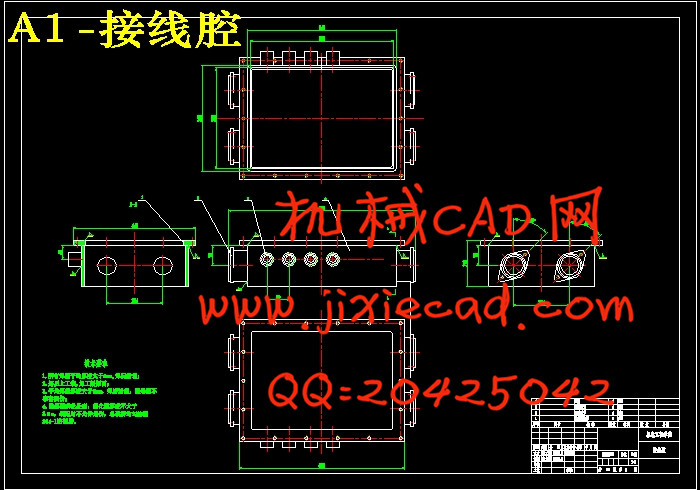

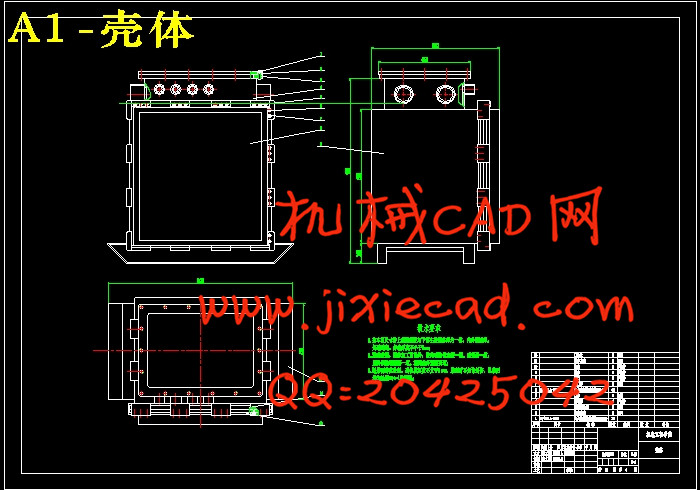

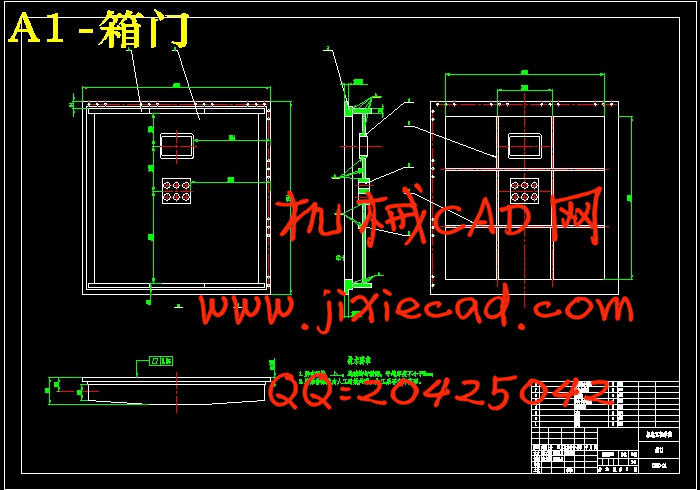

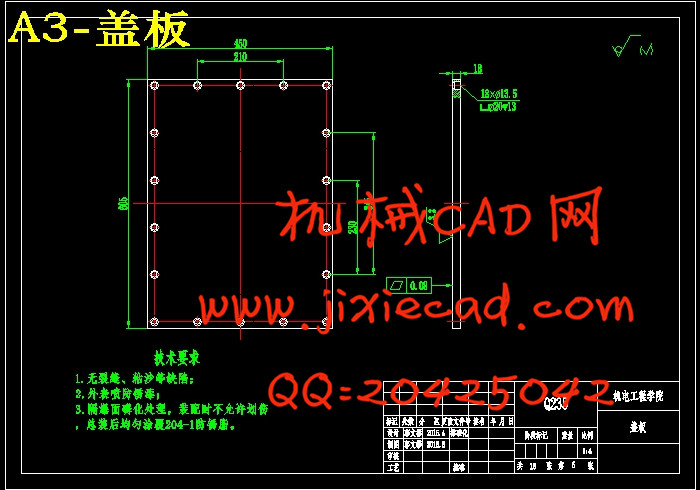

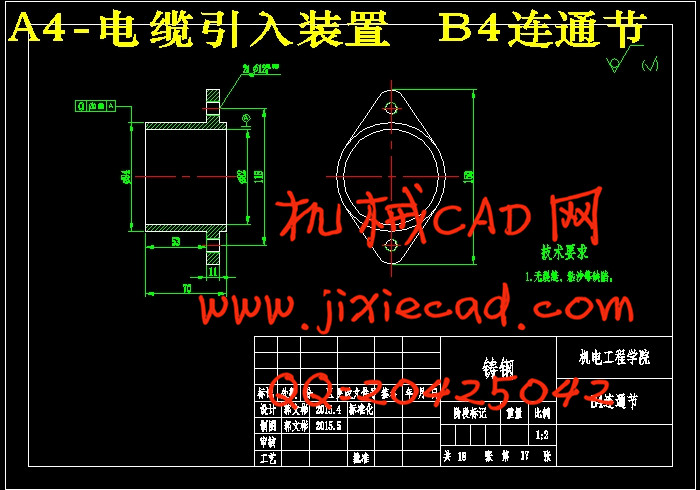

本文第三章重点分析了矿用防爆隔爆开关的防爆壳体的设计思路,以标准化隔爆级别和安装维护的方便为前提,从防爆外壳的选材,到结构型号,再到接线方式,结合面的配合程度,甚至外壳上配用的螺栓螺母,均按相应的国家技术标准要求设计完成了一套完整的产品装配图与零件图。

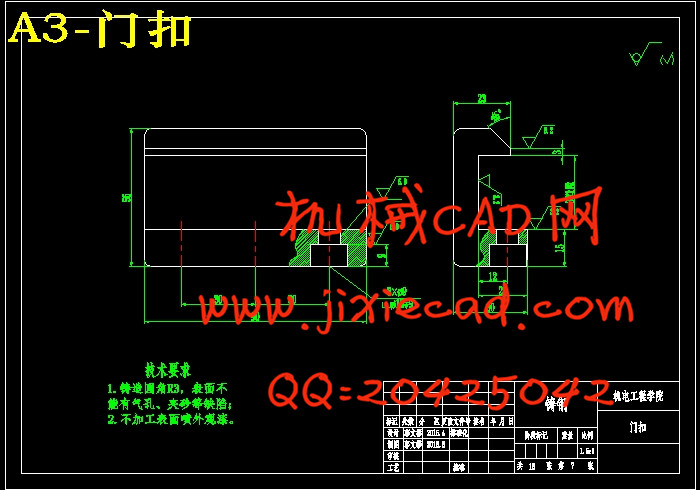

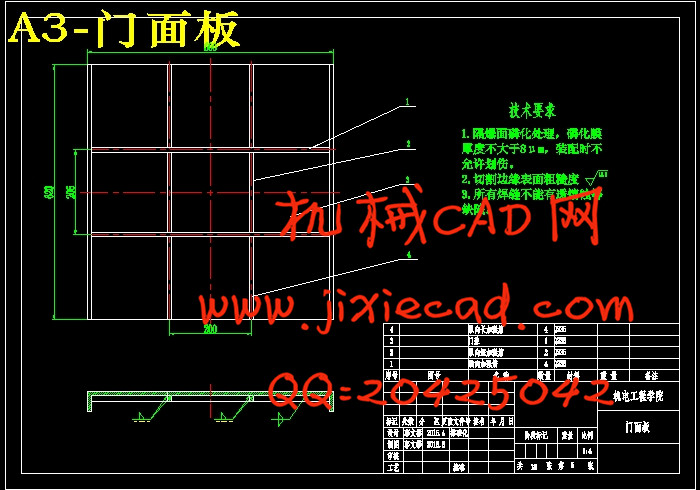

本文第四章分析了何种快开门机构适合本次设计的矿用防爆隔爆开关,并对快开门机构进行设计。

本文第五段进行了总结。

关键词:防爆技术,双速交流电动机,隔爆结构,本安电路

ABSTRACT

In the explosion danger area in the design of automatic control system, people accumulated explosion protection methods in practice, such as intrinsically safe, positive pressure ventilation type, flameproof, increased safety, filling sand, oil filled type, such as encapsulation type explosion-proof methods. Electric appliance co., LTD in jiyuan city branch spirit products as the background, in view of the present domestic flame-proof switch in special explosion-proof requirements in the workplace, in the original products of the company, on the basis of technology and equipment, this paper proposes a ideal explosion-proof and intrinsically safe design of double speed vacuum electromagnetic starter, explosion-proof and intrinsically safe explosion-proof technology combine with ac double-speed motor start technology development has completed the design of products.

In this paper, the first chapter firstly introduces the general situation of the coal mine explosion-proof technology, and the current situation and trend of development of explosion-proof motor starting technology. Further put forward the explosion-proof technology requirements of mining flame-proof device, this topic mainly solve the problem.

In this paper, the second chapter in the light of the principle, characteristics of intrinsically safe circuit and the requirements of national standard, this paper expounds the basic principles and methods of intrinsically safe circuit design. Analysis of the current mine motor control system pilot circuit principle of work, according to the requirements of the Ann circuit design specifications of the coal mine explosion-proof explosion-proof switch in the circuit structure and the selection of components for the design and calculation. Of mining flame-proof switch overall design were summarized, and illustrates the working principle of mining flame-proof switch, the main circuit design, according to the rating of components selection and flame-proof switch equipment used in the selection of electrical components (vacuum contactor), and flame-proof switch internal electrical structure design and the overall layout.

In this paper, the third chapter analyses the mine explosion-proof explosion-proof switch of flameproof shell design train of thought, in a standardized and isolation level and easy installation and maintenance of the premise, from material selection, explosion-proof enclosure to the structure model, and then to the connection mode, combined with the matching degree, even on the shell with bolt and nut, are designed according to the requirements of relevant national technical standards for a complete set of product assembly drawing and part drawing.

In this paper, the fourth chapter analyzes what is open mechanism suitable for the design of mine explosion-proof explosion-proof switch, and open the door for fast mechanism to carry on the design.

In this paper, the fifth section are summarized.

Keywords: explosion-proof technology, double speed ac motor, explosion-proof structure, the circuit

目 录

第一章 绪论………………………………………………………………………… 1在爆炸危险区域的自控系统设计中,人们在实践中积累了各种防爆方法,如本质安全型、正压通风型、隔爆型、增安型、充沙型、充油型、浇封型等各种防爆方法。本文以济源市科灵电器有限责任公司的产品为背景,针对目前国内隔爆开关在特殊工作场所中的防爆要求,在公司原有产品技术和设备的基础上,提出了一种较为理想的隔爆兼本质安全型双速真空电磁起动器的设计方案,将隔爆兼本质安全防爆技术与交流双速电机启动技术有机结合开发完成了本次设计产品。

本文第一章首先介绍了煤矿井下防爆技术的发展概况以及电动机防爆起动技术的现状与发展趋势。进一步提出矿用隔爆装置的防爆技术要求,点明本课题主要解决的问题。

本文第二章针对本质安全电路的原理、特点及国家标准的要求,阐述了本质安全电路设计的基本原则及方法。分析了目前矿井电动机控制系统先导电路的工作原理,按照本安电路设计规范要求对煤矿井下防爆隔爆开关的本安电路结构及元件的选型进行了设计计算。对矿用隔爆开关整体设计进行了概述,说明了矿用隔爆开关的工作原理、主电路设计,根据元件的额定值选型从而对隔爆开关设备中所使用的电气元件(真空接触器)进行选型,以及隔爆开关内部电器与整体布局结构设计。

本文第三章重点分析了矿用防爆隔爆开关的防爆壳体的设计思路,以标准化隔爆级别和安装维护的方便为前提,从防爆外壳的选材,到结构型号,再到接线方式,结合面的配合程度,甚至外壳上配用的螺栓螺母,均按相应的国家技术标准要求设计完成了一套完整的产品装配图与零件图。

本文第四章分析了何种快开门机构适合本次设计的矿用防爆隔爆开关,并对快开门机构进行设计。

本文第五段进行了总结。

关键词:防爆技术,双速交流电动机,隔爆结构,本安电路

ABSTRACT

In the explosion danger area in the design of automatic control system, people accumulated explosion protection methods in practice, such as intrinsically safe, positive pressure ventilation type, flameproof, increased safety, filling sand, oil filled type, such as encapsulation type explosion-proof methods. Electric appliance co., LTD in jiyuan city branch spirit products as the background, in view of the present domestic flame-proof switch in special explosion-proof requirements in the workplace, in the original products of the company, on the basis of technology and equipment, this paper proposes a ideal explosion-proof and intrinsically safe design of double speed vacuum electromagnetic starter, explosion-proof and intrinsically safe explosion-proof technology combine with ac double-speed motor start technology development has completed the design of products.

In this paper, the first chapter firstly introduces the general situation of the coal mine explosion-proof technology, and the current situation and trend of development of explosion-proof motor starting technology. Further put forward the explosion-proof technology requirements of mining flame-proof device, this topic mainly solve the problem.

In this paper, the second chapter in the light of the principle, characteristics of intrinsically safe circuit and the requirements of national standard, this paper expounds the basic principles and methods of intrinsically safe circuit design. Analysis of the current mine motor control system pilot circuit principle of work, according to the requirements of the Ann circuit design specifications of the coal mine explosion-proof explosion-proof switch in the circuit structure and the selection of components for the design and calculation. Of mining flame-proof switch overall design were summarized, and illustrates the working principle of mining flame-proof switch, the main circuit design, according to the rating of components selection and flame-proof switch equipment used in the selection of electrical components (vacuum contactor), and flame-proof switch internal electrical structure design and the overall layout.

In this paper, the third chapter analyses the mine explosion-proof explosion-proof switch of flameproof shell design train of thought, in a standardized and isolation level and easy installation and maintenance of the premise, from material selection, explosion-proof enclosure to the structure model, and then to the connection mode, combined with the matching degree, even on the shell with bolt and nut, are designed according to the requirements of relevant national technical standards for a complete set of product assembly drawing and part drawing.

In this paper, the fourth chapter analyzes what is open mechanism suitable for the design of mine explosion-proof explosion-proof switch, and open the door for fast mechanism to carry on the design.

In this paper, the fifth section are summarized.

Keywords: explosion-proof technology, double speed ac motor, explosion-proof structure, the circuit

目 录

1.1 乳化液泵站的描述……………………………………………………………… 1

1.2 工业防爆技术概况……………………………………………………………… 1

1.3 矿用防爆电器产品的技术创新和发展趋势……………………………………3

1.3.1 矿用防爆电器产品的技术创新………………………………………… 3

1.3.2 矿用防爆电器产品的发展趋势………………………………………… 5

1.4 起动装置的防爆技术要求……………………………………………………… 6

第二章 隔爆开关电路设计………………………………………………………… 9

2.1 隔爆开关的特点及主要性能…………………………………………………… 9

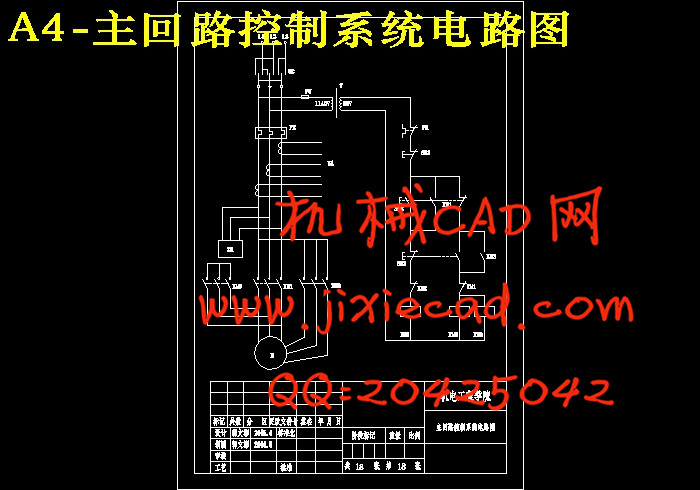

2.2 隔爆开关部分元件选型和主电路原理图……………………………………… 11

2.2.1 隔爆开关接触器选型…………………………………………………… 11

2.2.2 隔爆开关主电路原理图………………………………………………… 12

2.3 隔爆开关起动原理和保护……………………………………………………… 12

2.3.1 隔爆开关的起动原理…………………………………………………… 12

2.3.2 隔爆开关的保护………………………………………………………… 14

2.4 隔爆开关的使用和维护………………………………………………………… 14

2.5 隔爆开关内部电器与整体布局结构设计……………………………………… 15

2.5.1 外形结构………………………………………………………………… 15

2.5.2 主腔结构………………………………………………………………… 15

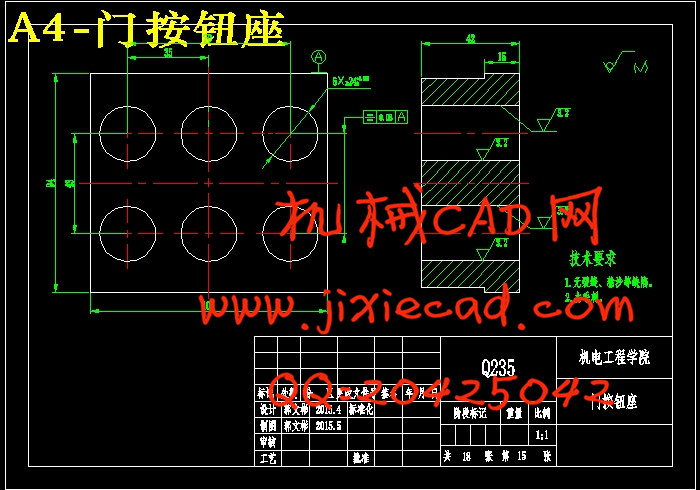

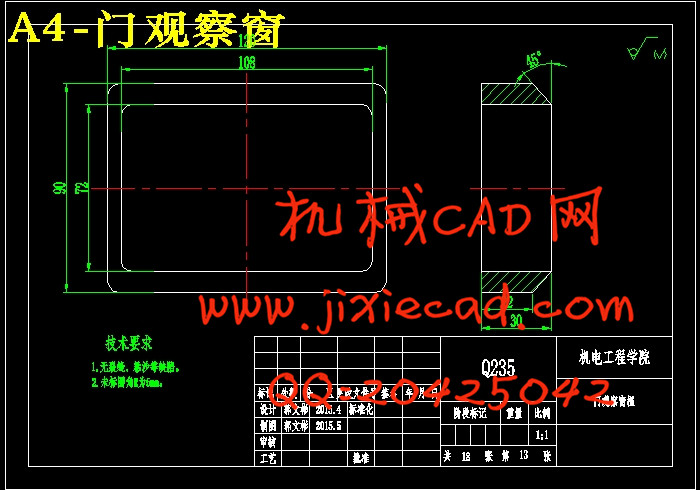

2.5.3 门上装置………………………………………………………………… 15

2.5.4 外壳接线腔……………………………………………………………… 16

第三章 隔爆开关隔爆结构设计………………………………………………… 17

3.1 隔爆壳体的设计研究…………………………………………………………… 17

3.2 隔爆开关的隔爆壳体设计……………………………………………………… 21

3.2.1 长方体隔爆壳体的设计方法…………………………………………… 21

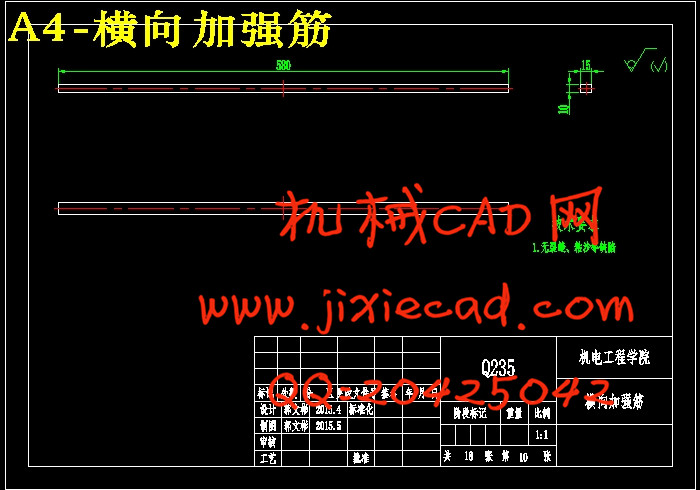

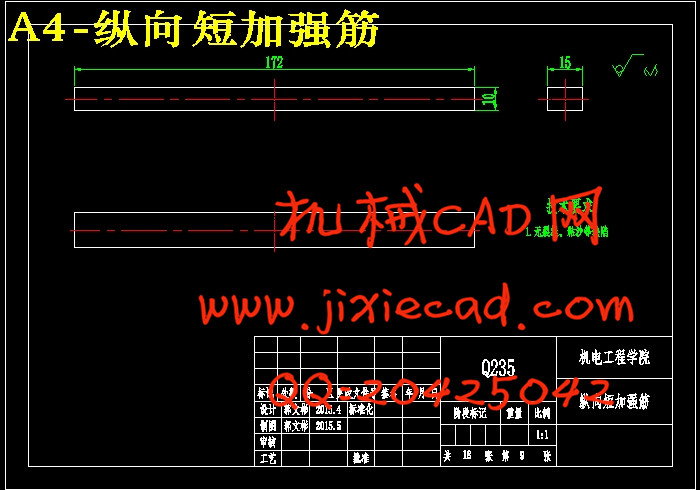

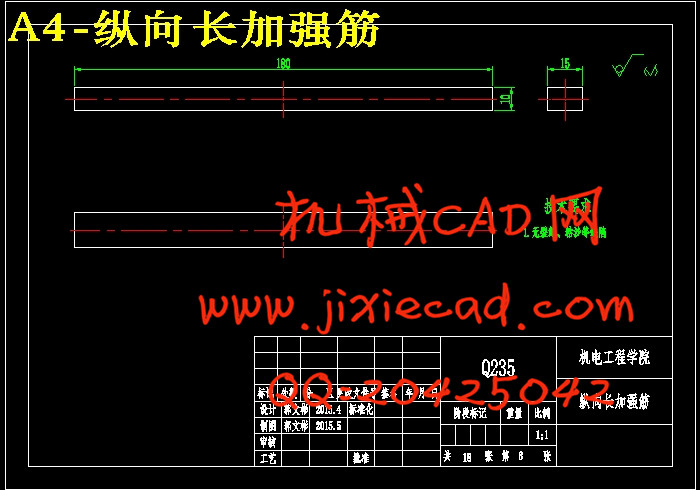

3.2.2 隔爆壳体加强筋的设计结果…………………………………………… 26

3.2.3 隔爆壳体壁板的设计方法……………………………………………… 28

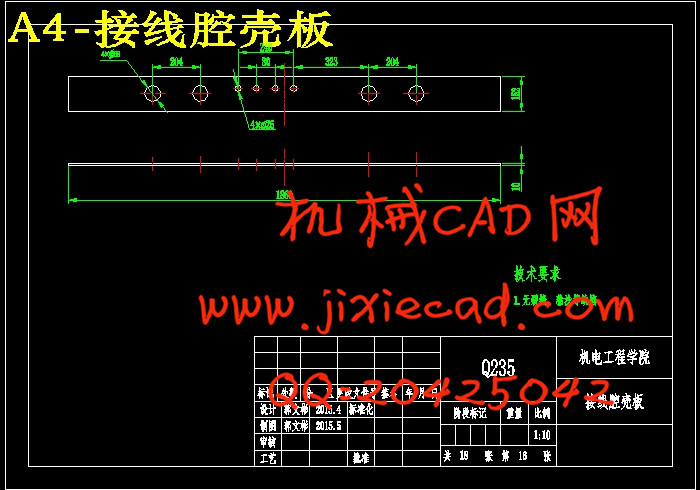

3.2.4 隔爆壳体壁板的设计结果……………………………………………… 28

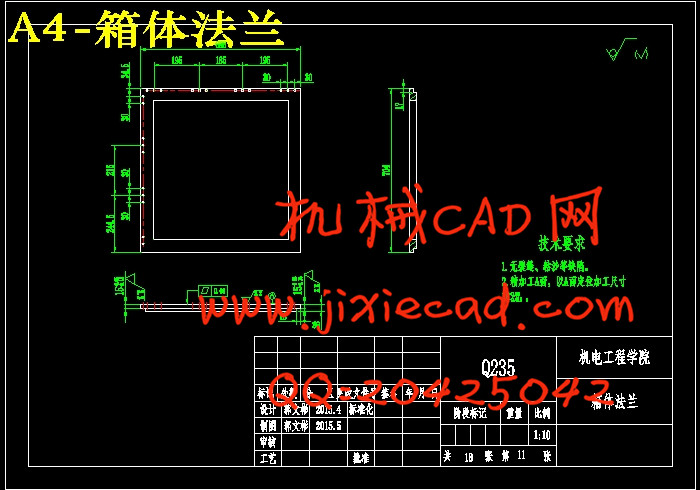

3.2.5 隔爆壳体法兰的刚度设计方法………………………………………… 29

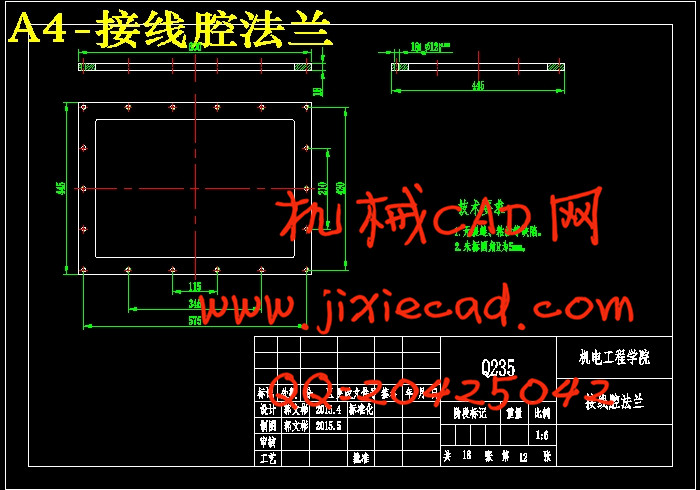

3.2.6 隔爆壳体法兰的设计结果……………………………………………… 31

3.3 连接螺钉的强度及数量………………………………………………………… 33

第四章 快开门机构设计…………………………………………………………… 36

4.1 快开门机构概述………………………………………………………………… 36

4.2 快开门机构的设计……………………………………………………………… 36

第五章 结论…………………………………………………………………………… 40

参考文献………………………………………………………………………………… 41

致谢……………………………………………………………………………………… 42