设计简介

摘要

气流干燥机是近年来一种新型物料干燥设备,传统的设计方法已经不能很好的满足产品设计的需要。它具有干燥效果好、体积小、热效率高、结构简单等特点,可广泛应用于化工、食品、医药、建材等行业的粒状、粉状并带有一定粘性物料的干燥。

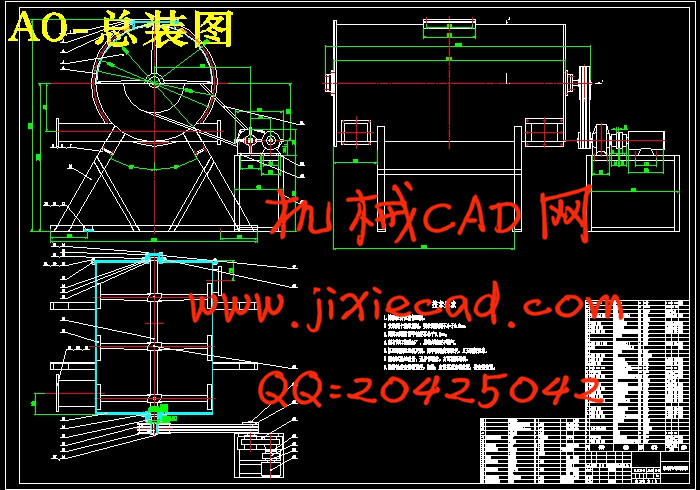

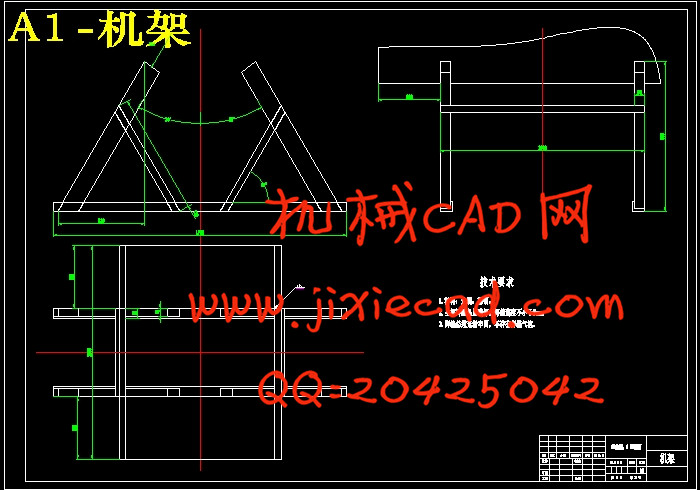

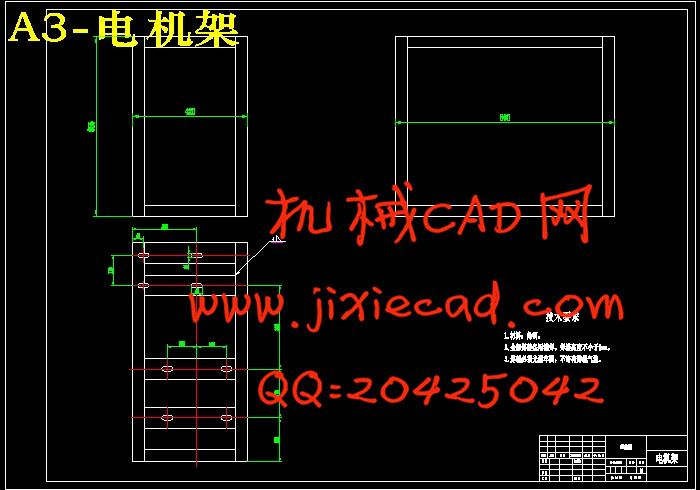

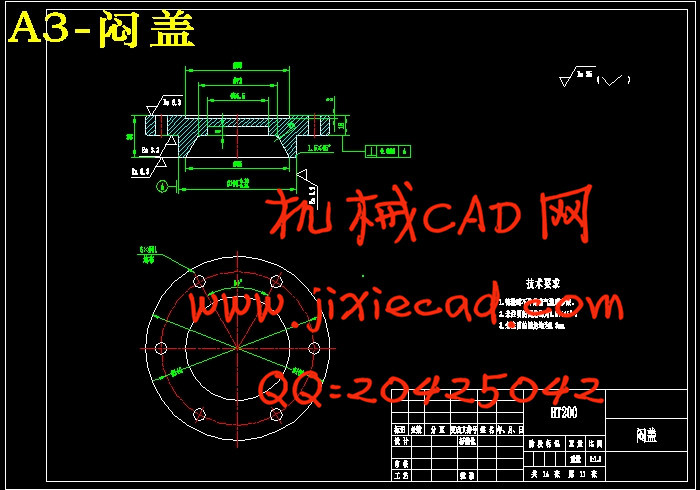

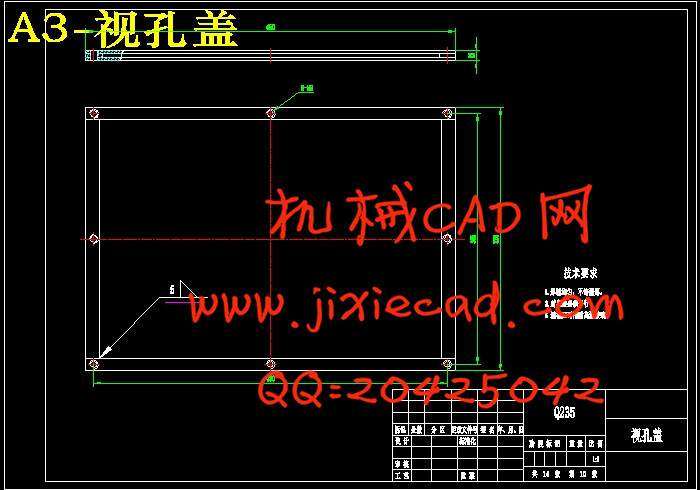

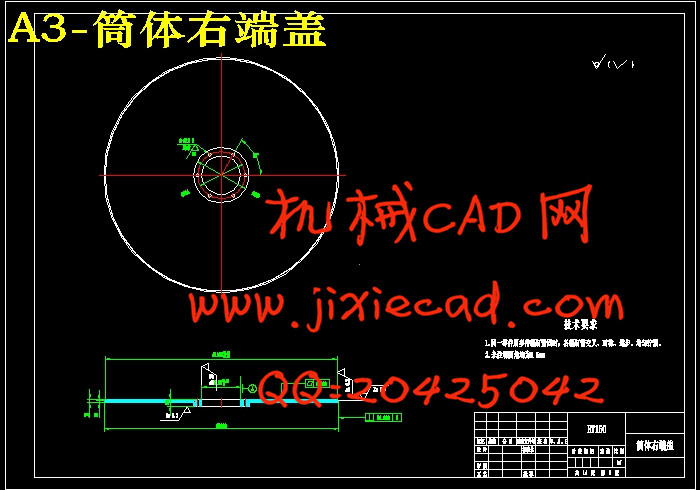

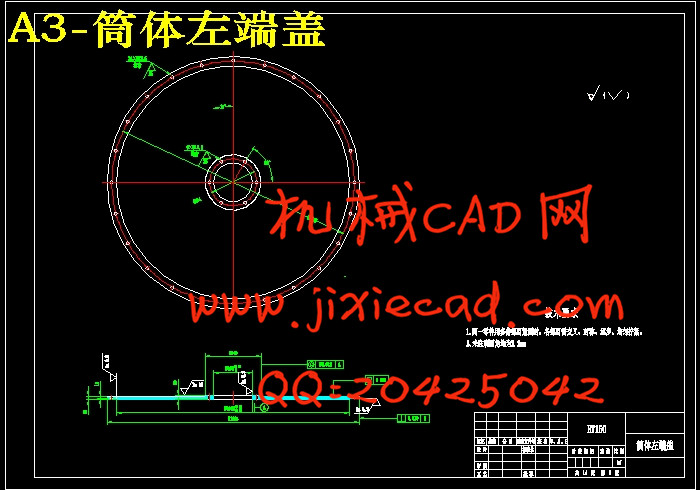

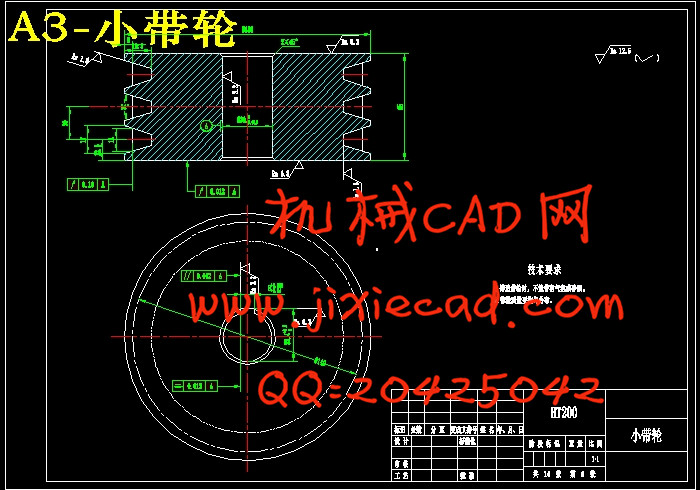

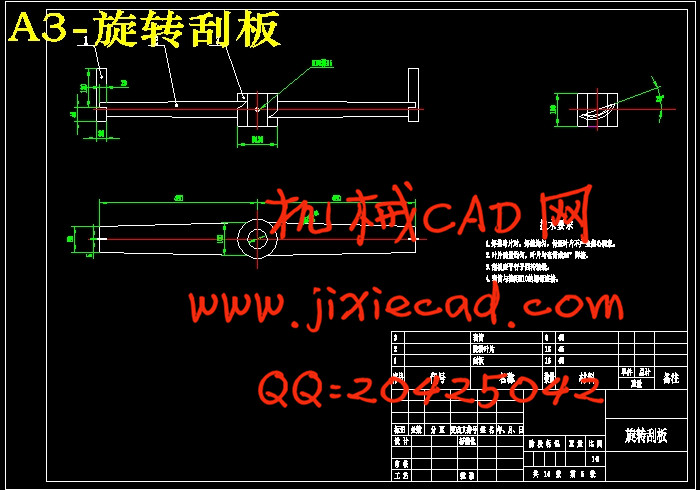

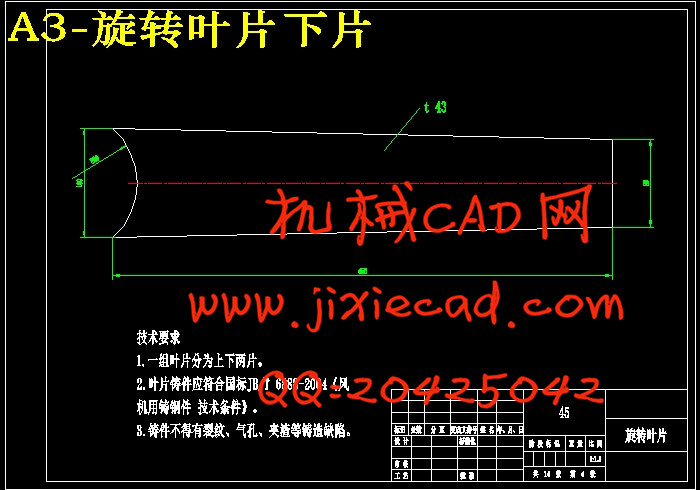

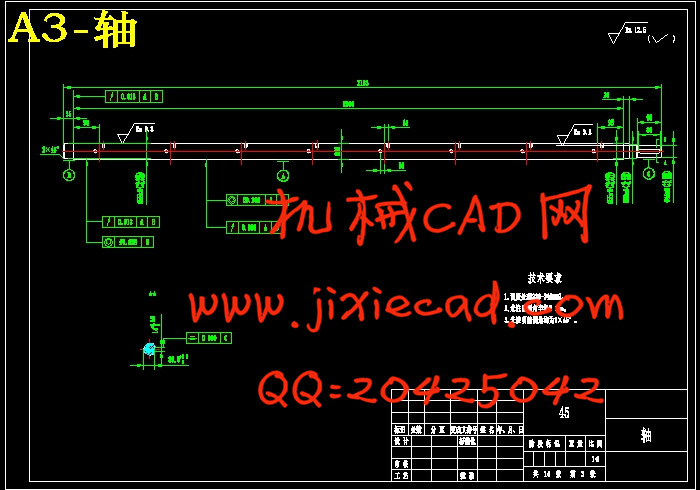

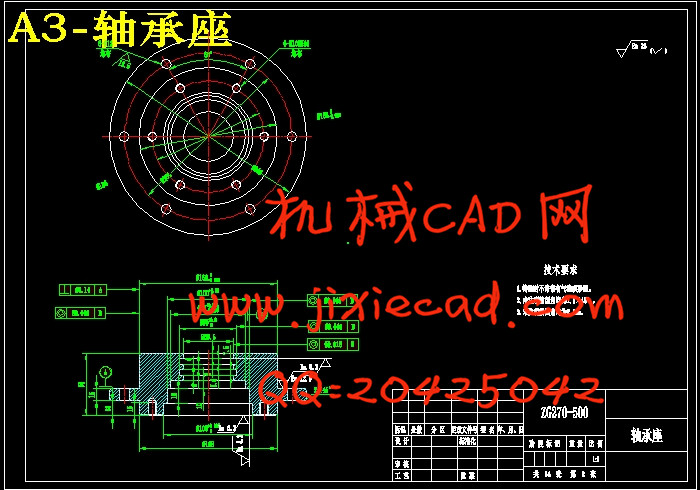

在查阅了相关文献资料并进行详细综述分析的基础上,介绍了气流干燥机在现代要求的工业环境中的发展历史、在各个行业中的应用及我国现在气流干燥机发展现状并讨论了今后的发展现状。本文主要分析了干燥机的工作原理,确定了干燥机筒体的长度,筒体的直径以及操作参数,,对传动部分进行了电机的选择,传动部分各零件的设计计算及校核。最后用 CAD 进行绘图,用 Solidworks 对部分典型零件进行了三维建模。

本次设计的干燥机体积小,工作效率高,而且结构简单,容易操作,便于维修,适合现代工业生产。

关键词:离心;干燥机;结构设计;三维建模

ABSTRACT

气流干燥机是近年来一种新型物料干燥设备,传统的设计方法已经不能很好的满足产品设计的需要。它具有干燥效果好、体积小、热效率高、结构简单等特点,可广泛应用于化工、食品、医药、建材等行业的粒状、粉状并带有一定粘性物料的干燥。

在查阅了相关文献资料并进行详细综述分析的基础上,介绍了气流干燥机在现代要求的工业环境中的发展历史、在各个行业中的应用及我国现在气流干燥机发展现状并讨论了今后的发展现状。本文主要分析了干燥机的工作原理,确定了干燥机筒体的长度,筒体的直径以及操作参数,,对传动部分进行了电机的选择,传动部分各零件的设计计算及校核。最后用 CAD 进行绘图,用 Solidworks 对部分典型零件进行了三维建模。

本次设计的干燥机体积小,工作效率高,而且结构简单,容易操作,便于维修,适合现代工业生产。

关键词:离心;干燥机;结构设计;三维建模

ABSTRACT

Air dryer is in recent years a new item, traditional design methods have been unable to match the needs of product design. It has a good effect on dry, small size, high thermal efficiency, simple structure, and other features, it can be widely applied in the chemical, food, medicine, building materials industries diffluence and somewhat viscous materials dry. First of all, the parametric design is establish by set up a geometric model whose characteristics and sizes are bound. And then, make some of the main parameters of the model as the entrance of driving the model regenerating. Finally, Change these parameters to generate a series of the geometric models associated with the original one.

In consulting the relevant documentation and detailed summary of the analysis, describes the drying machines in the modern requirements of industrial development in the context of history, in application of the various industries and our present state-of-the-art air dryer and discusses the development of the future. And analyzes the dryer works, determining the length of the drying cylinder, the diameter of the cylinder and operation parameters, etc. Last part with Solidworks on typical parts are three-dimensional modeling.

This design of dryer is small, efficient, and the structure is simple, easy to operate, easy maintenance, suitable for modern industrial production.

Key Words:Centrifugal;Drier;Architectural design;3D modeling

In consulting the relevant documentation and detailed summary of the analysis, describes the drying machines in the modern requirements of industrial development in the context of history, in application of the various industries and our present state-of-the-art air dryer and discusses the development of the future. And analyzes the dryer works, determining the length of the drying cylinder, the diameter of the cylinder and operation parameters, etc. Last part with Solidworks on typical parts are three-dimensional modeling.

This design of dryer is small, efficient, and the structure is simple, easy to operate, easy maintenance, suitable for modern industrial production.

Key Words:Centrifugal;Drier;Architectural design;3D modeling