设计简介

摘要

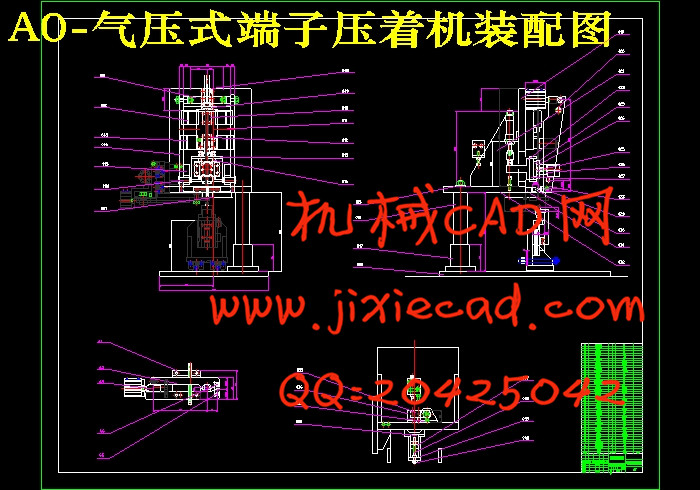

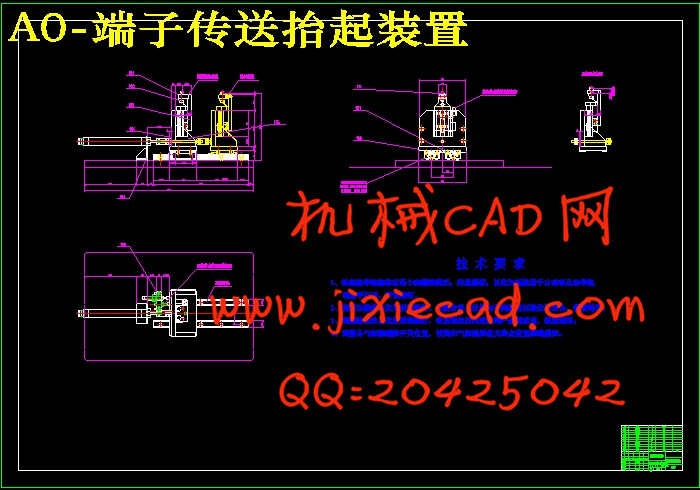

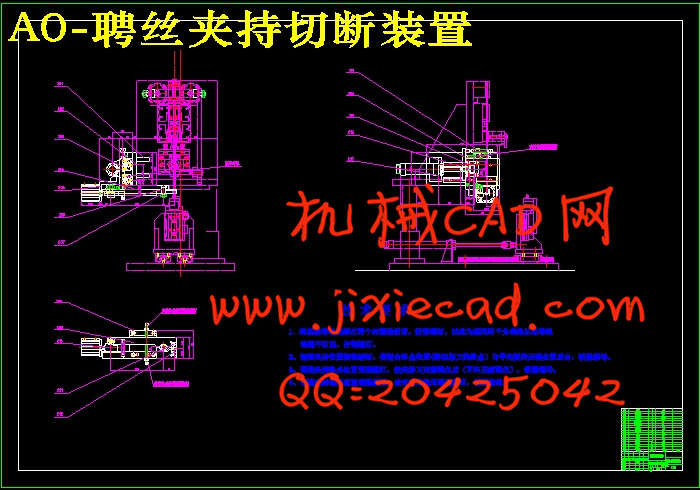

压着连接是端子连接器的连接或金属导体末尾与相似的金属器件连接的一种方式。端子压着机是完成聘丝与端子冷焊接的机械,端子压着机也属于进行线束加工的最后一道工序。气压式端子压着机是将传统的手动压接钳替换下来进行的改造设计,实现自动化装配功能。主要可分为三个装置:聘丝夹持切断装置;聘丝送进压溃装置;端子传送抬起装置。聘丝送进压溃装置的作用主要是对聘丝位置进行锁定,并输送;聘丝夹持切断装置的作用主要是将聘丝送进压溃装置输送的聘丝进行切割;端子传送抬起装置的作用主要是将端子传送到定点位置后抬起,使聘丝压入,整个工作就完成了。

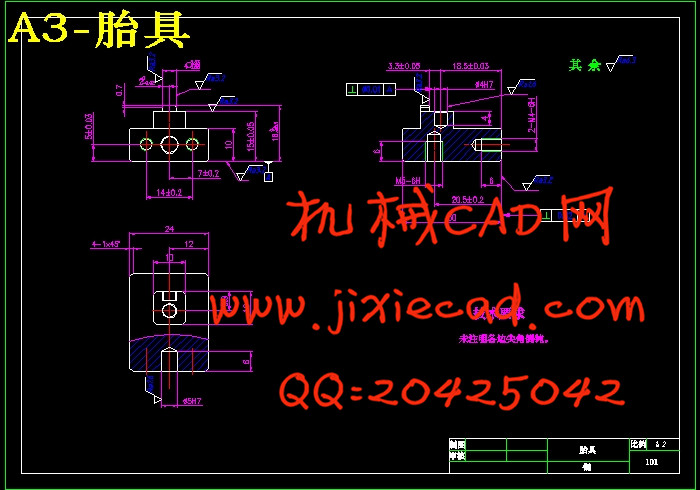

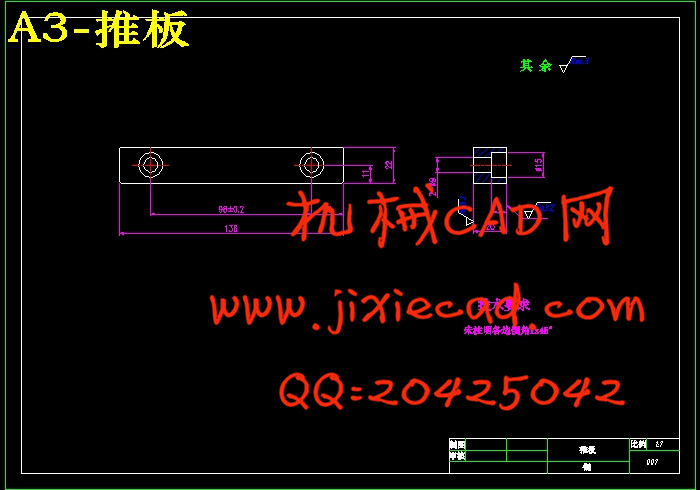

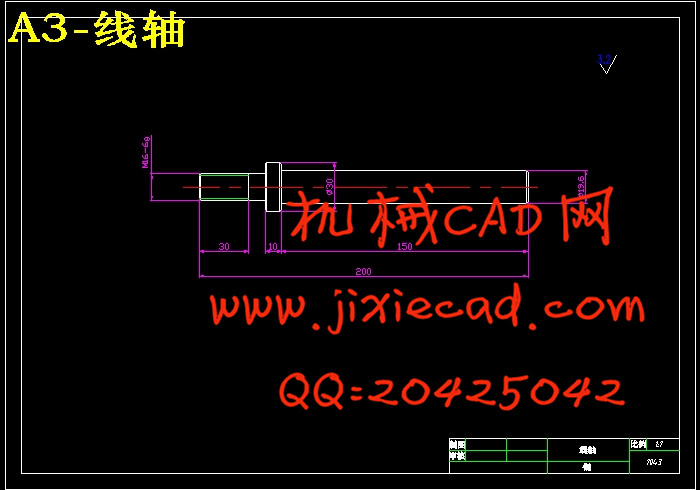

本次设计主要采用理论研究、计算、机械图绘制和计算机辅助设计的方法。通过查阅相关文献,了解端子压着机的工作原理、动作过程、各部件所起的作用,特别是对输送端子与定位装置的机械结构和工作原理进行研究,提出设计思路和方案;进行相关的理论计算,确定送输端子装置和定位装置主要零部件;采用CATIA表达出各装置三维模型。完成零件和部件的设计,并且用AutoCAD表达出各个机械结构图样。

本次机构整体设计不占用多余的空间,整体符合紧凑的实际理念。设计的气压式端子压着机解决了人工手动、产量和产品质量等问题,大大提高了工作效率,基本实现了自动化。

关键词:端子;自动化;压着连接;结构设计

ABSTRACT

The crimp connection is a way of connecting the terminal connector or the end of the metal conductor to a similar metal device.The terminal crimping machine belongs to the last process of harness processing, and is also the machine that completes the cold welding of the wire and the terminal.

Pneumatic terminal crimping machine is the traditional manual crimping pliers replaced by the transformation of the design, to achieve automatic assembly function.Mainly can be divided into three devices: wire clip holding device; wire into the crushing device; terminal transmission lifting device.The function of the wire feeding device is mainly to lock the position of the wire and convey it;The function of the wire holding and cutting device is to cut the wire to the crushing device,Terminal transmission lift device is the main function of the terminal to send to the fixed position after the lift, so that the hammer into the press, the whole work is completed.

This design mainly uses theoretical research, calculation, mechanical drawing and computer aided design method.By consulting the relevant literature, we can understand the working principle of the terminal crimping machine, the action process, the role of each component, especially the mechanical structure and working principle of the conveying terminal and positioning device, and put forward the design idea and scheme;Carry out the relevant theoretical calculation, determine the main components of the transmission terminal and positioning device;The three-dimensional model of each device was expressed by CATIA.Complete the design of parts and components, and use AutoCAD to express the various mechanical structure patterns.

The overall design of the agency does not take up extra space, the overall compliance with the actual concept of compact.The design of the pneumatic terminal crimping machine to solve the manual manual, yield and product quality and other issues, greatly improving the efficiency, the basic realization of the automation.

Key Words:Terminal; Automation; Crimping Connection; Institutional Design

目 录

摘要 Ι

ABSTRACT II

1 绪论 1

1.1 端子压着机概述 1

1.2 目前研究的概况和发展趋势 2

1.3 全自动端子压着机的特点 2

1.4 本设计工作内容 4

2 气压式端子压着机总体设计方案 5

2.1 导线剥离器的结构设计 5

2.2 整体设计思路和结构简图 6

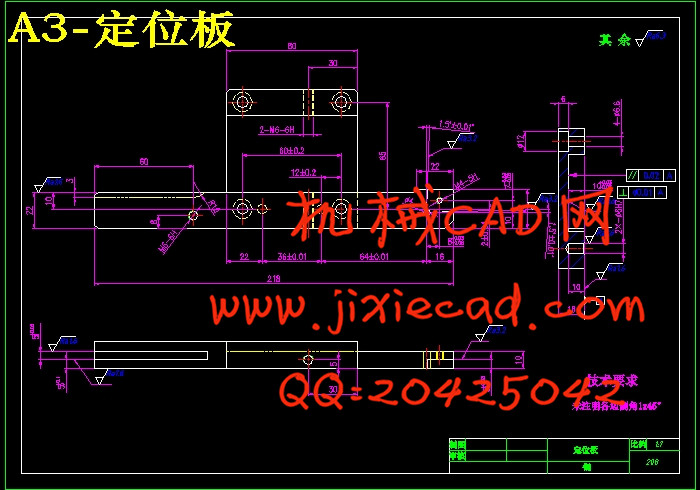

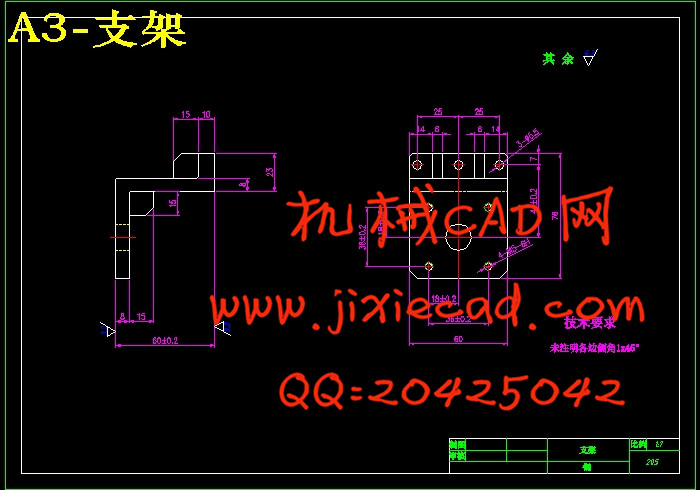

2.3 聘丝送进压溃装置设计 7

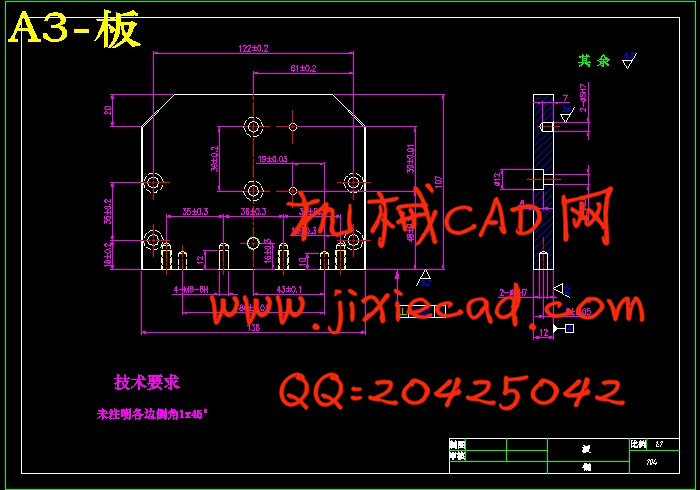

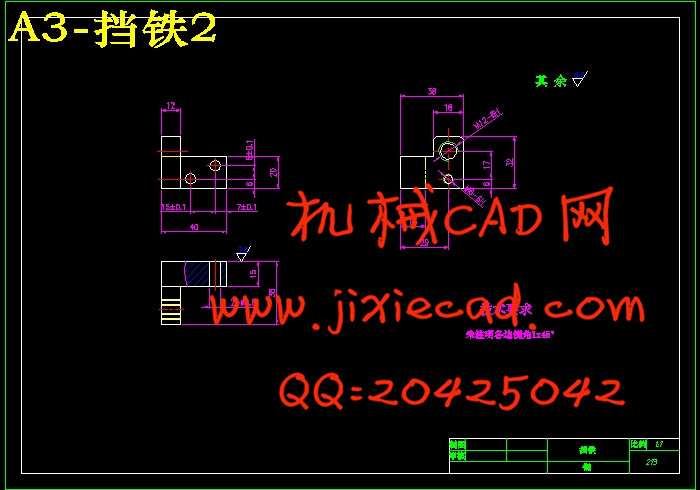

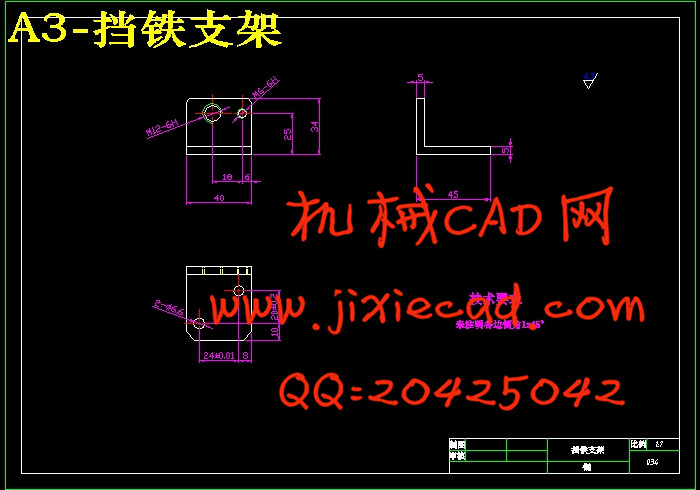

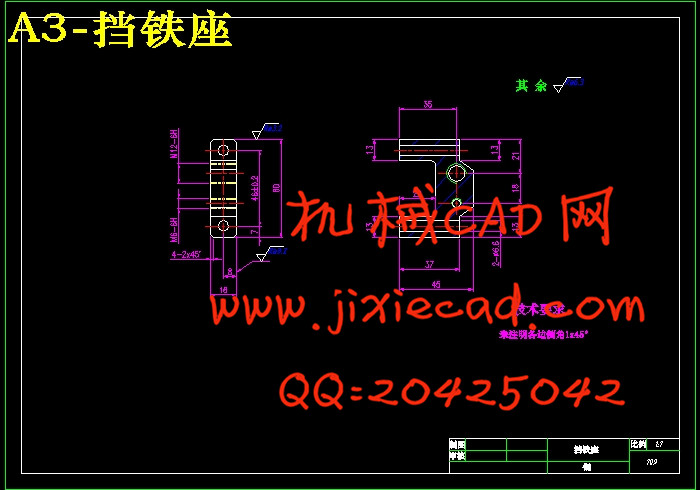

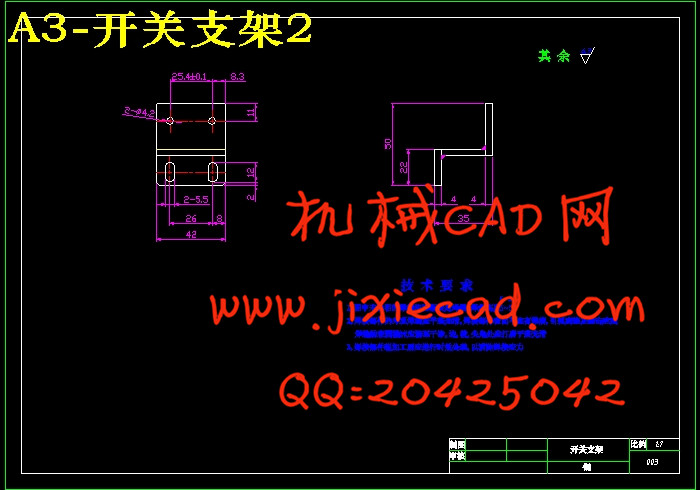

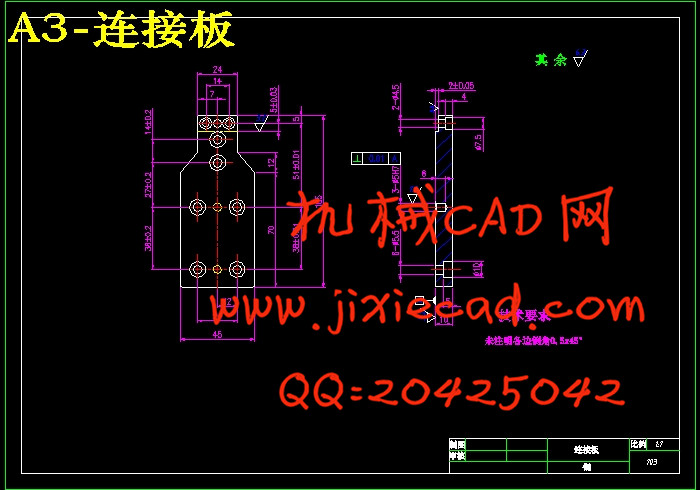

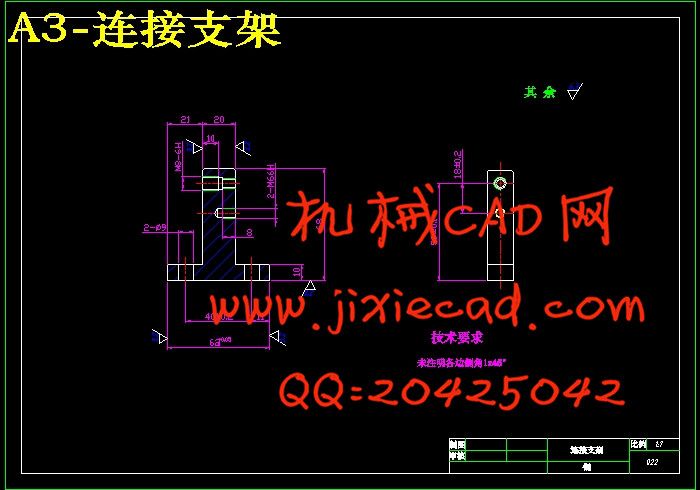

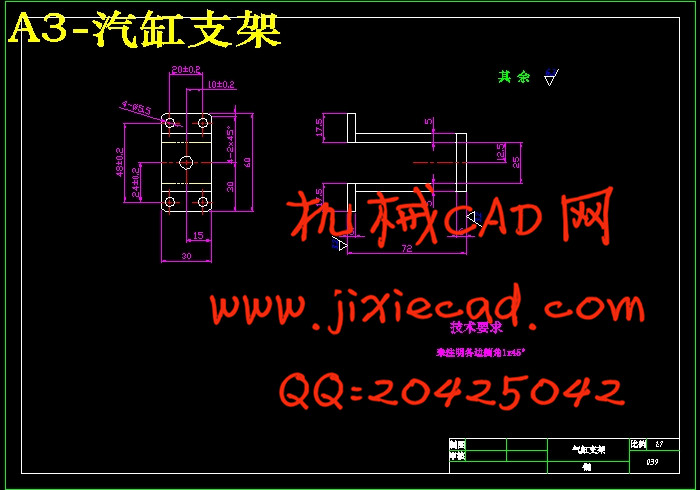

2.4 聘丝夹持切断装置设计 8

2.5 端子传送抬起装置设计 8

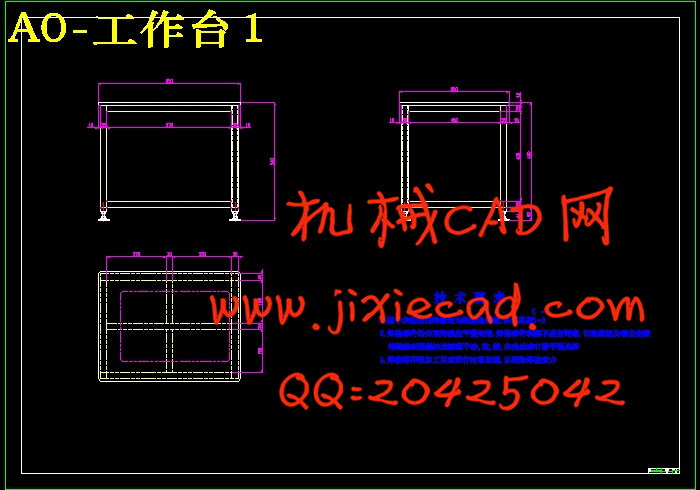

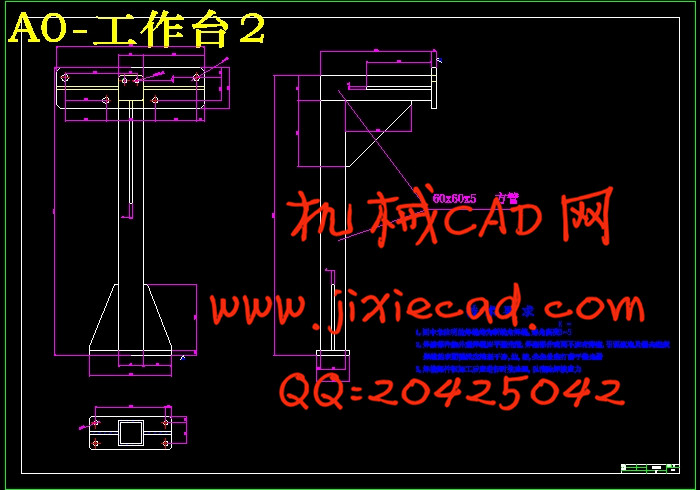

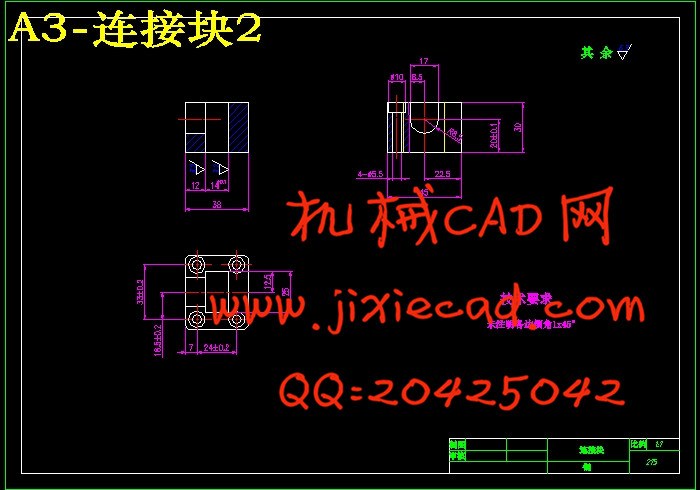

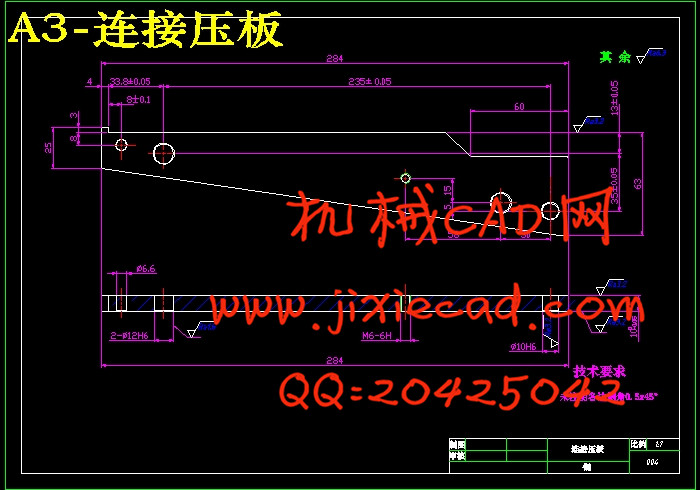

3 聘丝送进压溃装置设计 9

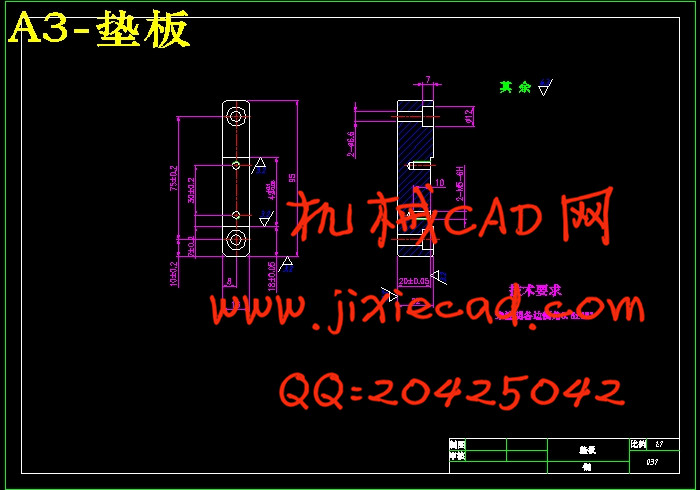

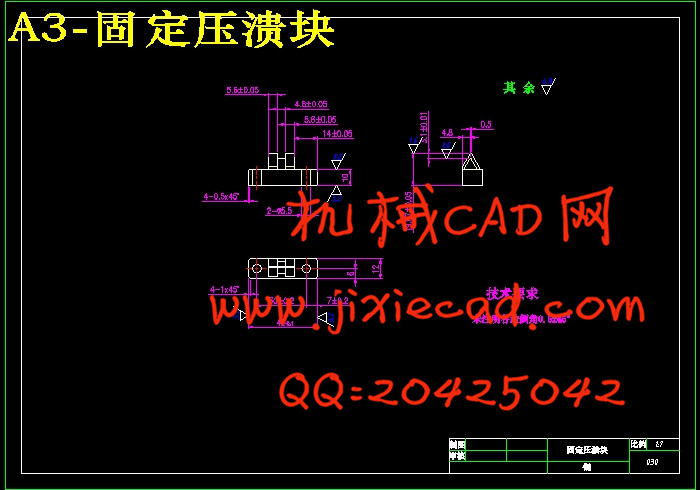

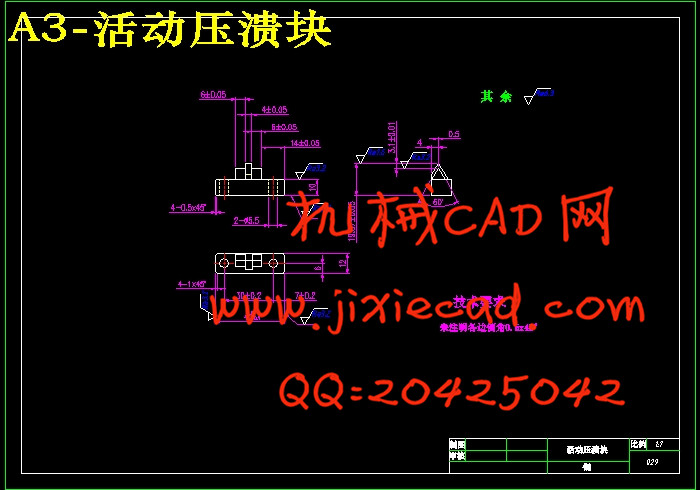

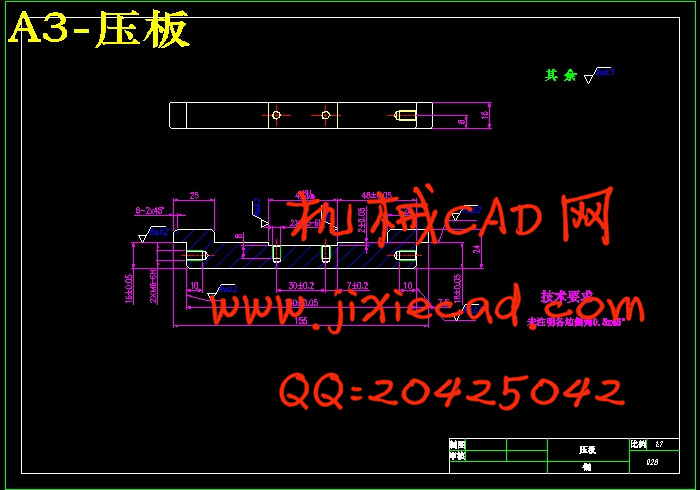

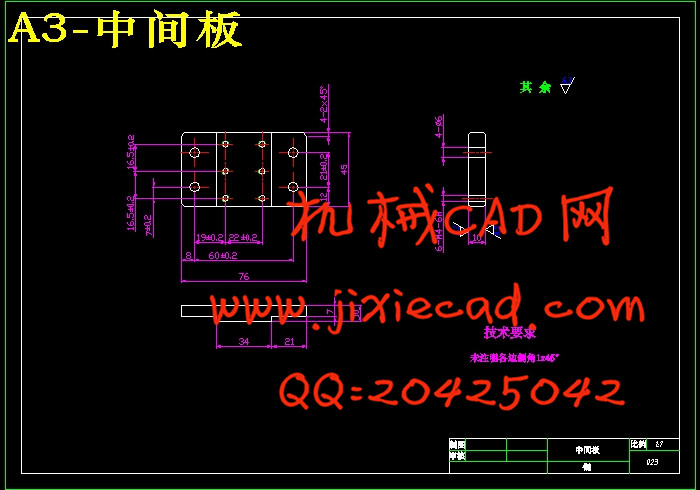

3.1 压溃块及导块设计 9

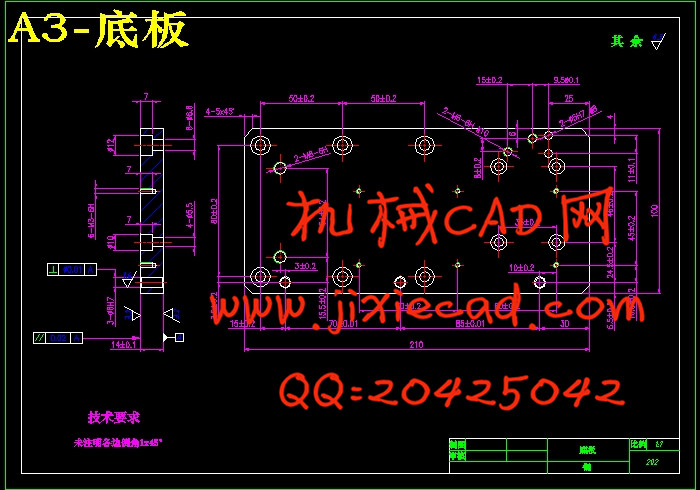

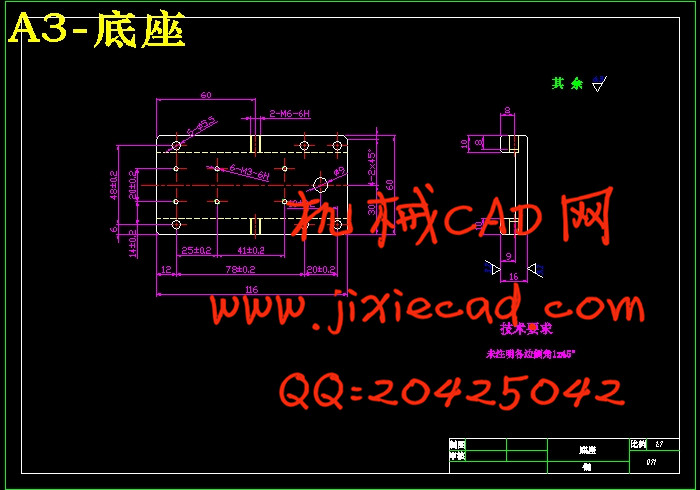

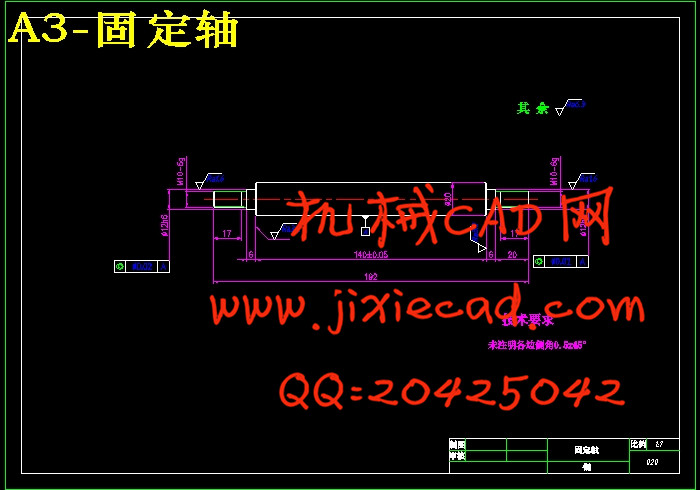

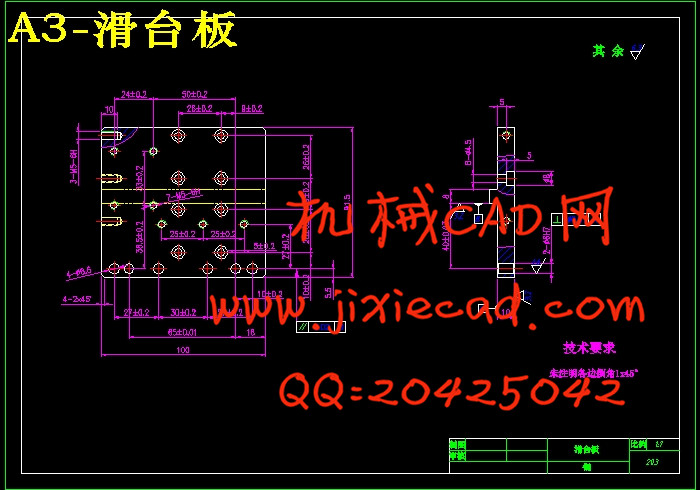

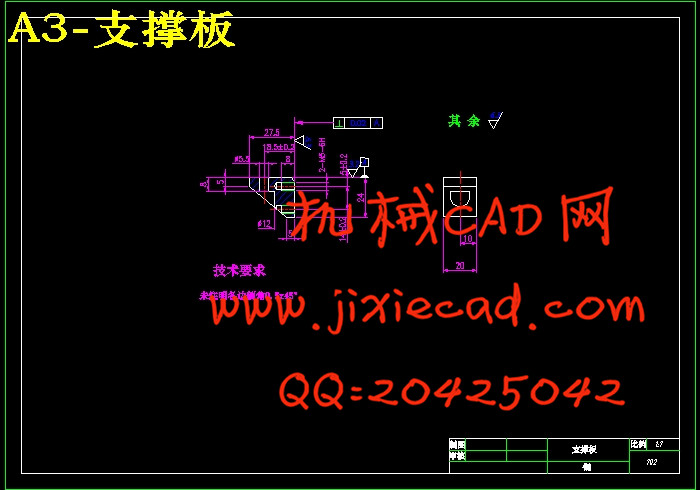

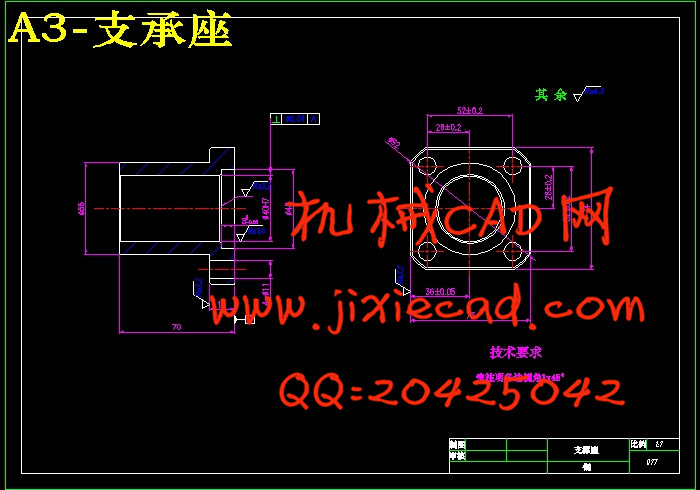

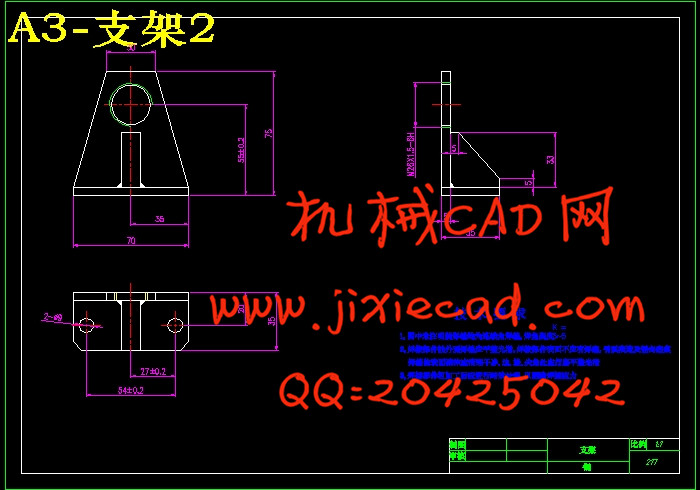

3.2 聘丝送进压溃装置支撑设计 14

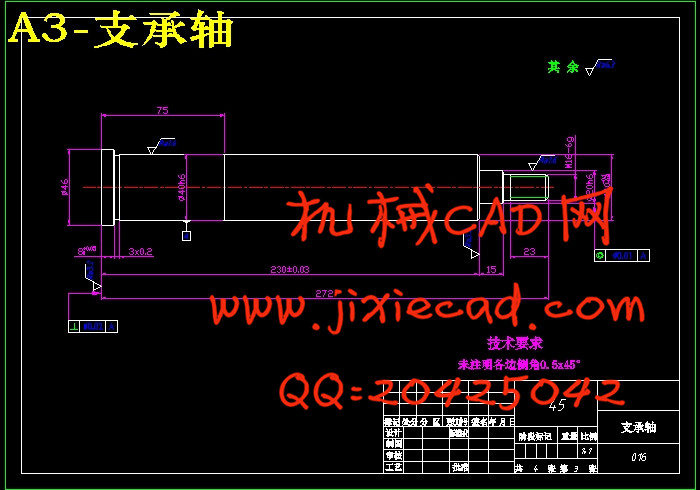

3.3 支承轴强度计算 18

4 聘丝夹持切断装置设计 21

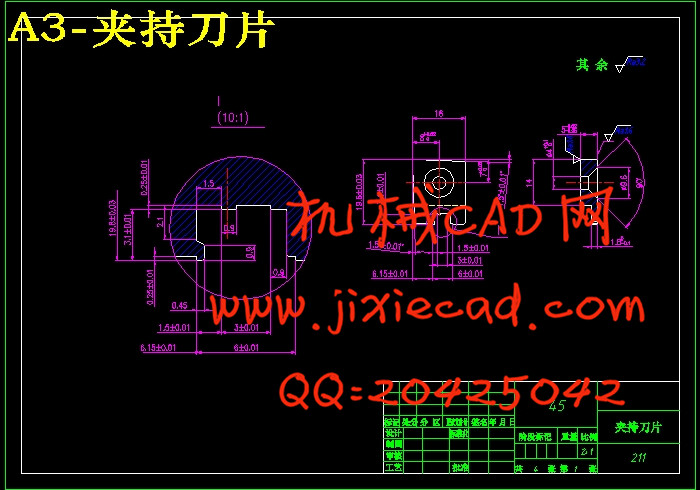

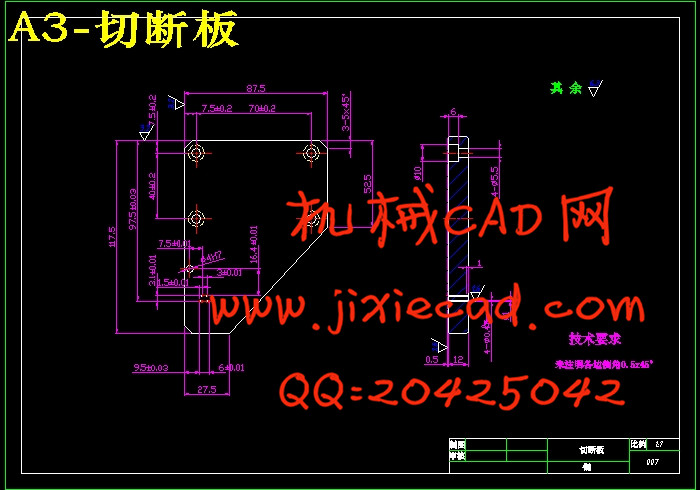

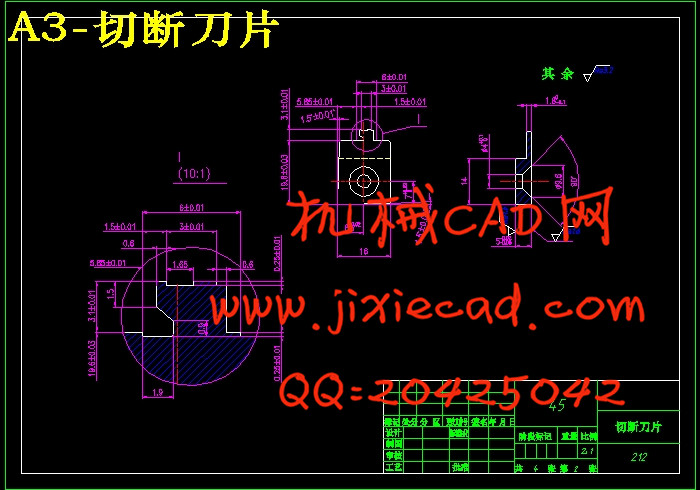

4.1 夹持刀片及切断刀片设计 21

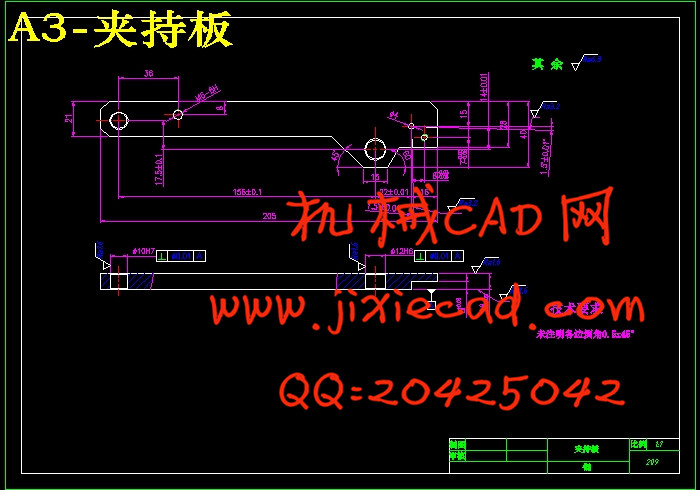

4.2 聘丝夹持切断装置结构设计 21

5 端子传送抬起装置设计 26

5.1 端子应力设计分析 26

5.2 端子保持力 27

5.3 应力释放 28

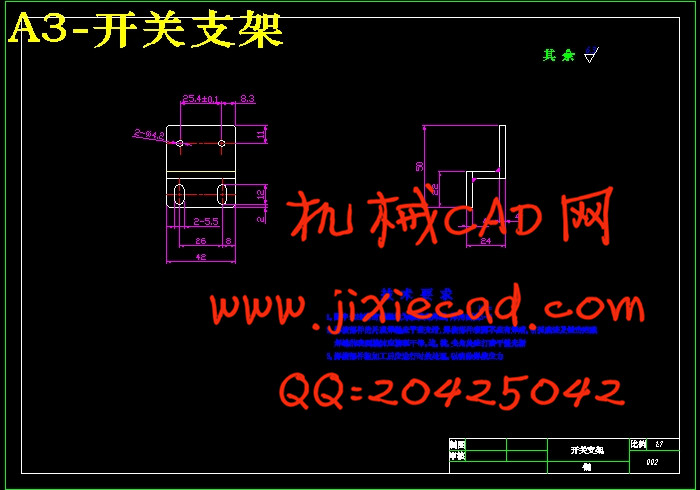

5.4 端子传送抬起装置结构设计 29

6 气压式端子压着机总体设计 33

7 结论 35

参考文献 36

致谢 37