设计简介

摘 要

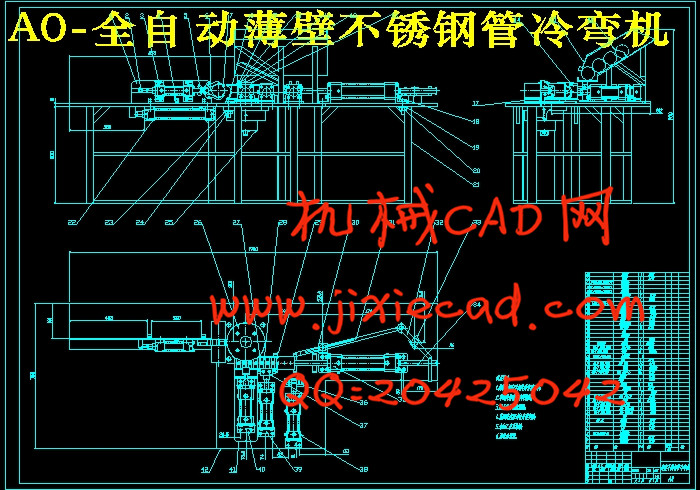

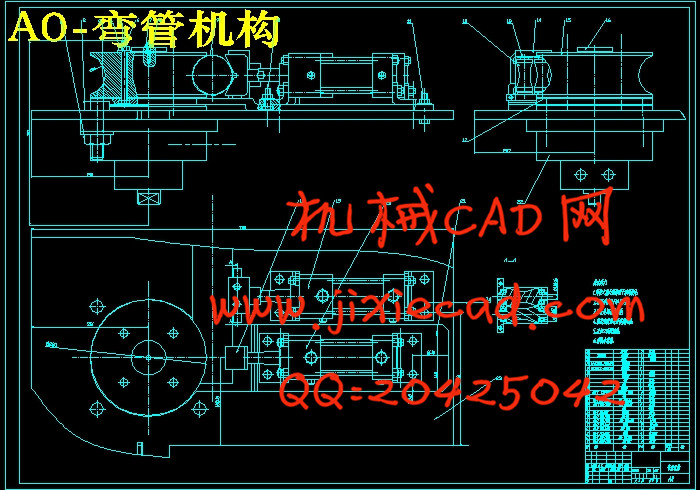

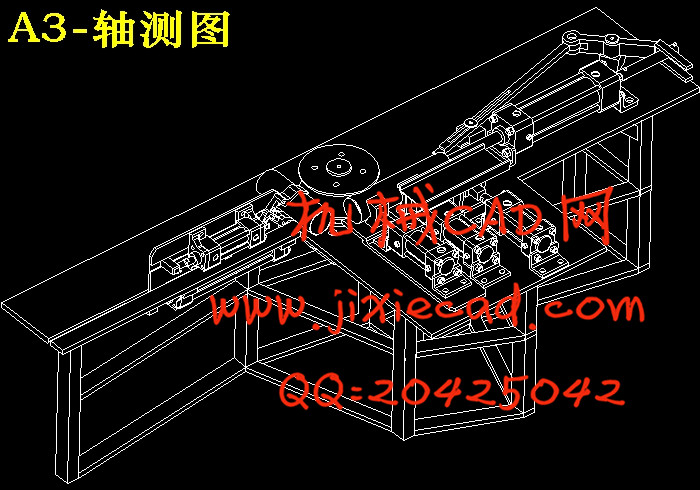

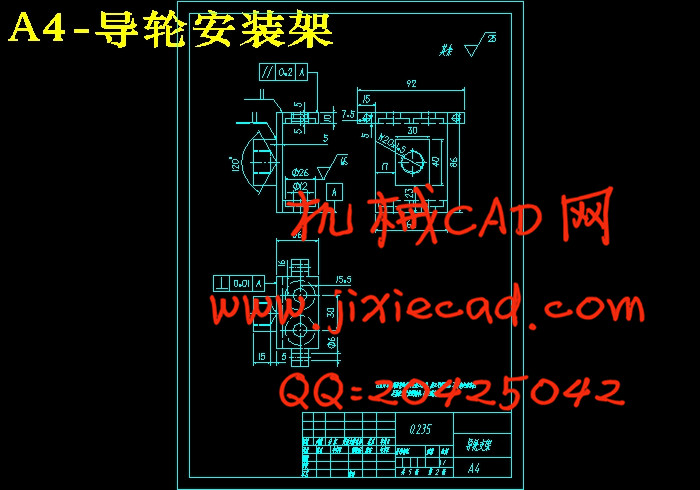

薄壁不锈钢管被大量应用于现代工业,而随着工业发展的进步,对不锈钢管的质量要求越来越高,相应的对最易引起管材质量问题的弯处提出了更高的要求。本文设计的全自动弯管机主要作用就是解决管材弯曲质量不稳定的问题。该装置以液压系统为基础,同时辅以 PLC 控制技术,为弯管的可靠性提供支撑。整个装置中穿芯机构、弯管机构为设计要点。穿芯机构中芯珠的形状、珠之间的连接方式将极大的影响弯管质量,因此采用高强度材料制作芯珠,链条式的连接来解决管材弯制过程中芯棒随管材一同弯曲的问题。弯管机构采取绕弯的方式,在液压缸作用下被压紧,最后液压马达带动模盘转动进行弯管。为满足范围角度及管材直径的弯管需要,模盘、芯珠等零件可随管材不同而相应更换。使用该弯管机进行弯管能明显提高生产效率与弯管质量,与传统管材弯曲机械相比具有明显的优越性。

关键词:薄壁不锈钢管;回转装置;全自动;冷弯

ABSTRACT

Thin-walled stainless steel tube is widely used in modern industry, and with the progress of industrial development, the quality of stainless steel tube of the increasingly high demand, corresponding to the most easy cause of bend pipe quality problem put forward higher requirements. The main function of the automatic pipe bending machine designed in this paper is to solve the problem of unstable quality of pipe bending. The device is based on hydraulic system and is supplemented by PLC control technology to provide support for the reliability of the bend. The core penetrating mechanism and the bent pipe mechanism are the key points in the design of the whole device. Connection between coring mechanism in core bead shape, bead will affect the bending quality greatly, so the production of high strength material core beads, connecting chain type to solve the mandrel tubing bending process with pipe bending problems together. Take the way of bending pipe bending mechanism, is pressed under the action of the hydraulic cylinder, the hydraulic motor drives the mold disc rotating pipe.In order to meet the angle of the pipe and the diameter of pipe, the parts can be replaced by different pipes. The bending tube can obviously improve the production efficiency and the bending quality, which is obviously superior to the traditional pipe bending machine.

Key words: thin wall stainless steel tube; rotary device;automatic; cold bending;

薄壁不锈钢管被大量应用于现代工业,而随着工业发展的进步,对不锈钢管的质量要求越来越高,相应的对最易引起管材质量问题的弯处提出了更高的要求。本文设计的全自动弯管机主要作用就是解决管材弯曲质量不稳定的问题。该装置以液压系统为基础,同时辅以 PLC 控制技术,为弯管的可靠性提供支撑。整个装置中穿芯机构、弯管机构为设计要点。穿芯机构中芯珠的形状、珠之间的连接方式将极大的影响弯管质量,因此采用高强度材料制作芯珠,链条式的连接来解决管材弯制过程中芯棒随管材一同弯曲的问题。弯管机构采取绕弯的方式,在液压缸作用下被压紧,最后液压马达带动模盘转动进行弯管。为满足范围角度及管材直径的弯管需要,模盘、芯珠等零件可随管材不同而相应更换。使用该弯管机进行弯管能明显提高生产效率与弯管质量,与传统管材弯曲机械相比具有明显的优越性。

关键词:薄壁不锈钢管;回转装置;全自动;冷弯

ABSTRACT

Thin-walled stainless steel tube is widely used in modern industry, and with the progress of industrial development, the quality of stainless steel tube of the increasingly high demand, corresponding to the most easy cause of bend pipe quality problem put forward higher requirements. The main function of the automatic pipe bending machine designed in this paper is to solve the problem of unstable quality of pipe bending. The device is based on hydraulic system and is supplemented by PLC control technology to provide support for the reliability of the bend. The core penetrating mechanism and the bent pipe mechanism are the key points in the design of the whole device. Connection between coring mechanism in core bead shape, bead will affect the bending quality greatly, so the production of high strength material core beads, connecting chain type to solve the mandrel tubing bending process with pipe bending problems together. Take the way of bending pipe bending mechanism, is pressed under the action of the hydraulic cylinder, the hydraulic motor drives the mold disc rotating pipe.In order to meet the angle of the pipe and the diameter of pipe, the parts can be replaced by different pipes. The bending tube can obviously improve the production efficiency and the bending quality, which is obviously superior to the traditional pipe bending machine.

Key words: thin wall stainless steel tube; rotary device;automatic; cold bending;