设计简介

摘 要

液压技术在机械行业上占有重要的地位,液压技术的应用使得加工精度和工件的表面质量得到了极大的提升,由于工业化进程的发展,机械行业随之迅猛的崛起,带动了液压设备的前进。

将液压技术应用到 600 型砂轮卸模机上,由液压系统提供动力源,并将其与电子控制技术相结合,使得卸模机实现了半自动化。磨料磨具行业近十年来的重大发展,同时给各国铸造行业在不同程度上带来了行业内部和外部的巨大挑战。想要在 21 世纪激烈的竞争中生存和发展,就得积极地将信息技术应用到铸造生产中。

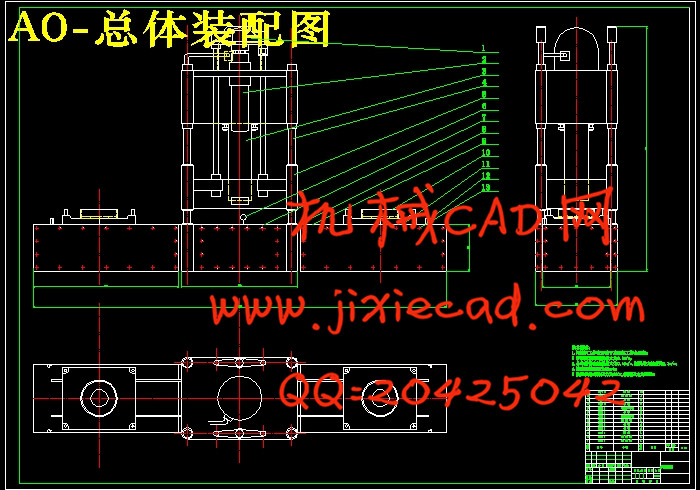

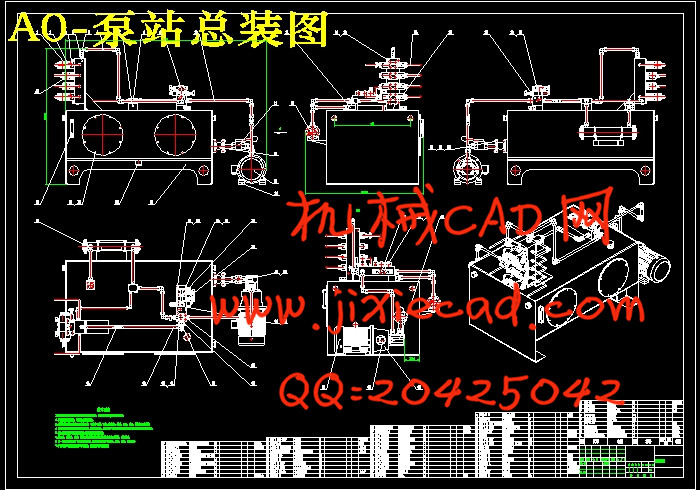

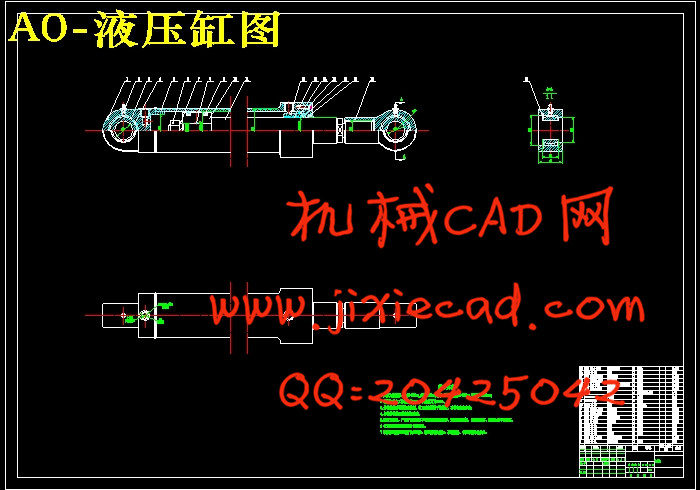

本次设计主要是对 600 型砂轮卸模机的液压系统进行设计,探讨分析了砂轮卸模机的功能及驱动要求。首先,了解了 600 型砂轮卸模机的工作原理和工作环境;然后对卸模机的液压系统进行了详细的设计和计算,先后进行了工况分析,参数计算,绘制了液压原理图;最后进行了液压元件的选择,完成了卸模机的泵站设计。

关键词:液压;600 型砂轮;卸模

液压技术在机械行业上占有重要的地位,液压技术的应用使得加工精度和工件的表面质量得到了极大的提升,由于工业化进程的发展,机械行业随之迅猛的崛起,带动了液压设备的前进。

将液压技术应用到 600 型砂轮卸模机上,由液压系统提供动力源,并将其与电子控制技术相结合,使得卸模机实现了半自动化。磨料磨具行业近十年来的重大发展,同时给各国铸造行业在不同程度上带来了行业内部和外部的巨大挑战。想要在 21 世纪激烈的竞争中生存和发展,就得积极地将信息技术应用到铸造生产中。

本次设计主要是对 600 型砂轮卸模机的液压系统进行设计,探讨分析了砂轮卸模机的功能及驱动要求。首先,了解了 600 型砂轮卸模机的工作原理和工作环境;然后对卸模机的液压系统进行了详细的设计和计算,先后进行了工况分析,参数计算,绘制了液压原理图;最后进行了液压元件的选择,完成了卸模机的泵站设计。

关键词:液压;600 型砂轮;卸模

ABSTRACT

Hydraulic technology occupies an important position in the machinery industry .With the application of hydraulic technology, the machining accuracy and surface quality of workpiece have been greatly improved. Due to the development of industrialization, the rapid rise of machinery industry has led to the progress of hydraulic equipment.

The hydraulic technology is applied to the 600 type wheel unloading machine. The power source is provided by the hydraulic system, and it is combined with the electronic control technology to make the demoulding machine semi automatic. The abrasives and abrasives industry has made great progress in the past ten years, and at the same time, the casting industry has brought enormous challenges both inside and outside the industry. If we want to survive and develop in the fierce competition in twenty-first Century, we must actively apply information technology to foundry production.

. This graduation project is mainly about the design of the hydraulic system of the 600 wheel dismounting machine. The functions and driving requirements of the wheel dismounting machine are discussed and analyzed. First, the working principle and working environment of the 600 type grinding wheel die unload machine are understood. Then the hydraulic system of the die unloading machine is designed and calculated in detail. The working condition analysis, the calculation of the parameters and the drawing of the hydraulic principle are carried out successively. Finally, the selection of the hydraulic components is carried out, and the design of the pump station of the die unloading machine is completed.

Key Words:Hydraulic pressure; Demoulding machine; 600 grinding wheel

Hydraulic technology occupies an important position in the machinery industry .With the application of hydraulic technology, the machining accuracy and surface quality of workpiece have been greatly improved. Due to the development of industrialization, the rapid rise of machinery industry has led to the progress of hydraulic equipment.

The hydraulic technology is applied to the 600 type wheel unloading machine. The power source is provided by the hydraulic system, and it is combined with the electronic control technology to make the demoulding machine semi automatic. The abrasives and abrasives industry has made great progress in the past ten years, and at the same time, the casting industry has brought enormous challenges both inside and outside the industry. If we want to survive and develop in the fierce competition in twenty-first Century, we must actively apply information technology to foundry production.

. This graduation project is mainly about the design of the hydraulic system of the 600 wheel dismounting machine. The functions and driving requirements of the wheel dismounting machine are discussed and analyzed. First, the working principle and working environment of the 600 type grinding wheel die unload machine are understood. Then the hydraulic system of the die unloading machine is designed and calculated in detail. The working condition analysis, the calculation of the parameters and the drawing of the hydraulic principle are carried out successively. Finally, the selection of the hydraulic components is carried out, and the design of the pump station of the die unloading machine is completed.

Key Words:Hydraulic pressure; Demoulding machine; 600 grinding wheel