设计简介

摘 要

移栽是农作物种植中的一个重要过程,移栽机械的发展是适应于农业发展的,目前移栽过程均采用人工移栽,劳动强度大,效率低,从而限制了生产规模的扩大,影响了农业的经济效益,自动移栽机可以大大提高农作物幼苗移栽的效率,这种自动化程度高的移栽机广泛用于农业生产中。

本次设计主要是移栽机进行结构功能设计和一些计算设计过程的说明,研究的主题是基于导苗管式的多功能移栽机,通过对幼苗种植间距等众多因素的分析,从而设计合适的尺寸。

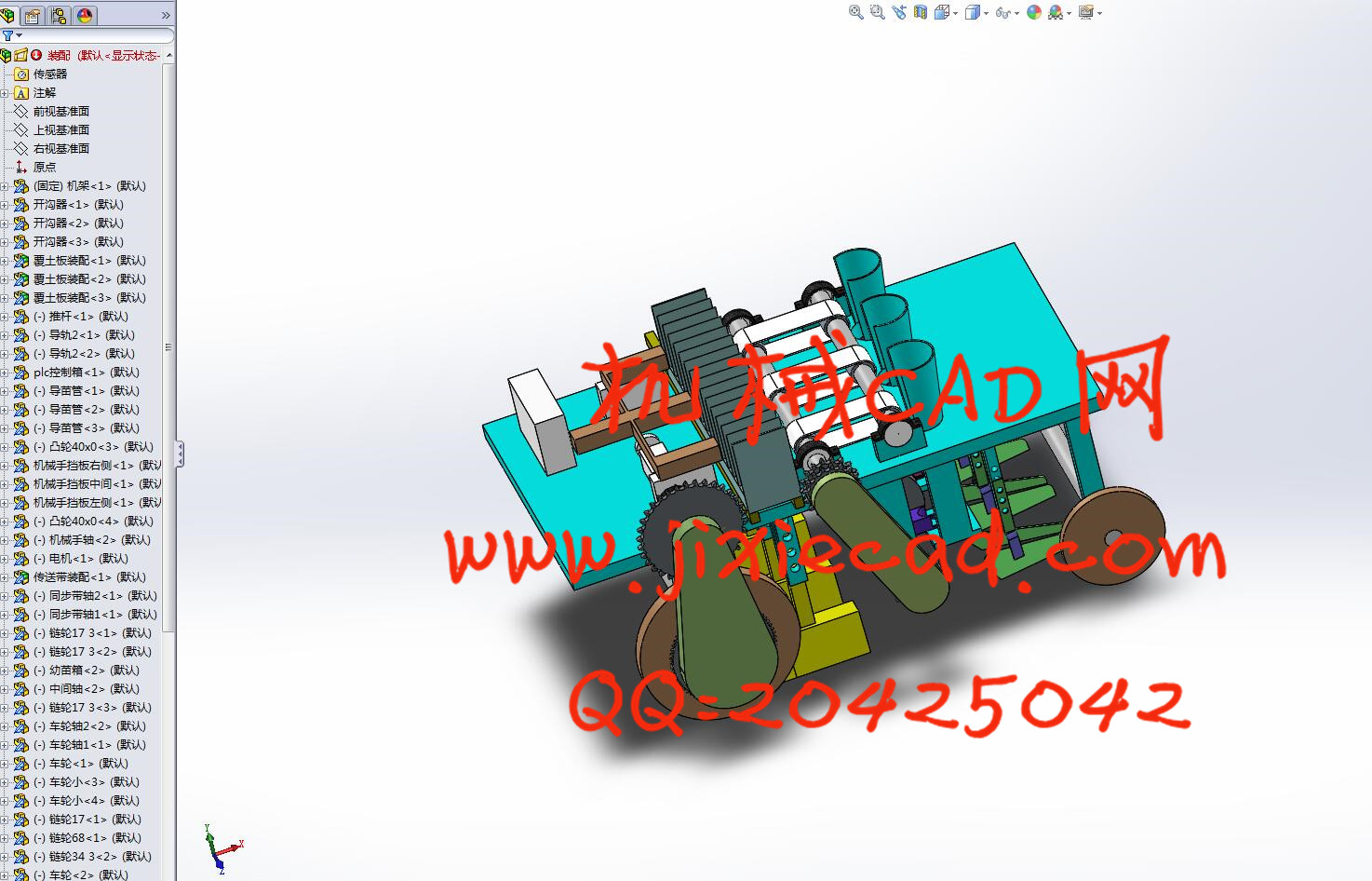

通过 SolidWorks 软件进行三维模型的设计、组装,同时为提高生产效率采用一次三行同时作业的设计。

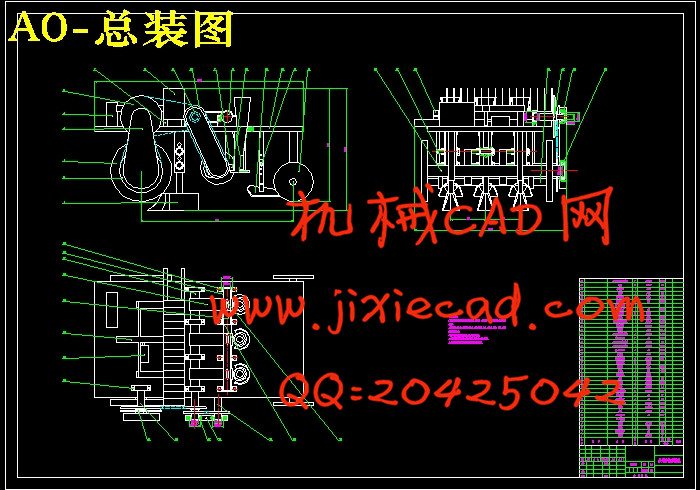

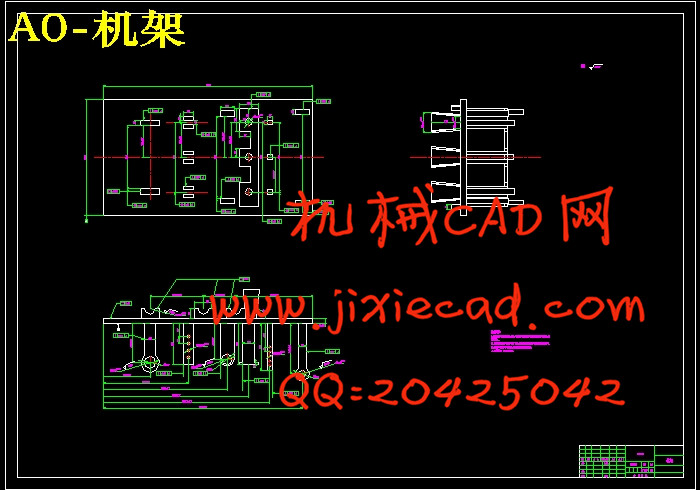

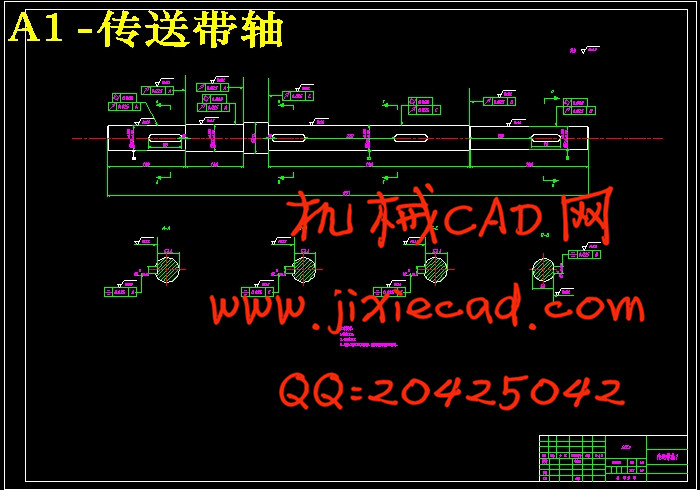

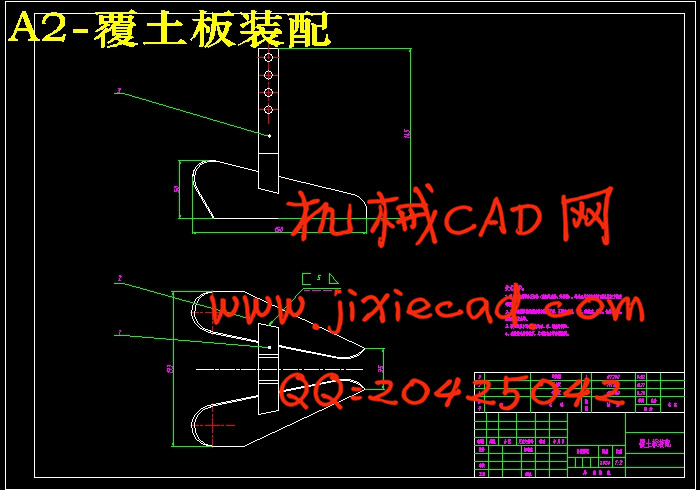

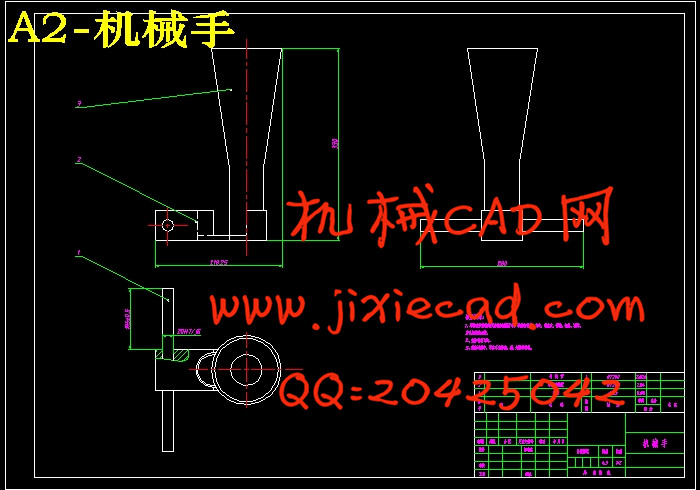

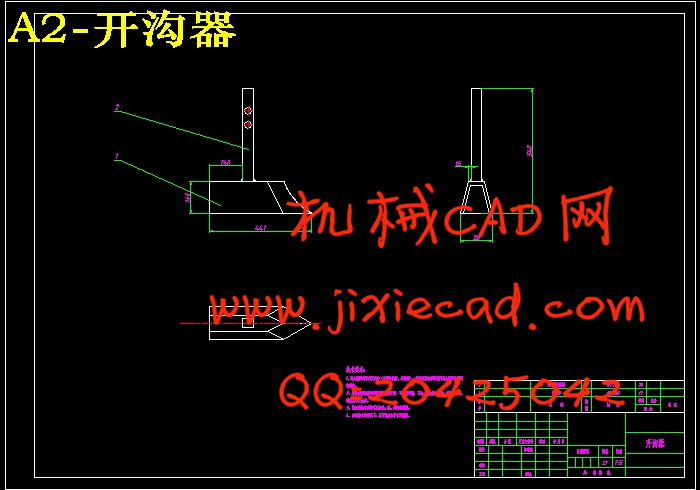

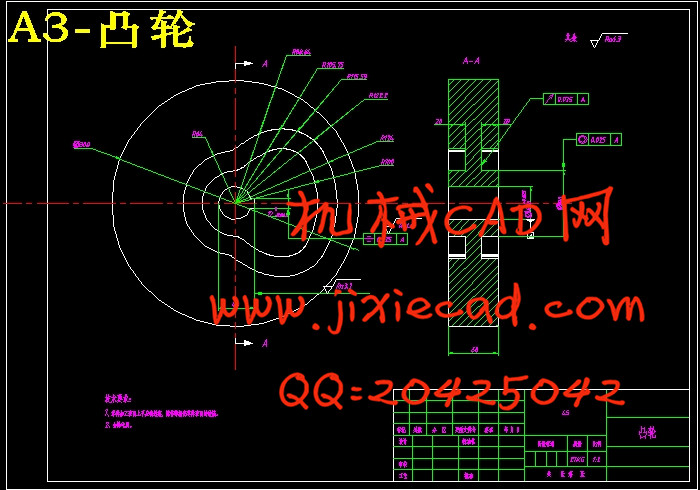

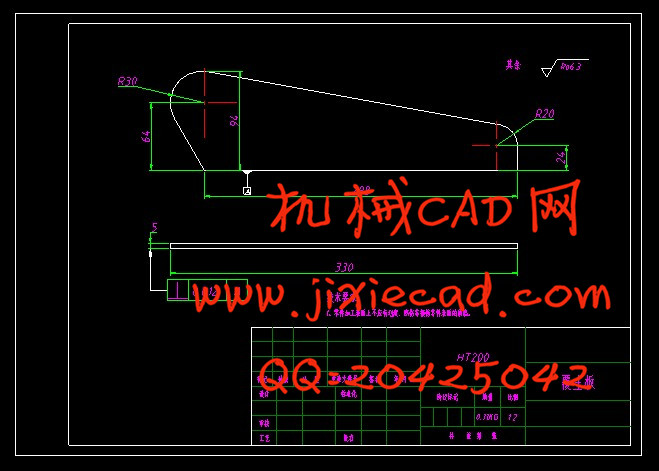

最后基于实际生产过程中开沟、覆土的需要,通过 CAD 软件进行了开土装置、落苗装置、覆土装置的设计,并且采用 PLC 进行送苗装置的控制,实现自动化生产。

说明书从分析国内外移栽机的发展历史和各种移栽机的优缺点入手,进而选择更优的送苗方式进行设计,并最终得出最终的设计方案和图纸。

关键词:移栽;机械结构设计;送苗装置;落苗装置

移栽是农作物种植中的一个重要过程,移栽机械的发展是适应于农业发展的,目前移栽过程均采用人工移栽,劳动强度大,效率低,从而限制了生产规模的扩大,影响了农业的经济效益,自动移栽机可以大大提高农作物幼苗移栽的效率,这种自动化程度高的移栽机广泛用于农业生产中。

本次设计主要是移栽机进行结构功能设计和一些计算设计过程的说明,研究的主题是基于导苗管式的多功能移栽机,通过对幼苗种植间距等众多因素的分析,从而设计合适的尺寸。

通过 SolidWorks 软件进行三维模型的设计、组装,同时为提高生产效率采用一次三行同时作业的设计。

最后基于实际生产过程中开沟、覆土的需要,通过 CAD 软件进行了开土装置、落苗装置、覆土装置的设计,并且采用 PLC 进行送苗装置的控制,实现自动化生产。

说明书从分析国内外移栽机的发展历史和各种移栽机的优缺点入手,进而选择更优的送苗方式进行设计,并最终得出最终的设计方案和图纸。

关键词:移栽;机械结构设计;送苗装置;落苗装置

ABSTRACT

Transplanting is an important process in the cultivation of crops. The development of transplanting machinery is adapted to the development of agriculture.At present,the transplanting process uses manual transplanting,which has great labor intensity and low efficiency,which limits the expansion of production scale and affects the economic benefits of agriculture.Automatic transplanters can greatly increase the efficiency of crop seedling transplanting.This highly automated transplanter is widely used in agricultural production.

This design is mainly a description of the structural function design of the transplanter and some calculation and design processes.The research theme is a multi-functional transplanter based on seedling tube type.Through the analysis of many factors such as seedling planting spacing to design appropriate size.

Design and assembly of 3D models using SolidWorks software.At the same time,a three-line simultaneous operation design was adopted to increase production efficiency.

Finally,based on the needs of trenching and earth covering in the actual production process,the design of open earthing devices,falling seedling devices,and earth-covering devices was performed through CAD software,and use PLC to send the control of the seedling device to achieve automated production.

The instructionsl starts with an analysis of the development history of transplanting machines at home and abroad and the advantages and disadvantages of various transplanting machines,and then selects a better way of sending seedlings for design,and finally draws final design plans and drawings.

Key Words:Transplanting; Mechanical design; Sending device; Falling seedling device

Transplanting is an important process in the cultivation of crops. The development of transplanting machinery is adapted to the development of agriculture.At present,the transplanting process uses manual transplanting,which has great labor intensity and low efficiency,which limits the expansion of production scale and affects the economic benefits of agriculture.Automatic transplanters can greatly increase the efficiency of crop seedling transplanting.This highly automated transplanter is widely used in agricultural production.

This design is mainly a description of the structural function design of the transplanter and some calculation and design processes.The research theme is a multi-functional transplanter based on seedling tube type.Through the analysis of many factors such as seedling planting spacing to design appropriate size.

Design and assembly of 3D models using SolidWorks software.At the same time,a three-line simultaneous operation design was adopted to increase production efficiency.

Finally,based on the needs of trenching and earth covering in the actual production process,the design of open earthing devices,falling seedling devices,and earth-covering devices was performed through CAD software,and use PLC to send the control of the seedling device to achieve automated production.

The instructionsl starts with an analysis of the development history of transplanting machines at home and abroad and the advantages and disadvantages of various transplanting machines,and then selects a better way of sending seedlings for design,and finally draws final design plans and drawings.

Key Words:Transplanting; Mechanical design; Sending device; Falling seedling device

目 录