设计简介

摘 要

根据《产品标识标注管理规定》,产品标识是指用于识别产品及其质量、数量、特征、特性和使用方法所做出的各种表示方法的统称。机械及其相关产品在生产过程中需要对其零部件实现有效可行的管理,进入市场后需要对其进行质量追踪和监控,标识刻制设备可以很好地实现产品管理。标识刻制设备大概分为三类:金属电印标识刻制设备、激光标识刻制设备、气动标识刻制设备。三种标识刻制设备各有其优缺点,其中,气动标识刻制设备作为机电一体化产品,集成机械、电子、计算机等技术于一体。因其应用范围广、功能性强大、普遍适应性良好以及刻制出的标识难以被仿造等优势,所以近几年能够迅速占领标识刻制设备的市场,得到了广泛的应用和普及。虽然标记质量的好坏一般不会影响机械零部件的使用寿命及其性能,但是,因起作为产品综合质量的一个重要方面仍不容忽视,尤其是在当前竞争激烈的市场经济条件状况下,企业若要追求可观的经济效益和良好的市场口碑,必须重新审视产品标识的意义并提高标记刻制的质量。

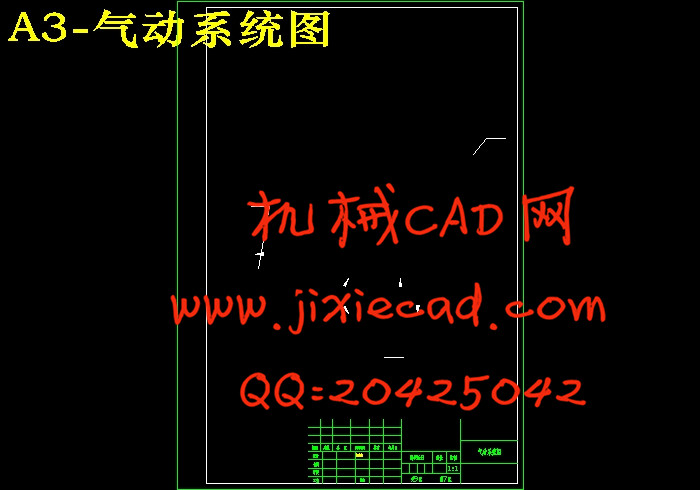

气动标识刻制设备的系统组成主要包括:控制系统、传动系统、气动系统、标记系统。它的基本工作原理是联通来自计算机的控制信号,当计算机接到来自Y原点控制开关和X原点控制开关的信号后,带动标记头在驱动气源的配合下高速冲击,形成字符或图形点阵。

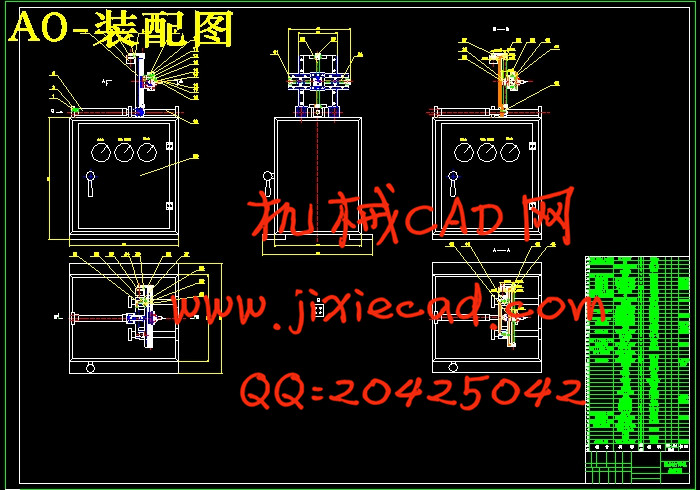

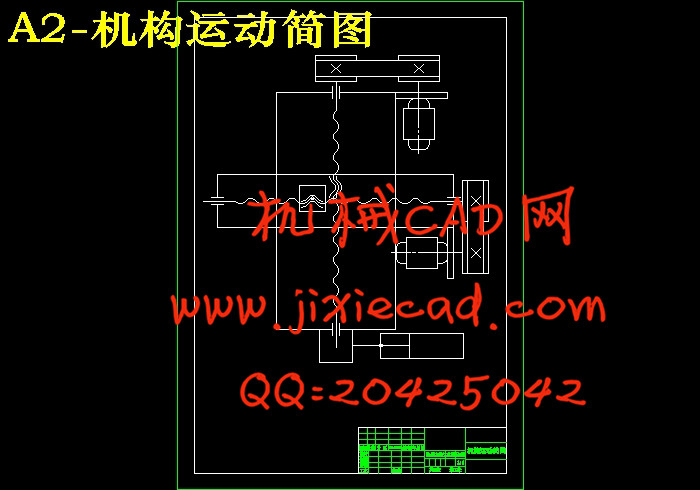

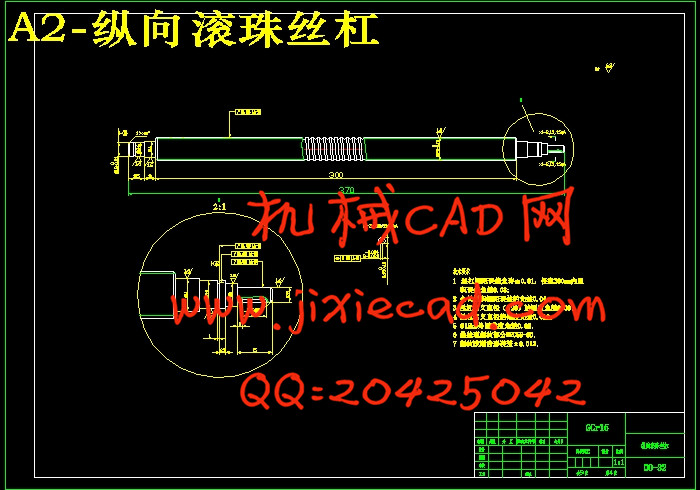

通过对气动标识刻制设备的组成和工作原理的了解,本文主要介绍的工作为气动标识刻制设备传动系统的设计,包括运动简图的设计、步进电机的选择、导轨、滚珠丝杠螺母副、同步带轮的设计和整体结构的设计,以及气动系统设计和打字程序的数控编程。

关键词:气动标识刻制设备;传动系统;气动系统;数控编程

根据《产品标识标注管理规定》,产品标识是指用于识别产品及其质量、数量、特征、特性和使用方法所做出的各种表示方法的统称。机械及其相关产品在生产过程中需要对其零部件实现有效可行的管理,进入市场后需要对其进行质量追踪和监控,标识刻制设备可以很好地实现产品管理。标识刻制设备大概分为三类:金属电印标识刻制设备、激光标识刻制设备、气动标识刻制设备。三种标识刻制设备各有其优缺点,其中,气动标识刻制设备作为机电一体化产品,集成机械、电子、计算机等技术于一体。因其应用范围广、功能性强大、普遍适应性良好以及刻制出的标识难以被仿造等优势,所以近几年能够迅速占领标识刻制设备的市场,得到了广泛的应用和普及。虽然标记质量的好坏一般不会影响机械零部件的使用寿命及其性能,但是,因起作为产品综合质量的一个重要方面仍不容忽视,尤其是在当前竞争激烈的市场经济条件状况下,企业若要追求可观的经济效益和良好的市场口碑,必须重新审视产品标识的意义并提高标记刻制的质量。

气动标识刻制设备的系统组成主要包括:控制系统、传动系统、气动系统、标记系统。它的基本工作原理是联通来自计算机的控制信号,当计算机接到来自Y原点控制开关和X原点控制开关的信号后,带动标记头在驱动气源的配合下高速冲击,形成字符或图形点阵。

通过对气动标识刻制设备的组成和工作原理的了解,本文主要介绍的工作为气动标识刻制设备传动系统的设计,包括运动简图的设计、步进电机的选择、导轨、滚珠丝杠螺母副、同步带轮的设计和整体结构的设计,以及气动系统设计和打字程序的数控编程。

关键词:气动标识刻制设备;传动系统;气动系统;数控编程

ABSTRACT

According to the " product identification label management regulations" product identification refers to the identification of products and their quality, quantity, characteristics and methods of use made by all kinds of representations. Mechanical products in the production process need to carry out effective management of parts, after entering the market need to carry out quality tracking monitoring, marking equipment can be very good to achieve product management. Marking engraving equipment is generally divided into three categories: metal electrical marking engraving equipment, laser marking engraving equipment, pneumatic marking engraving equipment. Three kinds of marking engraving equipment have their own advantages and disadvantages, among them, pneumatic marking engraving equipment as an electromechanical integration products, mechanical, electronic information, computer technology in one. Because of its advantages such as wide application, strong function, high universality and difficult to be imitated, it has rapidly occupied the market of marking and engraving equipment in recent years, and has been widely used and popularized.

The system composition of pneumatic marking and engraving equipment mainly includes: control system, transmission system, pneumatic system and marking system. Its basic working principle is to connect the control signals from the computer, when the computer receives the signals from the y origin control switch and the x origin control switch, drive the marking head to impact at high speed under the cooperation of the driving air source to form the character or graphics lattice.

Through the understanding of the composition and working principle of pneumatic marking engraving equipment, this paper mainly introduces the design of pneumatic marking engraving equipment transmission system, including the design of motion diagram, selection of stepper motor, guide rail, ball screw nut pair, synchronous belt wheel design and overall structure design, as well as pneumatic system design and numerical control programming of typing program.

Keywords: pneumatic marking and engraving equipment ;transmission agent ;pneumatic system ;Nc programming

According to the " product identification label management regulations" product identification refers to the identification of products and their quality, quantity, characteristics and methods of use made by all kinds of representations. Mechanical products in the production process need to carry out effective management of parts, after entering the market need to carry out quality tracking monitoring, marking equipment can be very good to achieve product management. Marking engraving equipment is generally divided into three categories: metal electrical marking engraving equipment, laser marking engraving equipment, pneumatic marking engraving equipment. Three kinds of marking engraving equipment have their own advantages and disadvantages, among them, pneumatic marking engraving equipment as an electromechanical integration products, mechanical, electronic information, computer technology in one. Because of its advantages such as wide application, strong function, high universality and difficult to be imitated, it has rapidly occupied the market of marking and engraving equipment in recent years, and has been widely used and popularized.

The system composition of pneumatic marking and engraving equipment mainly includes: control system, transmission system, pneumatic system and marking system. Its basic working principle is to connect the control signals from the computer, when the computer receives the signals from the y origin control switch and the x origin control switch, drive the marking head to impact at high speed under the cooperation of the driving air source to form the character or graphics lattice.

Through the understanding of the composition and working principle of pneumatic marking engraving equipment, this paper mainly introduces the design of pneumatic marking engraving equipment transmission system, including the design of motion diagram, selection of stepper motor, guide rail, ball screw nut pair, synchronous belt wheel design and overall structure design, as well as pneumatic system design and numerical control programming of typing program.

Keywords: pneumatic marking and engraving equipment ;transmission agent ;pneumatic system ;Nc programming

目 录

摘 要 I

ABSTRACT II

1.绪论 2

1.1铁基表面产品标识刻制设备设计的背景意义 2

1.2气动标识刻制设备的研究现状与发展趋势 3

1.3 本课题所要研究的主要内容 5

2.气动标识刻制设备的组成与工作原理 5

2.1气动标识刻制设备的组成 5

2.2气动标识刻制设备的工作原理 6

3. 气动标识刻制设备的传动系统设计 6

3.1气动标识刻制设备的机构运动简图 6

3.2步进电机的选择 7

3.3导轨的设计 9

3.4同步带轮的设计 11

3.5滚珠丝杠螺母副的设计 13

4.气动标识刻制设备的整体结构设计 22

4.1整体机构的简述 22

4.2装配图 22

5.气动标识刻制设备的气动系统设计 24

5.1气动系统的简述 24

5.2气动系统原理图设计 24

6.气动标识刻制设备打字程序的数控编制 25

6.1数控技术的简述 25

6.2编程实例 25

参考文献 27

致 谢 39