设计简介

摘 要

随着我国经济的发展,人民生活水平的进一步提高,牛奶的消费总量在快速的增长,同时奶制品、食用油、饮料等行业对产品运输的要求越来越大,大型奶罐车的需求量日益增加。奶罐车在制造以及投入运营运输液态食品时,常遇到以下问题:保温效果较差,剩余率较高,对液态食品的清洗效果不够理想。基于对奶罐车发展趋势的理解和对其存在问题的认识,本文介绍了一款性能更优良的奶罐车的设计方案。

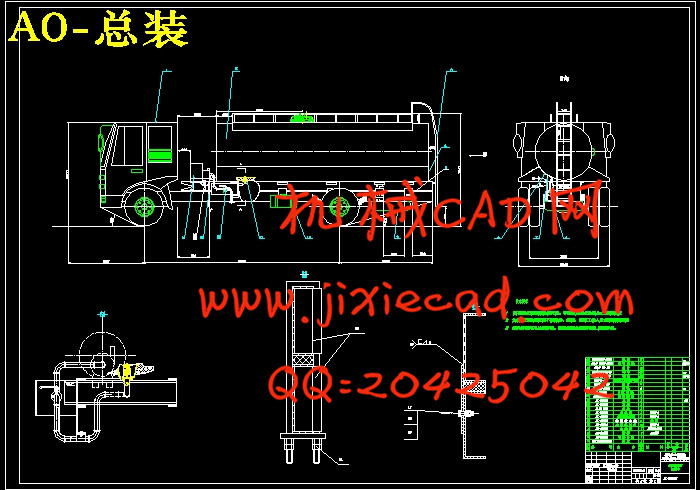

在查阅大量相关资料的基础上,对二类底盘进行选型,在以罐体总成为主要设计主体进行设计,在整个设计过程中将参考其他液态食品罐汽车罐体截面的基本形状,选择简单、工艺性好、容积率最高的圆形截面。为了保证牛奶的口味,需要低温运输,参照隔热保温车的隔热保温原理,设计有隔热保温层。隔热保温结构是将罐体设计成双层罐,并在两层罐体之间填充隔热材料,防止外界的温度对关内液体温度的影响。由于牛奶是一种能使细菌迅速繁殖的理想营养基质,牛奶等液体食品在使用之后,如果不及时﹑彻底地进行清洗,将会是细菌大量繁殖,从而影响产品的卫生质量,所以要对清洗装置进行设计。最后进行整车动力性、燃油经济性进行了计算。

整车设计完成后,对奶罐车使用要求进行分析,经过对局部的修改,得到一个可以利用的设计方案。

关键词:罐式汽车;奶罐车;罐体;隔热层;排液系统

ABSTRACT

As China's economic development, to further improve people's living standards, consumption of milk in the rapid growth, while dairy products, edible oil, beverage and other industries for product transportation requirements increasing, the demand for large-scale milk tanker increasing. Milk tanker and put into operation in the manufacture of liquid food transport, often encounter the following problems: insulation less effective, and the remaining higher rate, the cleaning effect of the liquid food is not ideal. Trends for milk tanker based understanding and awareness of its problems, this paper describes a performance of better milk tanker design.

After reviewing a lot of relevant information based on the selection of second-class chassis, the total tank in order to become a major design of the main design, the entire design process will make reference to other liquid food can cross-section of the basic shape of the tank car, choose a simple , technology is good, the highest rate of circular cross-section volume. In order to ensure the taste of milk, cold chain needs, with reference to the car thermal insulation thermal insulation principle, the design of thermal insulation layer. Thermal insulation structure is designed to double the tank tanks, and filling in between two layers of insulation material tank to prevent the outside temperature on the temperature of the liquid off. Because milk is a way for bacteria multiply rapidly ideal nutritional substrate, milk and other liquid food after use, if not ﹑ thoroughly cleaned, the bacteria will multiply, thus affecting the quality of health products, so the cleaning device design. Finally, the vehicle power, fuel economy was calculated.

Vehicle design is complete, the milk tanker requirements analysis, through the local changes to get a design that can be used.

Key words: Tank Car; Milk Tanker; Tanks; Insulating Layer; Drainage System

摘要 I

Abstract II

第1章 绪论 1

1.1概述 1

1.2目的和意义 1

1.3专用车的现状和发展趋势 1

1.3.1近年专用车的产销发展现状 1

1.3.2罐式车的发展方向 2

1.3.3专用汽车的发展展望 2

1.4设计内容 3

1.5设计方法、手段 3

第2章 罐车的总体布置 4

2.1总布置的原则 4

2.2奶罐车的总体布置 4

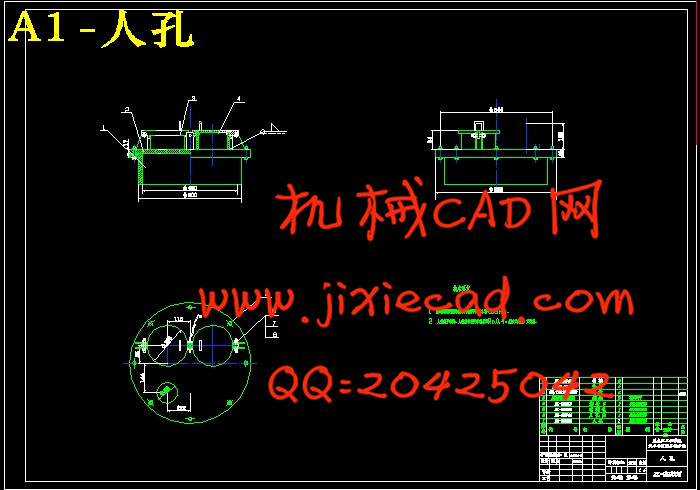

2.2.1罐体的结构 4

2.2.2副车架与主车架的连接 6

2.3整车重心 7

2.4本章小结 7

第3章 底盘的选择 8

3.1车型介绍 8

3.2总成结构 10

3.2.1发动机 10

3.2.2离合器 10

3.2.3变速器 10

3.2.4传动轴 10

3.2.5前轴 10

3.2.6驱动桥 11

3.2.7车轮及轮胎 11

3.2.8悬架 11

3.2.9车架 11

3.3本章小结 11

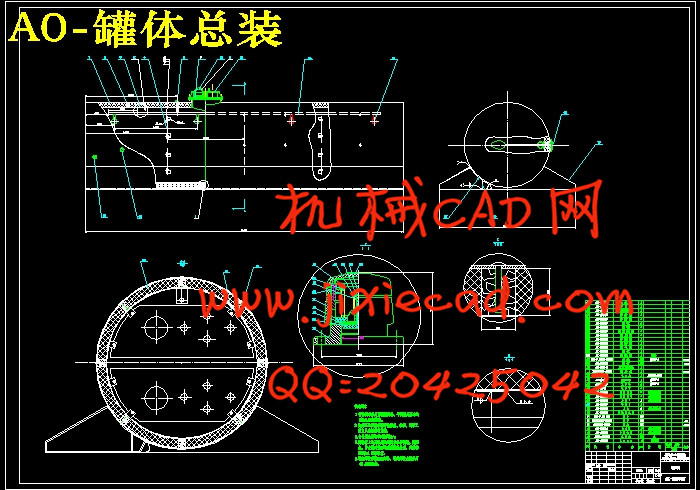

第4章 罐体的设计 12

4.1罐体的截面的设计 12

4.2罐体容积的确定 12

4.3内罐罐体厚度的确定 13

4.4外罐罐体厚度的确定 14

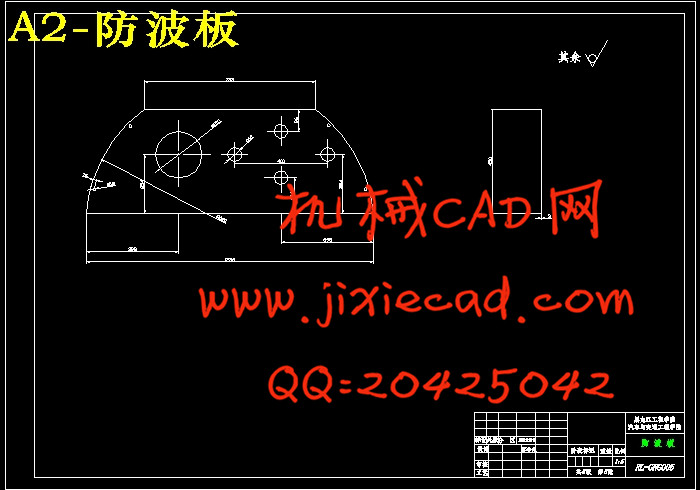

4.5防波板的设计 15

4.6喷淋清洗管路 15

4.7 保温层的设计 17

4.7.1隔热材料的选择 18

4.7.2断热桥结构设计 20

4.8罐体总成质量的计算 20

4.9本章小结 21

第5章 排料系统设计 22

5.1奶泵的选取 22

5.2排料系统 22

5.3本章小结 24

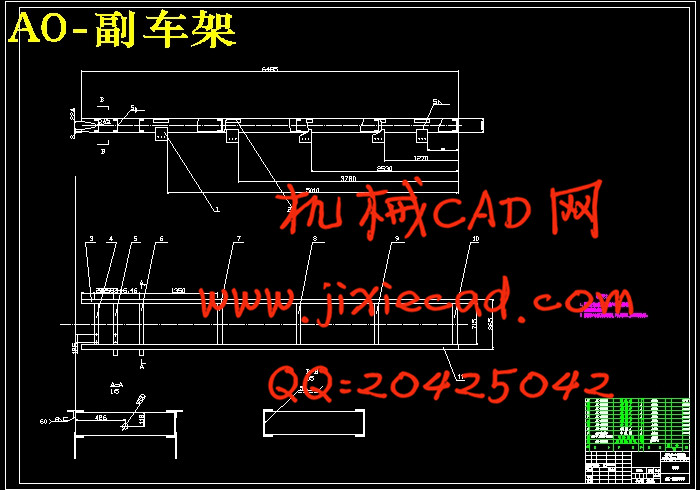

第6章 副车架的设计 25

6.1副车架的外形设计计算 25

6.1.1副车架的截面形状设计计算 25

6.1.2副车架的前端形状选型 25

6.2副车架与主车架的连接方式 25

6.3副车架主要尺寸设计 26

6.4本章小结 27

第7章 整车性能计算 28

7.1汽车最高车速的计算 28

7.2最大爬坡度计算 32

7.3汽车燃油经济性的计算 33

7.4本章小结 34

结论 35

参考文献 36

致谢 37