设计简介

摘 要

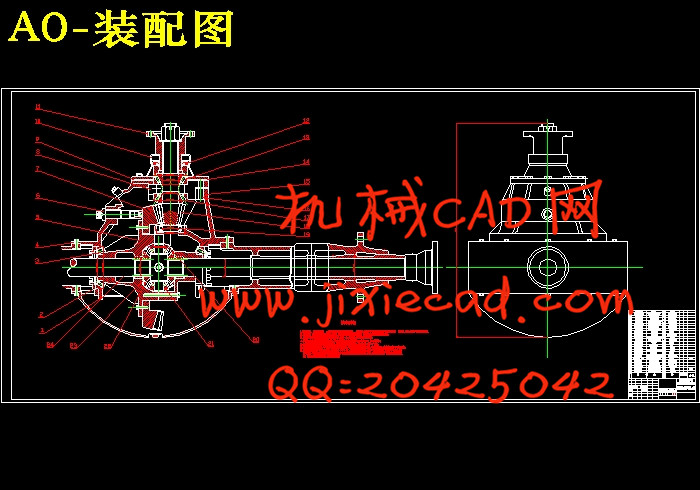

本设计课题是13吨级重型载货汽车驱动桥的设计,汽车驱动桥是汽车底盘的重要组成部分,一般由主减速器,差速器,车轮转动装置和桥壳等组成,转向驱动桥还有等速万向节。它的作用是将万向传动装置传来的动力折过90度角,改变力的传递方向,并由主减速器降低转速,增大转矩后,经差速器分配给左右半轴和驱动轮。汽车驱动桥是汽车的重大总成,承载着汽车的满载以及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;驱动桥还传递着传动系中的最大转矩,桥壳还承受着反作用力矩,汽车驱动桥结构形式和设计参数除对汽车的可靠性与耐久性有重要形影外,也对汽车的行驶性能,如动力性、经济性、平顺性、通过性、机动性和操作稳定性等有直接影响,另外,汽车驱动桥在汽车的各种总成中也是涵盖机械零件、部件、分总成等的品种最多的大总成,因此,汽车驱动桥设计涉及的机械零部件及元件的种类十分的广泛,对这些零部件的设计制造涉及很多的现代机械制造工艺,通过对汽车驱动桥的学习和设计实践,可以更好的学习并掌握现代汽车设计与机械设计的全面知识和技能。

关键词: 驱动桥;设计;计算;零件;CAD

本设计课题是13吨级重型载货汽车驱动桥的设计,汽车驱动桥是汽车底盘的重要组成部分,一般由主减速器,差速器,车轮转动装置和桥壳等组成,转向驱动桥还有等速万向节。它的作用是将万向传动装置传来的动力折过90度角,改变力的传递方向,并由主减速器降低转速,增大转矩后,经差速器分配给左右半轴和驱动轮。汽车驱动桥是汽车的重大总成,承载着汽车的满载以及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;驱动桥还传递着传动系中的最大转矩,桥壳还承受着反作用力矩,汽车驱动桥结构形式和设计参数除对汽车的可靠性与耐久性有重要形影外,也对汽车的行驶性能,如动力性、经济性、平顺性、通过性、机动性和操作稳定性等有直接影响,另外,汽车驱动桥在汽车的各种总成中也是涵盖机械零件、部件、分总成等的品种最多的大总成,因此,汽车驱动桥设计涉及的机械零部件及元件的种类十分的广泛,对这些零部件的设计制造涉及很多的现代机械制造工艺,通过对汽车驱动桥的学习和设计实践,可以更好的学习并掌握现代汽车设计与机械设计的全面知识和技能。

关键词: 驱动桥;设计;计算;零件;CAD

ABSTRACT

This design task is 13 tonnage heavy cargo automobile driving axle design, car driving axle is an important part of car chassis, general by main reducer, differential, wheel rotation device and bridge shell and other components, steering axles and patterned constant speed universal it is the role of the power transmission device universal coming over 90 degree Angle folding, change directionandthetransmission force of calm And the main reducer reduce speed, and increase torque, assigned to the differential around half shaft and the drive wheels cars driving axle is the great assembly car, bearing the car carrying and ground via wheel frame and integral by suspension of body vertical force to lead its transverse force longitudinal strength and impact load torque,; Driving axle also delivers the drivetrain And impact load; Driving axle also delivers the transmission, the maximum torque is under bridge housing, cars driving axle backlash torque structure form and design parameters in addition to the reliability of the automobile and durability are important for car around outside, also driving performance, such as dynamic economy through sexual mobility and smooth operating stability, etc have straight In addition, automobile driven axle of the various auto assembly in also covers the mechanical parts components such as varieties most portion assembly of large assembly, therefore, automobile driving axle design of mechanical parts and components involved the species is widespread For these parts of the design and manufacture of modern machinery involved a lot of car manufacturing process, through the drive axle of studying and designing practice, can better learning and mastery of the modern car design and mechanical design of the comprehensive knowledge and skills

Keywords: driving axle; Design; Calculation; Parts; CAD

This design task is 13 tonnage heavy cargo automobile driving axle design, car driving axle is an important part of car chassis, general by main reducer, differential, wheel rotation device and bridge shell and other components, steering axles and patterned constant speed universal it is the role of the power transmission device universal coming over 90 degree Angle folding, change directionandthetransmission force of calm And the main reducer reduce speed, and increase torque, assigned to the differential around half shaft and the drive wheels cars driving axle is the great assembly car, bearing the car carrying and ground via wheel frame and integral by suspension of body vertical force to lead its transverse force longitudinal strength and impact load torque,; Driving axle also delivers the drivetrain And impact load; Driving axle also delivers the transmission, the maximum torque is under bridge housing, cars driving axle backlash torque structure form and design parameters in addition to the reliability of the automobile and durability are important for car around outside, also driving performance, such as dynamic economy through sexual mobility and smooth operating stability, etc have straight In addition, automobile driven axle of the various auto assembly in also covers the mechanical parts components such as varieties most portion assembly of large assembly, therefore, automobile driving axle design of mechanical parts and components involved the species is widespread For these parts of the design and manufacture of modern machinery involved a lot of car manufacturing process, through the drive axle of studying and designing practice, can better learning and mastery of the modern car design and mechanical design of the comprehensive knowledge and skills

Keywords: driving axle; Design; Calculation; Parts; CAD

目 录

摘要………………………………………………………………………………………….I

Abstract………………………………………………….……….....................................II

第1章 绪论 ……………………………………………………………………….…….1

1.1汽车驱动桥设计的意义和目的…………………………………………………….1

1.2汽车驱动的研究现状及发展趋势………………………………………………….1

1.3 汽车驱动桥不同机构形式的比较…………………………………………………3

1.3.1驱动桥的结构和种类………………………………………………………….3

1.3.2汽车车桥的种类……………………………………………………………….3

1.3.3驱动桥结构组成……………………………………………………………….4

1.4 设计的主要内容…………………………………………………………...............9

1.5 设计的基本数据…………………………………………………………...............9

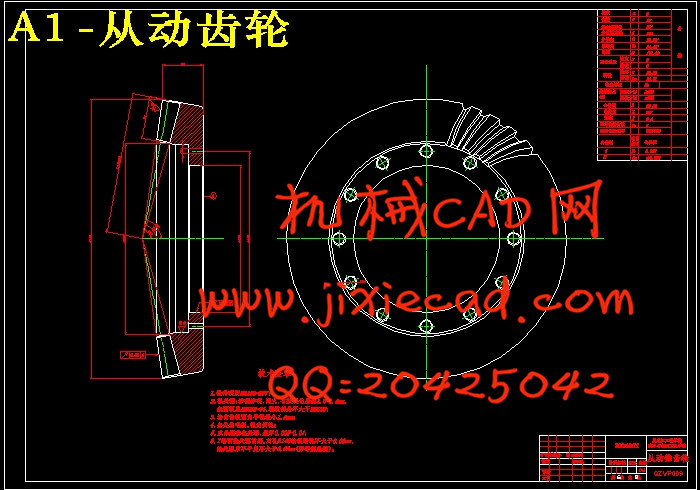

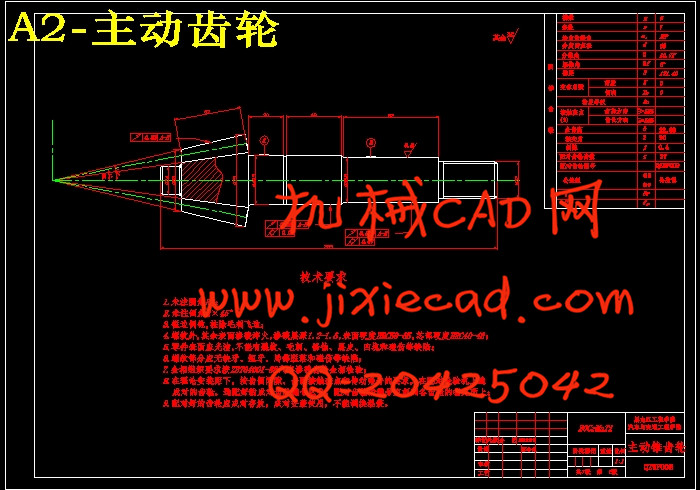

第2章 主减速器的设计…………………………………………………………..….10

2.1主减速器的结构形式……………………………………………………………..10

2.1.1主减速器的齿轮类型…………………………………………………...…11

2.1.2主减速器主、从动锥齿轮的支承形式…………………………………...11

2.2主减速器的基本参数选择与设计计算…………………………………………..12

2.2.1主减速器计算载荷的确定………………………………………………...12

2.2.2主减速器基本参数的选择...........................................................................13

2.2.3主减速器双曲面齿轮的几何尺寸计算…………………………………...16

2.2.4主减速器双曲面齿轮的强度计算…………………………………...……17

2.2.5主减速器轴承的载荷计算…………………………………………….......19

2.3 本章小结………………………………………………………………… …23

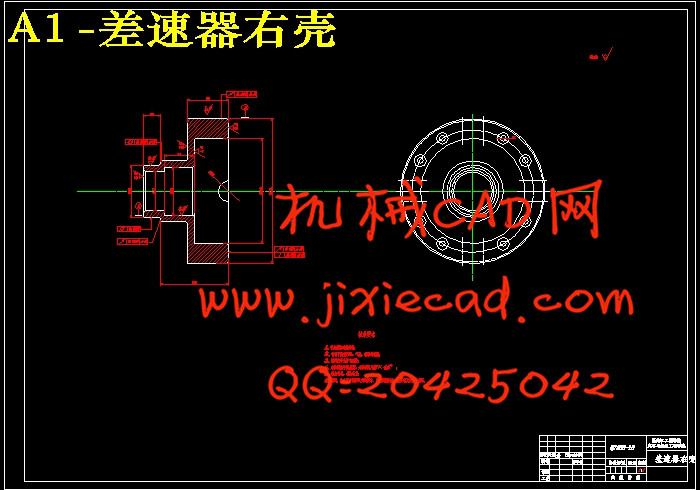

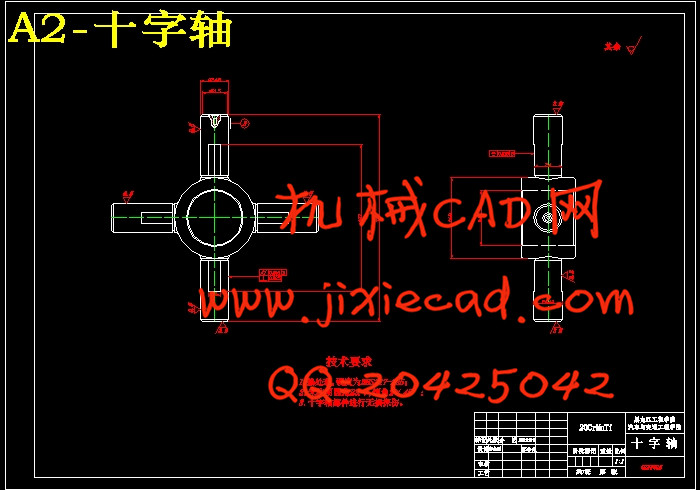

第3章 差速器设计………………………………………………………………….…24

3.1对称式圆锥行星齿轮差速器的差速原理…………………………………...…...24

3.2对称式圆锥行星齿轮差速器的结构………………………………………..........25

3.3对称式圆锥行星齿轮差速器的设计……………………………………………..25

3.3.1差速器齿轮的基本参数的选择…………………………………………...26

3.3.2差速器齿轮的几何计算……………………………………………......….28

3.3.3差速器齿轮的强度计算…………………………………………………...29

3.4本章小结………………………………………………………………………….29

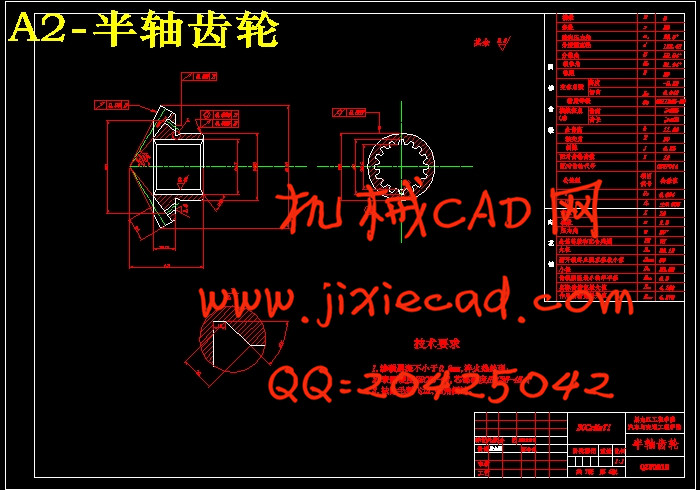

第4章 驱动半轴的设计………………………………………………………………31

4.1结构形式分析…………………………………………………………………......31

4.2全浮式半轴的设计…………………………………………………………......…33

4.3半轴花键的强度计算………………………………………………………......…34

4.4半轴的结构设计及材料与热处理…………………………………………......…35

4.5本章小结…………………………………………………………………………..35

第5章驱动桥壳的设计 ……………………………………………………….……..37

5.1铸造整体式桥壳的结构……………………………………………………......…37

5.2桥壳的受力分析与强度计算………………………………………………......…38

5.2.1桥壳的静弯曲应力计算………………………………………………....….38

5.2.2在不平路面冲击载荷作用下桥壳的强度计算…………………………….39

5.2.3汽车以最大牵引力行驶时的桥壳的强度计算………………………....….39

5.2.4汽车紧急制动时的桥壳强度计算……………………………………….…41

5.3本章小结…………………………………………………………………………41

结论……………………………………………………………………………………...…45

参考文献………………………………………………………………………………….46

致谢………………………………………………………………………………………...62