设计简介

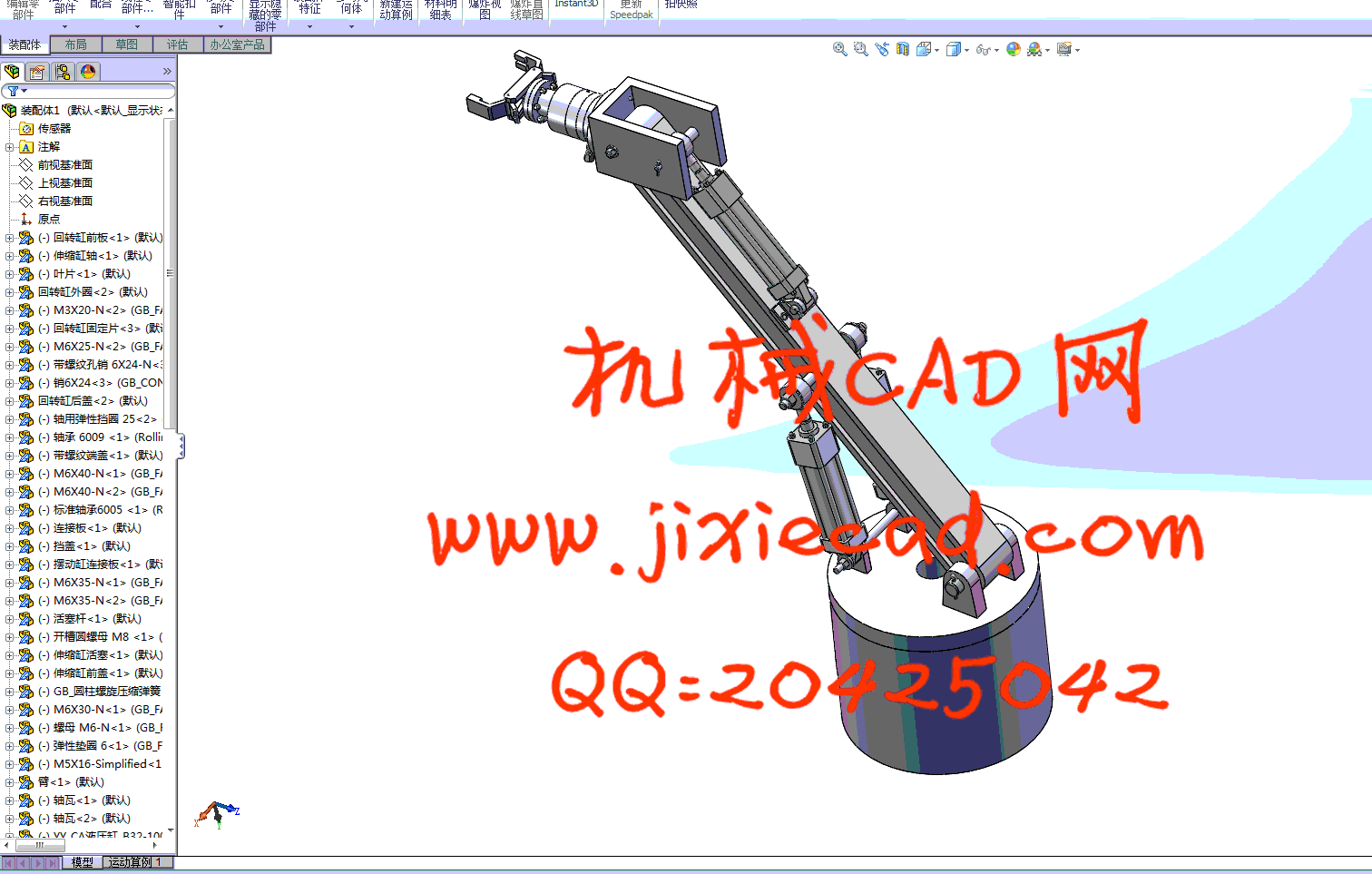

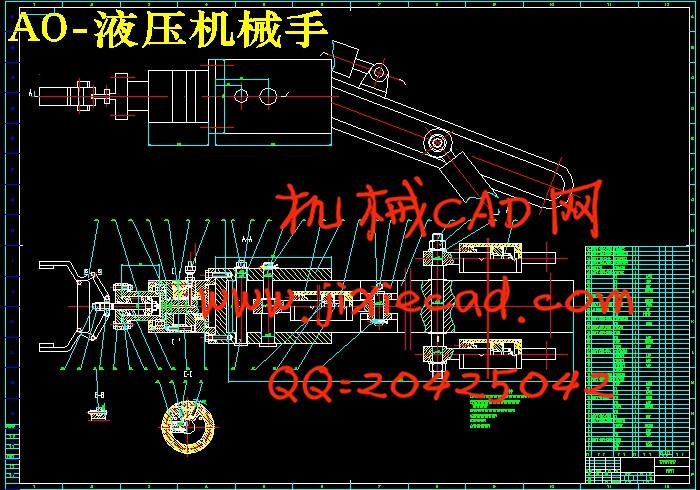

摘要:R175柴油机机体自动加工线多功能液压机械手采用活塞液压缸机构,通过活塞杆的直线运动带动杠杆机构和手爪,将工件夹紧,完成抓取动作。当液压缸断油时,活塞杆通过弹簧复位,从而松开工件。腕部采用叶片式回转缸机构,叶片带动机械手回转轴转动,完成机械手转动动作。手臂采用液压缸和连杆的组合机构,活塞杆与手臂铰接,通过活塞杆的直线运动来实现俯仰动作。本设计机械手为R175型柴油机机体加工自动线上的辅助装置,能完成上料、转位和翻转功能,能够在球面空间内完成送料。

关键词:液压传动;机构;动作

Abstract: The hydraulic mechanical hand installed on the production line is used for producing the R175-type diesel engine block, the mechanical hand uses telescopic hydraulic cylinder mechanism, it will clamp the workpiece tightly through piston rod’s linear motion which can drive leverage and gripper. Piston rod will reset by the force of the sping, and the workpiece will be released, when the oil is cut off . The wrist is equipped with vanetype rotary cylinder. so, manipulator moves with the axis of rotation when driven by the vanes, completing its translocation movement .The arm is a combination of hydraulic cylinder and connecting rod ,and the piston rod is hinged on the arm.So the mechnical hand can achieve the pitching movement throught the piston rod’s linear motion .The design of the mechnical hand is a piece of auxiliary facility for automatic online processing of the R175-type diesel,which can feed, translocate and turn,what’s more, it can feed in a spherical space.

Keyword :Hydraulic cylinder;Mechanism;Movement

目 录

前言…………………………………………………………1

第1章 液压机械手总体方案设计.……………………2

1.1 总体方案的拟定…………………………………………2

1.2 总体方案的选定………………………………………3

1.3 主要参数设计校核……………………………………4

第2章 执行机构的设计………………….…….………7

2.1 机械手抓取机构设计 …………………………………7

2.2 机械手腕部设计………………………………………18

2.3 机械手臂部设计………………………………………20

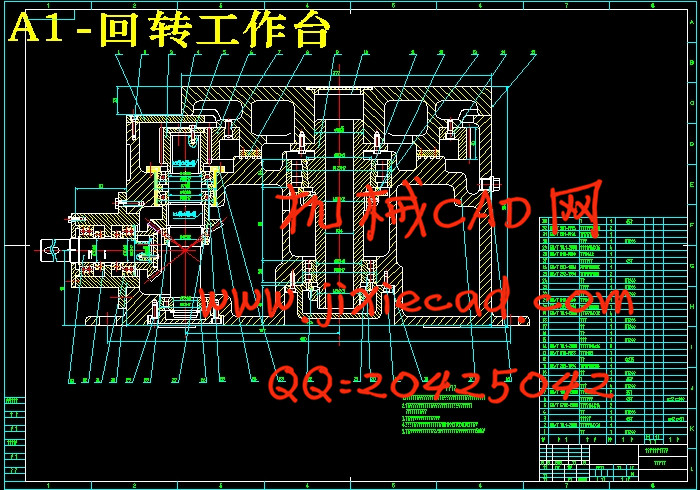

2.4 机械手底座机身设计…………………………………23

2.5 回转工作台设计………………………………………25

第3章 液压驱动、控制系统的设计……………………33

3.1 液压驱动回路设计……………………………………33

3.2 控制系统方案设计……………………………………36

3.3 液压泵及液压原件选择………………………………37

3.4 驱动液压缸选择………………………………………37

参考文献……………………………………………………39

谢辞…………………………………………………………40

关键词:液压传动;机构;动作

Abstract: The hydraulic mechanical hand installed on the production line is used for producing the R175-type diesel engine block, the mechanical hand uses telescopic hydraulic cylinder mechanism, it will clamp the workpiece tightly through piston rod’s linear motion which can drive leverage and gripper. Piston rod will reset by the force of the sping, and the workpiece will be released, when the oil is cut off . The wrist is equipped with vanetype rotary cylinder. so, manipulator moves with the axis of rotation when driven by the vanes, completing its translocation movement .The arm is a combination of hydraulic cylinder and connecting rod ,and the piston rod is hinged on the arm.So the mechnical hand can achieve the pitching movement throught the piston rod’s linear motion .The design of the mechnical hand is a piece of auxiliary facility for automatic online processing of the R175-type diesel,which can feed, translocate and turn,what’s more, it can feed in a spherical space.

Keyword :Hydraulic cylinder;Mechanism;Movement

目 录

前言…………………………………………………………1

第1章 液压机械手总体方案设计.……………………2

1.1 总体方案的拟定…………………………………………2

1.2 总体方案的选定………………………………………3

1.3 主要参数设计校核……………………………………4

第2章 执行机构的设计………………….…….………7

2.1 机械手抓取机构设计 …………………………………7

2.2 机械手腕部设计………………………………………18

2.3 机械手臂部设计………………………………………20

2.4 机械手底座机身设计…………………………………23

2.5 回转工作台设计………………………………………25

第3章 液压驱动、控制系统的设计……………………33

3.1 液压驱动回路设计……………………………………33

3.2 控制系统方案设计……………………………………36

3.3 液压泵及液压原件选择………………………………37

3.4 驱动液压缸选择………………………………………37

参考文献……………………………………………………39

谢辞…………………………………………………………40