设计简介

QY3型石油管道牵引机主机设计

摘 要

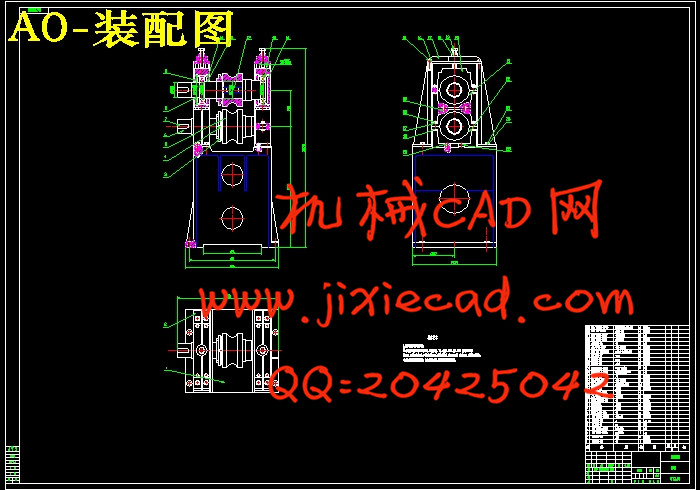

石油管道牵引机研究的是在油田工地的输送油管装置的机器,就是在油田工地作业时对输油管其牵引作用的机械装置。此牵引机可以提供连续传输油管时的牵引力,它主要由主机部分、齿轮基座、减速装置、传动装置、输送装置等几部分组成。本课题是设计牵引机的主机部分。需要对输油管牵引机械进行特性分析、整体方案的拟定、动力机的选择等工作。并对输油管牵引机整体系统的各个零部件进行详细的设计计算、强度校核、和图纸设计,要包括输油管牵引机主机中主要零件,如轴、滚筒、支架、轴承座、键螺钉及螺母等的设计校核与选用,也对牵引机的机体等进行结构设计和分析。

关键词:牵引机,主机,输送装置

QY3 oil pipeline the tractor host design

Abstract

Oil pipeline traction research machine conveyor tubing in the oil field site installations in the oil field site operations' s pipeline of its traction mechanism. This tractor can provide traction when the continuous transmission pipeline, it mainly consists of the host portion of the gear base, deceleration device, transmission device, conveying device composed of several parts. This topic is the host portion of the design of tractor. The need for pipeline traction mechanical characteristic analysis, the formulation of the overall program, the power machine of choice. The various components of the traction machine overall system and pipeline detailed design calculations, the strength check, and the design drawings, to include the main parts in the pipeline tractor host, such as shafts, rollers, brackets, bearing key screws and nuts, etc. design verification and selection, structural design and analysis of the tractor body.

Keywords: tractor, the host, delivery device

目 录

1.绪论 1

1.1课题背景及目的 1

2.设计方案说明 3

2.1总要求 3

2.2 给定的条件和要求 3

2.3设备的介绍 3

2.4牵引机的分类 3

2.5滚筒式牵引机结构 4

2.6滚筒式牵引机主机结构方案 4

3.方案对比 6

4. 设计计算 9

4.1 确定滚筒的数量 9

4.1.1 选用一组滚筒(两个)对滚牵引油管 9

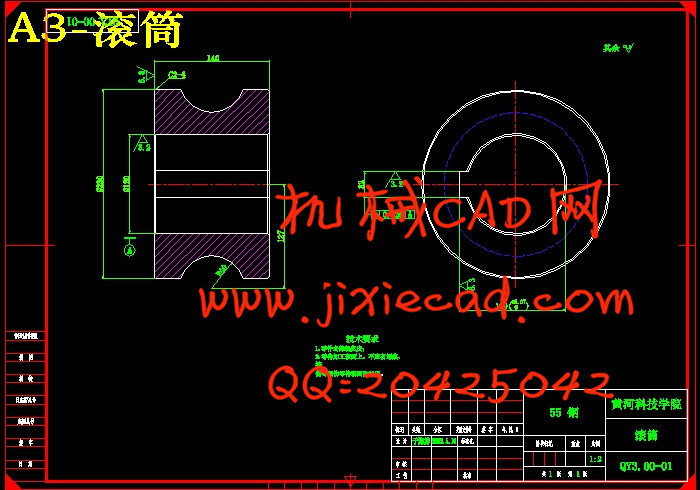

4.2 滚筒的计算 10

4.2.1滚筒接触直径的确定 10

4.2.2 滚筒结构确定 10

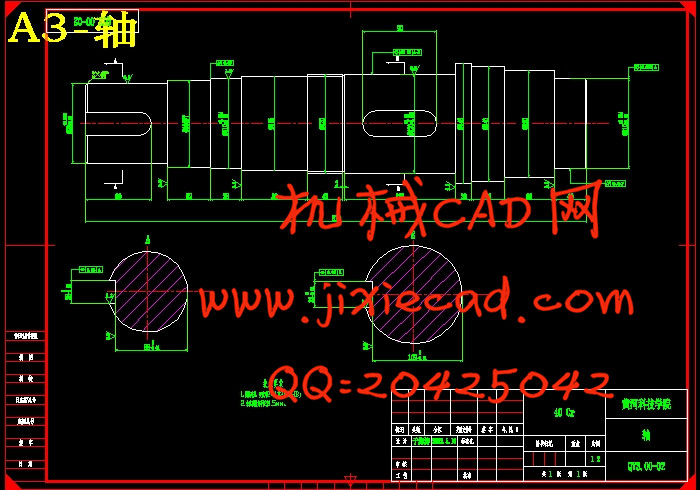

4.3 轴的设计与校核 11

4.3.1 轴的设计 11

4.3.2 轴径的校核计算 13

4.4 轴承的选用和校核 15

4.4.1 预选轴承 15

4.4.2 校核轴承 16

4.5 键的选择 16

4.6 轴承端盖的设计 17

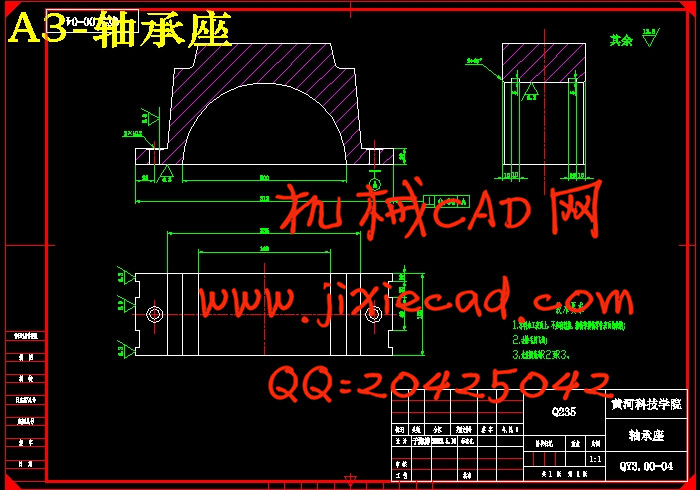

4.7 轴承座的确定 18

4.8 弹簧的选定 19

4.8.1 弹簧所应平衡的自重估算 20

4.8.2 弹簧的选用 21

4.9 压板的确定 21

4.9.1 压紧螺栓的选用 21

4.9.2 压板的结构分析 22

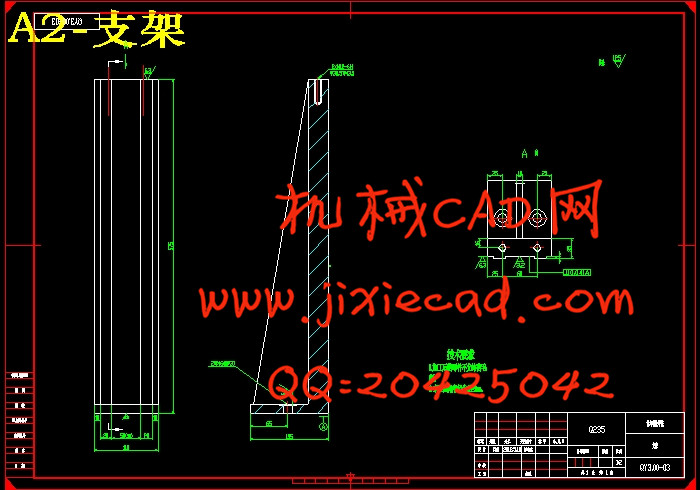

4.10 支架结构设计 22

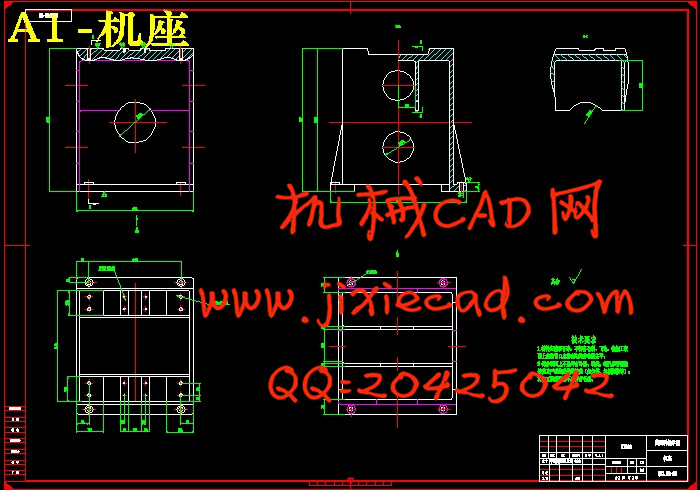

4.11 机身结构分析 23

4.12 联轴器的选择 24

设计总结 25

致 谢 26

参考文献 27

摘 要

石油管道牵引机研究的是在油田工地的输送油管装置的机器,就是在油田工地作业时对输油管其牵引作用的机械装置。此牵引机可以提供连续传输油管时的牵引力,它主要由主机部分、齿轮基座、减速装置、传动装置、输送装置等几部分组成。本课题是设计牵引机的主机部分。需要对输油管牵引机械进行特性分析、整体方案的拟定、动力机的选择等工作。并对输油管牵引机整体系统的各个零部件进行详细的设计计算、强度校核、和图纸设计,要包括输油管牵引机主机中主要零件,如轴、滚筒、支架、轴承座、键螺钉及螺母等的设计校核与选用,也对牵引机的机体等进行结构设计和分析。

关键词:牵引机,主机,输送装置

QY3 oil pipeline the tractor host design

Abstract

Oil pipeline traction research machine conveyor tubing in the oil field site installations in the oil field site operations' s pipeline of its traction mechanism. This tractor can provide traction when the continuous transmission pipeline, it mainly consists of the host portion of the gear base, deceleration device, transmission device, conveying device composed of several parts. This topic is the host portion of the design of tractor. The need for pipeline traction mechanical characteristic analysis, the formulation of the overall program, the power machine of choice. The various components of the traction machine overall system and pipeline detailed design calculations, the strength check, and the design drawings, to include the main parts in the pipeline tractor host, such as shafts, rollers, brackets, bearing key screws and nuts, etc. design verification and selection, structural design and analysis of the tractor body.

Keywords: tractor, the host, delivery device

目 录

1.绪论 1

1.1课题背景及目的 1

2.设计方案说明 3

2.1总要求 3

2.2 给定的条件和要求 3

2.3设备的介绍 3

2.4牵引机的分类 3

2.5滚筒式牵引机结构 4

2.6滚筒式牵引机主机结构方案 4

3.方案对比 6

4. 设计计算 9

4.1 确定滚筒的数量 9

4.1.1 选用一组滚筒(两个)对滚牵引油管 9

4.2 滚筒的计算 10

4.2.1滚筒接触直径的确定 10

4.2.2 滚筒结构确定 10

4.3 轴的设计与校核 11

4.3.1 轴的设计 11

4.3.2 轴径的校核计算 13

4.4 轴承的选用和校核 15

4.4.1 预选轴承 15

4.4.2 校核轴承 16

4.5 键的选择 16

4.6 轴承端盖的设计 17

4.7 轴承座的确定 18

4.8 弹簧的选定 19

4.8.1 弹簧所应平衡的自重估算 20

4.8.2 弹簧的选用 21

4.9 压板的确定 21

4.9.1 压紧螺栓的选用 21

4.9.2 压板的结构分析 22

4.10 支架结构设计 22

4.11 机身结构分析 23

4.12 联轴器的选择 24

设计总结 25

致 谢 26

参考文献 27