设计简介

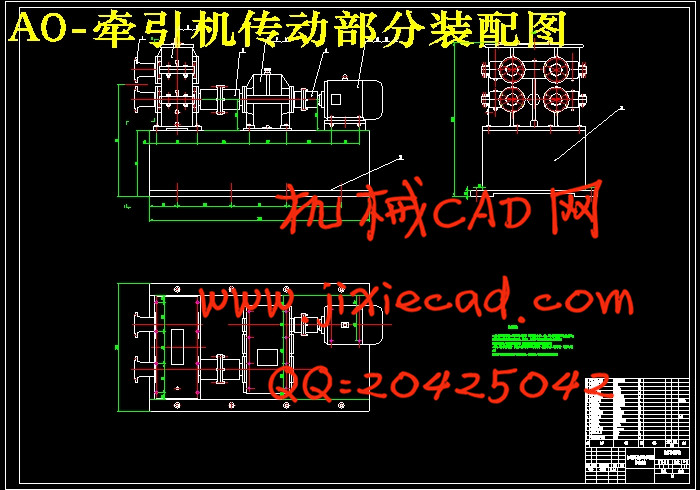

QY3型石油管道牵引机传动系统设计

摘 要

石油开采过程中要对所使用的钢管进行检测和修复。检测时需将成卷的钢管由牵引输送机将其开卷,矫直并连续送入检测装置。本文介绍了一种采用多对辊子通过接触摩擦力实现钢管的定速输送的钢管牵引输送机。较详细的阐述了该机的结构和工作原理,辊子数量、辊径及传动系统参数的设计计算过程。

首先本文介绍了石油管道牵引机的工作原理和特点,并简单分析了牵引机的发展趋势和本设计的设计方案。

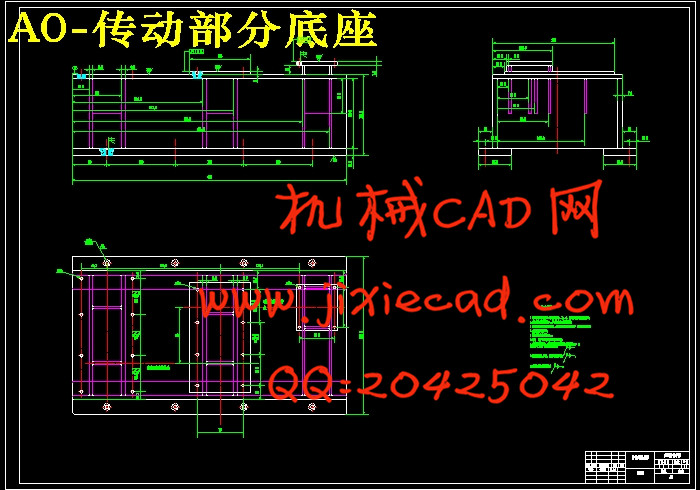

其次本文进行了减速机的选择,齿轮的设计计算,轴的设计和校核,轴承的校核设计,键的设计,箱体的设计,润滑密封的选择工作。

关键词:牵引输送机,工作原理,设计计算

The transmission system design for tractive retractor of the steel pipe

Abstract

The steel tube is tested and repaired In the process of exploiting oil. volumes of steel tube are opened, straighten and conveyed continuously into detection device. The paper introduces a kind of tractive retractor with many even rollers which realises invariable speed feeding by the use of tangent friction. Otherwise it comparatively introduces the structure and work theory, numbers and diameter of rollers, the process of designing calculation of transmission system parameter of tractive retractor in order to provide a kind of reliable method for the homologous mechanism.

Firstly, I will describe the principle design method and the turning method of the tractive retractor of the steel pipe and then the development trends of trator and my design program.

Secondly, I will introduce the choice of reducer, gear design calculations, design and verification of the shaft, button design, cabinet design and the choice of lubrication and sealing.

Key words: tractive retractor, work theory, design calculation

目 录

1设计方案说明 1

1.1设备介绍 1

1.1.1 输油管牵引机的组成及工作原理 1

1.1.2 输送机的发展趋势 2

1.2 设计要求 2

2设计方案分析 5

3设计计算 6

3.1 电动机的选择 6

3.2 减速机的选择 7

3.3 计算传动装置的运动和动力参数 7

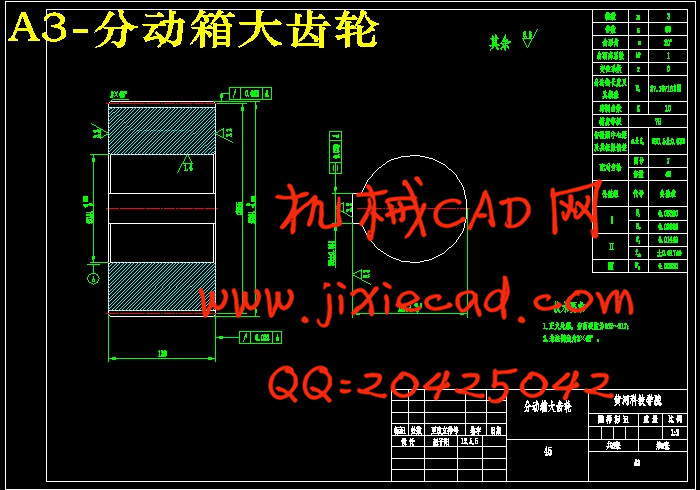

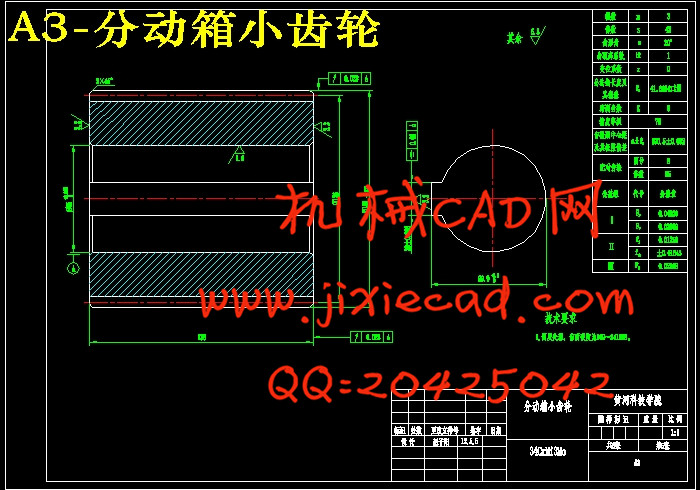

3.4 齿轮的设计 8

3.4.1 齿轮传动的设计计算 8

3.4.2 初步设计齿轮传动的主要尺寸 8

3.4.3 设计计算 9

3.4.4 齿根弯曲疲劳强度设计 10

3.5 轴的设计 13

3.5.2 按弯曲扭转合成应力校核轴的强度 15

3.6 滚动轴承的校核设计 16

3.7 键的校核 17

3.8 箱体结构的设计 18

3.9 润滑密封设计 21

设计总结 22

致谢 23

参考文献 24

摘 要

石油开采过程中要对所使用的钢管进行检测和修复。检测时需将成卷的钢管由牵引输送机将其开卷,矫直并连续送入检测装置。本文介绍了一种采用多对辊子通过接触摩擦力实现钢管的定速输送的钢管牵引输送机。较详细的阐述了该机的结构和工作原理,辊子数量、辊径及传动系统参数的设计计算过程。

首先本文介绍了石油管道牵引机的工作原理和特点,并简单分析了牵引机的发展趋势和本设计的设计方案。

其次本文进行了减速机的选择,齿轮的设计计算,轴的设计和校核,轴承的校核设计,键的设计,箱体的设计,润滑密封的选择工作。

关键词:牵引输送机,工作原理,设计计算

The transmission system design for tractive retractor of the steel pipe

Abstract

The steel tube is tested and repaired In the process of exploiting oil. volumes of steel tube are opened, straighten and conveyed continuously into detection device. The paper introduces a kind of tractive retractor with many even rollers which realises invariable speed feeding by the use of tangent friction. Otherwise it comparatively introduces the structure and work theory, numbers and diameter of rollers, the process of designing calculation of transmission system parameter of tractive retractor in order to provide a kind of reliable method for the homologous mechanism.

Firstly, I will describe the principle design method and the turning method of the tractive retractor of the steel pipe and then the development trends of trator and my design program.

Secondly, I will introduce the choice of reducer, gear design calculations, design and verification of the shaft, button design, cabinet design and the choice of lubrication and sealing.

Key words: tractive retractor, work theory, design calculation

目 录

1设计方案说明 1

1.1设备介绍 1

1.1.1 输油管牵引机的组成及工作原理 1

1.1.2 输送机的发展趋势 2

1.2 设计要求 2

2设计方案分析 5

3设计计算 6

3.1 电动机的选择 6

3.2 减速机的选择 7

3.3 计算传动装置的运动和动力参数 7

3.4 齿轮的设计 8

3.4.1 齿轮传动的设计计算 8

3.4.2 初步设计齿轮传动的主要尺寸 8

3.4.3 设计计算 9

3.4.4 齿根弯曲疲劳强度设计 10

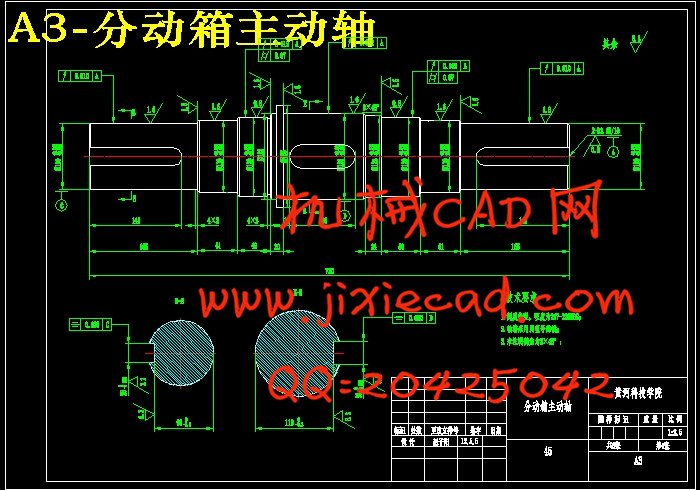

3.5 轴的设计 13

3.5.2 按弯曲扭转合成应力校核轴的强度 15

3.6 滚动轴承的校核设计 16

3.7 键的校核 17

3.8 箱体结构的设计 18

3.9 润滑密封设计 21

设计总结 22

致谢 23

参考文献 24