设计简介

摘要

塔式起重机作为建筑施工的主要设备,在建筑等行业发挥着极其重要的作用。塔式起重机属于臂架型起重机,由于其臂架铰接在较高的塔身上,且可回转,臂架长度较大,结构轻巧、安装拆卸运输方便,适于露天作业,因此大多数用于工业与民用建筑施工。

塔式起重机是为了满足高层建筑施工、设备安装而设计的新型起重运输机械,QTZ40塔式起重机是由建设部长沙建设机械研究院设计的新型建筑用塔式起重机,该机为水平臂架,小车变幅,上回转自升式多用途塔机。

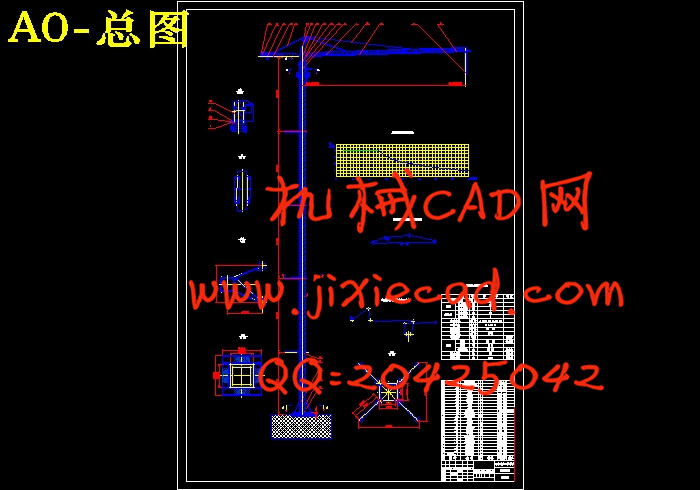

本设计的题目是固定式QTZ40塔式起重机起升系统的设计。QT40塔式起重机有多种形式,此次设计的形式为上回转液压顶升自动加节,可随着建筑物的升高而升高,固定式高度为36米,在附着状态下可达到100米,其工作幅度为50米。

本设计书主要包括四部分:第一部分主要是对现今国内外塔式起重机的发展现状、趋势以及QTZ40塔式起重机特点、应用场合,做了一个简要的概述;第二部分是QTZ40塔式起重机总体方案的选择及总体设计计算过程;第三部分是起升机构设计和计算;第四部分是吊钩组的设计。

关键词: QTZ40塔式起重机 起升机构 吊钩组

ABSTRACT

As an important facility, the tower crane plays an important role in construction industry. The tower crane belongs to the arm rack type crane. Its arm is hinged on the high tower body, and it may rotate. It has longer arm, dexterous structure. What’s more, it is easy to be assembled, disassembled and transported. It is suitable for the open-air work and mainly used for industry and civil construction

Tower cranes are to meet high-rise construction building, equipment installation and design as a new type machinery of lifting transport. The QTZ40 tower cranes are new tower cranes designed by Changsha Institute of the Ministry of Construction Machinery used in construction building. The aircraft is horizontal boom, trolley luffing, on the back or decanted from the tower-type multi-purpose machines .

The design topic is the stationary QTZ40 tower crane system and the design of lifting structure. There are many kinds of QTZ40 tower crane. The form of this design is as below. With an upper rotating hydraulic pressure propping system, the machine could add height automatically and thus rise with the building ascension. The stationary type is 36meter high; it could reach the height of 100meters when it is being adhered. Its work scope is 50 meters.

This design book mainly includes four parts. The first part summarizes the present situation and the development tendency of the Tower crane in both our country and abroad, as well as the characteristic and application occasion.The second part is the QTZ40 tower crane overall concept choice and the system design computation process; the third part is the organization design and the computation of lifting mechanism;and the last is the design of the hook group.

KEY WORDS: QTZ40 tower crane lifting mechanism hook group

目录

第1章 前言·················································································1

1.1塔式起重机概述········································································1

1.2塔式起重机的发展趋势································································1

第2章 总体设计···········································································1

2.1 概述···················································································2

2.2 总体设计方案的确定··································································2

2.2.1金属结构···········································································2

2.2.2工作机构··········································································19

2.2.3安全保护装置·····································································26

2.3总体设计原则······································································· 28

2.3.1整机工作级别································································· 28

2.3.2机构工作级别································································· 28

2.3.3主要技术性能参数··························································· 29

2.4平衡臂与平衡重的计算·······························································29

2.5起重特性曲线··········································································31

2.6塔机风力计算··········································································32

2.6.1工作工况Ⅰ······································································33

2.6.2工作工况Ⅱ······································································36

2.6.3非工作工况Ⅲ ··································································39

2.7整机的抗倾翻稳定性计算····························································41

2.7.1工作工况Ⅰ·······································································42

2.7.2工作工况Ⅱ········································································43

2.7.3非工作工况Ⅲ·····································································44

2.7.4工作工况Ⅳ·······································································45

第3章 起升机构的设计和计算·······················································47

3.1起升机构的形式·······································································47

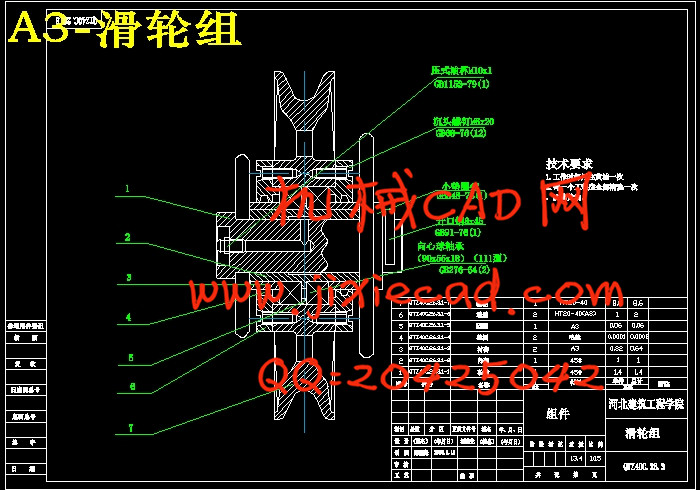

3.2 确定起升机构滑轮组倍率···························································49

3.3 钢丝绳的选择········································································50

3.4 确定卷筒的尺寸·····································································51

3.5 选择电动机···········································································52

3.6计算传动比,确定卷筒直径·························································53

3.7 校验卷筒··············································································54

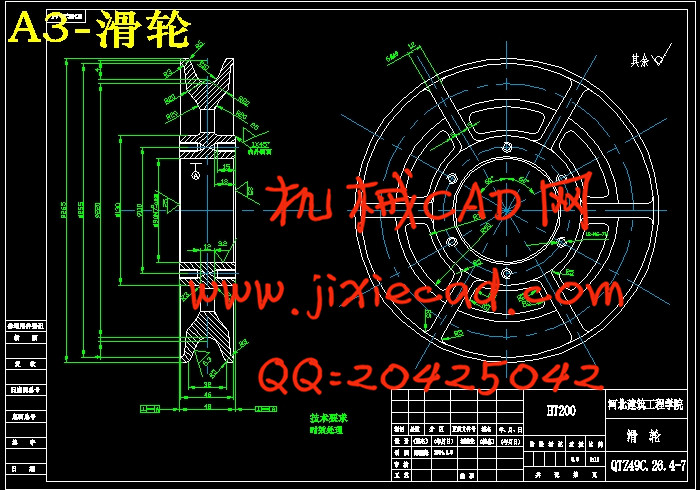

3.8 选择滑轮··············································································54

3.9 选择减速器、制动器、联轴器······················································55

3.10 电动机及起升机构起、制动时间校验············································58

第4章 吊钩组的设计····································································61

4.1 吊钩组的形式·········································································61

4.2 吊钩的形式············································································61

4.3 吊钩计算···············································································62

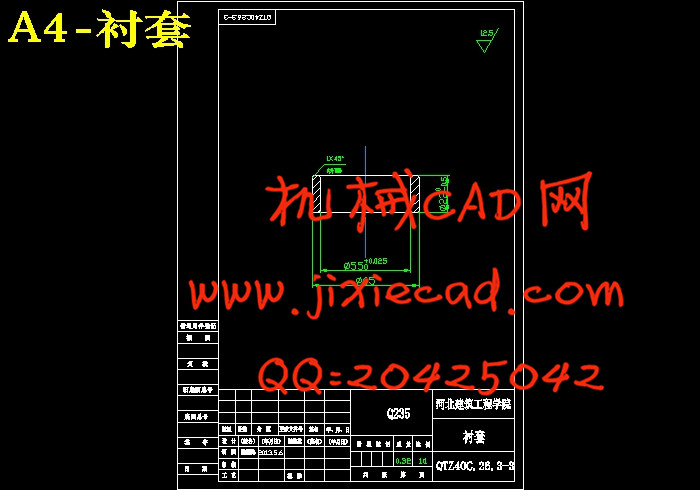

4.4 吊钩横梁计算·········································································64

设计小结··············································································66

参考文献·····················································································67

塔式起重机作为建筑施工的主要设备,在建筑等行业发挥着极其重要的作用。塔式起重机属于臂架型起重机,由于其臂架铰接在较高的塔身上,且可回转,臂架长度较大,结构轻巧、安装拆卸运输方便,适于露天作业,因此大多数用于工业与民用建筑施工。

塔式起重机是为了满足高层建筑施工、设备安装而设计的新型起重运输机械,QTZ40塔式起重机是由建设部长沙建设机械研究院设计的新型建筑用塔式起重机,该机为水平臂架,小车变幅,上回转自升式多用途塔机。

本设计的题目是固定式QTZ40塔式起重机起升系统的设计。QT40塔式起重机有多种形式,此次设计的形式为上回转液压顶升自动加节,可随着建筑物的升高而升高,固定式高度为36米,在附着状态下可达到100米,其工作幅度为50米。

本设计书主要包括四部分:第一部分主要是对现今国内外塔式起重机的发展现状、趋势以及QTZ40塔式起重机特点、应用场合,做了一个简要的概述;第二部分是QTZ40塔式起重机总体方案的选择及总体设计计算过程;第三部分是起升机构设计和计算;第四部分是吊钩组的设计。

关键词: QTZ40塔式起重机 起升机构 吊钩组

ABSTRACT

As an important facility, the tower crane plays an important role in construction industry. The tower crane belongs to the arm rack type crane. Its arm is hinged on the high tower body, and it may rotate. It has longer arm, dexterous structure. What’s more, it is easy to be assembled, disassembled and transported. It is suitable for the open-air work and mainly used for industry and civil construction

Tower cranes are to meet high-rise construction building, equipment installation and design as a new type machinery of lifting transport. The QTZ40 tower cranes are new tower cranes designed by Changsha Institute of the Ministry of Construction Machinery used in construction building. The aircraft is horizontal boom, trolley luffing, on the back or decanted from the tower-type multi-purpose machines .

The design topic is the stationary QTZ40 tower crane system and the design of lifting structure. There are many kinds of QTZ40 tower crane. The form of this design is as below. With an upper rotating hydraulic pressure propping system, the machine could add height automatically and thus rise with the building ascension. The stationary type is 36meter high; it could reach the height of 100meters when it is being adhered. Its work scope is 50 meters.

This design book mainly includes four parts. The first part summarizes the present situation and the development tendency of the Tower crane in both our country and abroad, as well as the characteristic and application occasion.The second part is the QTZ40 tower crane overall concept choice and the system design computation process; the third part is the organization design and the computation of lifting mechanism;and the last is the design of the hook group.

KEY WORDS: QTZ40 tower crane lifting mechanism hook group

目录

第1章 前言·················································································1

1.1塔式起重机概述········································································1

1.2塔式起重机的发展趋势································································1

第2章 总体设计···········································································1

2.1 概述···················································································2

2.2 总体设计方案的确定··································································2

2.2.1金属结构···········································································2

2.2.2工作机构··········································································19

2.2.3安全保护装置·····································································26

2.3总体设计原则······································································· 28

2.3.1整机工作级别································································· 28

2.3.2机构工作级别································································· 28

2.3.3主要技术性能参数··························································· 29

2.4平衡臂与平衡重的计算·······························································29

2.5起重特性曲线··········································································31

2.6塔机风力计算··········································································32

2.6.1工作工况Ⅰ······································································33

2.6.2工作工况Ⅱ······································································36

2.6.3非工作工况Ⅲ ··································································39

2.7整机的抗倾翻稳定性计算····························································41

2.7.1工作工况Ⅰ·······································································42

2.7.2工作工况Ⅱ········································································43

2.7.3非工作工况Ⅲ·····································································44

2.7.4工作工况Ⅳ·······································································45

第3章 起升机构的设计和计算·······················································47

3.1起升机构的形式·······································································47

3.2 确定起升机构滑轮组倍率···························································49

3.3 钢丝绳的选择········································································50

3.4 确定卷筒的尺寸·····································································51

3.5 选择电动机···········································································52

3.6计算传动比,确定卷筒直径·························································53

3.7 校验卷筒··············································································54

3.8 选择滑轮··············································································54

3.9 选择减速器、制动器、联轴器······················································55

3.10 电动机及起升机构起、制动时间校验············································58

第4章 吊钩组的设计····································································61

4.1 吊钩组的形式·········································································61

4.2 吊钩的形式············································································61

4.3 吊钩计算···············································································62

4.4 吊钩横梁计算·········································································64

设计小结··············································································66

参考文献·····················································································67