设计简介

摘要

环保与节能是当前全世界发展的一大主题。我国也提出建设节约型社会的基本国策,实现这一目标的重要手段就有电动汽车。由于国家的支持,社会的需要,电动汽车正处于发展的上升期。但是也面临着许多难以解决的问题。电池、电机、控制系统的性能与价格问题,使得电动汽车的发展遇到难题。本文主要介绍了电动汽车的控制系统,电动机,汽车主减速器等电动汽车汽车核心部件的发展状况,未来电动汽车控制系统的发展趋势,并指出了研究的重点与难点。

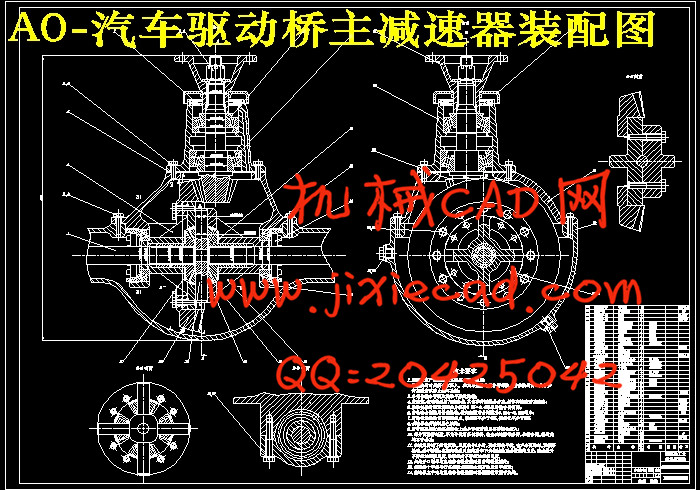

汽车主减速器和差速器是汽车传动中的最核心的部件之一。它能够将传动装置产生的发动机转矩传给驱动车轮,以实现降低速度增大扭矩。本次设计的是有关家用轿车汽车的传动系统以及主减速器总成。并使其具有通过性。本次设计通过对市面上各种不同形式样式的控制系统,电机,减速器的对比后,参考实际家用轿车为原始设计参数,对比不同类型的控制系统、电机、减速器后。确定主传动比,并对其中主要的齿轮进行齿面接触强度和齿轮弯曲强度进行校核。对轴承的选用在满足需求的基础上,力求结构简单,寿命长,经济实惠。对轴的设计过程中,着重于齿轮的安置,并对其所受最大载荷的危险截面进行了强度校核。最终设计出一种合理可靠,经济实惠的电动汽车减速器。希望能对电动汽车发展尽绵薄之力,让世界生态环境越来越好。

关键词:电动汽车,控制系统,主减速器,电机,轴承,传动比

Abstract

Environmental protection and energy conservation is a major theme of the current development of the world. China also put forward the construction of a conservation oriented society, the basic national policy, to achieve this goal is an important means of electric vehicles. Due to the support of the state, the needs of the community, electric vehicles are in the development of the rising period. But there are many difficult problems to solve. Battery, motor, control system performance and price issues, making the development of electric vehicles encountered problems. This paper mainly introduces the control system of electric vehicle, motor vehicle main reducing gear for electric vehicles, such as core auto parts development, the future electric vehicle control system development trend, and points out the emphases and difficulties of the research.

Automobile main reducer and differential is one of the most important parts in automobile transmission. The engine torque of the transmission device can be transmitted to the driving wheel to realize the reduction of the speed increasing torque. This design is about the car's drive system and the main reducer assembly. And make it through sex. This design through to market a variety of different forms of control system, motor, reducer after contrast, reference actual domestic car as the original design parameters, comparison of different types of control system, a motor, a speed reducer. Determine the main transmission ratio, and the main gear tooth contact strength and gear bending strength to check. Bearing selection on the basis of meeting the needs, and strive to simple structure, long life, economic benefits. In the design process of the shaft, the gear placement is emphasized, and the strength check of the dangerous section of the maximum load is carried out. Finally, the design of a reasonable and reliable, affordable electric vehicle reducer.We hope to contribute the development of electric vehicles, to make the world better ecological environment.

Key words: electric vehicle, control system, main reducer, motor, bearing, transmission ratio

目 录

引言 1

第一章绪 论 2

1.1课题研究背景 2

1.2研究的意义 2

1.3电动汽车发展状况 3

1.3.1国外电动汽车的发展概况 4

1.3.2我国电动汽车的研究开发 4

1.4研究内容 5

第二章整体设计方案 6

2.1驱动方式简介 6

2.2电动汽车驱动系统的比较 6

2.3驱动系统的确定 7

2.4纯电动汽车整车参数及性能指标确定 8

第三章驱动电机和电池匹配 10

3.1驱动电动机种类比较及选择 10

3.2 驱动电机型号的确定及参数 11

3.3传动比的确定 13

3.4蓄电池的参数匹配 14

第四章汽车主减速器设计 17

4.1汽车主减速器概述 17

4.1.1主减速器的作用 17

4.2主减速器分类及介绍 18

4.2.1按数目分类 18

4.2.2按传动比档数分 18

4.2.3按结构型式分 18

4.2主减速器结构的设计 18

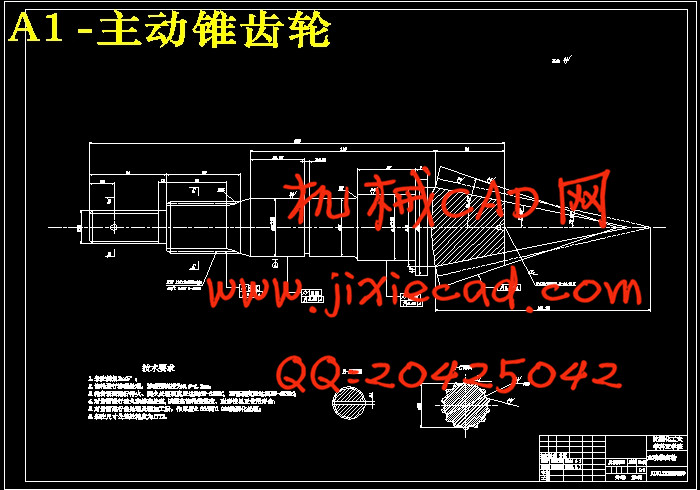

4.3.1主减速器类型确定 19

4.3.2主减速器主动锥齿轮的支承型式及安置方法 19

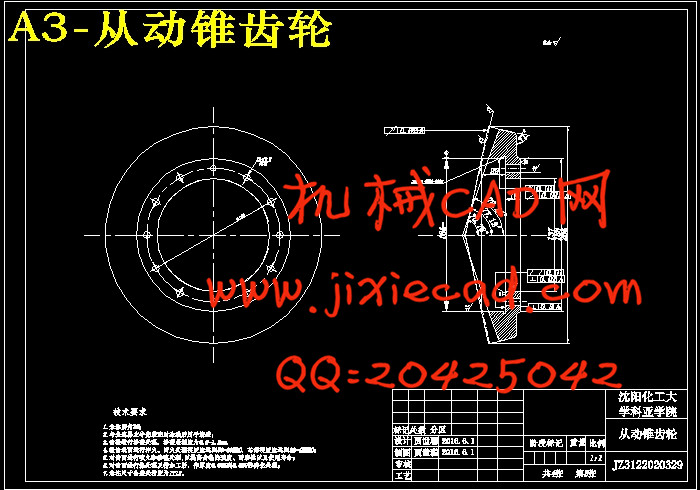

4.3.3主减速器从动锥齿轮的支承型式及安置方法 20

第五章主减速器的基本参数选择与计算载荷的确定 21

5.1齿轮计算载荷的确定 21

5.2主减速器齿轮基本参数的选择 22

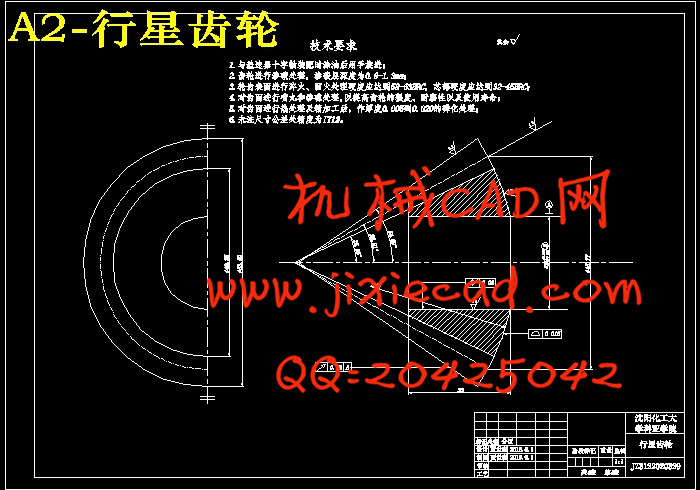

5.2.1齿数的选择 22

5.2.2节圆直径的选择 23

5.2.3齿轮端面模数的选择 24

5.2.4齿面宽的选择 24

5.2.5双曲面齿轮的偏移距E值 24

5.2.6齿轮螺旋方向 25

5.2.7螺旋角β的选择 25

5.2.8齿轮法向压力角的选择 27

5.3螺旋锥齿轮几何尺寸计算 28

5.4主减速器螺旋锥齿轮强度计算 30

5.4.1计算圆周力 30

5.4.2轮齿弯曲强度: 32

5.4.3轮齿接触强度: 33

5.5齿轮的材料及热处理: 34

第六章轴承的选用 36

6.1锥齿轮齿面上的作用力 36

6.2齿宽中点处的圆周力 37

6.3齿轮的轴向力和径向力 38

6.4主减速器轴承载荷的计算 39

6.4.1齿轮轴承径向载荷的计算 39

6.4.2轴承的校核 40

6.5本章小结 43

第七章轴的设计与校核 44

7.1主动齿轮轴的机构设计 44

7.2主动锥齿轮轴的校核 44

7.3本章小结 47

第八章绘图 48

结 论 55

参考文献 56

致谢 57

环保与节能是当前全世界发展的一大主题。我国也提出建设节约型社会的基本国策,实现这一目标的重要手段就有电动汽车。由于国家的支持,社会的需要,电动汽车正处于发展的上升期。但是也面临着许多难以解决的问题。电池、电机、控制系统的性能与价格问题,使得电动汽车的发展遇到难题。本文主要介绍了电动汽车的控制系统,电动机,汽车主减速器等电动汽车汽车核心部件的发展状况,未来电动汽车控制系统的发展趋势,并指出了研究的重点与难点。

汽车主减速器和差速器是汽车传动中的最核心的部件之一。它能够将传动装置产生的发动机转矩传给驱动车轮,以实现降低速度增大扭矩。本次设计的是有关家用轿车汽车的传动系统以及主减速器总成。并使其具有通过性。本次设计通过对市面上各种不同形式样式的控制系统,电机,减速器的对比后,参考实际家用轿车为原始设计参数,对比不同类型的控制系统、电机、减速器后。确定主传动比,并对其中主要的齿轮进行齿面接触强度和齿轮弯曲强度进行校核。对轴承的选用在满足需求的基础上,力求结构简单,寿命长,经济实惠。对轴的设计过程中,着重于齿轮的安置,并对其所受最大载荷的危险截面进行了强度校核。最终设计出一种合理可靠,经济实惠的电动汽车减速器。希望能对电动汽车发展尽绵薄之力,让世界生态环境越来越好。

关键词:电动汽车,控制系统,主减速器,电机,轴承,传动比

Abstract

Environmental protection and energy conservation is a major theme of the current development of the world. China also put forward the construction of a conservation oriented society, the basic national policy, to achieve this goal is an important means of electric vehicles. Due to the support of the state, the needs of the community, electric vehicles are in the development of the rising period. But there are many difficult problems to solve. Battery, motor, control system performance and price issues, making the development of electric vehicles encountered problems. This paper mainly introduces the control system of electric vehicle, motor vehicle main reducing gear for electric vehicles, such as core auto parts development, the future electric vehicle control system development trend, and points out the emphases and difficulties of the research.

Automobile main reducer and differential is one of the most important parts in automobile transmission. The engine torque of the transmission device can be transmitted to the driving wheel to realize the reduction of the speed increasing torque. This design is about the car's drive system and the main reducer assembly. And make it through sex. This design through to market a variety of different forms of control system, motor, reducer after contrast, reference actual domestic car as the original design parameters, comparison of different types of control system, a motor, a speed reducer. Determine the main transmission ratio, and the main gear tooth contact strength and gear bending strength to check. Bearing selection on the basis of meeting the needs, and strive to simple structure, long life, economic benefits. In the design process of the shaft, the gear placement is emphasized, and the strength check of the dangerous section of the maximum load is carried out. Finally, the design of a reasonable and reliable, affordable electric vehicle reducer.We hope to contribute the development of electric vehicles, to make the world better ecological environment.

Key words: electric vehicle, control system, main reducer, motor, bearing, transmission ratio

目 录

引言 1

第一章绪 论 2

1.1课题研究背景 2

1.2研究的意义 2

1.3电动汽车发展状况 3

1.3.1国外电动汽车的发展概况 4

1.3.2我国电动汽车的研究开发 4

1.4研究内容 5

第二章整体设计方案 6

2.1驱动方式简介 6

2.2电动汽车驱动系统的比较 6

2.3驱动系统的确定 7

2.4纯电动汽车整车参数及性能指标确定 8

第三章驱动电机和电池匹配 10

3.1驱动电动机种类比较及选择 10

3.2 驱动电机型号的确定及参数 11

3.3传动比的确定 13

3.4蓄电池的参数匹配 14

第四章汽车主减速器设计 17

4.1汽车主减速器概述 17

4.1.1主减速器的作用 17

4.2主减速器分类及介绍 18

4.2.1按数目分类 18

4.2.2按传动比档数分 18

4.2.3按结构型式分 18

4.2主减速器结构的设计 18

4.3.1主减速器类型确定 19

4.3.2主减速器主动锥齿轮的支承型式及安置方法 19

4.3.3主减速器从动锥齿轮的支承型式及安置方法 20

第五章主减速器的基本参数选择与计算载荷的确定 21

5.1齿轮计算载荷的确定 21

5.2主减速器齿轮基本参数的选择 22

5.2.1齿数的选择 22

5.2.2节圆直径的选择 23

5.2.3齿轮端面模数的选择 24

5.2.4齿面宽的选择 24

5.2.5双曲面齿轮的偏移距E值 24

5.2.6齿轮螺旋方向 25

5.2.7螺旋角β的选择 25

5.2.8齿轮法向压力角的选择 27

5.3螺旋锥齿轮几何尺寸计算 28

5.4主减速器螺旋锥齿轮强度计算 30

5.4.1计算圆周力 30

5.4.2轮齿弯曲强度: 32

5.4.3轮齿接触强度: 33

5.5齿轮的材料及热处理: 34

第六章轴承的选用 36

6.1锥齿轮齿面上的作用力 36

6.2齿宽中点处的圆周力 37

6.3齿轮的轴向力和径向力 38

6.4主减速器轴承载荷的计算 39

6.4.1齿轮轴承径向载荷的计算 39

6.4.2轴承的校核 40

6.5本章小结 43

第七章轴的设计与校核 44

7.1主动齿轮轴的机构设计 44

7.2主动锥齿轮轴的校核 44

7.3本章小结 47

第八章绘图 48

结 论 55

参考文献 56

致谢 57