设计简介

摘 要

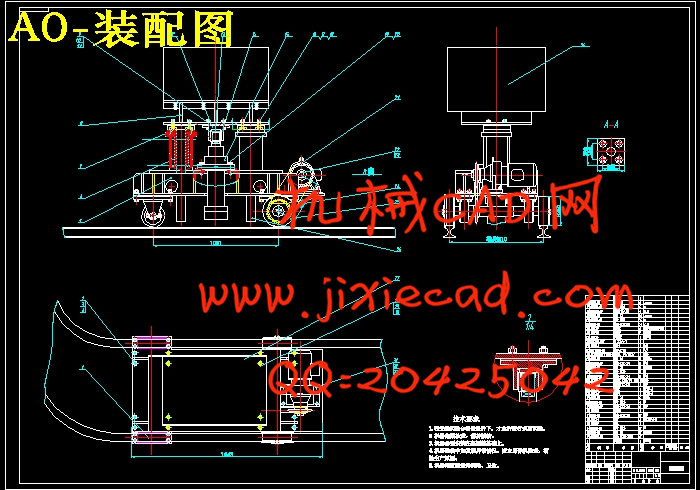

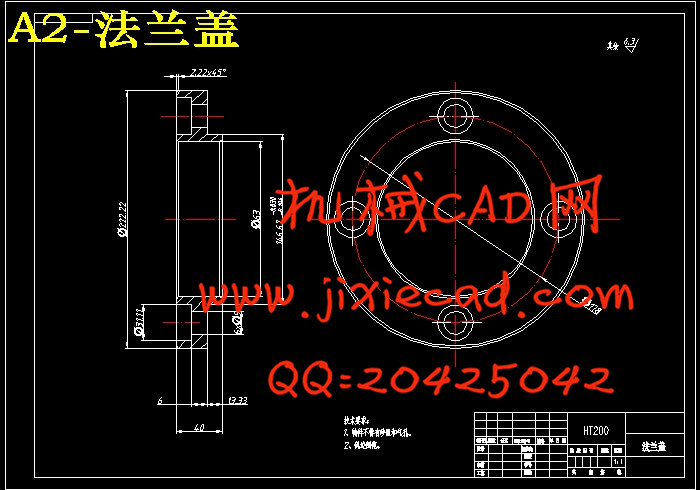

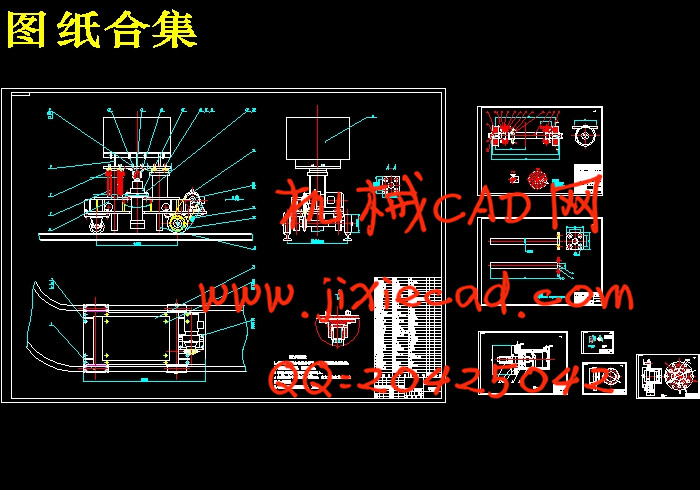

目前大型养猪场中使用的喂料方式有人工喂养和管道喂养,但是这些喂养方式都会产生诸如人工喂养中饲料污染、饲料浪费、每日喂料不规范、管道喂养中管道残留饲料和管道堵塞和管道老化等问题。我国是一个养殖业大国,畜禽养殖量全球第一,但养殖技术落后,生产设施十分简陋,养殖效益差,这一状况已严重影响我国畜禽养殖业的发展。但是目前大规模养殖占的总养值比例很小。我国生猪养殖业70% 以上是由农户散养,养殖结构以分散和农户养殖为主,养殖体系很脆弱。本文通过自动喂料小车实现养殖场自动喂料,自动喂料小车采用轮轨式结构,车体转角处采用圆角过渡。本设计的自动喂料小车结构如图2 所示。小车前端包括三菱PLC 控制系统和1 台前轮牵引电机两部分。小车前轮牵引电机是小车动力的来源,牵引电机的启闭控制小车的前进喂料和后退加料。小车后端包括小车饲料箱、小车喂料箱、两台电机和小车后轮4部分。小车饲料箱的作用是将饲料暂时储存在小车中,需要喂料时饲料箱电机启动,饲料就通过饲料箱口加入到小车喂料箱中。小车喂料箱的作用是喂料时饲料先从饲料箱中加入到喂料箱中,然后喂料箱电机启动,饲料就从喂料箱口加入到猪圈里的食槽中。饲料箱和喂料箱分开设计是为了防止每个圈的喂料量波动范围过大,不会因为喂料量的不同而影响猪的生长,且分开设计能够更好地减少喂料过程中的饲料浪费现象,节约了成本。小车前轮只是起到辅助的作用,并没有动力。

本文对养殖场自动喂料装置设计进行设计,主要完成机械结构部分设计,最后还对小车的控制系统进行了PLC控制设计。

关键词:养殖场;机械结构;自动上料

Abstract

Feeding methods currently used for large-scale pig farm of artificial feeding and tube feeding, but the Fed will produce problems such as artificial feeding in the feed, feed waste pollution, daily feeding is not standardized, pipeline feeding in the residue feed and the blockage of pipelines and pipe aging. China is a big country of livestock and poultry breeding, the amount of the first in the world, but in backward technology, production facilities is very simple, the breeding benefit difference, this situation has seriously affected the development of animal husbandry in china. But the current large-scale farms account for a very small proportion of the total breeding value. In China more than 70% pig breeding by backyard farms, breeding structure to disperse and farmers farming, breeding system is very fragile.

In this paper, the farm automatic feeding through automatic feeding vehicle, automatic feeding car with wheel track structure, the body corner fillet. Automatic feeding carriage of the design of the structure as shown in figure 2. The car front includes Mitsubishi PLC control system and the 1 front wheel traction two part of motor. Car front wheel traction motor is the source power of the car, traction control of opening and closing of the car forward feeding and backward feeding motor. The car rear end comprises a trolley car feed box, feed box, two motors and the car rear part 4. The car feed box is the role of the feed is temporarily stored in the car, start the feed box motor need to feed, feed by feed box opening into the trolley feeding box. Trolley feeding box is the role of feeding and feed from the feed box was added to the feed box, and then feeding box motor starting, feed from the feed box mouth into pigsties trough. Feed box and a feed box is designed to prevent from feeding quantity fluctuation range of each circle is too large, not because the feeding quantity is influenced by different pig growth, and separate design can better reduce feed waste feeding process, saving the cost. Car front wheel just play a supporting role, and no power.

This paper carries on the design to the farms automatic feeding device design, mainly completes the design of mechanical structure, and finally to the car control system using PLC control design.

Key Words: farms; mechanical structure; automatic feeding

In this paper, the farm automatic feeding through automatic feeding vehicle, automatic feeding car with wheel track structure, the body corner fillet. Automatic feeding carriage of the design of the structure as shown in figure 2. The car front includes Mitsubishi PLC control system and the 1 front wheel traction two part of motor. Car front wheel traction motor is the source power of the car, traction control of opening and closing of the car forward feeding and backward feeding motor. The car rear end comprises a trolley car feed box, feed box, two motors and the car rear part 4. The car feed box is the role of the feed is temporarily stored in the car, start the feed box motor need to feed, feed by feed box opening into the trolley feeding box. Trolley feeding box is the role of feeding and feed from the feed box was added to the feed box, and then feeding box motor starting, feed from the feed box mouth into pigsties trough. Feed box and a feed box is designed to prevent from feeding quantity fluctuation range of each circle is too large, not because the feeding quantity is influenced by different pig growth, and separate design can better reduce feed waste feeding process, saving the cost. Car front wheel just play a supporting role, and no power.

This paper carries on the design to the farms automatic feeding device design, mainly completes the design of mechanical structure, and finally to the car control system using PLC control design.

Key Words: farms; mechanical structure; automatic feeding

目 录

摘 要 IVAbstract V

目 录 VI

第1章 绪论 1

1.1本选题研究的目的 1

1.2选题意义 1

1.3国内外发展状况 1

1.5研究内容和方法 7

2. 养殖场自动喂料装置总体方案设计 8

2.1 总体设计要求 8

2.2 自动喂料小车总体结构 8

2.3 传动装置的结构 10

2.4 自动喂料小车车轮组安装结构 10

2.5自动喂料小车行走机构的设计 11

2.6选择车轮与轨道并验算其强度 11

2.6.1轮压值校核及选择车轮和轨道 11

2.6.2车轮疲劳计算 12

2.6.3车轮强度计算 12

2.7 运行阻力计算 13

2.7.1摩擦阻力矩计算 13

2.7.2摩擦阻力计算 13

2.8 选择电动机 13

2.8.1类型的选择 13

2.8.2功率的确定 13

2.8.3工作机的阻力 14

2.8.4电动机的转速的确定 14

2.9计算传动装置的运动参数和动力参数 15

2.10轴的设计与校核 17

2.10.1轴的设计 17

2.10.2 轴的强度校核 17

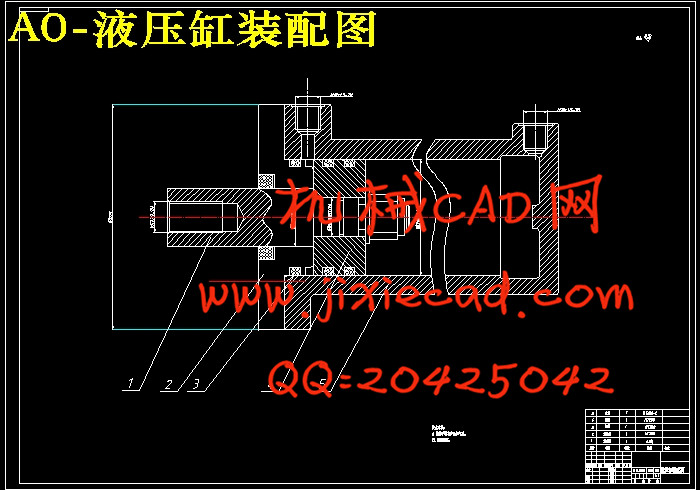

第3章 液压部分设计 21

3.1 液压系统原理设计 21

3.2计算液压缸尺寸及工况 21

3.3液压缸主要尺寸确定 23

3.3.1顶升油缸壁厚及外径计算 23

3.3.2工作行程确定 24

第4章 系统总体设计 26

4.1 总体思路 26

4.2 主电路设计 26

4.3 PLC选型 27

4.4 系统变量定义及分配表 27

4.5 PLC系统接线图 28

4.6系统软件设计 28

结束语 30

参考文献 31

致 谢 32