设计简介

摘 要

机械手是一种典型的机电一体化产品,锻打机械手是机械手研究领域的热点。研究锻打机械手需要结合机械、电子、信息论、人工智能、生物学以及计算机等诸多学科知识,同时其自身的发展也促进了这些学科的发展。锻打机械手的定义,世界各国尚未统一,分类也不尽相同。最近联合国国际标准化组织采纳了美国机械手协会给锻打机械手下的定义:锻打机械手是一种可重复编程的多功能操作装置,可以通过改变动作程序,来完成各种工作,主要用于搬运材料,传递工件。参考国外的定义,结合我国的习惯用语,对锻打机械手作如下定义:

锻打机械手是一种机体独立,动作自由度较多,程序可灵活变更,能任意定位,自动化程度高的自动操作机械。是可进行自动喷漆或关节其他涂料的工业机械手。

锻打机械手以刚性高的手臂为主体,与人相比,可以有更快的运动速度,可以搬运更重的东西,而且定位精度相当高,它可以根据外部来的信号,自动进行各种操作。

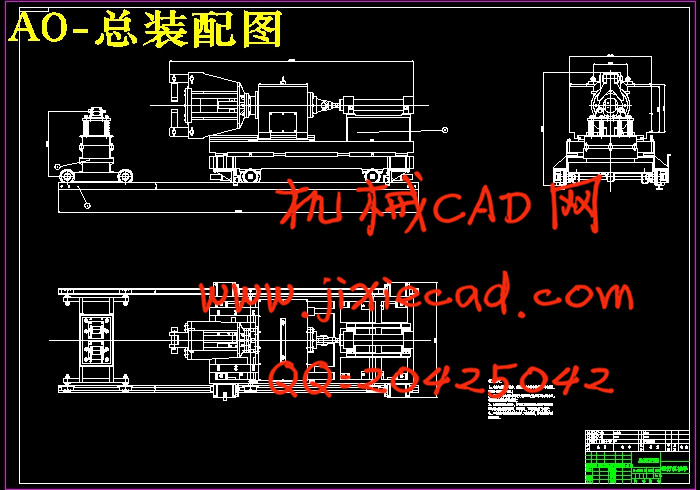

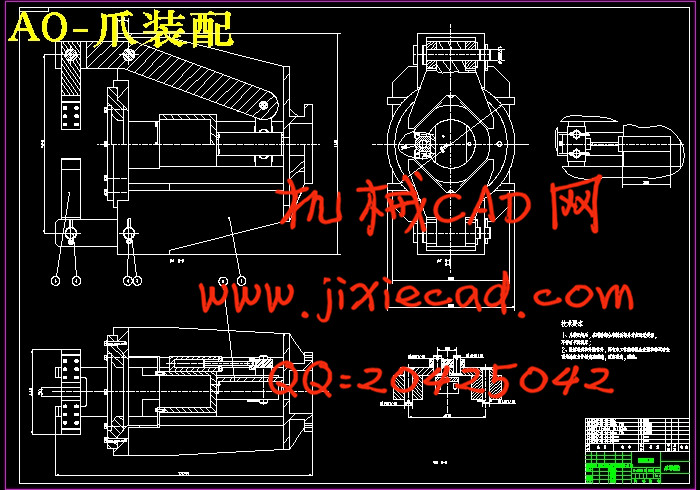

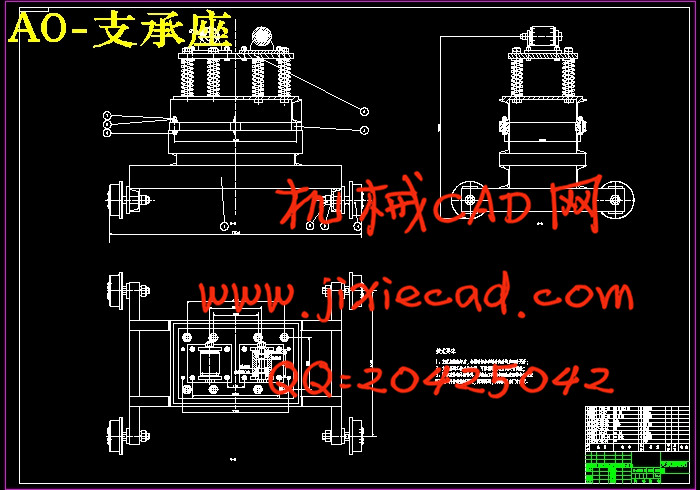

本文对一种使用在锻打机械手的结构进行设计,并完成总装配图和零件图的绘制。要求对机械手模型进行力学分析,估算各关节所需转矩和功率,完成电机和减速器的选型。其次从电机和减速器的连接和固定出发,设计关节结构,并对机构中的重要连接件进行强度校核。

关键词: 结构设计,机器臂,关节型机械手,结构分析

Abstract

The manipulator is a typical mechatronics product, the forging manipulator is the research focus in the field of mechanical hand. Study on the forging manipulator requires a combination of machinery, electronics, information theory, artificial intelligence, biology, computer and other disciplines of knowledge, at the same time, its development also promotes the development of these disciplines.

The definition of a forging manipulator, the world has not yet unified, classification is not the same. The definition of the international organization for Standardization in recent United Nations adopted the manipulator for forging machinery's: forging manipulator is a kind of multifunction operation device can repeat programming, can be changed by the action program, to complete all kinds of work, mainly used for material handling, transmission parts. The definition of the reference of foreign countries, combined with Chinese idioms, are defined as the forging manipulator:

Forging manipulator is a body independent of the action more degrees of freedom, the program can be flexibly changed to any location, automatic operation, high degree of automation. Is available for industrial manipulator automatic spray paint or other coating joint.

Forging manipulator arm with rigid high as the main body, compared with others, can have faster movement speed, can carry more weight, and the positioning accuracy is very high, it can automatically according to the signal to the outside, to carry out various operations.

In this paper, the design of a structure in the forging manipulator, and draw the general assembly drawing and parts drawing. For the mechanical analysis of the model of the manipulator, the joint estimation of the required torque and power, electrical motor and gear selection. Secondly, from the motor and the reducer is connected and fixed on the design of joint structure, and the connection strength check.

Key Words: structural design, the machine arm, joint type manipulator, structure analysis

目 录

摘 要 IIThe definition of a forging manipulator, the world has not yet unified, classification is not the same. The definition of the international organization for Standardization in recent United Nations adopted the manipulator for forging machinery's: forging manipulator is a kind of multifunction operation device can repeat programming, can be changed by the action program, to complete all kinds of work, mainly used for material handling, transmission parts. The definition of the reference of foreign countries, combined with Chinese idioms, are defined as the forging manipulator:

Forging manipulator is a body independent of the action more degrees of freedom, the program can be flexibly changed to any location, automatic operation, high degree of automation. Is available for industrial manipulator automatic spray paint or other coating joint.

Forging manipulator arm with rigid high as the main body, compared with others, can have faster movement speed, can carry more weight, and the positioning accuracy is very high, it can automatically according to the signal to the outside, to carry out various operations.

In this paper, the design of a structure in the forging manipulator, and draw the general assembly drawing and parts drawing. For the mechanical analysis of the model of the manipulator, the joint estimation of the required torque and power, electrical motor and gear selection. Secondly, from the motor and the reducer is connected and fixed on the design of joint structure, and the connection strength check.

Key Words: structural design, the machine arm, joint type manipulator, structure analysis

目 录

Abstract III

目 录 IV

1 绪论 1

1.1引言 1

1.2 锻打机械手研究概况 2

1.2.1 国外研究现状 2

1.2.2 国内研究现状 3

1.3 锻打机械手的总体结构 4

1.4 主要内容 5

2 总体方案设计 5

2.1 机械手工程概述 5

2.2 工业机械手总体设计方案论述 6

2.3 机械手机械传动原理 7

2.4 机械手总体方案设计 9

2.5 本章小结 10

3 锻打机械手机械部分的设计计算 10

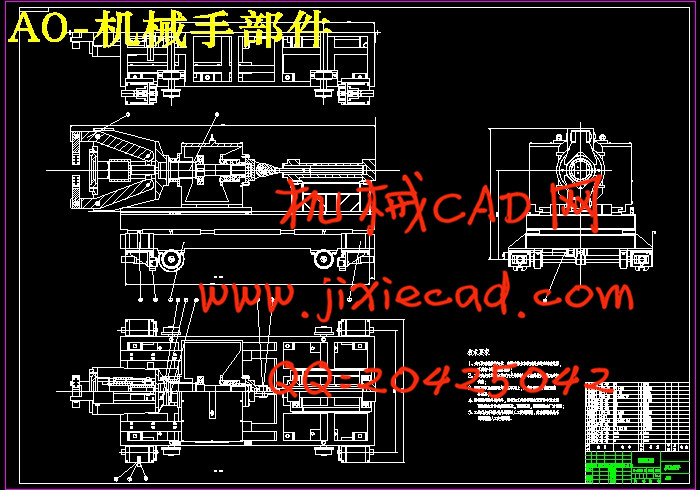

3.1 手部要求及选型 10

3.2机械手手抓的设计计算 11

3.2.1选择手抓的类型及夹紧装置 11

3.2.2 手抓的力学分析 12

3.2.3 夹紧力及驱动力的计算 14

3.2.4 手爪夹持范围计算 15

3.3 机械手手爪夹持精度的分析计算 15

3.4油缸的设计计算 17

3.4.1 初步确系统压力 17

3.4.2 活塞杆的计算校核 19

3.4.3 液压缸工作行程的确定 20

3.4.4 活塞的设计 21

3.4.5 导向套的设计与计算 21

3.4.6 端盖和缸底的计算校核 22

3.4.7 缸体长度的确定 22

3.4.8 缓冲装置的设计 22

3.4.9 液压缸的选型 23

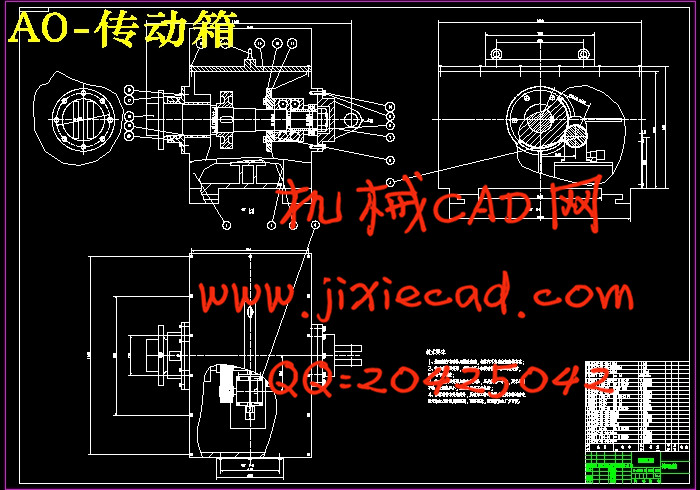

4 传动箱设计计算 25

4.1传动齿轮计算步骤 25

4.2传动轴结构的初步拟定 27

4.3传动轴的材料与热处理 28

4.4传动轴的技术要求 29

4.5传动轴结构图 30

4.6传动轴组件的验算 30

4.6.1 支承的简化 30

4.6.2传动轴的挠度 31

4.6.3 传动轴倾角 32

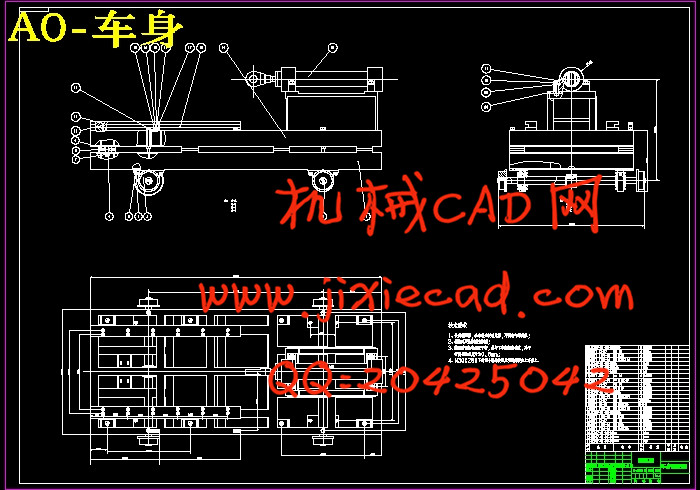

5 车身行走机构总体结构 33

5.1 传动装置的结构 33

5.2车轮组安装结构 33

5.3小车行走机构的设计 33

5.4选择车轮与轨道并验算其强度 34

5.4.1轮压值校核及选择车轮和轨道 34

5.4.2车轮疲劳计算 34

5.4.3车轮强度计算 35

5.5 运行阻力计算 35

5.5.1摩擦阻力矩计算 35

5.5.2摩擦阻力计算 35

5.6 选择电动机 36

5.6.1类型的选择 36

5.6.2功率的确定 36

5.6.3工作机的阻力 36

5.6.4电动机的转速的确定 37

5.7计算传动装置的运动参数和动力参数 37

5.7.1 计算总传动比i 37

5.7.2各轴的转速 37

5.7.3 各轴的功率 37

5.7.4各轴的转距 37

5.7.5链轮、链条的选取校核 38

5.7.6 轴承的选取校核 39

5.8轴的设计与校核 39

总结 43

参考文献 44

致 谢 45