设计简介

摘 要

在论文中,首先,对蜗轮蜗杆作了简单的介绍,接着,阐述了蜗轮蜗杆的设计原理和理论计算。然后按照设计准则和设计理论设计了环面蜗轮蜗杆减速器。接着对减速器的部件组成进行了尺寸计算和校核。该设计代表了蜗轮蜗杆设计的一般过程。对其他的蜗轮蜗杆的设计工作也有一定的价值。

目前,在环面蜗轮蜗杆减速器的设计、制造以及应用上,国内与国外先进水平相比仍有较大差距。国内在设计制造环面蜗轮蜗杆减速器过程中存在着很大程度上的缺点,正如论文中揭示的那样,重要的问题如:轮齿的根切;蜗杆毛坯的正确设计;蜗轮蜗杆的校核。

关键词:蜗轮蜗杆减速器, 蜗杆, 滚动轴承

Abstract

In this paper, firstly, the worm are introduced, then, expounds the design principle and the theoretical calculation of the worm and worm gear. Then in accordance with the design criteria and design theory to the design of toroidal worm reducer. Then the components of the reducer to the size of the calculation and verification. The design represents the general process of worm gear design. On the other worm design work also has a certain value.

At present, the torus worm reducer design, manufacture and application of domestic, compared with foreign advanced level there are still large gaps. There are a lot of defects in the design and manufacture of toroidal worm reducer process, as revealed by the paper, important issues such as: cutting the root of the tooth; Worm rough the correct design; the worm check.

Key words: worm gear reducer, worm, rolling bearing

目 录

摘 要 2Abstract 3

目 录 4

1 选定设计方案 5

2 电动机的选择 6

2.1 初选电动机类型和结构型式 6

2.2 电动机的功率 6

2.3运动参数计算 8

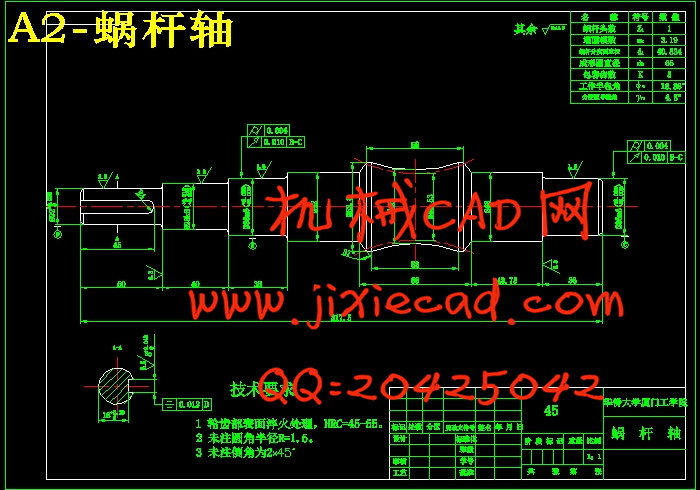

2.3.1蜗杆轴的输入功率、转速与转矩 8

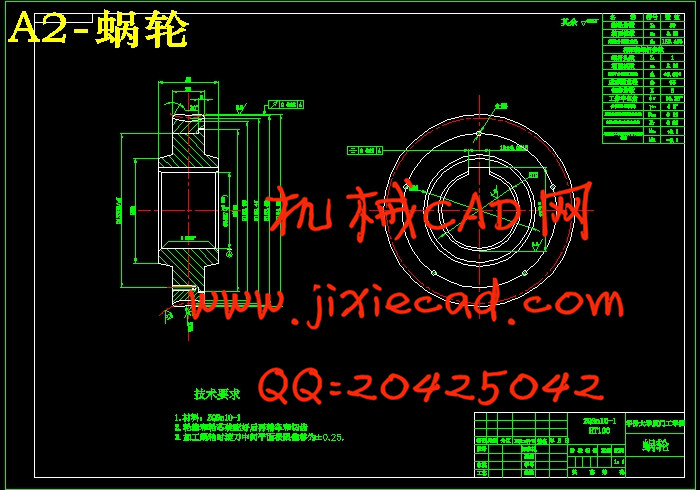

2.3.2蜗轮轴的输入功率、转速与转矩 8

2.3.3传动滚筒轴的输入功率、转速与转矩 8

2.4蜗轮蜗杆的传动设计 9

2.5蜗杆、蜗轮的基本尺寸设计 13

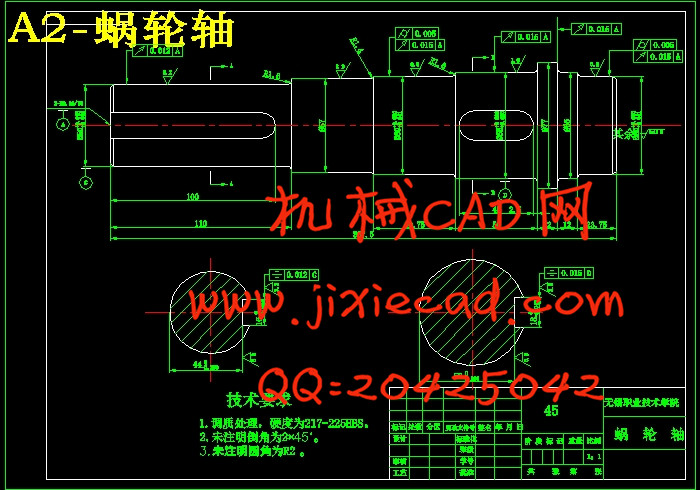

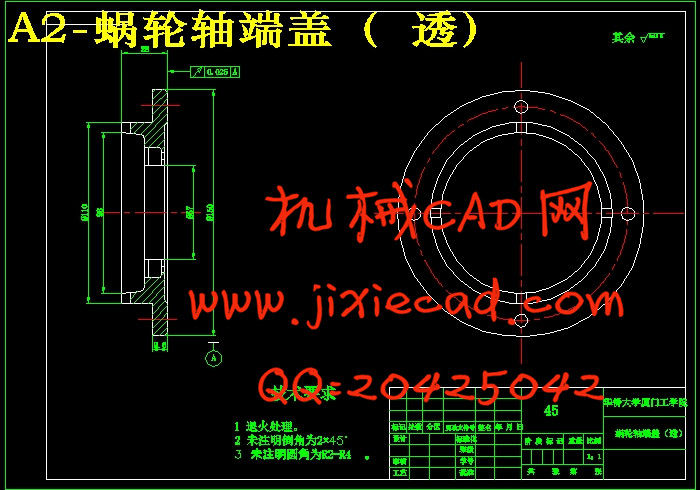

2.6蜗轮轴的尺寸设计与校核 14

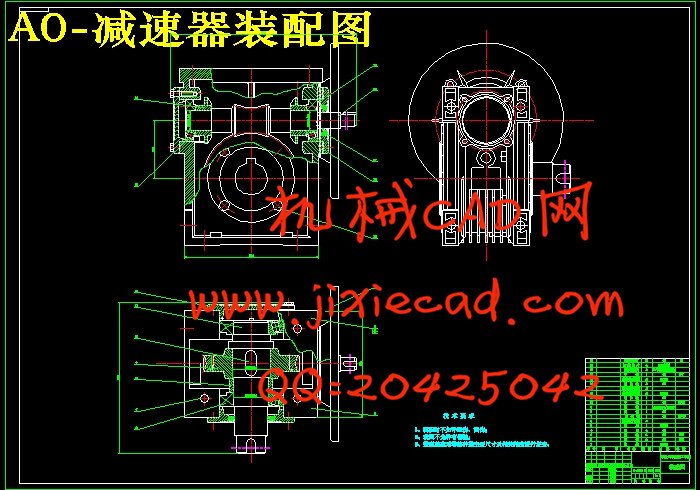

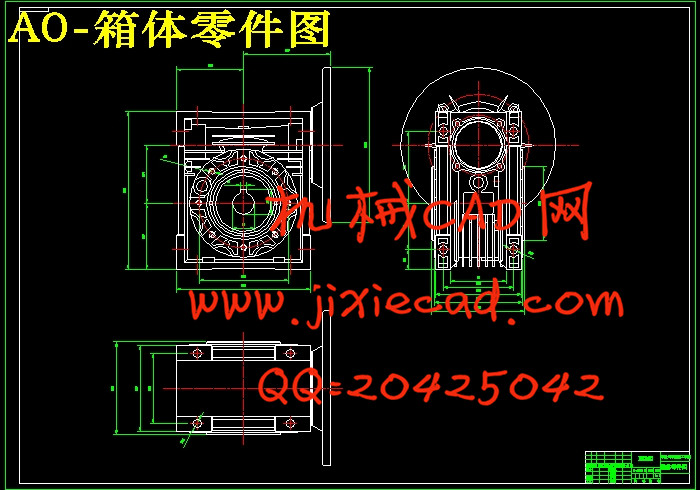

2.7减速器箱体的结构设计 15

3 轴的校核 18

3.1蜗杆轴的强度校核 18

3.2蜗轮轴的强度校核 21

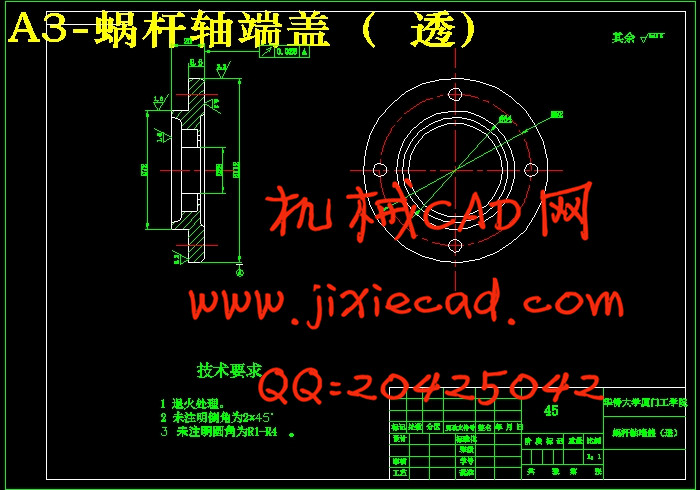

3.3 滚动轴承的选择及校核 24

3.3.1 蜗杆轴滚动轴承的选择及校核 24

3.3.2 蜗轮轴上轴承的校核 26

3.4 键联接的强度校核 28

.3.4.1 蜗杆轴上安装联轴器处的键联接 28

3.4.2 蜗轮轴上装蜗轮处的键联接 29

3.4.3 蜗轮轴上装联轴器处的键联接 29

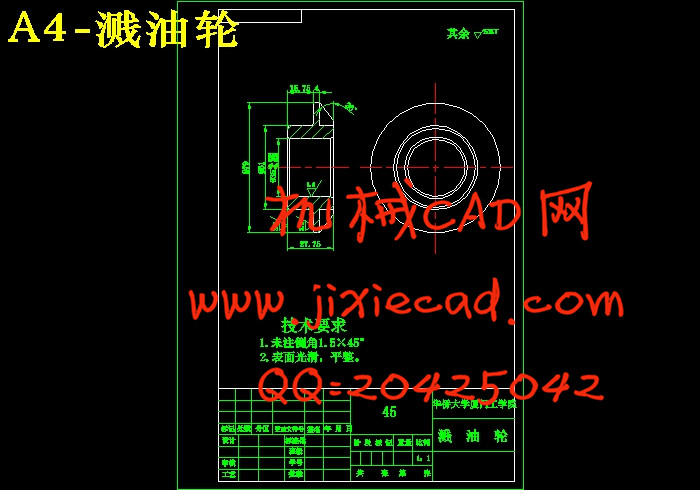

3.5 减速器的润滑和密封 29

总结 31

参考文献 32

致 谢 33