设计简介

中文摘要

起重机械是一种间歇作业方式对物料进行起升、下降和水平移动的搬运机械。起重机械作业通常是重复循环的,一个完整的作业循环一般包括取物起升、平移、下降、卸载等环节。经常起动、制动、正反向运动是起重机械的基本特点。

近些年来,伴随着我国固定资产投资的飞速增长、基础设施建设和大型项目的不断上马,使得我国工程机械行业获得了空前的发展,也受到了人们越来越多的关注。我国的起吊机制造商与欧美的竞争对手相比在技术上还存在着差距,在产业链条,产品结构方面也存在着一定的劣势,但这并非遥不可及。更主要的是,我国在这一领域从未放弃过自主研发,而且已经具备了相当大的产业规模,创造了几个蜚声全球的知名品牌。

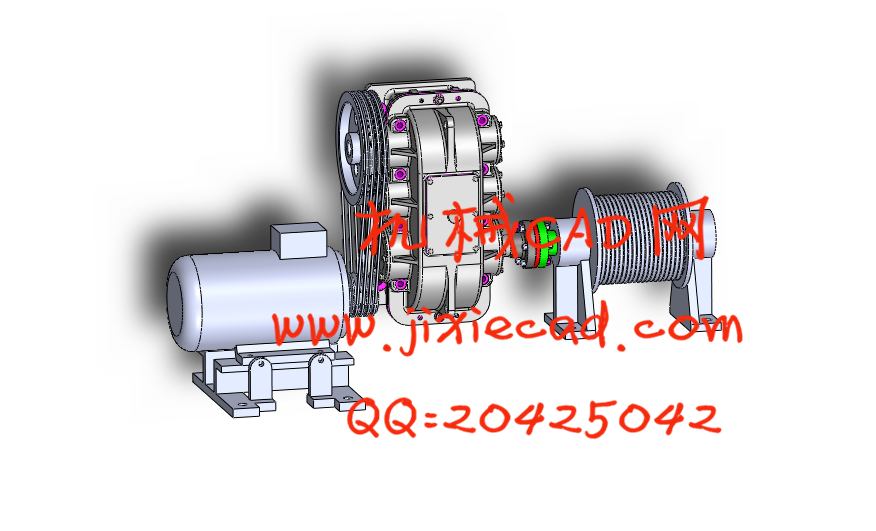

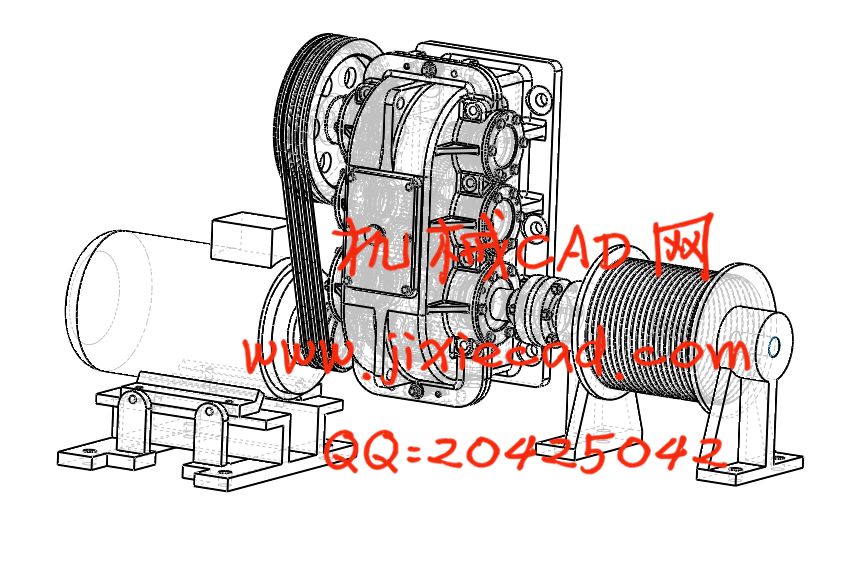

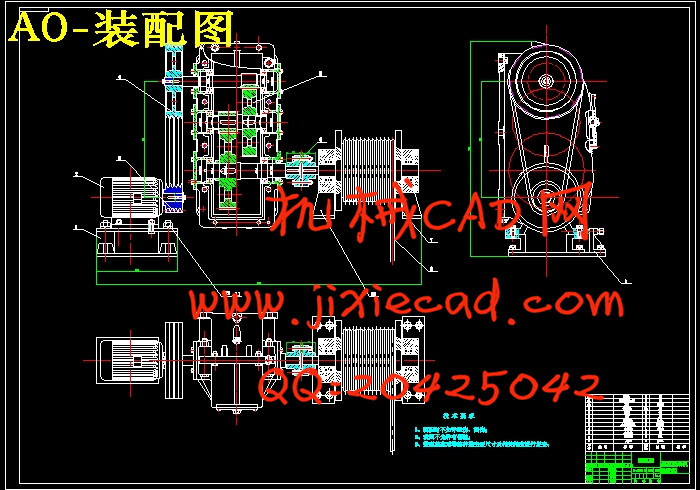

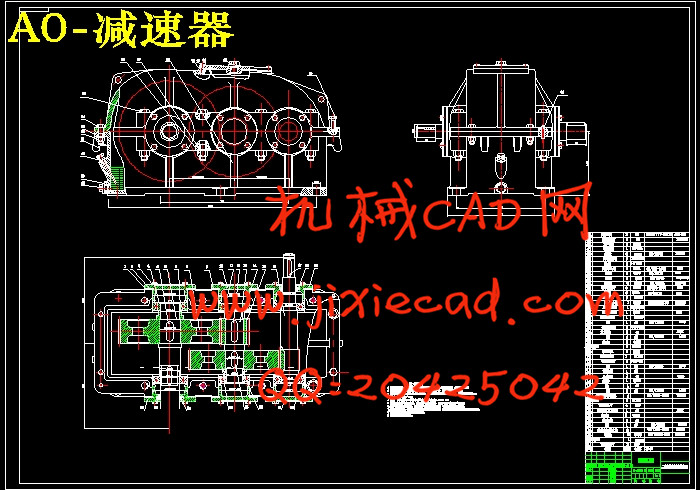

本课题研究的主要内容有:垂直起吊机构方案的拟定与选择、起升机构总体设计、减速器类型选择、缓冲器的选用,另外,本课题还从性价比等方面的因素来选择或设计了电动机、带的类型、齿轮的设计、缓冲器等一些部件和机构。

关键词:起重机械,起吊机,总体设计,减速器

Abstract

Lifting is an intermittent job of materials lifting way down and horizontally moving handling machinery. Lifting operations are usually repeated cycles, a complete operating cycle generally includes extracts lifting, translation, down, unloading and other links. Often starting, braking, forward and backward movement is the basic characteristics of lifting machinery.

In recent years, with the rapid growth of China's fixed asset investment, we continue to be launched infrastructure and large-scale projects, so that China's construction machinery industry achieved unprecedented development, but also by the people more and more attention. Our lifting machine manufacturer compared to European and American competitors in technology, there are still gaps in the industrial chain, product structure there are also some disadvantages, but it is achievable. More important it is that China has never given up in this area of independent research and development, and already has a fairly large industrial scale, created several world renowned brands.

The main contents of the research are: to develop and select vertical lifting body of the program, the overall design of the lifting mechanism, reducer type selection, the choice of the buffer, in addition, this issue also be selected or designed from factor cost and other aspects of the electric motor type belt, gear design, buffer and some other components and agencies.

Keywords: lifting machinery, lifting machines, general design, speed reducer

中文摘要 II

Abstract III

第1章 绪论 1

1.1 起重机概念及知识 1

1.2 起重机发展及存在问题 1

1.3 未来发展趋势 1

第2章 初步计算 8

2.1 钢丝绳的选择 8

2.2 滑轮卷筒的计算 8

2.3 传动方案分析 10

第3章 电机的选择及传动装置的运动和动力参数的计算 11

3.1 电机类型和结构形式的选择 11

3.2 选择电机的容量 11

3.3 确定电机转速 12

3.4 传动比分配 13

3.5 传动装置各轴的运动和动力参数 13

第4章 带传动的计算 15

4.1 带传动设计 15

4.2 选择带型 16

4.3 确定带轮的基准直径并验证带速 16

4.4 确定中心距离、带的基准长度并验算小轮包角 17

4.5 确定带的根数z 18

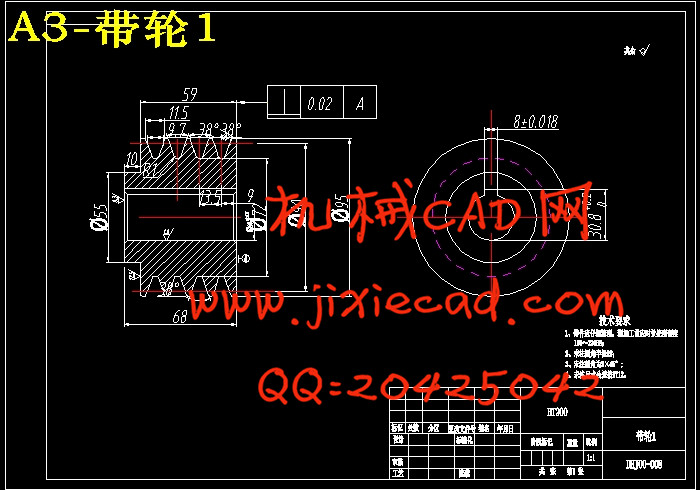

4.6 确定带轮的结构和尺寸 18

4.7 确定带的张紧装置 18

第5章 传动零件的设计计算 21

5.1 高速级齿轮的设计计算 21

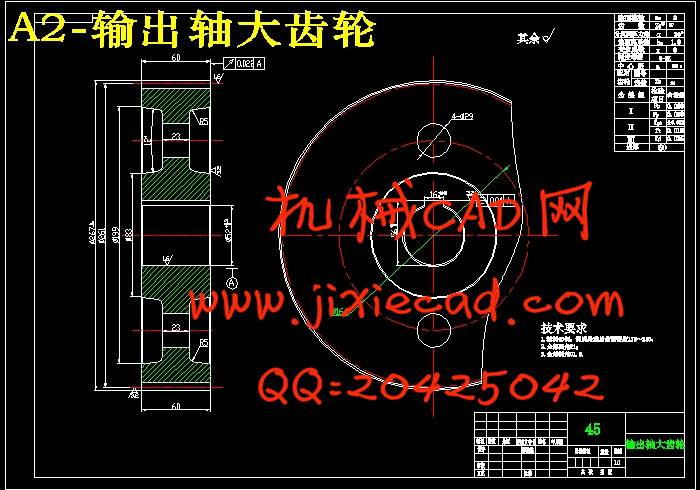

5.2 低速级齿轮的设计计算 24

第6章 轴的计算 28

6.1 高速轴的计算 28

6.2 中间轴的计算 31

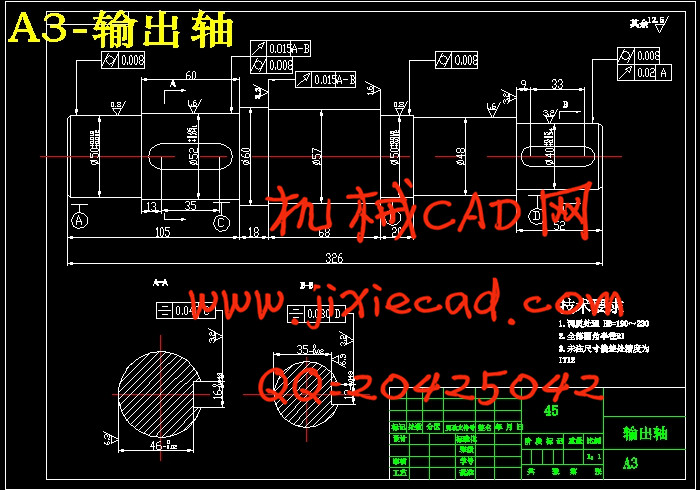

6.3 低速轴的计算 35

第7章 键连接的选择和计算 38

7.1 高速轴(I轴)上键的选择及校核 38

7.2 中间轴(II轴)上键的选择及校核 38

7.3 高速轴(III轴)上键的选择及校核 39

第8章 滚动轴承的选择和计算 40

第9章 联轴器的选择和计算 43

总论 44

参考文献 45

致谢 46