设计简介

摘要

最近几年石材加工行业发展十分迅速,已经有了很大的市场规模.桥式切边机是在这个领域应用最广泛的机械之一.

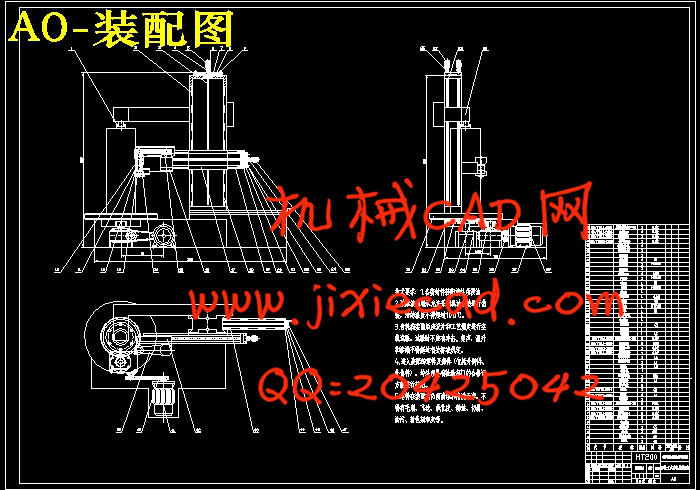

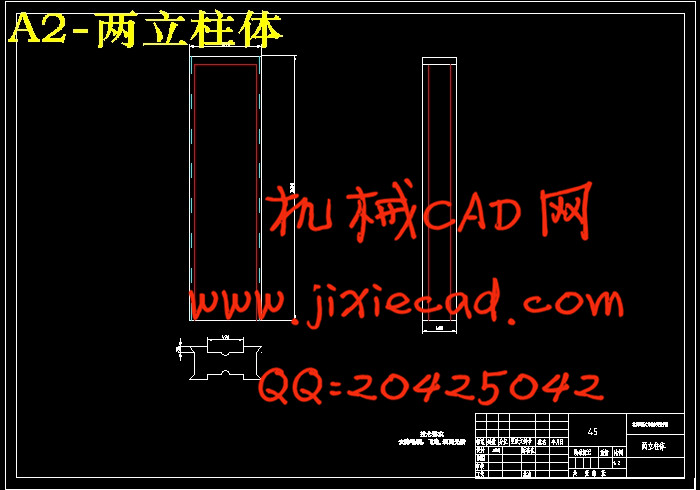

石材立式圆柱磨机是主要对石材圆柱表面进行磨削和抛光的设备。整机是在立式车床的工作原理的基础上,进行改进、提高而研制成的。对石材圆柱体加工生产效率高、产品的质量稳定。立柱体上安装丝杠对磨头溜板机构起上下固定作用,以此来调节磨头高度,实现石材圆柱体在高度方向上的进给磨削运动。磨头横向进给机构也由丝杠来控制,用手轮控制磨头的横向进给量,使磨头始终与石材圆柱体相接触。工作台在电动机带动下转动,以实现石材圆柱体的回转面加工。转盘部分电动机竖直放置,电动机与减速器为一体。他们带动转盘轴转动,实现石材圆柱体的转动,磨头固定不动。

设备的基本参数为:

(1)加工范围

① 圆柱直径2000mm

② 加工高度1500mm

(2)主电动机功率 5.5KW

(3)总功率 10KW

(4)设备外形尺寸(长)*(宽)*(高)5770*2000*3500mm

该机器的主要机构为:主轴电机带动主轴旋转,工件装卡在工作台和三角架之间三家架主要是起卡紧作用。在另外的刀具那边是由一个电机带动刀具进行磨削,有精密的数控工作台控制。

本设计结合实际需求,同时注重商品化设计中的成本问题,考虑经济效益,务求产品安全合理、环保、经济。

图纸包括工程简图,总装配图和部分零件图,总图量不少于3张0号图附带设计说明书一份

关键词:石材;圆柱;磨削;加工;设计

Abstract

Recently several year stone material processing profession development was extremely rapid, already and it had a very large market scale. The bridge cutting edger machine is appliesed one of most widespread machineries in this domain.

Stone material vertical arc grinding machine is the main arc plate surface grinding and polishing equipment. The machine is designed based on vertical lathe, it is greatly improved, enhanced and developed in construction. To the vertical arc grinding, the production efficiency is high , and the product quality is stable. Install the guide screw on the cylinder and play the fixed function on grinding head from top to bottom, in order to adjust the grinding head height, achieve a high degree of the vertical arc grinding in the direction of feed grinding campaign. Grinder horizontal feed screw by agencies to control and hand control of the grinding head round the horizontal feed rate, make ends always in contact the vertical arc cylinder. Worktable in motor driven rotation, in order to achieve the vertical arc cylinder rotary processing. Some dial motor vertical, motor and reducer of integration. They led dial-axis rotating, the vertical arc cylinder rotation, the grinding head fixed moves.

(1) Equipment for the basic parameters:

① A processing area cylinder diameter 2000mm

② processing high 1500mm

(2) Main electrical power 5.5KW

(3) the total power 10KW

(4) Equipment dimensions (length) * (w) * (H) 5770 * 2000 * 3500mm

The main organization of that machine is: The principal axis electrical engineering arouses the principal axis revolves, the work piece packs the card to press at the worktable and the tripod, the tripod’s main is rise tight function in card. Having in the another knife that direction be aroused by an electrical engineering the knife have the proceeding incise, and having the precise number control the work set.

This design combines the actual need, paying attention to commercialize the cost in the design problem at the same time, considering the economic performance, striving for the product safety reasonable, environmental protection, economy

Including engineering schematic drawings, maps and assemble some of the parts plan, the general plan is not less than five O map attached a design manual.

Key words : Stone material;Cylinder;Cutting;Process;Design

目录

第一章 绪论 1

1.1石材品种分类 1

1.1.1大理石 1

1.1.2花岗岩 4

1.1.3石灰岩 5

1.2石材市场前景 7

1.3我国石材工业的发展与现状 8

1.4石材加工机械发展趋势 10

第二章 工作原理和总体设计 12

2.1石材立式磨机的构成 12

2.2运动系统 13

2.3传动系统 13

第三章 传动系统的结构设计 15

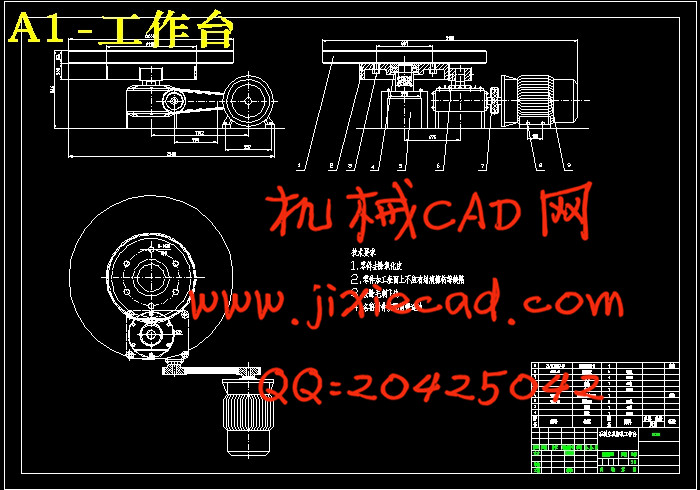

3.1工作台设计 15

3.2电机的选择 16

3.2.1底座电机 16

3.2.2顶端电机 16

3.2.3主电机 17

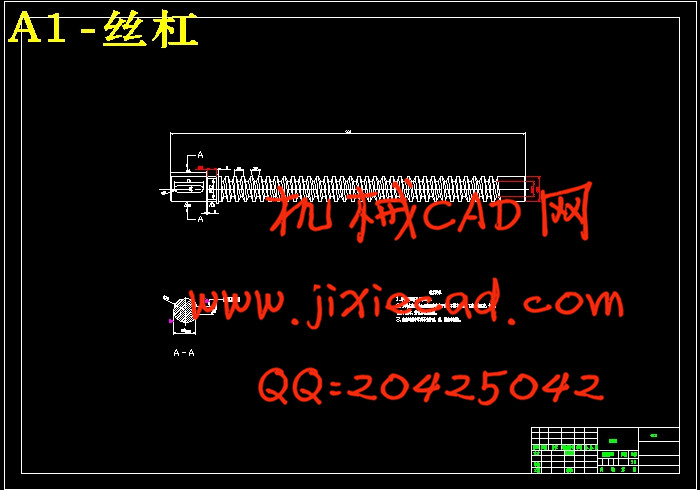

3.3横向丝杠的设计 17

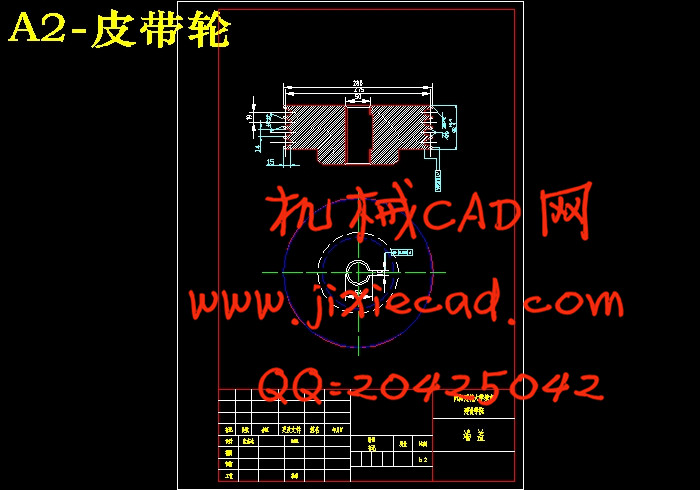

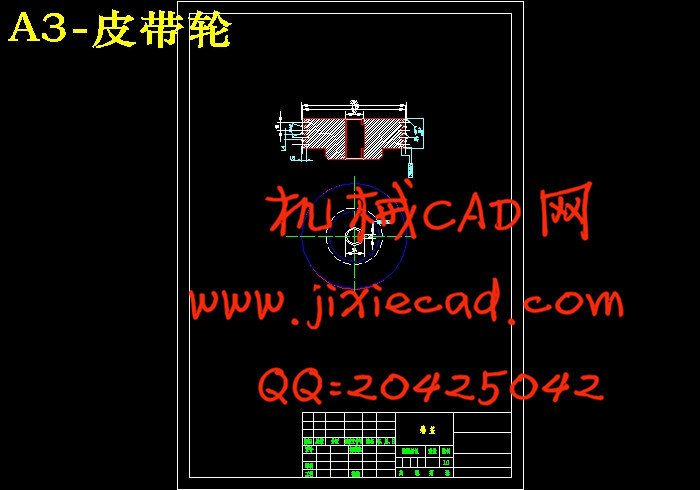

3.4带传动的结构设计 18

3.5轴的结构设计 20

3.6珠丝杠副 22

3.6.1润滑 22

3.6.2防尘 22

3.6.3滚珠丝杠副在使用时注意事项 22

3.6.4安装 23

3.7减速器设计 23

3.8冷却系统 26

3.9润滑系统的设计 26

第四章 强度校核 27

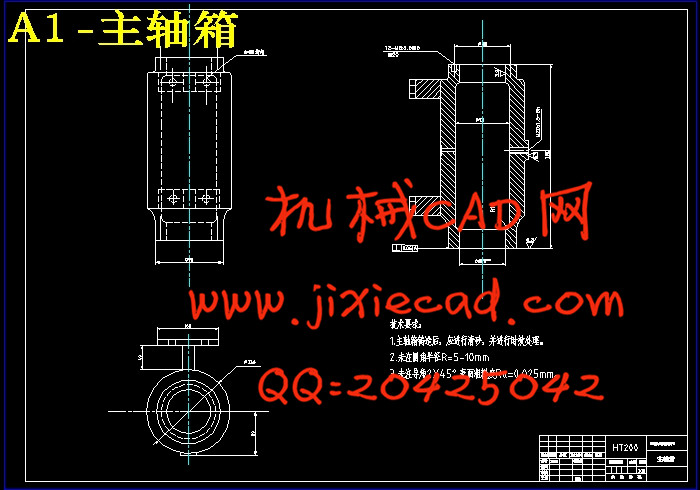

4.1 主轴的校核计算 27

4.2横向丝杆的强度校核 30

第五章 安装与保养 31

5.1 安装 31

5.2使用与保养 31

第六章 经济效益分析 32

结论 33

参考文献 34

致谢 35

最近几年石材加工行业发展十分迅速,已经有了很大的市场规模.桥式切边机是在这个领域应用最广泛的机械之一.

石材立式圆柱磨机是主要对石材圆柱表面进行磨削和抛光的设备。整机是在立式车床的工作原理的基础上,进行改进、提高而研制成的。对石材圆柱体加工生产效率高、产品的质量稳定。立柱体上安装丝杠对磨头溜板机构起上下固定作用,以此来调节磨头高度,实现石材圆柱体在高度方向上的进给磨削运动。磨头横向进给机构也由丝杠来控制,用手轮控制磨头的横向进给量,使磨头始终与石材圆柱体相接触。工作台在电动机带动下转动,以实现石材圆柱体的回转面加工。转盘部分电动机竖直放置,电动机与减速器为一体。他们带动转盘轴转动,实现石材圆柱体的转动,磨头固定不动。

设备的基本参数为:

(1)加工范围

① 圆柱直径2000mm

② 加工高度1500mm

(2)主电动机功率 5.5KW

(3)总功率 10KW

(4)设备外形尺寸(长)*(宽)*(高)5770*2000*3500mm

该机器的主要机构为:主轴电机带动主轴旋转,工件装卡在工作台和三角架之间三家架主要是起卡紧作用。在另外的刀具那边是由一个电机带动刀具进行磨削,有精密的数控工作台控制。

本设计结合实际需求,同时注重商品化设计中的成本问题,考虑经济效益,务求产品安全合理、环保、经济。

图纸包括工程简图,总装配图和部分零件图,总图量不少于3张0号图附带设计说明书一份

关键词:石材;圆柱;磨削;加工;设计

Abstract

Recently several year stone material processing profession development was extremely rapid, already and it had a very large market scale. The bridge cutting edger machine is appliesed one of most widespread machineries in this domain.

Stone material vertical arc grinding machine is the main arc plate surface grinding and polishing equipment. The machine is designed based on vertical lathe, it is greatly improved, enhanced and developed in construction. To the vertical arc grinding, the production efficiency is high , and the product quality is stable. Install the guide screw on the cylinder and play the fixed function on grinding head from top to bottom, in order to adjust the grinding head height, achieve a high degree of the vertical arc grinding in the direction of feed grinding campaign. Grinder horizontal feed screw by agencies to control and hand control of the grinding head round the horizontal feed rate, make ends always in contact the vertical arc cylinder. Worktable in motor driven rotation, in order to achieve the vertical arc cylinder rotary processing. Some dial motor vertical, motor and reducer of integration. They led dial-axis rotating, the vertical arc cylinder rotation, the grinding head fixed moves.

(1) Equipment for the basic parameters:

① A processing area cylinder diameter 2000mm

② processing high 1500mm

(2) Main electrical power 5.5KW

(3) the total power 10KW

(4) Equipment dimensions (length) * (w) * (H) 5770 * 2000 * 3500mm

The main organization of that machine is: The principal axis electrical engineering arouses the principal axis revolves, the work piece packs the card to press at the worktable and the tripod, the tripod’s main is rise tight function in card. Having in the another knife that direction be aroused by an electrical engineering the knife have the proceeding incise, and having the precise number control the work set.

This design combines the actual need, paying attention to commercialize the cost in the design problem at the same time, considering the economic performance, striving for the product safety reasonable, environmental protection, economy

Including engineering schematic drawings, maps and assemble some of the parts plan, the general plan is not less than five O map attached a design manual.

Key words : Stone material;Cylinder;Cutting;Process;Design

目录

第一章 绪论 1

1.1石材品种分类 1

1.1.1大理石 1

1.1.2花岗岩 4

1.1.3石灰岩 5

1.2石材市场前景 7

1.3我国石材工业的发展与现状 8

1.4石材加工机械发展趋势 10

第二章 工作原理和总体设计 12

2.1石材立式磨机的构成 12

2.2运动系统 13

2.3传动系统 13

第三章 传动系统的结构设计 15

3.1工作台设计 15

3.2电机的选择 16

3.2.1底座电机 16

3.2.2顶端电机 16

3.2.3主电机 17

3.3横向丝杠的设计 17

3.4带传动的结构设计 18

3.5轴的结构设计 20

3.6珠丝杠副 22

3.6.1润滑 22

3.6.2防尘 22

3.6.3滚珠丝杠副在使用时注意事项 22

3.6.4安装 23

3.7减速器设计 23

3.8冷却系统 26

3.9润滑系统的设计 26

第四章 强度校核 27

4.1 主轴的校核计算 27

4.2横向丝杆的强度校核 30

第五章 安装与保养 31

5.1 安装 31

5.2使用与保养 31

第六章 经济效益分析 32

结论 33

参考文献 34

致谢 35