设计简介

采用同步矩形运动传送机械是提高产品质量与劳动生产率,实现生产过程自动化,改善劳动条件,减轻劳动强度的一种有效手段。按照预定要求输送工件或握持工具进行操作的自动化技术装备。同步矩形传送可以代替人手的繁重劳动,显著减轻工人的劳动强度,改善劳动条件,提高劳动生产率和生产自动化水平。工业生产中经常出现的笨重工件的搬运和长期、频繁、单调的操作,采用同步矩形传送是有效的;此外,它能在高温、低温、深水、宇宙、放射性和其它有毒、污染环境条件下进行操作,更显示其优越性,有着广阔的发展前途。

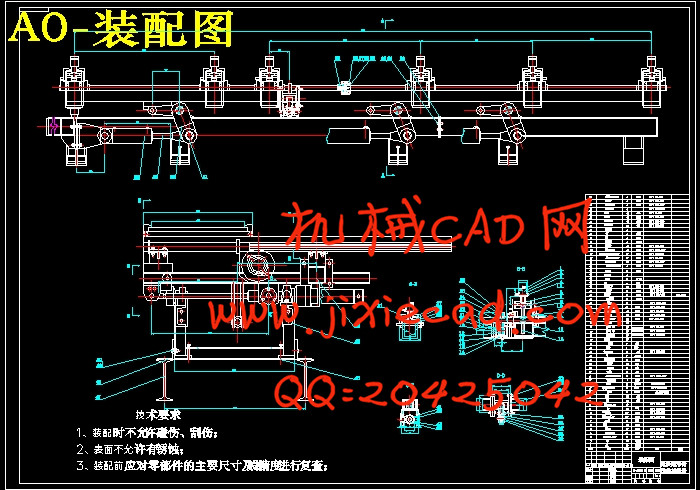

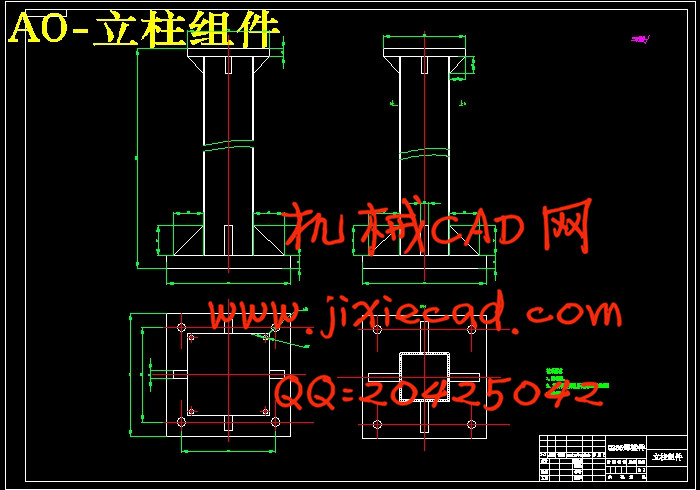

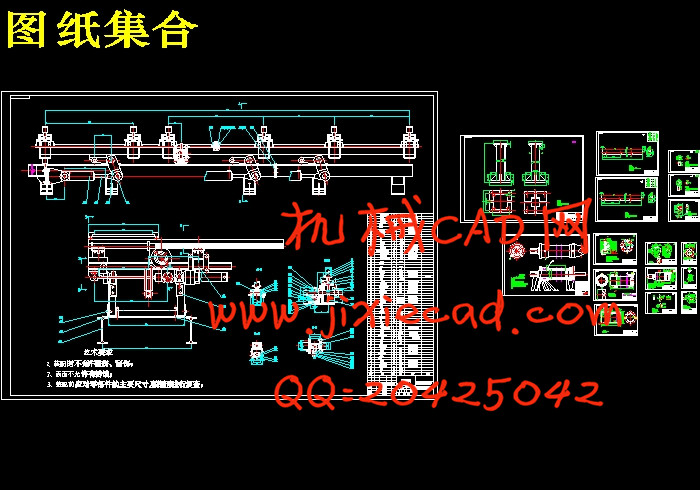

本课题的主要内容是采用同步矩形运动传送机械,设计横移机构,使产品沿水平方向移动1100mm,保证结构的刚度足够,结构合理、可靠。设计升降机构,使产品垂直升降150mm。计同步机构,使30组横移梁同步运动,误差在可控范围。

结合设计的各方面的知识,在设计过程中学会怎样发现问题。解决问题.研究问题。并且在设计中融入自己的想法和构思,提高自己的创新能力。尽力使同步矩形传送使用方便,结构简单。

关键词: 同步矩形;结构设计;步进电机;回转

The synchronous rectangular transmitting motion machinery is to improve product quality and productivity, the realization of the production process automation, improve working conditions, reduce labor intensity is an effective means of. According to the predetermined requirements of automation technology and equipment or hold the tools to operate. The heavy labor synchronous rectangular transmission can substitute for manpower, greatly reduce the labor intensity of workers, improve working conditions, improve labor productivity and automation level of production. Industrial production in the often cumbersome workpiece handling and frequent, the long, monotonous operation, using synchronous rectangular transfer is effective; in addition, it can operate in high temperature, low temperature, water, the universe, radioactive and other toxic, environmental pollution condition, but also show its superiority, there are broad prospects for the development.

The main content of this paper is using synchronous rectangular transmitting motion machine, design of shogging mechanism, make the product moves 1100mm along the horizontal direction, ensure that the stiffness of the structure is adequate, reasonable structure, reliable. Design of lifting mechanism, make the product vertical lifting 150mm. Meter synchronization mechanism, so that the 30 groups of transverse beam motion synchronization, error in the controllable range.

Combined with the design of all aspects of knowledge, in the design process, learn how to find problems. To solve the problem. The problem. And into his thoughts and ideas in the design, improve their innovation ability. Try to make synchronous rectangular transmission is easy to use, simple in structure.

Keywords :synchronous rectangle; structure design; stepping motor; rotary

目 录

1 绪 论 1

2 同步矩形传送机构总体方案设计 2

2.1规格参数 2

2.2有效负载 2

2.3运动特性 2

2.4 工作范围(工作半径) 2

2.5 同步矩形传送材料的选择 2

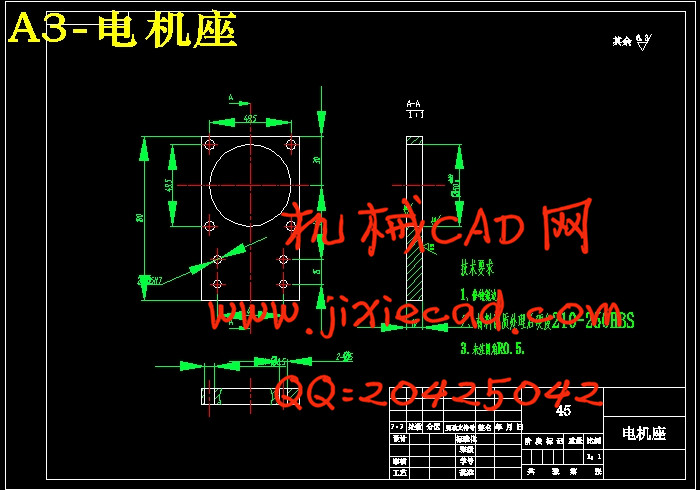

2.6同步矩形传送的驱动元件 3

2.7 水平方向移动计算 4

2.7.1 电机计算 4

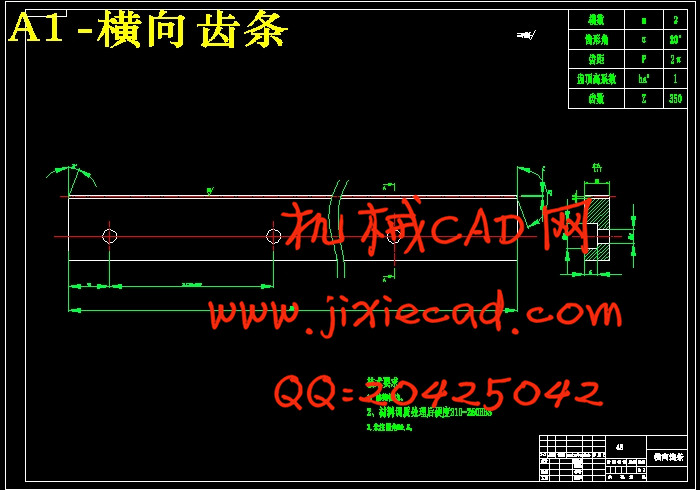

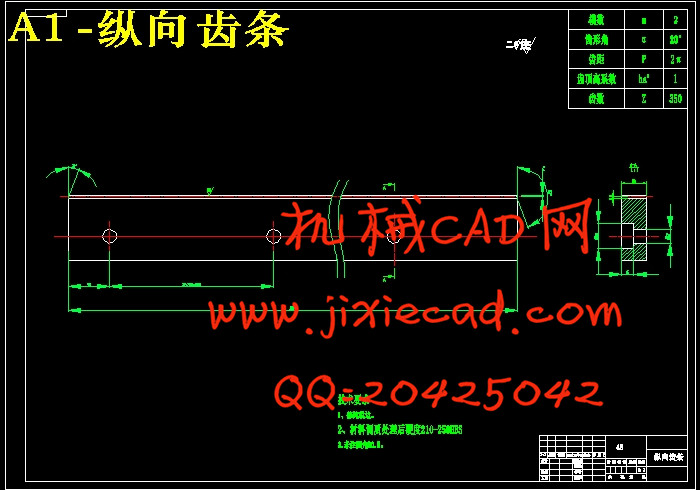

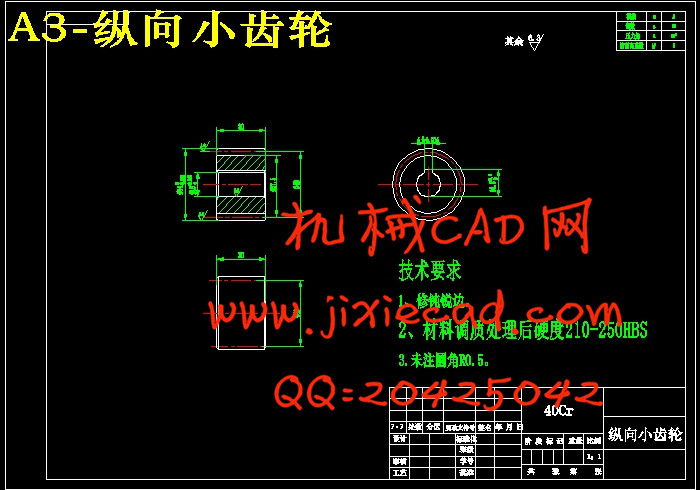

2.7.2齿轮齿条的设计计算 7

2.7.3齿条齿部弯曲强度的计算 11

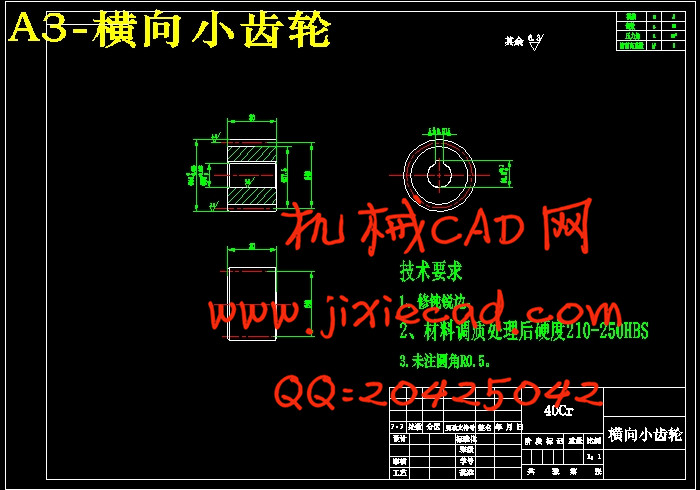

2.8 小齿轮的强度计算 11

2.8.1齿面接触疲劳强度计算 11

2.8.2齿轮齿跟弯曲疲劳强度计算 14

2.9 升降方向结构计算 16

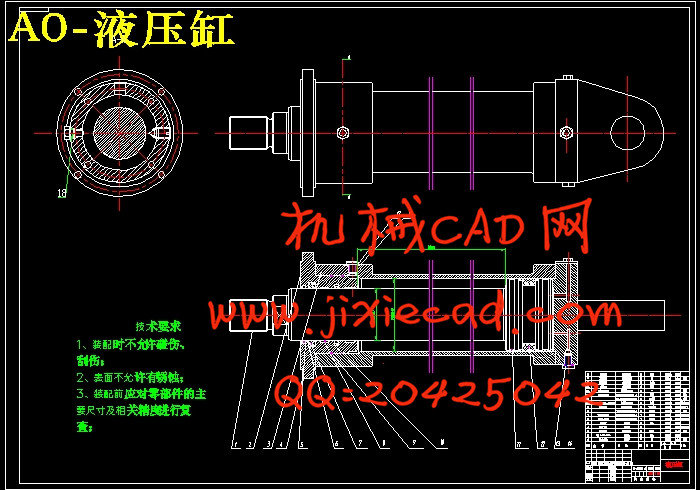

3 液压部分的设计计算 18

3.1油缸主要参数的确定 18

3.1.1液压缸内径的计算 18

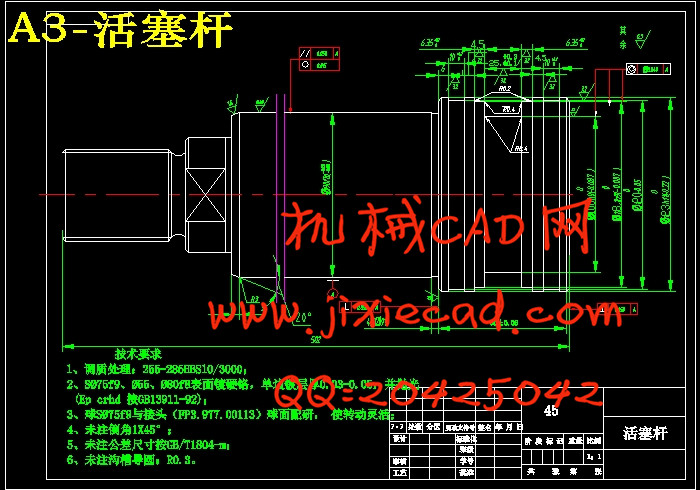

3.1.2活塞杆直径的设计 18

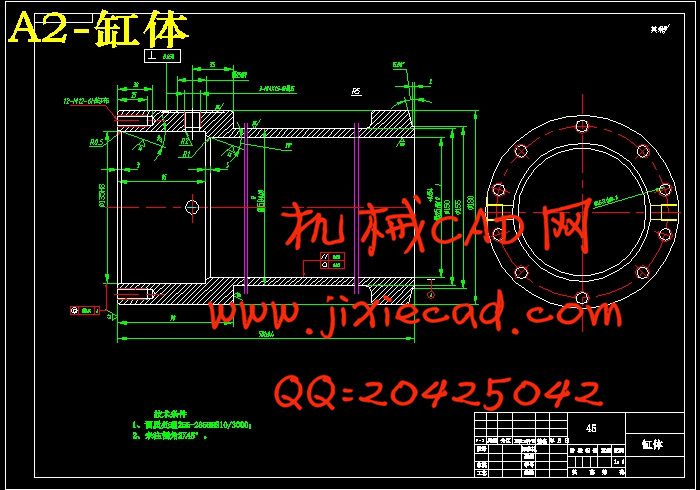

3.1.3液压缸缸体厚度计算 18

3.1.4.液压缸长度的确定 19

3.1.5活塞杆直径的设计 19

3.2油缸主要部位的计算校核 21

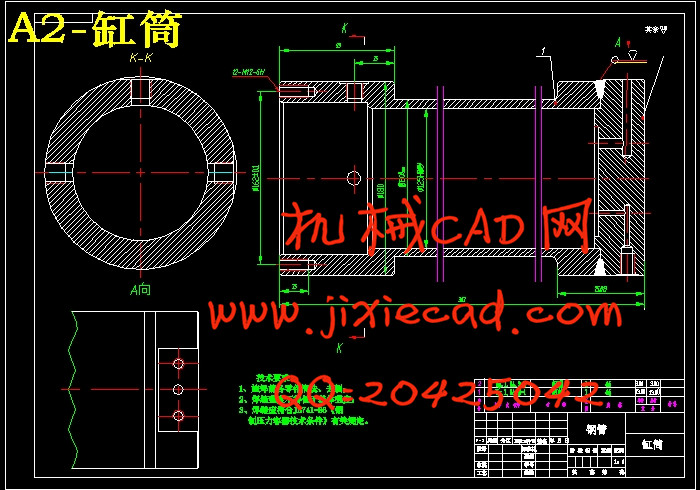

3.2.1缸筒壁厚的计算 21

3.2.2 活塞杆强度和液压缸稳定性计算 21

3.2.3缸筒壁厚的验算 23

3.2.4 缸筒的加工要求 25

3.2.5法兰设计 25

3.2.6 (缸筒端部)法兰连接螺栓的强度计算 26

3.3 活塞的设计 28

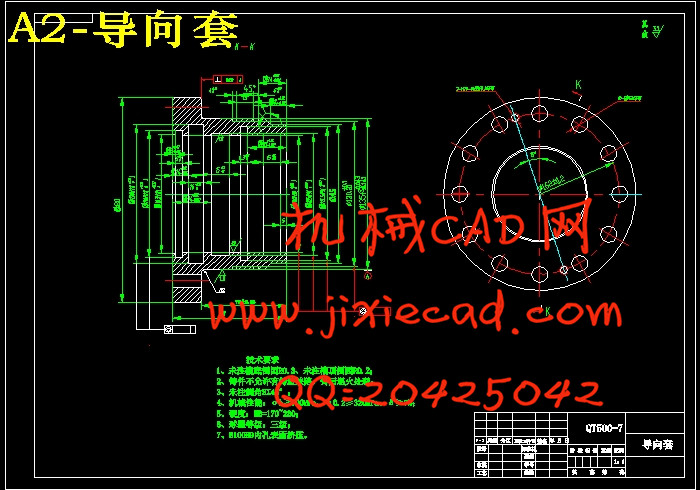

3.4 导向套的设计与计算 28

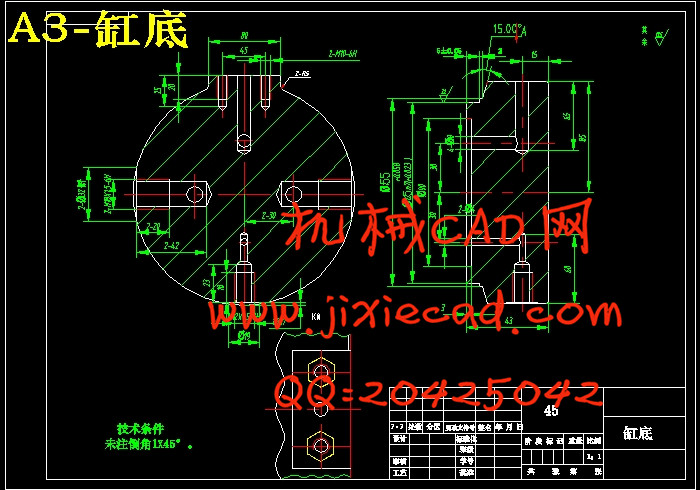

3.5 端盖和缸底的设计与计算 30

3.6 液压泵的参数计算 31

3.7 电动机的选择 31

3.8 液压元件的选择 32

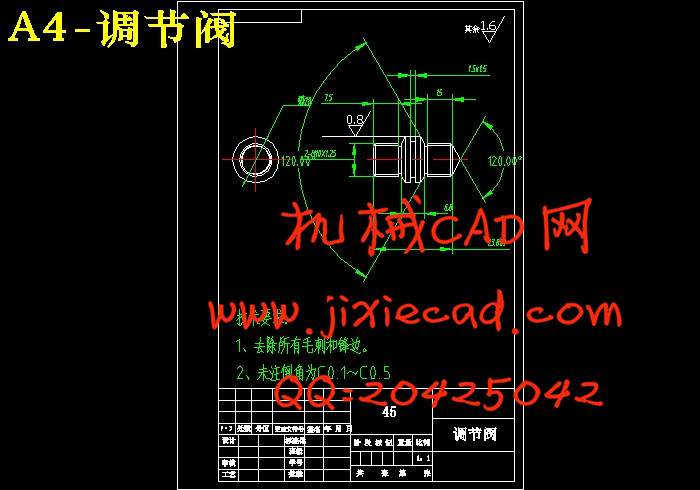

3.8.1 液压元件的选择 32

3.8.2 油管的选择 34

3.9 验算液压系统性能 35

3.9.1 压力损失的验算及泵压力的调整 35

3.9.2 液压系统的发热和温升验算 37

3.10 油箱设计 38

3.10.1油箱有效容积的确定 38

3.10.2 油箱容积的验算 38

3.11辅助元件 40

4 横梁等其他结构件的设计 41

总 结 52

致 谢 53

参考文献 54

本课题的主要内容是采用同步矩形运动传送机械,设计横移机构,使产品沿水平方向移动1100mm,保证结构的刚度足够,结构合理、可靠。设计升降机构,使产品垂直升降150mm。计同步机构,使30组横移梁同步运动,误差在可控范围。

结合设计的各方面的知识,在设计过程中学会怎样发现问题。解决问题.研究问题。并且在设计中融入自己的想法和构思,提高自己的创新能力。尽力使同步矩形传送使用方便,结构简单。

关键词: 同步矩形;结构设计;步进电机;回转

The synchronous rectangular transmitting motion machinery is to improve product quality and productivity, the realization of the production process automation, improve working conditions, reduce labor intensity is an effective means of. According to the predetermined requirements of automation technology and equipment or hold the tools to operate. The heavy labor synchronous rectangular transmission can substitute for manpower, greatly reduce the labor intensity of workers, improve working conditions, improve labor productivity and automation level of production. Industrial production in the often cumbersome workpiece handling and frequent, the long, monotonous operation, using synchronous rectangular transfer is effective; in addition, it can operate in high temperature, low temperature, water, the universe, radioactive and other toxic, environmental pollution condition, but also show its superiority, there are broad prospects for the development.

The main content of this paper is using synchronous rectangular transmitting motion machine, design of shogging mechanism, make the product moves 1100mm along the horizontal direction, ensure that the stiffness of the structure is adequate, reasonable structure, reliable. Design of lifting mechanism, make the product vertical lifting 150mm. Meter synchronization mechanism, so that the 30 groups of transverse beam motion synchronization, error in the controllable range.

Combined with the design of all aspects of knowledge, in the design process, learn how to find problems. To solve the problem. The problem. And into his thoughts and ideas in the design, improve their innovation ability. Try to make synchronous rectangular transmission is easy to use, simple in structure.

Keywords :synchronous rectangle; structure design; stepping motor; rotary

目 录

1 绪 论 1

2 同步矩形传送机构总体方案设计 2

2.1规格参数 2

2.2有效负载 2

2.3运动特性 2

2.4 工作范围(工作半径) 2

2.5 同步矩形传送材料的选择 2

2.6同步矩形传送的驱动元件 3

2.7 水平方向移动计算 4

2.7.1 电机计算 4

2.7.2齿轮齿条的设计计算 7

2.7.3齿条齿部弯曲强度的计算 11

2.8 小齿轮的强度计算 11

2.8.1齿面接触疲劳强度计算 11

2.8.2齿轮齿跟弯曲疲劳强度计算 14

2.9 升降方向结构计算 16

3 液压部分的设计计算 18

3.1油缸主要参数的确定 18

3.1.1液压缸内径的计算 18

3.1.2活塞杆直径的设计 18

3.1.3液压缸缸体厚度计算 18

3.1.4.液压缸长度的确定 19

3.1.5活塞杆直径的设计 19

3.2油缸主要部位的计算校核 21

3.2.1缸筒壁厚的计算 21

3.2.2 活塞杆强度和液压缸稳定性计算 21

3.2.3缸筒壁厚的验算 23

3.2.4 缸筒的加工要求 25

3.2.5法兰设计 25

3.2.6 (缸筒端部)法兰连接螺栓的强度计算 26

3.3 活塞的设计 28

3.4 导向套的设计与计算 28

3.5 端盖和缸底的设计与计算 30

3.6 液压泵的参数计算 31

3.7 电动机的选择 31

3.8 液压元件的选择 32

3.8.1 液压元件的选择 32

3.8.2 油管的选择 34

3.9 验算液压系统性能 35

3.9.1 压力损失的验算及泵压力的调整 35

3.9.2 液压系统的发热和温升验算 37

3.10 油箱设计 38

3.10.1油箱有效容积的确定 38

3.10.2 油箱容积的验算 38

3.11辅助元件 40

4 横梁等其他结构件的设计 41

总 结 52

致 谢 53

参考文献 54