设计简介

摘 要

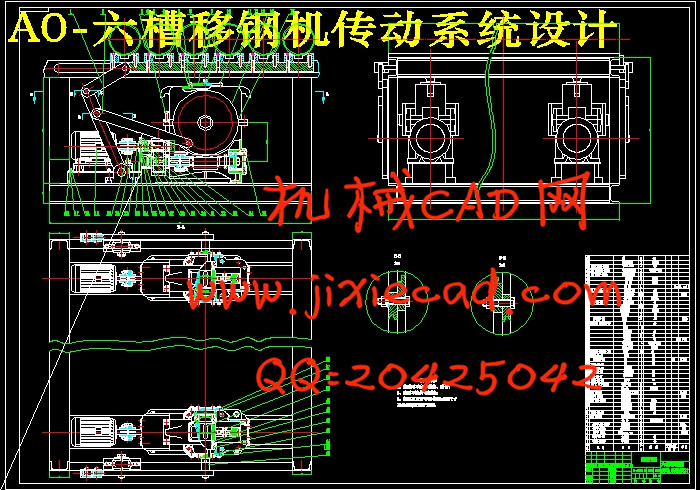

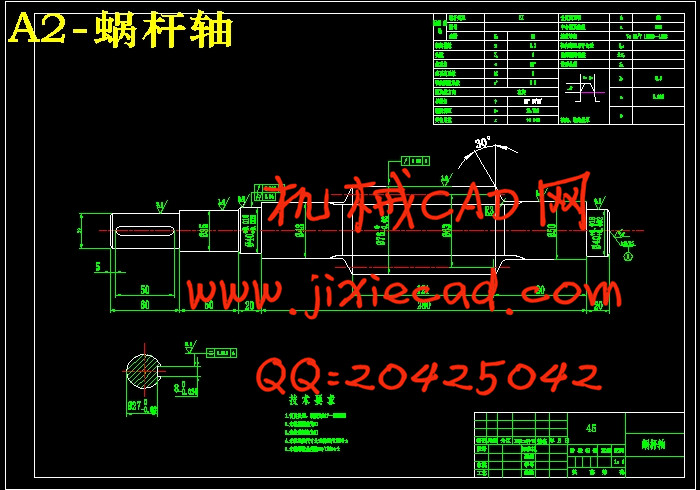

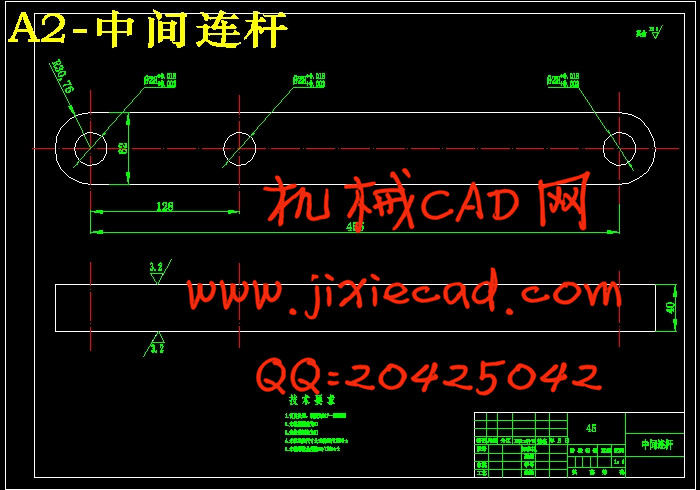

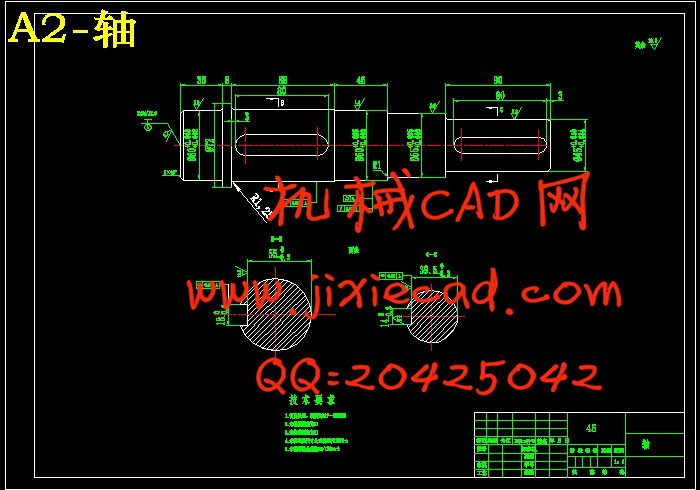

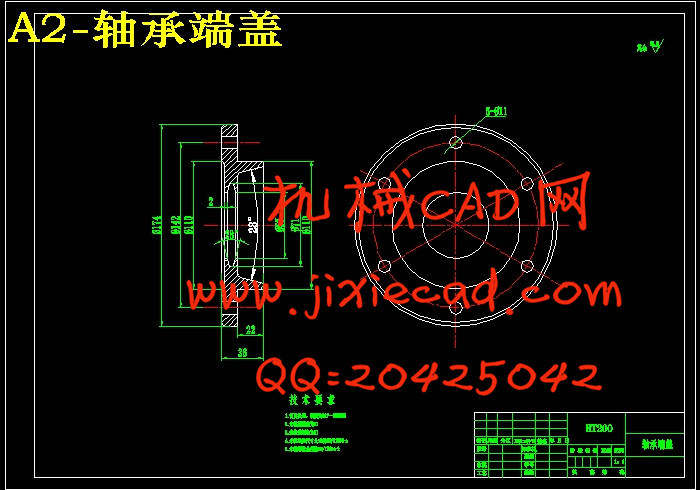

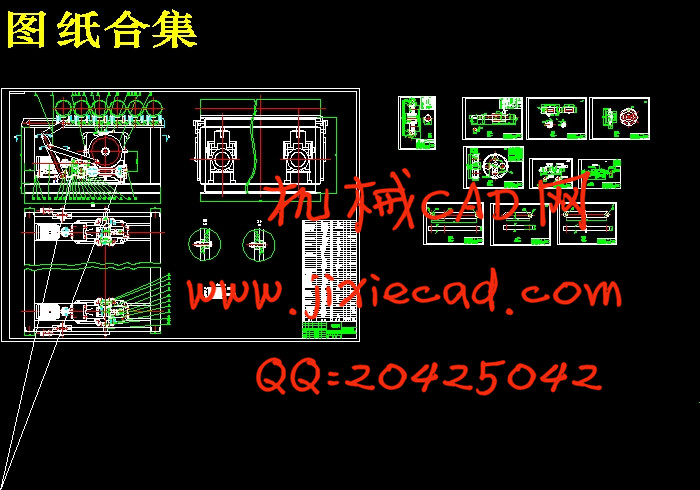

本次毕业设计是关于六槽移钢机的设计。首先对六槽移钢机作了简单的概述;接着分析了六槽移钢机的选型原则及计算方法;然后根据这些设计准则与计算选型方法按照给定参数要求进行选型设计;接着对所选择的六槽移钢机各主要零部件进行了校核。在六槽移钢机的设计、制造以及应用方面,目前我国与国外先进水平相比仍有较大差距,国内在设计制造六槽移钢机过程中存在着很多不足。整机结构主要由电动机产生动力将需要的动力通过联轴器传递到齿轮上,通过齿轮再过渡到另外一组齿轮上,然后再通过齿轮过渡到蜗轮蜗杆上。同时本文对该方案六槽移钢机的关键零部件设计过程进行了详细阐述,其主要内容包括系统总体方案的设计、电动机的选择、执行机构的设计、传动零部件的设计、轴的设计与校核以及轴承的选择、等。

本文主要介绍六槽移钢机的发展状况,六槽移钢机结构设计原理,六槽移钢机总体方案分析及确定,六槽移钢机结构设计内容所包含的机械图纸的绘制,的计算,结构设计结论与建议。

本论文研究内容:

(1) 六槽移钢机总体结构设计。

(2) 六槽移钢机工作性能分析。

(3)电动机的选择。

(4) 六槽移钢机的传动系统、执行部件。

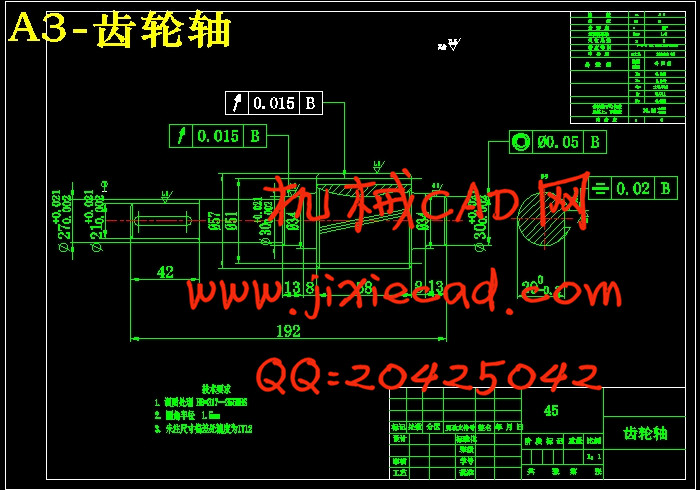

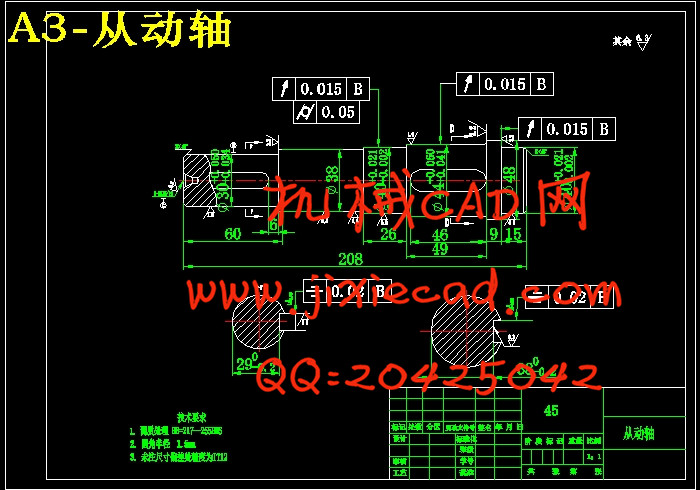

(5)对设计零件进行设计计算分析和校核。

(6)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词:六槽移钢机,传动装置,连杆,减速器

Abstract

This graduation design is about the design of the six slot steel machine. First of six trough moving steel machine has made the simple outline; then analyzes the six slot steel machine type selection and calculation method of displacement. Then according to these design criteria and selection method in accordance with the given parameters requirements selection of design; then on the selected six tank shift steel machine and the main components were checked. Groove in the shift steel machine design, manufacturing and application, at present our country and the overseas advanced level compared to still have a large gap, in the design and manufacture of domestic six trough steel moving machine process exists many problems.The whole structure mainly by the motor generates dynamics will require the power through the coupling transfer to the gear, through the gear and the transition to another set of gear, and then through the transition gear to worm. At the same time, the paper on the six slot shift steel machine is the key part of the design process are detailed. The main contents include the design of the overall scheme of the system design, motor selection, actuator design, transmission parts, the shaft of the design and check and bearing selection, etc..

This paper mainly introduces the groove shift the development condition of the steel machine, the six slot shift steel structure design principle, six trough shift the overall scheme of steel machine analysis and determination, the six slot shift steel structure design content contained in the mechanical drawing of rendering, the calculation of structure design conclusion and suggestions.

Research content of this thesis:

(1) the overall structure design of the six slot steel machine.

(2) analysis of working performance of the six slot machine.

(3) motor selection.

(4) transmission system and executing component of the six slot machine.

(5) design and calculation analysis and verification of design parts.

(6) drawing the assembly drawing and the assembly drawing of the important parts.

Key words: Six slot machine, transmission device, connecting rod, reducer

目 录

摘 要 II

Abstract III

1 绪论 1

1.1 六槽移钢机的发展史 1

1.2 六槽移钢机的用途 1

1.3 六槽移钢机的优越性 2

1.3.1 六槽移钢机的特点 2

1.3.2 六槽移钢机与其他移钢机的比较 2

1.4六槽移钢机减速器 3

2 六槽移钢机总体方案 6

2.1 六槽移钢机设计方案 6

2.1.1六槽移钢机方案一 6

2.1.2 六槽移钢机方案二 6

2.1.3六槽移钢机方案三 7

2.1.4六槽移钢机方案四 7

2.2 六槽移钢机执行机构的选型与设计 8

2.3 六槽移钢机传动装置方案确定 9

3 电动机选择、传动系统运动和动力参数计算 11

3.1 主要参数 11

3.2电动机的选择 11

3.3 传动装置总传动比的确定及各级传动比的分配 13

3.4 运动参数和动力参数计算 14

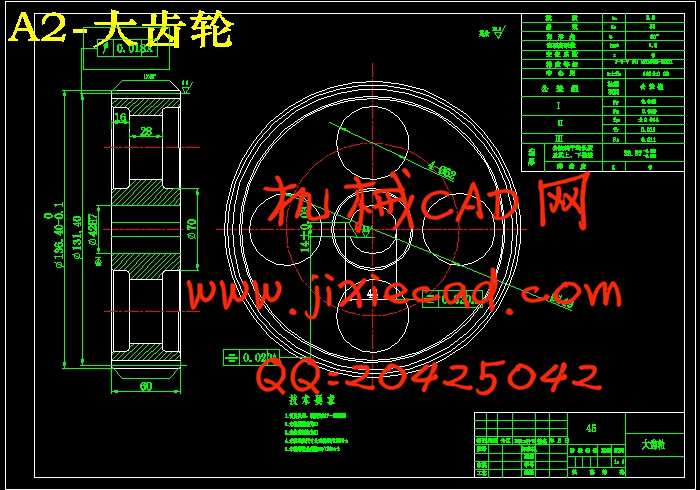

4 圆柱齿轮传动零件的设计计算 15

4.1 选择齿轮材料及精度等级 15

4.2按齿面接触疲劳强度设计 15

4.3 根据齿根弯曲疲劳强度设计 17

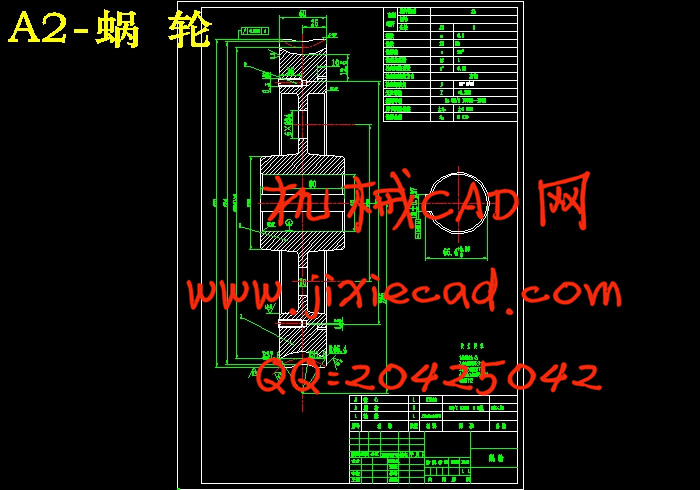

5 蜗轮蜗杆传动设计计算 20

5.1 选择蜗杆传动类型 20

5.2 选择材料 20

5.3 按齿面接触疲劳强度进行设计 20

5.4 蜗杆与蜗轮的主要参数与几何尺寸 22

5.5 校核齿根弯曲疲劳强度 22

5.6 验算效率

5.7 精度等级公差和表面粗糙度的确定 23

5.8 热平衡核算 24

6 轴的设计计算 25

6.1 Ⅰ轴的结构设计 25

6.2 Ⅱ轴的结构设计 28

6.3 Ⅲ轴的结构设计 30

6.4 校核Ⅱ轴的强度 32

7 轴承的选择和校核 38

7.1 高速轴轴承的校核 38

7.2 低速轴轴承的校核 39

7.3 计算输入轴轴承 41

7.4 计算输出轴轴承 44

8 键联接的选择和校核 46

8.1 键的选择 46

8.2 键的校核 46

8.3 联轴器的选择 47

9 减速器的润滑、密封和润滑牌号的选择 48

9.1 传动零件的润滑 48

9.1.1 齿轮传动润滑 48

9.1.2滚动轴承的润滑 48

9.2 减速器密封 48

9.2.1 轴外伸端密封 48

9.2.2 轴承靠箱体内侧的密封 48

9.2.3 箱体结合面的密封 48

10 减速器箱体设计及附件的选择和说明 49

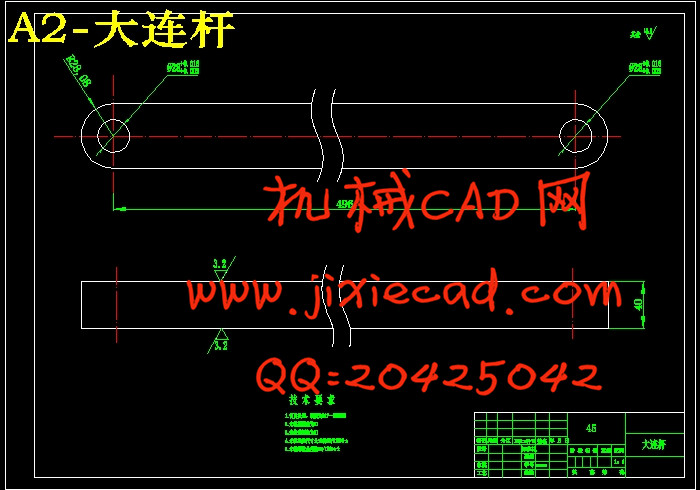

11 六槽移钢机其他零件设计 51

结束语 53

参考文献 54

致谢 55