设计简介

摘 要

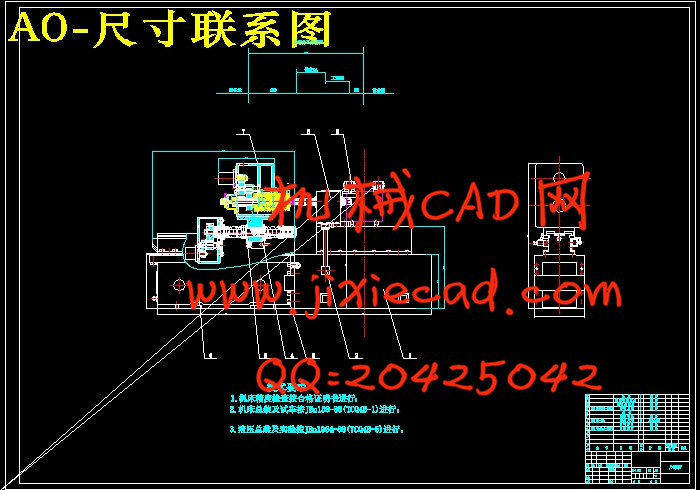

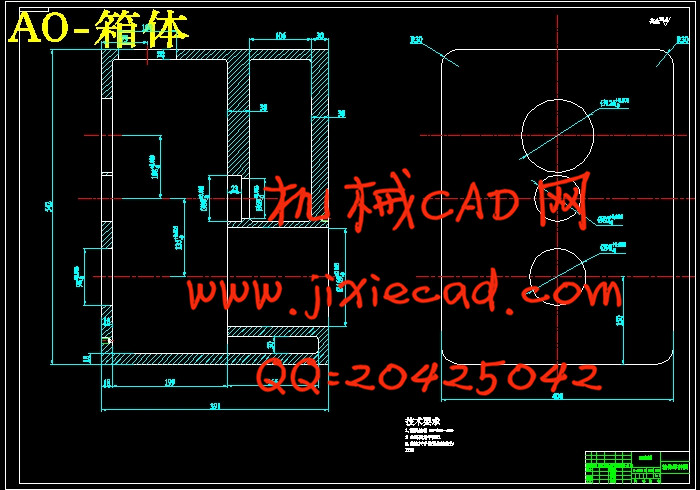

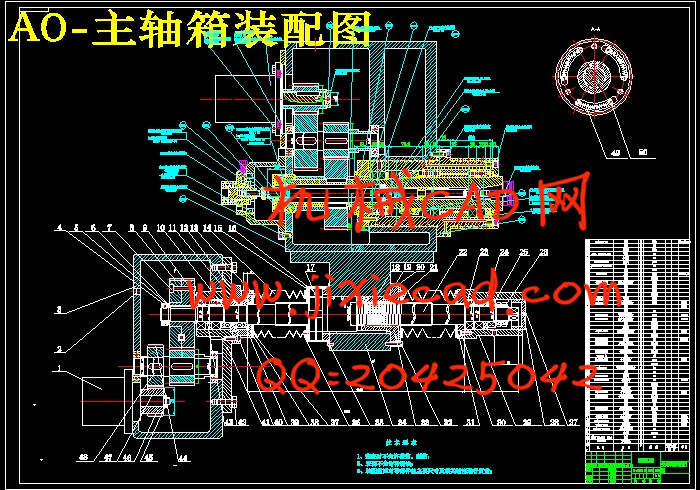

本次设计是对螺纹在线加工部件的设计。在这里主要包括: 主轴箱传动机构的设计、进给部件的设计、刀具卡紧部件系统的设计这次毕业设计对设计工作的基本技能的训练,提高了分析和解决工程技术问题的能力,并为进行一般机械的设计创造了一定条件。整机结构主要由电动机产生动力通过联轴器将需要的动力传递到丝杆上,丝杆带动丝杆螺母,从而带动整机进给运动,而主轴箱通过二级齿轮减速带动主轴旋转运动,

改设计提高劳动生产率和生产自动化水平。更显示其优越性,有着广阔的发展前途。

本论文研究内容:

(1) 螺纹在线加工部件总体结构设计。

(2) 螺纹在线加工部件工作性能分析。

(3)电动机的选择。

(4) 螺纹在线加工部件的传动系统、执行部件及机架设计。

(5)对设计零件进行设计计算分析和校核。

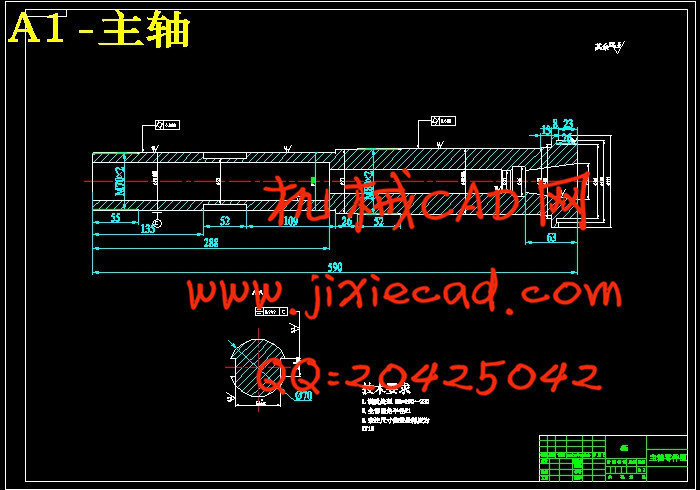

(6)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词:螺纹在线加工部件,滚珠丝杠,进给传动,主轴箱

Abstract

This design is the design of the thread on-line processing parts.. Here mainly include: the ability to design and tool design of spindle box transmission mechanism, a feeding part of card tight component system the design of the graduation design on the design of the basic skills training, improve the analysis and solve engineering problems, and for general mechanical design created certain conditions.

Whole structure mainly by the motor generate power through the coupling will need the power delivered to the screw rod and screw rod drives the screw rod nut, so as to drive the machine feed movement, and spindle box by secondary gear deceleration drive the spindle rotating motion,

Improving labor productivity and production automation level. It has a broad prospect for its development..

Research content of this thesis:

(1) the overall structure design of the online machining parts of the screw threads.

(2) working performance analysis of the screw online working part.

(3) motor selection.

(4) the transmission system, the execution parts and the frame design of the thread processing parts.

(5) design and calculation of the design parts for calculation and verification.

(6) drawing the assembly drawings and important parts of the assembly drawings and parts drawings of the design parts.

Key words: online processing parts, ball screw, feed drive, spindle box

目 录

摘 要 IIWhole structure mainly by the motor generate power through the coupling will need the power delivered to the screw rod and screw rod drives the screw rod nut, so as to drive the machine feed movement, and spindle box by secondary gear deceleration drive the spindle rotating motion,

Improving labor productivity and production automation level. It has a broad prospect for its development..

Research content of this thesis:

(1) the overall structure design of the online machining parts of the screw threads.

(2) working performance analysis of the screw online working part.

(3) motor selection.

(4) the transmission system, the execution parts and the frame design of the thread processing parts.

(5) design and calculation of the design parts for calculation and verification.

(6) drawing the assembly drawings and important parts of the assembly drawings and parts drawings of the design parts.

Key words: online processing parts, ball screw, feed drive, spindle box

目 录

Abstract III

1 绪论 1

1.1 螺纹在线加工部件的要求 1

1.2 课题的目的及意义 1

1.3 国内外概况综述 3

1.4 本课题研究的内容及方法 4

1.4.1 主要的研究内容 4

1.4.2 设计要求 4

1.4.3 关键的技术问题 4

2 螺纹在线加工部件总体结构设计 5

2.1 螺纹在线加工部件的构成 5

2.2 螺纹在线加工部件的工作原理 5

2.3 钻孔的基本尺寸和切削用量 7

2.4 减速机构设计 10

3 进给结构及传动设计 12

3.1 进给部位齿轮的传动计算 12

3.2 高速级齿轮的设计计算 12

3.3 低速级齿轮的设计计算 15

3.4进给丝杠传动设计 18

3.5 轴向进给滚珠丝杆副的选择 19

3.5.1 导程确定 19

3.5.2 确定丝杆的等效转速 19

3.5.3 估计工作台质量及负重 19

3.5.4 确定丝杆的等效负载 20

3.5.5 确定丝杆所受的最大动载荷 20

3.5.6 精度的选择 21

3.5.7 选择滚珠丝杆型号 21

3.6 校核 22

3.6.1 临界压缩负荷验证 22

3.6.2 临界转速验证 23

3.6.3 丝杆拉压振动与扭转振动的固有频率 23

3.7 电机的选择 24

3.7.1 电机轴的转动惯量 24

3.7.2 电机扭矩计算 25

4 主轴箱的设计计算 27

4.1进给结构及传动设计 27

4.2低速级齿轮的设计计算 31

4.3 轴的计算 34

4.3.1 高速轴的计算 34

4.3.2 中间轴的计算 38

4.3.3 低速轴的计算 42

5 键连接的选择和计算 46

5.1 高速轴(I轴)上键的选择及校核 46

5.2 中间轴(II轴)上键的选择及校核 46

5.3 高速轴(III轴)上键的选择及校核 47

6 滚动轴承的选择和计算 48

7 主轴的设计计算 51

7.1 自动松拉刀系统 52

7.2 自动松拉刀系统的关键零件 53

结 论 55

参考文献 56

致 谢 58