设计简介

摘 要

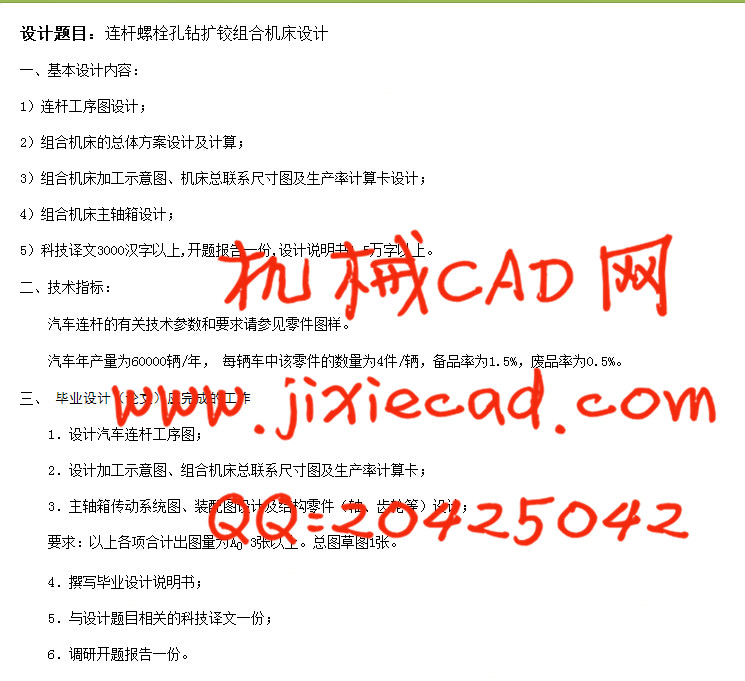

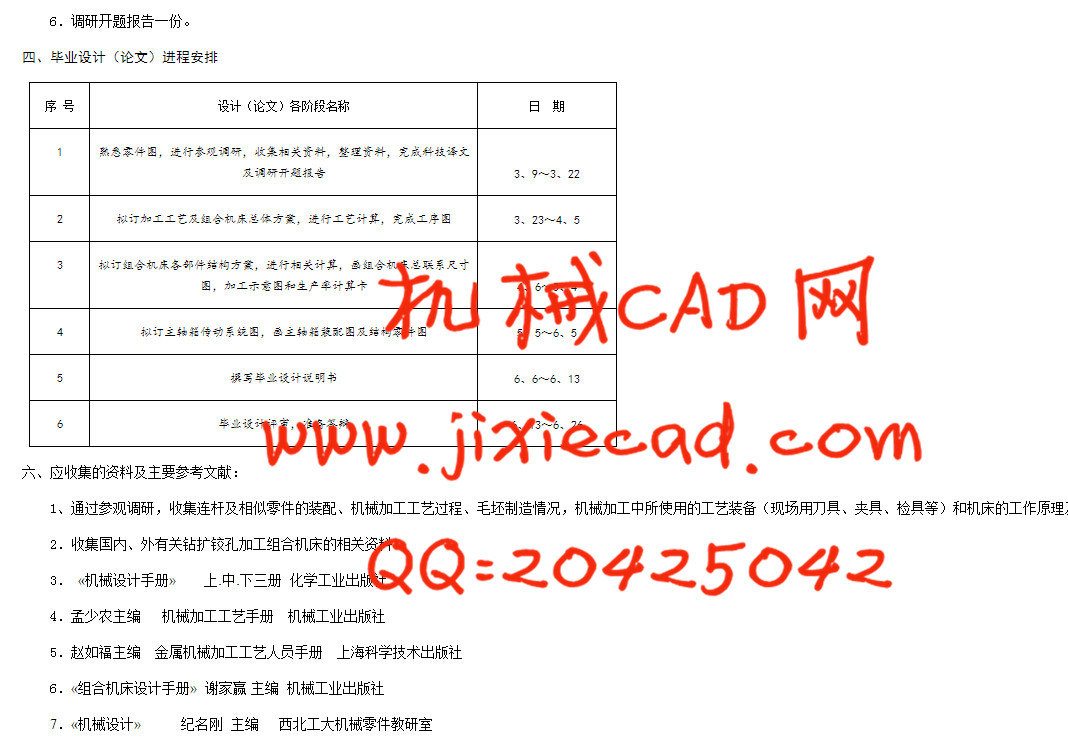

根据设计任务书的要求,本设计说明书针对连杆机床的设计及专用夹具设计进行说明。要内容包括组合机床工艺方案的制定、组合机床配置型式的选择、组合机床总体设计以及主轴箱设计。全文要包括组合机床的总体设计和主轴箱设计两部分。机床总体设计要是在选定工艺方案并确定机床配置形式、结构方案基础上确定“三图一卡”,主轴箱设计根据“三图一卡”,整理编绘出主轴箱原始依据图,重点分析传动系统,经过各种方案的比较,最后确定最优方案。

关键词:主轴箱;组合机床;夹具

Abstract

According to the requirements of the mission design, design for wallboard machine and special fixture for the design specification is described. The main contents include aggregate machine-tool craft plan formulation, combined machine tool configuration choice, aggregate machine-tool system design and main shaft case design.The full text mainly includes overall design and main shaft box combination milling machine design two parts. The overall design of machine tool is mainly in the selected process and determine the basis of machine tool configuration, structure scheme to determine the "three charts and a card", the headstock design according to "three charts and a card", reorganizes the compilation to leave the headstock primitive basis chart, the key analysis transmission system, through the comparison of various schemes, and finally to determine the optimal scheme. In addition, in order to improve labor productivity, reduce labor intensity, guaranteed the processing quality, need to design special jig.

Keywords: spindle box; modular machine tool; fixture

目 录

摘 要 II

Abstract III

1 绪论 1

1.1 课题研究意义 1

1.2钻孔专用设备应用 1

1.3 钻孔专用设备 2

1.3.1多轴头 2

1.3.2 主轴箱 2

1.3.3多轴钻床 3

1.3.4 自动更换主轴箱机床 3

1.4 钻孔专用设备趋势 4

1.5 组合机床总体设计 4

1.5.1 组合机床的概述 4

1.5.2 组合机床的技术发展趋势 5

2 组合机床的总体设计 8

2.1 组合机床方案的制定 8

2.1.1制定工艺方案 8

2.1.2确定组合机床的配置形式和结构方案 9

2.2 确定切削用量及选择刀具 11

2.2.1确定工序间余量 11

2.2.2选择切削用量 11

2.2.3确定切削力、切削扭矩、切削功率 12

2.2.4选择刀具结构 12

2.3 钻孔组合机床总设计“三图一卡”的编制 12

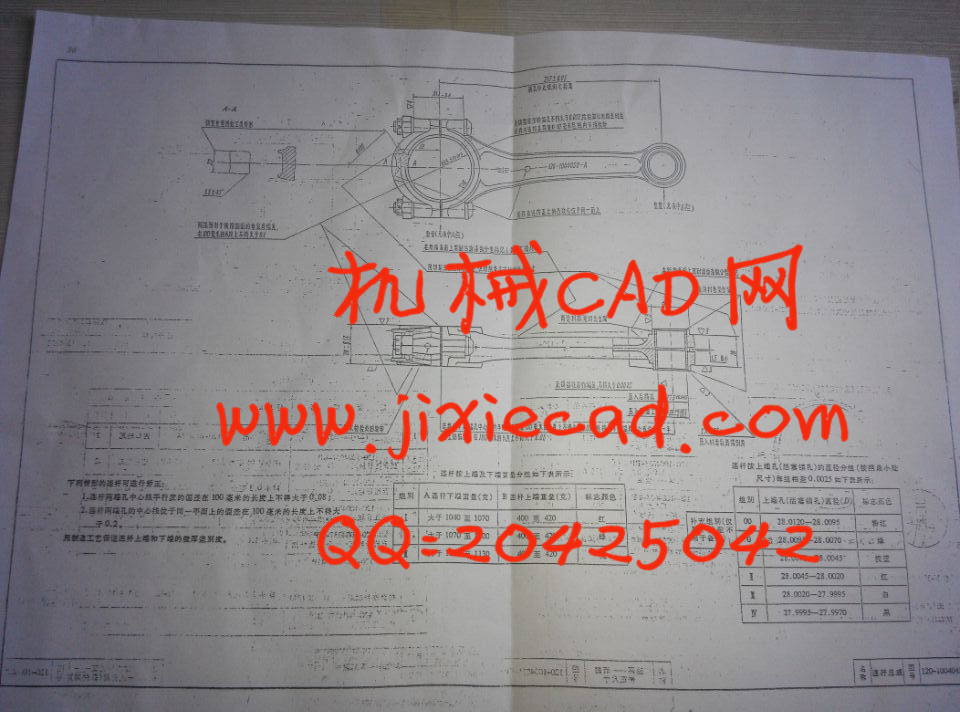

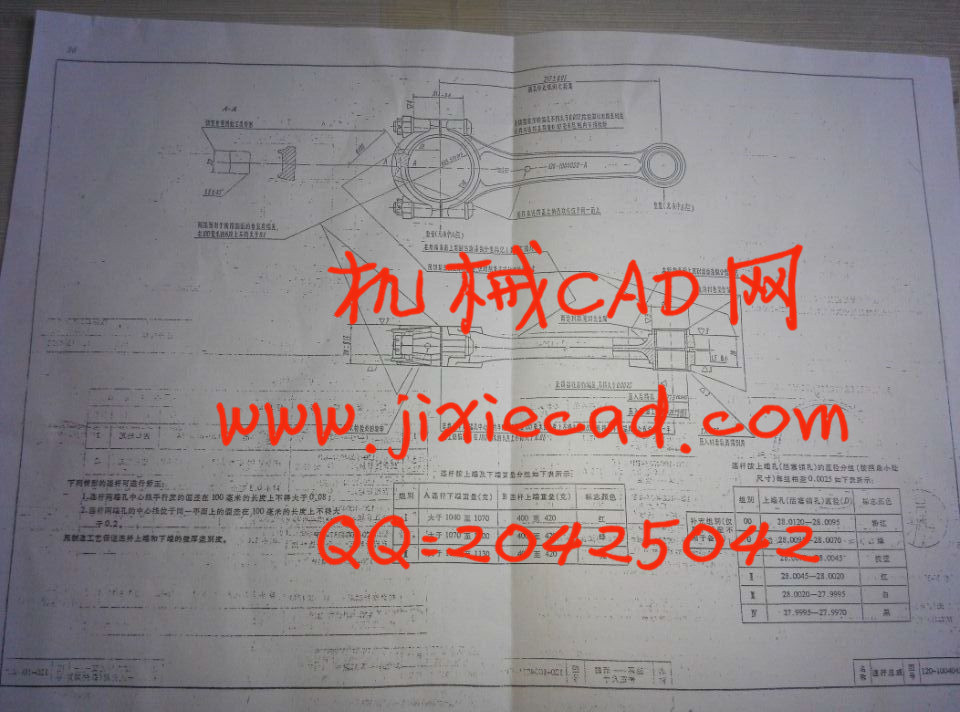

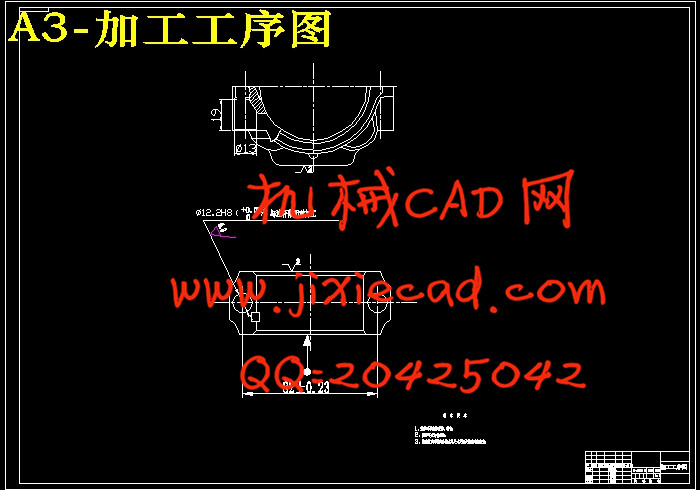

2.3.1 被加工零件工序图 13

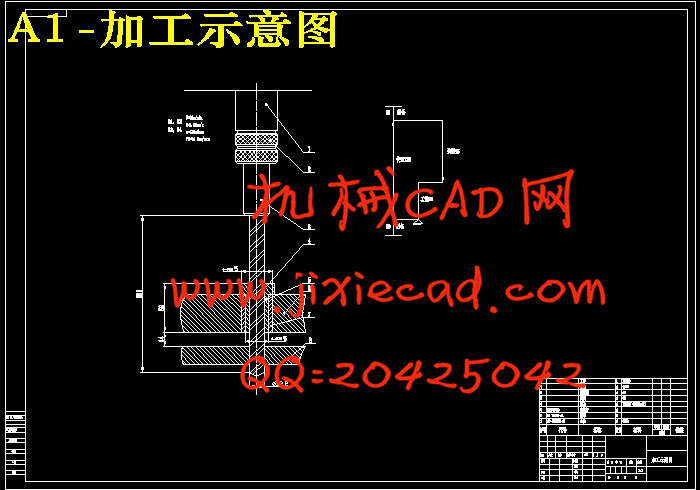

2.3.2 加工示意图 13

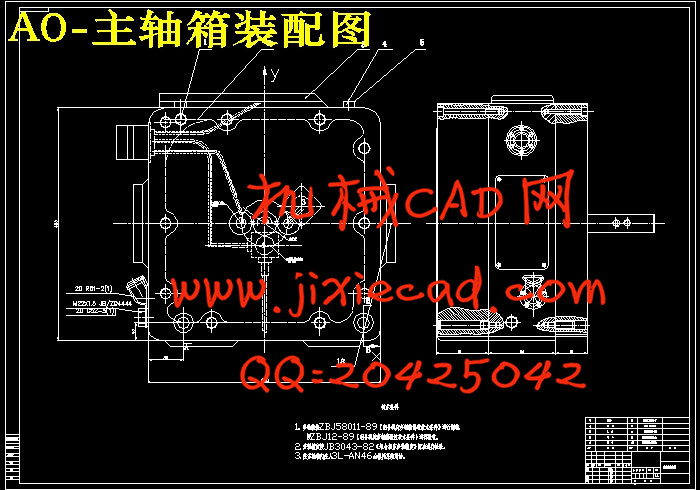

2.3.3机床联系尺寸图 17

2.3.4生产率计算卡 19

3 主轴箱的设计 21

3.1 主轴箱的设计 21

3.1.1绘制主轴箱设计原始依据图 21

3.1.2齿轮模数选择 22

3.1.3主轴箱的传动设计 22

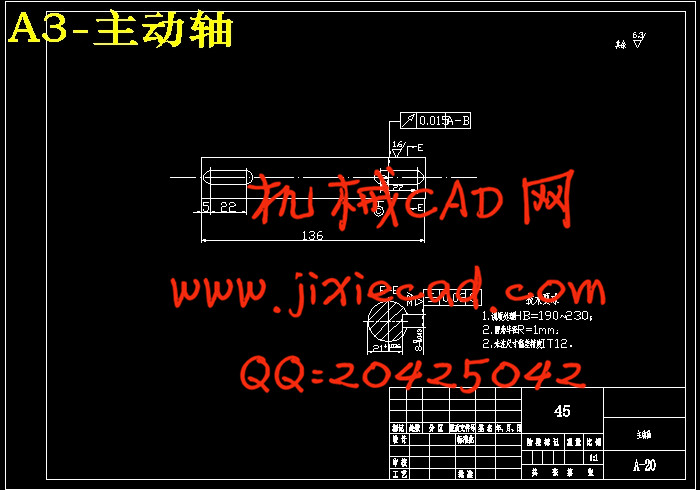

3.1.4绘制传动系统图 24

3.2 传动轴的直径估算 25

3.2.1 确定各轴转速 25

3.2.2传动轴直径的估算:确定各轴最小直径 26

3.2.3 键的选择 27

3.3 传动轴的校核 27

3.3.1 传动轴的校核 28

3.3.2 键的校核 28

结论 30

致 谢 31

参考文献 32