设计简介

摘 要

金属带钢卷,也被称为卷钢,钢材经过热、冷压成型为卷状。为了方便储存和运输,各种钢材的暂时处理方法(如加工成钢带等)。

金属带钢卷包装是钢卷储存和运输的重要保护措施。传统的钢卷包装为手工作业,包装质量差、生产效率低和工人劳动强度大是这一落后包装技术的致命弱点。特别是,随着轧制速度的提高,新建的冷轧生产线的能力都在百万吨级,低效率的手工包装根本不能满足生产要求。工业发达国家的钢铁企业都非常重视钢卷包装,将其提高到 保证安全储运,提升产品档次!的高度,开发出完整的钢卷包装工艺技术和装备,基本实现了钢卷包装的自动化。

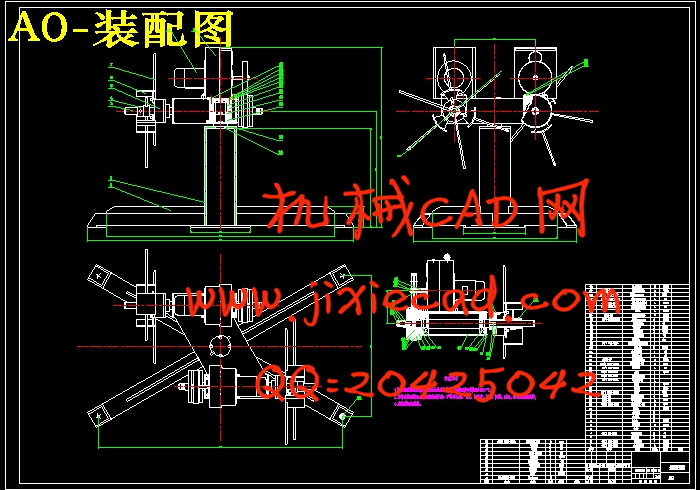

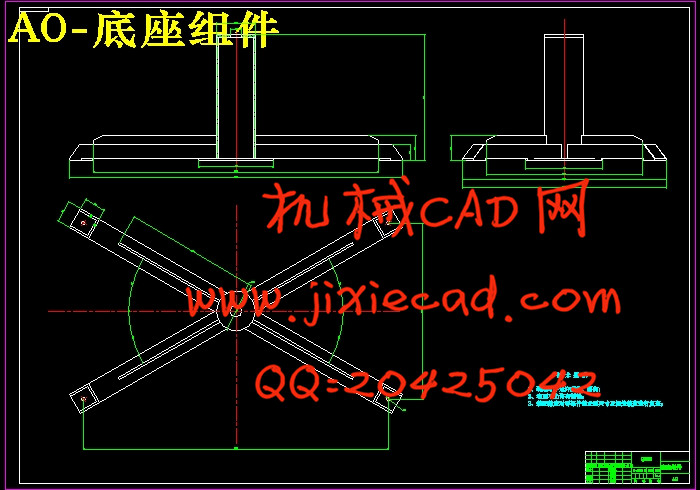

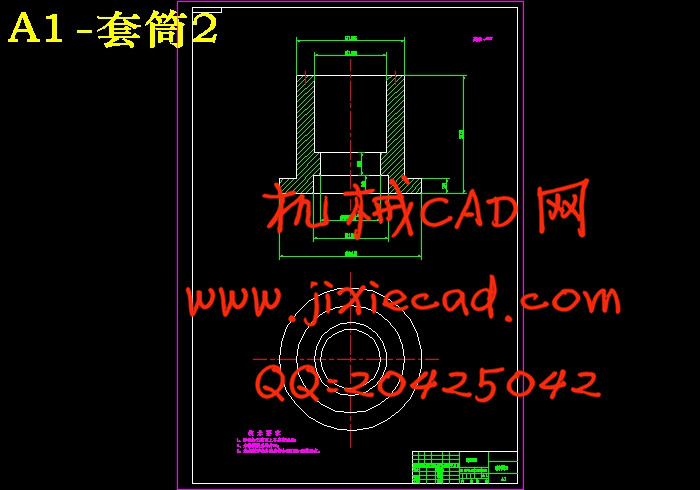

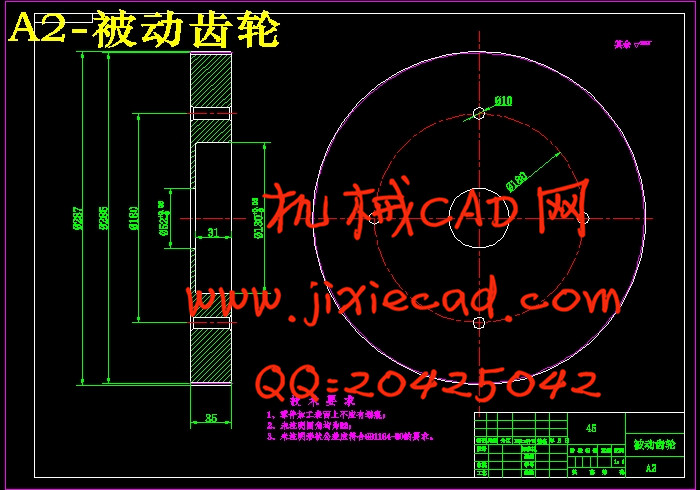

本文对收卷装置进行设计,主要完成机械结构部分设计。整机结构主要由电动机产生动力将需要的动力传递到减速器上,然后通过齿轮传递到齿轮,通过齿轮再过渡到卷筒轴上,卷筒轴上装有收卷机构。同时本文对该方案收卷装置关键零部件设计过程进行了详细阐述,其主要内容包括系统总体方案的设计、电动机的选择、执行机构的设计、传动零部件的设计、轴的设计与校核以及轴承的选择等。

本论文研究内容:

(1) 收卷装置总体结构设计。

(2) 收卷装置工作性能分析。

(3)电动机的选择。

(4) 收卷装置的传动系统、执行部件。

(5)对设计零件进行设计计算分析和校核。

(6)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词: 金属带;机械结构;收卷装置;双工位

Abstract

金属带钢卷,也被称为卷钢,钢材经过热、冷压成型为卷状。为了方便储存和运输,各种钢材的暂时处理方法(如加工成钢带等)。

金属带钢卷包装是钢卷储存和运输的重要保护措施。传统的钢卷包装为手工作业,包装质量差、生产效率低和工人劳动强度大是这一落后包装技术的致命弱点。特别是,随着轧制速度的提高,新建的冷轧生产线的能力都在百万吨级,低效率的手工包装根本不能满足生产要求。工业发达国家的钢铁企业都非常重视钢卷包装,将其提高到 保证安全储运,提升产品档次!的高度,开发出完整的钢卷包装工艺技术和装备,基本实现了钢卷包装的自动化。

本文对收卷装置进行设计,主要完成机械结构部分设计。整机结构主要由电动机产生动力将需要的动力传递到减速器上,然后通过齿轮传递到齿轮,通过齿轮再过渡到卷筒轴上,卷筒轴上装有收卷机构。同时本文对该方案收卷装置关键零部件设计过程进行了详细阐述,其主要内容包括系统总体方案的设计、电动机的选择、执行机构的设计、传动零部件的设计、轴的设计与校核以及轴承的选择等。

本论文研究内容:

(1) 收卷装置总体结构设计。

(2) 收卷装置工作性能分析。

(3)电动机的选择。

(4) 收卷装置的传动系统、执行部件。

(5)对设计零件进行设计计算分析和校核。

(6)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词: 金属带;机械结构;收卷装置;双工位

Abstract

The metal strip coil, also known as the steel coil, steel after heat, cold pressing roll. In order to facilitate storage and transportation, temporary processing methods of different kinds of steel (such as processed intosteel belt).

The metal strip coil packaging is an important protection measures of steel storage and transportation. The traditional steel coil packaging for manual operation, the packaging of poor quality, low production efficiencyand high labor intensity of workers is the backwardness of the fatal weakness of packaging technology.Especially, with the rolling speed increasing, the ability of the new cold rolling production line are in million tons of low efficient manual packaging, simply can not meet the requirement of production. Industrialdeveloped countries have attached great importance to the iron and steel enterprises steel coil packaging, it will be increased to ensure the safety of storage and transportation, improve product quality! Height,developed a complete steel rolling technology and equipment package, the basic realization of the automaticsteel coil packaging.

This paper carries on the design to the winding device, mainly completes the design of mechanical structure.The whole structure is mainly produced by motor power will need to transfer the power to the drive, and thentransferred to the gear through the gear, the gear and the transition to the drum shaft, drum shaft is provided with a rolling mechanism. At the same time, this article on the scheme of winding device of key parts of the design process in detail, the main contents include system architecture design, the choice of motor,actuator design, transmission parts of the design, shaft design and checking and choice of bearings.

This thesis research content:

(1) the overall structure design of winding device.

(2) the analysis of roll device work performance.

(3) the choice of motor.

(4) transmission system, the executive component rewinding device.

(5) the design of parts of design calculation and check.

(6) drawing machine assembly drawing and assembly drawing design of important parts and parts drawings.

Keywords: metal belt; mechanical structure; winding device; double station

The metal strip coil packaging is an important protection measures of steel storage and transportation. The traditional steel coil packaging for manual operation, the packaging of poor quality, low production efficiencyand high labor intensity of workers is the backwardness of the fatal weakness of packaging technology.Especially, with the rolling speed increasing, the ability of the new cold rolling production line are in million tons of low efficient manual packaging, simply can not meet the requirement of production. Industrialdeveloped countries have attached great importance to the iron and steel enterprises steel coil packaging, it will be increased to ensure the safety of storage and transportation, improve product quality! Height,developed a complete steel rolling technology and equipment package, the basic realization of the automaticsteel coil packaging.

This paper carries on the design to the winding device, mainly completes the design of mechanical structure.The whole structure is mainly produced by motor power will need to transfer the power to the drive, and thentransferred to the gear through the gear, the gear and the transition to the drum shaft, drum shaft is provided with a rolling mechanism. At the same time, this article on the scheme of winding device of key parts of the design process in detail, the main contents include system architecture design, the choice of motor,actuator design, transmission parts of the design, shaft design and checking and choice of bearings.

This thesis research content:

(1) the overall structure design of winding device.

(2) the analysis of roll device work performance.

(3) the choice of motor.

(4) transmission system, the executive component rewinding device.

(5) the design of parts of design calculation and check.

(6) drawing machine assembly drawing and assembly drawing design of important parts and parts drawings.

Keywords: metal belt; mechanical structure; winding device; double station

目 录

1 绪论 1

1.1金属带钢卷概念 1

1.2 带钢收卷装置国内外发展现状 2

1.3 冷带钢收卷装置的类型和特点 2

1.4 双工位金属带收卷装置研究内容和方法 3

2双工位金属带收卷装置方案的选择与评述 4

2.1毕业设计(论文)的内容 4

2.2毕业设计(论文)的要求与数据 4

2.3收卷装置方案 4

3 主要结构尺寸的选择 6

3.1 卷筒直径的确定 6

3.2 卷筒筒身长度的确定 6

3.3 初选电动机容量 6

3.4 电动机轴上的力矩的计算 7

3.5 电动机的校核 9

3.6 减速机的选型 9

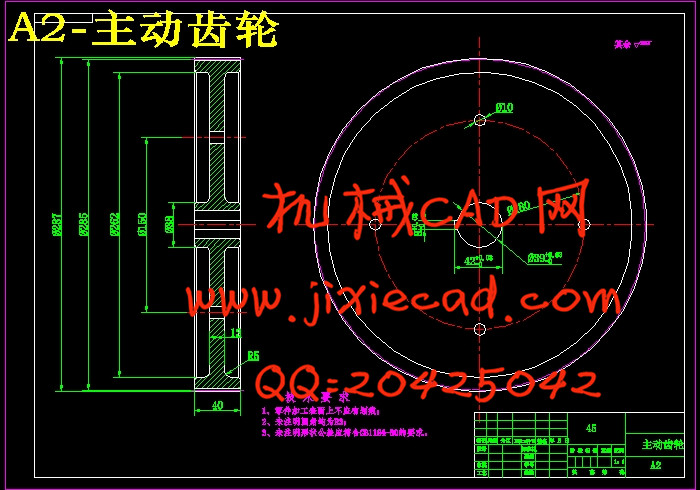

4 齿轮传动设计计算 10

4.1选择材料 10

4.2 压力角

4.3 齿数和模数的选择 10

4.4齿宽系数 10

4.5确定齿轮传动的精度 10

4.6齿轮的校核 12

5 主要零件的强度计算 15

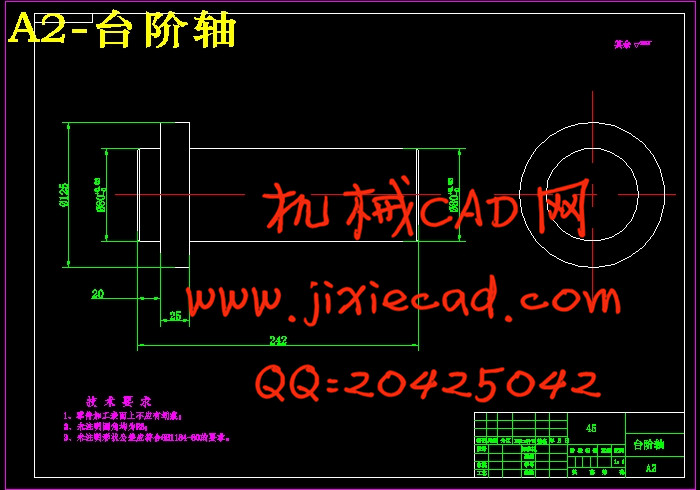

5.1 卷筒轴的设计与计算 15

5.1.1 轴的材料 15

5.1.2 卷筒轴转矩的计算 15

5.1.3 卷筒轴的计算 16

5.2 卷筒轴轴承的计算 22

6 润滑方法及润滑油的选择 23

6.1 润滑油的选择 23

6.2 润滑方法 24

7 设备可靠性与经济评价 24

7.1 机械设备的有效度 24

7.2 投资回收期 24

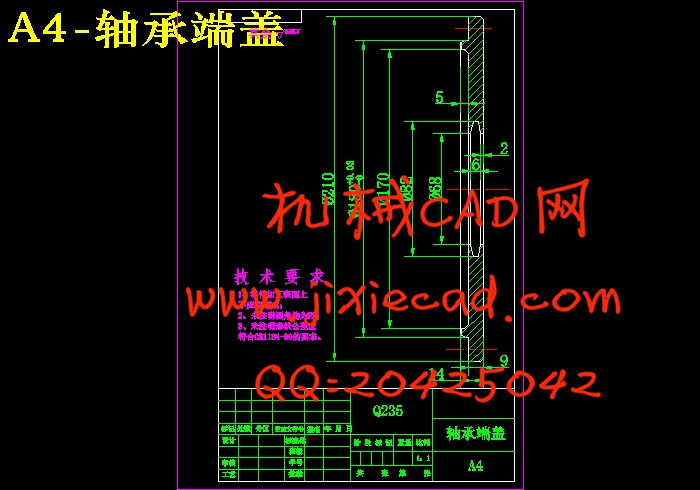

8 典型零件的工艺设计 25

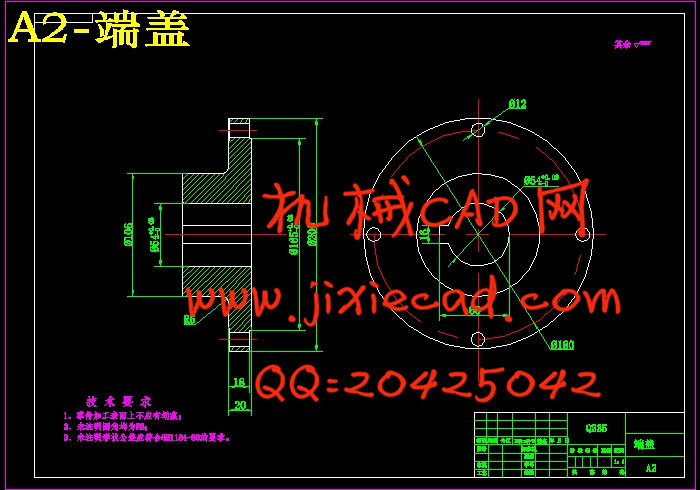

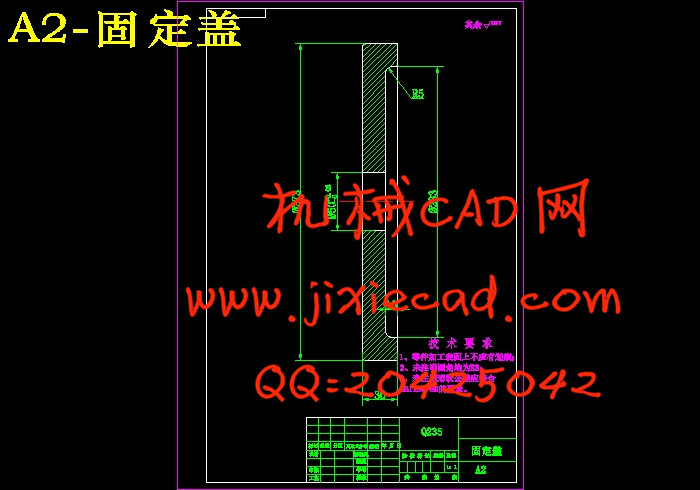

8.1 零件的形状 25

8.2零件的工艺分析 26

8.3 确定毛坯的制造形式 27

8.4 基面的选择 27

8.5 制定工艺路线 27

8.6 选择加工设备和工艺装备 29

8.7 机械加工余量、工序尺寸及毛坯尺寸的确定 29

8.8 确定切削用量及基本工时 30

总 结 41

致 谢 42

参考文献 44