设计简介

摘要

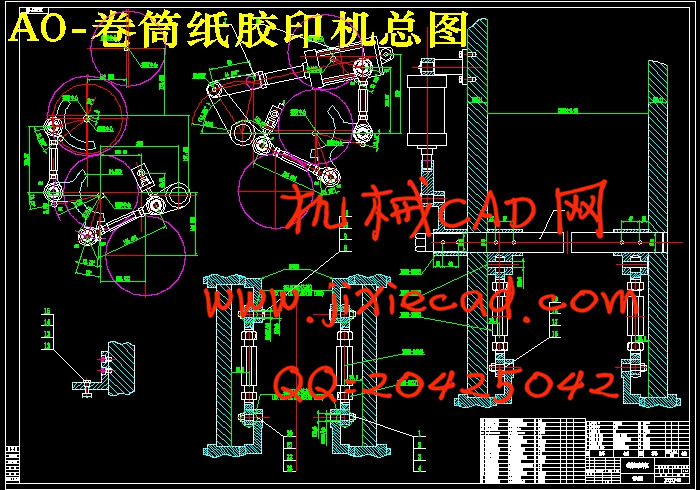

离合压机构是印刷机的一个重要部件,当印刷机发生双张、超张等故障的时候,印刷机要及时离压;而当故障解除开始印刷时,印刷机要及时的合压。当前胶印机的离合压机构大部分是采用凸轮连杆式的离合压机构,这种机械式的离合压机构随着印刷速度的提高,由凸轮产生的振动和冲击也越来越大,且传递到印刷滚筒上,在一定的程度上影响印刷质量离合压的方式有两种,一种是同时离合压;另一种是顺序离合压。根据滚筒的排列可以看出:同时离合压,即橡皮滚筒同压印滚筒和印版滚筒同时接触和分离,滚筒的缺口必须和滚筒的排列角一样大,防止第一张纸一半印上,一半印不上。滚筒的排列角一般占滚筒的三分之一以上,这样大大地降低了滚筒表面的利用率。要完成大幅面的印刷,必须增大滚筒的直径。滚筒的直径越大,带来的问题就越多,这种结构现已被淘汰。顺序合压,即橡皮滚筒先同印版滚筒合压,后同压印滚筒合压;离压时,先同压印滚筒离压,后同印版滚筒离压。关键词:离合压机构;印刷机;滚筒

Abstract

The on-off pressure mechanism is an important part of the printing machine, when the double Zhang, Zhang faults such as the printing machine, printing machine time away from the pressure; and when the failure to lift started printing, printing machine and timely closure pressure. Most of the current offset press clutch mechanism adopts a clutch cam connecting rod type pressure mechanism, clutch the mechanical pressure mechanism with the printing speed, vibration and impact generated by the cam is also growing, and passed on to the printing roller, in a certain extent impact on printing quality clutch pressure in two ways at the same time, a clutch pressure; another is the order of clutch pressure According to the cylinder arrangement can be seen: the clutch pressure, rubber roller with nano imprint lithography drum and. a printing plate roller and contact and separation, must drum gap and roller arrangement angle as large, prevent the first piece of paper printed on India half half, not. The cylinder is arranged for the 1/3 roller angle, thus greatly reduces the utilization rate of the drum surface. To complete the large format printing, you must increase the diameter of the cylinder. The diameter of the cylinder is bigger, bring more problems, this structure has been eliminated. The order of pressing, namely the rubber drum with a printing plate cylinder and pressure, with nano imprint lithography drum pressure; away from the pressure, first with nano imprint lithography drum pressure, with a printing plate cylinder from the pressure.Keyword:The on-off Pressure Mechanism; Printing Machine; Roller

目 录

摘要 2

Abstract 3

第1章 绪论 5

1.1 课题研究的目的和意义 5

1.2 卷筒纸印刷机的发展趋势 6

1.2.1 卷筒纸印刷机的发展趋势 7

1.3 国内外卷筒纸印刷机的特点 8

1.4卷筒纸印刷机的分类 9

第2章 卷筒胶印机离合压机构设计 12

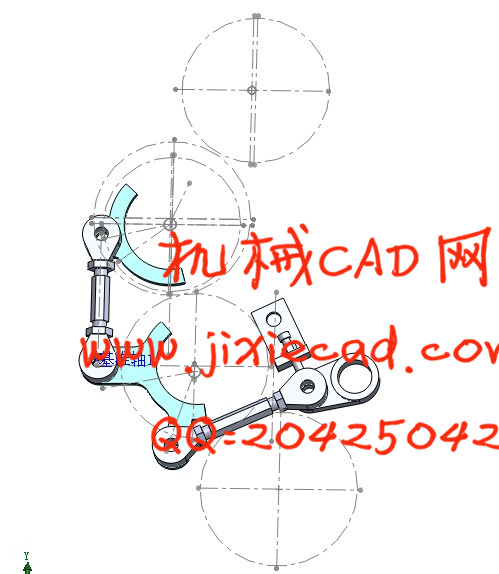

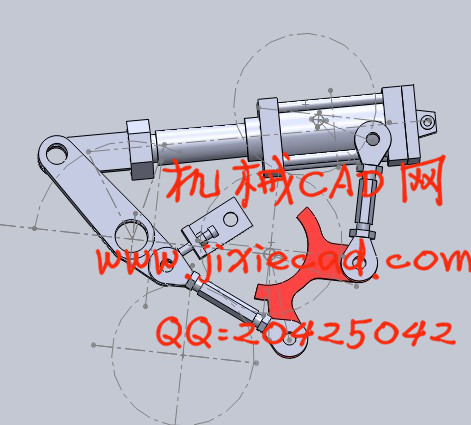

2.1离合压机构的工作原理 12

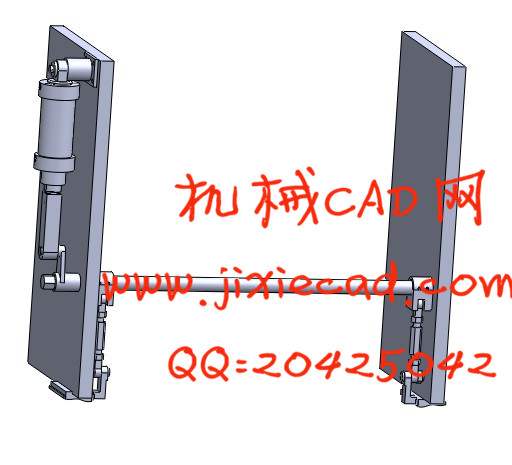

2.2调压机构 13

2.3离合压机构的限位装置 14

2.4 结构设计及运动分析 14

第3章 滚筒纸胶印机离合压机零部件设计 17

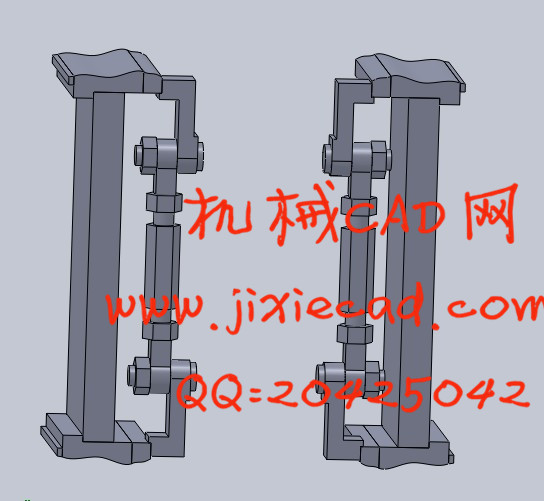

3.1 气缸支座的设计校核 17

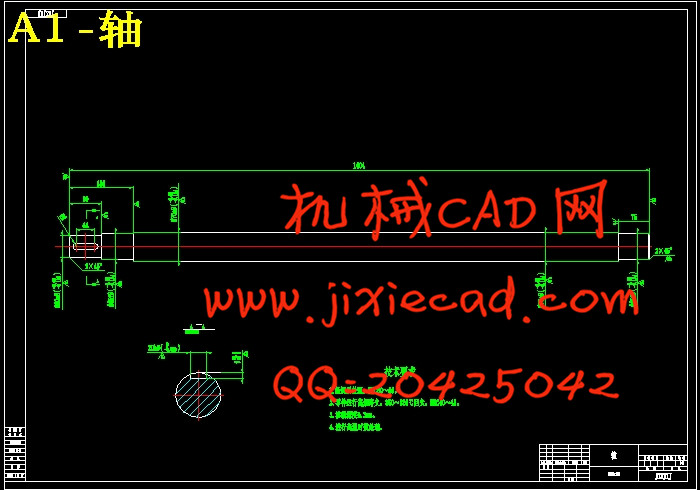

3.2 轴的设计及强度校核 18

3.2.1 轴强度计算 19

3.2.2 轴的疲劳强度校核 20

3.2.3 轴的接触应力校核 22

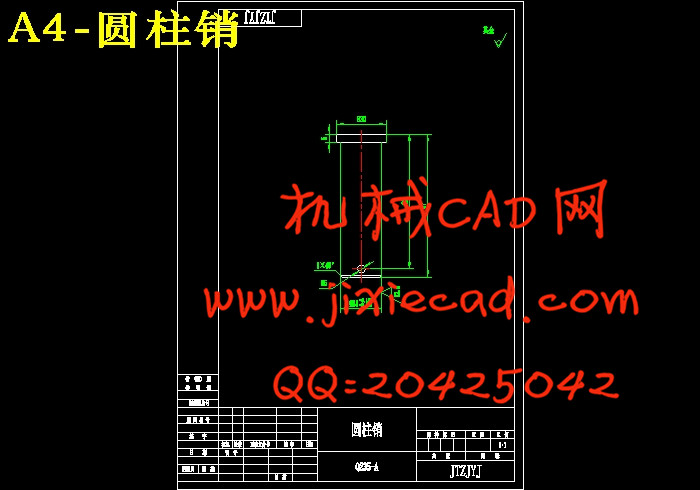

3.3 圆柱销的设计与校核 23

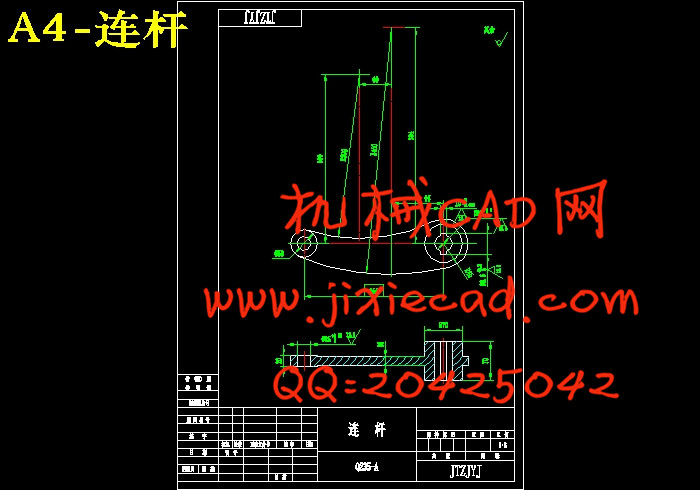

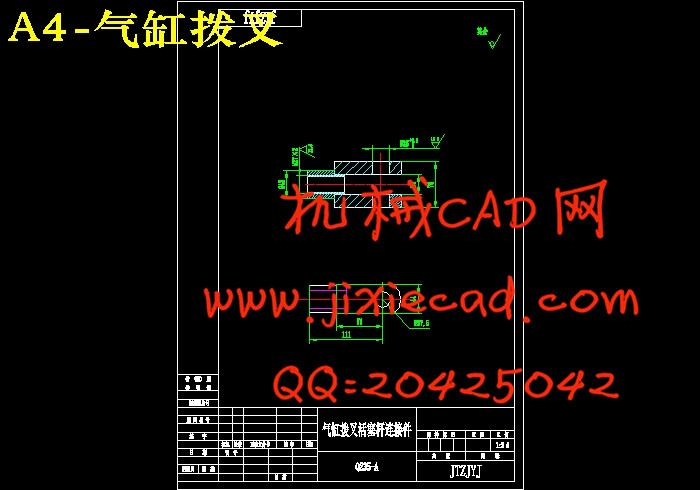

3.4 气缸拨叉的校核 25

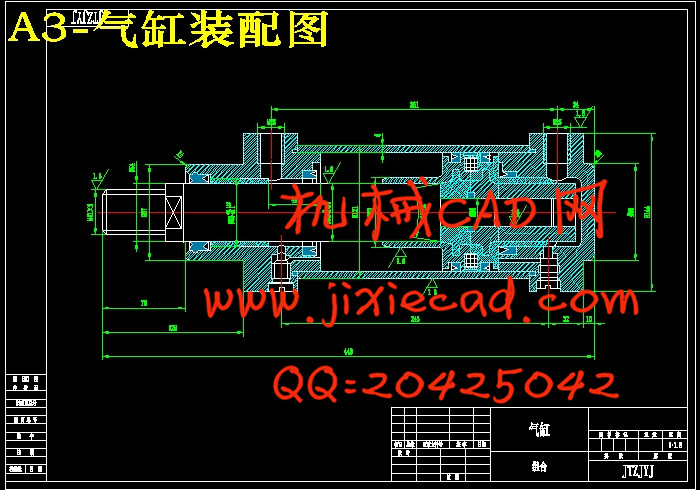

3.5 气缸的设计计算 26

3.6 气缸的校核 30

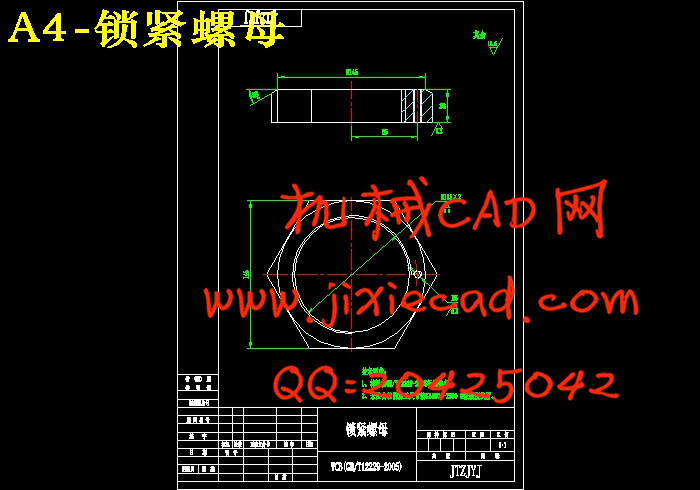

3.7螺栓的校核 31

致谢 33

参考文献 34