设计简介

摘 要

随着现代科技的高速发展,作为印后加工中的重要设备,自动模切机已经面向高速度,高精度,高效率的方向发展。自动平压模切机是包装印刷工业中重要的表面整饰设备。给纸部分机构是自动模切机的核心工作部件,其性能的优劣将直接影响模切机的模切精度和速度。

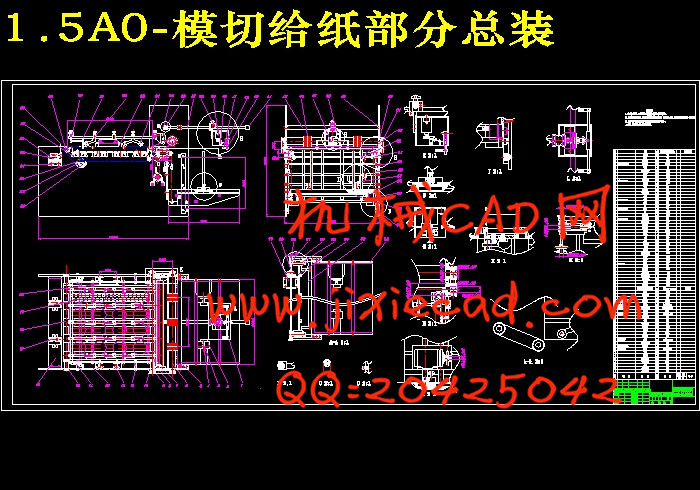

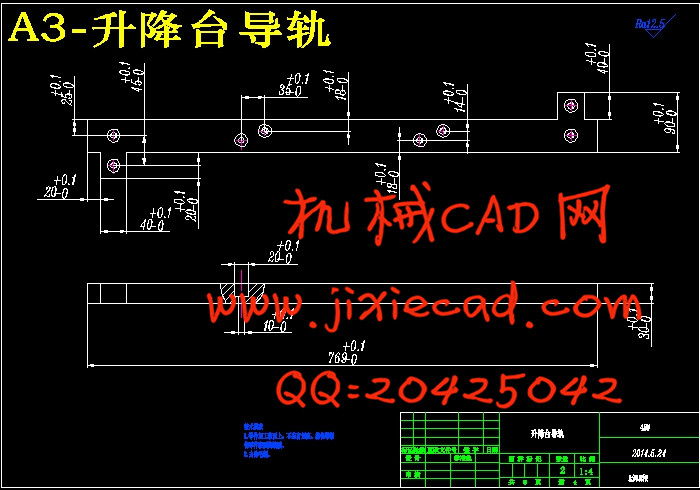

本文主要介绍模切机的发展状况,在认真分析现有模切机给纸部分特点后,大量查阅资料,确定一种更为合适的方案进行设计。该方案的原理是由电动机产生动力带动链条使纸堆升降台上升,由分纸头的吹气、吸气过程分离出单张纸,再由吸气滚轮将纸递到输纸机构,输纸机构的皮带带动纸运动,经过侧规、前规规整后传递到模切部分。

文章阐述了给纸部分的设计方案,包括纸堆升降装置、单张纸分离装置、递纸装置和输纸装置。

关键词:模切机给纸部分 结构设计 步进电机

ABSTRACT

With the rapid development of modern technology, as the important equipment in printing industry, automatic die-cutting machine has been oriented to high speed,high precision, high efficiency development of. Automatic die-cutting machine is important for the surface finishing equipment, packaging and printing industry.Paper feeding part mechanism is the core parts of automatic die-cutting machine,its performance will directly affect the die-cutting machine die cutting precision and speed.

This paper mainly introduces the development status of the die-cutting, die-cutting machine to a careful analysis of the existing advantages and disadvantages of part of the paper, looking up large amounts of data, to determine a more suitable for the design of. This method is generated by the motor drives the chain that stack lift rise, by blowing, paper suction processseparate sheet, then the suction roller will be paper to the paper feeding mechanism, paper feeding mechanism of belt driven paper movement, throughthe side, the former syndiospecific structured and transmitted to the die-cuttingpart.

This paper describes the design of a stack of paper paper, including lifting device, sheet separation device, paper feeding device and feeding device.

Keywords: die cutting machine overall and transmission parts structure design

目 录

1 绪论 1

1.1课题研究背景 1

1.2 课题研究意义 1

1.3 课题主要研究内容 2

2 方案设计 3

2.1模切机给纸部分设计要求 3

2.2方案的设计思路 3

2.3模切机给纸部分工艺流程 3

2.4模切机给纸部分方案的确定 4

2.4.1纸堆升降台的方案确定 4

2.4.2分纸机构的方案确定 5

2.4.3递纸机构的方案确定 8

2.5模切机输纸部分方案的确定 10

3 分纸头机构设计分析 12

3.1 给纸机构中分纸头介绍 12

3.2 分纸头的功用和组成 12

3.3 分纸头机构分析 13

3.4 吸纸滚轮机构分析 15

4 模切机给纸部分的机械计算 17

4.1电机的选择 17

4.2 同步带传动计算 20

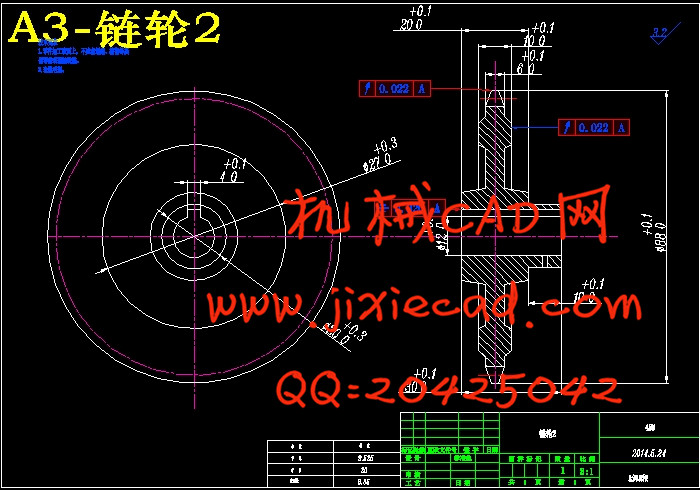

4.2.1 同步带计算选型 20

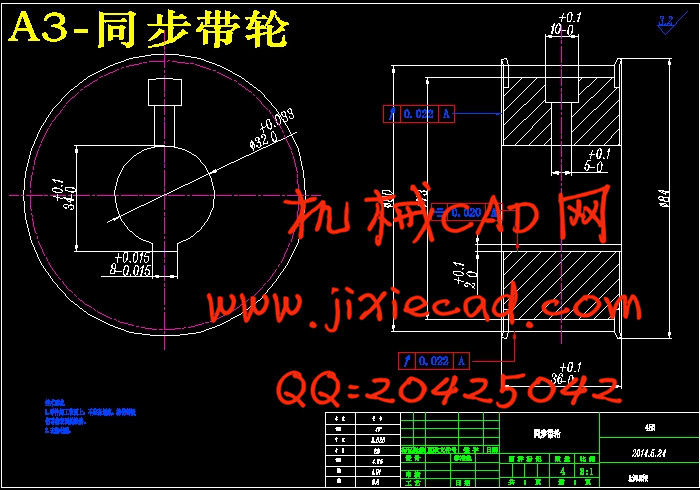

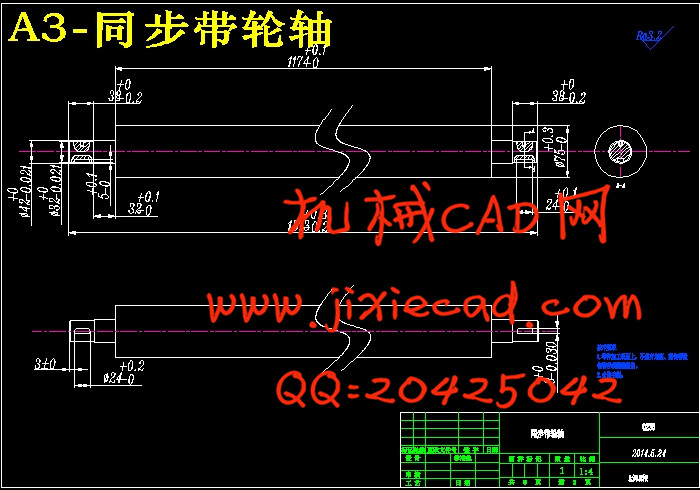

4.2.2 同步带的主要参数(结构部分) 23

4.3 同步带的设计 25

4.4 同步带轮的设计 26

结 论 27

参考文献 28

致 谢 29

随着现代科技的高速发展,作为印后加工中的重要设备,自动模切机已经面向高速度,高精度,高效率的方向发展。自动平压模切机是包装印刷工业中重要的表面整饰设备。给纸部分机构是自动模切机的核心工作部件,其性能的优劣将直接影响模切机的模切精度和速度。

本文主要介绍模切机的发展状况,在认真分析现有模切机给纸部分特点后,大量查阅资料,确定一种更为合适的方案进行设计。该方案的原理是由电动机产生动力带动链条使纸堆升降台上升,由分纸头的吹气、吸气过程分离出单张纸,再由吸气滚轮将纸递到输纸机构,输纸机构的皮带带动纸运动,经过侧规、前规规整后传递到模切部分。

文章阐述了给纸部分的设计方案,包括纸堆升降装置、单张纸分离装置、递纸装置和输纸装置。

关键词:模切机给纸部分 结构设计 步进电机

ABSTRACT

With the rapid development of modern technology, as the important equipment in printing industry, automatic die-cutting machine has been oriented to high speed,high precision, high efficiency development of. Automatic die-cutting machine is important for the surface finishing equipment, packaging and printing industry.Paper feeding part mechanism is the core parts of automatic die-cutting machine,its performance will directly affect the die-cutting machine die cutting precision and speed.

This paper mainly introduces the development status of the die-cutting, die-cutting machine to a careful analysis of the existing advantages and disadvantages of part of the paper, looking up large amounts of data, to determine a more suitable for the design of. This method is generated by the motor drives the chain that stack lift rise, by blowing, paper suction processseparate sheet, then the suction roller will be paper to the paper feeding mechanism, paper feeding mechanism of belt driven paper movement, throughthe side, the former syndiospecific structured and transmitted to the die-cuttingpart.

This paper describes the design of a stack of paper paper, including lifting device, sheet separation device, paper feeding device and feeding device.

Keywords: die cutting machine overall and transmission parts structure design

目 录

1 绪论 1

1.1课题研究背景 1

1.2 课题研究意义 1

1.3 课题主要研究内容 2

2 方案设计 3

2.1模切机给纸部分设计要求 3

2.2方案的设计思路 3

2.3模切机给纸部分工艺流程 3

2.4模切机给纸部分方案的确定 4

2.4.1纸堆升降台的方案确定 4

2.4.2分纸机构的方案确定 5

2.4.3递纸机构的方案确定 8

2.5模切机输纸部分方案的确定 10

3 分纸头机构设计分析 12

3.1 给纸机构中分纸头介绍 12

3.2 分纸头的功用和组成 12

3.3 分纸头机构分析 13

3.4 吸纸滚轮机构分析 15

4 模切机给纸部分的机械计算 17

4.1电机的选择 17

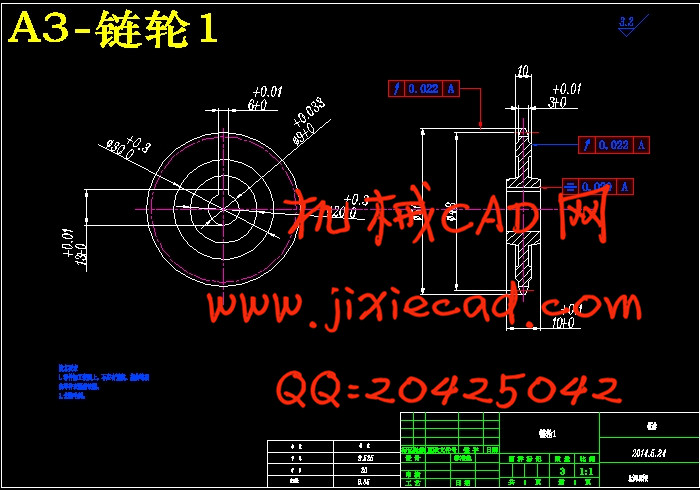

4.2 同步带传动计算 20

4.2.1 同步带计算选型 20

4.2.2 同步带的主要参数(结构部分) 23

4.3 同步带的设计 25

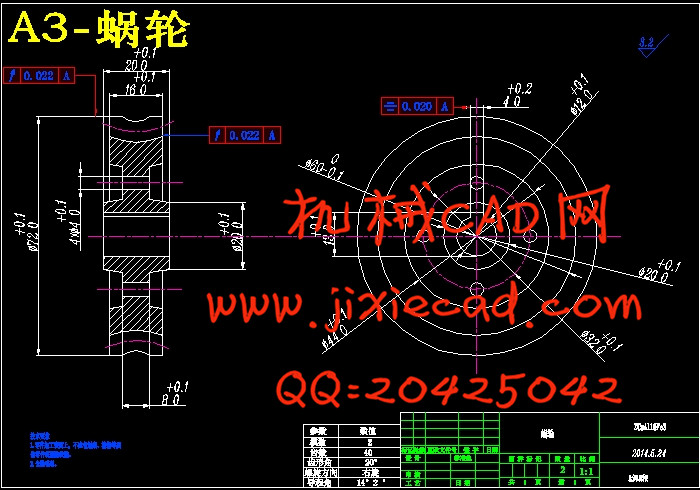

4.4 同步带轮的设计 26

结 论 27

参考文献 28

致 谢 29