设计简介

摘 要

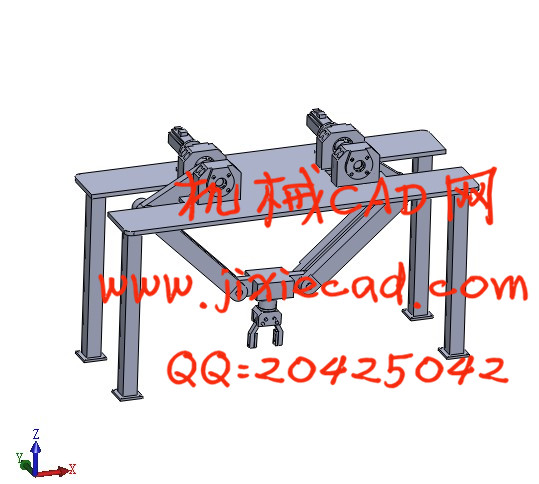

纽扣自动冲压组装台异形零件夹持装置采用夹持机构进行设计.夹持机构具有刚度大、承载能力强、误差小、精度高、自重负荷比小、动力性能好、控制容易等一系列优点可以作为航天上的对接器、航海上的潜艇救援对接器;工业上可以作为大件的装配机器人、精密操作的微动器;可以在汽车总装线上自动安装车轮部件;另外,医用机器人,天文望远镜等都利用了并联技术。

本文夹持机构的研究方向:

(1)夹持机构组成原理的研究

研究夹持机构自由度计算、运动副类型、支铰类型以及运动学分析、建模与仿真等问题。

(2)夹持机构运动空间的研究

(3)夹持机构结构设计的研究

夹持机构的结构设计包括很多内容,如机构的总体布局、安全机构设计。

由于本人水平有限,文中的错误和不足在所难免,恳请各位老师给予批评和指正。

关键词:机械手;虚拟样机;夹持机构

纽扣自动冲压组装台异形零件夹持装置采用夹持机构进行设计.夹持机构具有刚度大、承载能力强、误差小、精度高、自重负荷比小、动力性能好、控制容易等一系列优点可以作为航天上的对接器、航海上的潜艇救援对接器;工业上可以作为大件的装配机器人、精密操作的微动器;可以在汽车总装线上自动安装车轮部件;另外,医用机器人,天文望远镜等都利用了并联技术。

本文夹持机构的研究方向:

(1)夹持机构组成原理的研究

研究夹持机构自由度计算、运动副类型、支铰类型以及运动学分析、建模与仿真等问题。

(2)夹持机构运动空间的研究

(3)夹持机构结构设计的研究

夹持机构的结构设计包括很多内容,如机构的总体布局、安全机构设计。

由于本人水平有限,文中的错误和不足在所难免,恳请各位老师给予批评和指正。

关键词:机械手;虚拟样机;夹持机构

Abstract

Parallel mechanism with high rigidity, strong bearing capacity, small error, high precision, small self-weight loading ratio, good dynamic performance, easy control and a series of advantages can be used as a submarine rescue docking docking device, maritime space on; the industry can be used as micro - actuator assembly machines, large precision operation; you can automatically install the wheel assembly in automobile assembly line; in addition, medical robotics, astronomical telescope, using parallel technology.

The direction of the research of parallel mechanism:

(1) study on the principle of parallel mechanism.

The degree of freedom parallel mechanism, motion pair of calculation type, hinge type and kinematic analysis, modeling and Simulation of the.

(2) for parallel mechanism workspace

Including the motion space analysis and simulation, the reachable workspace solution (such as numerical method, sphere coordinate searching method etc.), mechanism of interference analysis and location.

(3) for parallel mechanism structure design

Structure design of parallel mechanism includes many contents, such as the design of general layout, organization security mechanism.

Because of my limited ability, mistakes and shortcomings in this paper can hardly be avoided, ask teachers to give the criticism and correction.

Key words: three degree of freedom parallel mechanism; virtual prototype;

Parallel mechanism with high rigidity, strong bearing capacity, small error, high precision, small self-weight loading ratio, good dynamic performance, easy control and a series of advantages can be used as a submarine rescue docking docking device, maritime space on; the industry can be used as micro - actuator assembly machines, large precision operation; you can automatically install the wheel assembly in automobile assembly line; in addition, medical robotics, astronomical telescope, using parallel technology.

The direction of the research of parallel mechanism:

(1) study on the principle of parallel mechanism.

The degree of freedom parallel mechanism, motion pair of calculation type, hinge type and kinematic analysis, modeling and Simulation of the.

(2) for parallel mechanism workspace

Including the motion space analysis and simulation, the reachable workspace solution (such as numerical method, sphere coordinate searching method etc.), mechanism of interference analysis and location.

(3) for parallel mechanism structure design

Structure design of parallel mechanism includes many contents, such as the design of general layout, organization security mechanism.

Because of my limited ability, mistakes and shortcomings in this paper can hardly be avoided, ask teachers to give the criticism and correction.

Key words: three degree of freedom parallel mechanism; virtual prototype;

目 录

1 前 言 1

1.1 课题研究背景意义 1

1.2 国内外研究现状 2

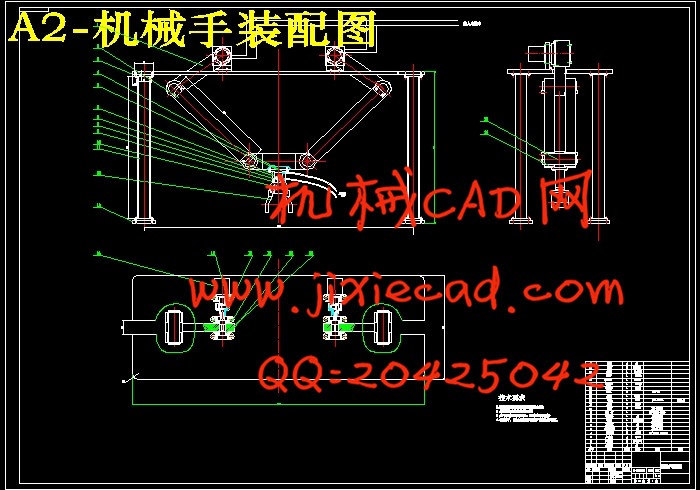

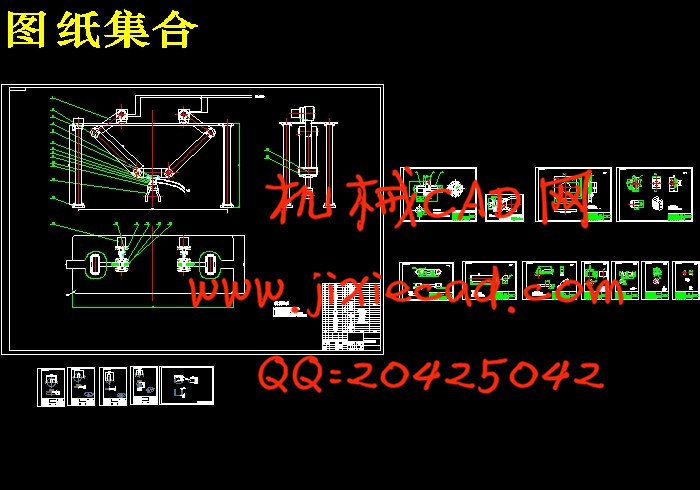

2 并联机械手的结构及工作原理 6

2.1 并联运动机构概述 6

2.2并联的结构及机械运动原理 7

2.3 控制系统结构及工作原理 7

2.4 夹持机构工作空间的分析 9

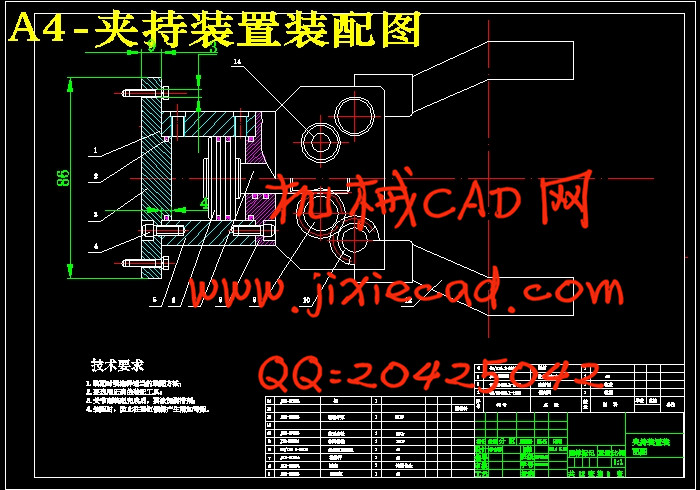

3 夹持机构主要部件的设计 10

3.1 电动机选型 10

3.1.1电机的分类 10

3.1.2选择步进电机的计算 11

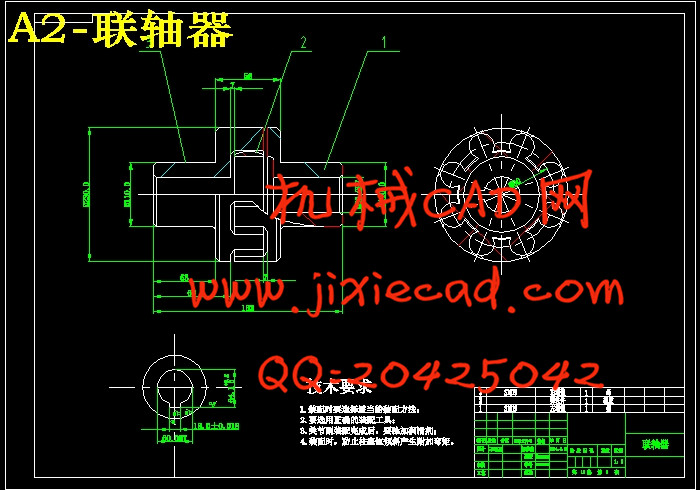

3.2 传动结构形式的选择 14

3.3 几何参数的计算 14

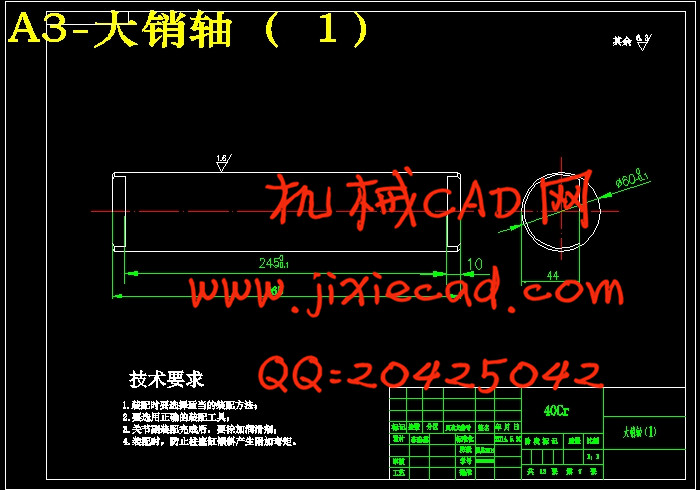

3.4 轴的设计及校核 15

3.5 轴承的寿命校核 17

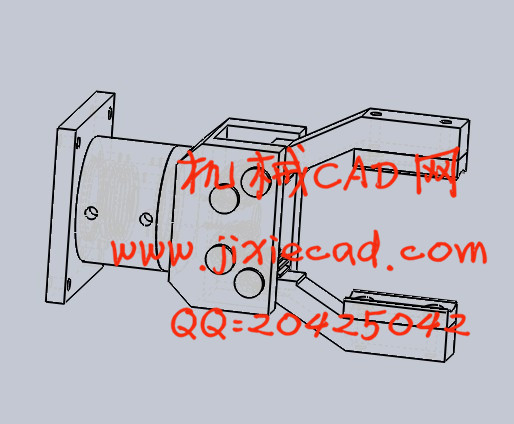

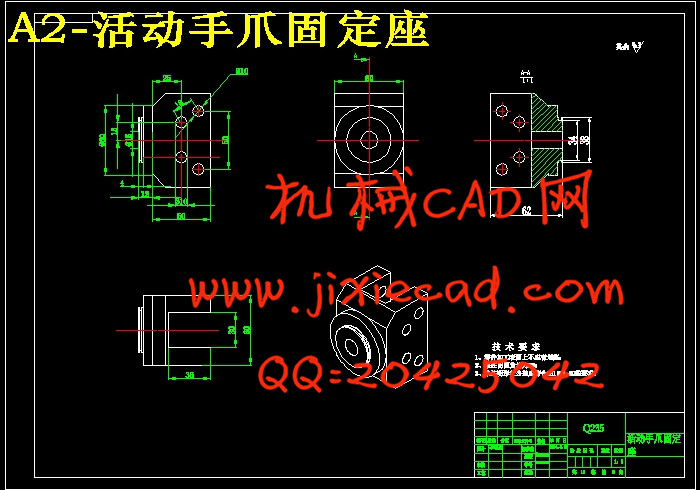

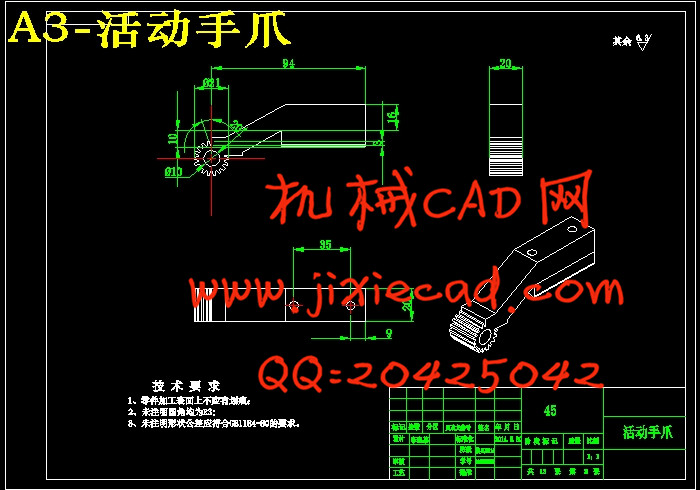

3.6 手爪夹持器结构设计与校核 19

3.6.1手爪夹持器种类 19

3.6.2夹持器设计计算 20

3.7 夹持装置气缸设计计算 21

3.7.1 初步确系统压力 21

3.7.2气缸计算 22

3.7.3 活塞杆的计算校核 24

3.7.4 气缸工作行程的确定 24

3.7.5 活塞的设计 25

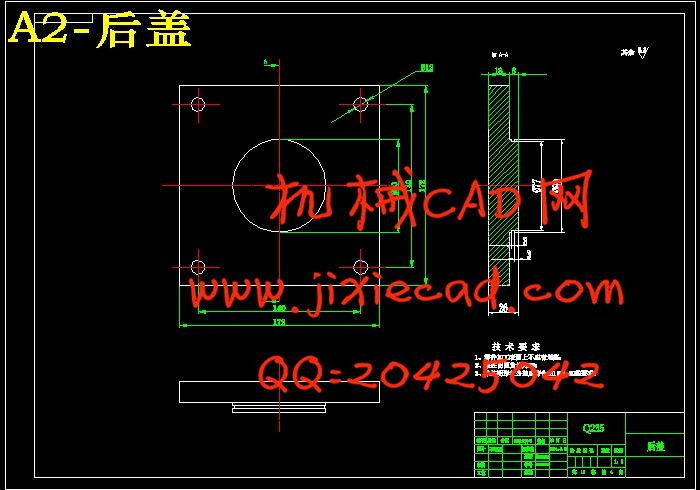

3.7.6 导向套的设计与计算 25

3.7.7 端盖和缸底的计算校核 26

3.7.8 缸体长度的确定 27

3.7.9 缓冲装置的设计 27

3.8 气压元件选取及工作原理 27

3.8.1 气源装置 27

3.8.2 执行元件 28

3.8.3 控制元件 29

3.8.4 辅助元件 30

3.8.5 真空发生器 31

4 夹持机构机夹持机构空间分析 32

4.1夹持机构夹持机构机的运动学约束 32

4.1.1 连杆杆长约束 32

4.1.2 运动副转角约束 32

4.1.3 连杆杆间干涉 33

4.2 确定夹持机构空间的基本方法 33

总 结 34

参 考 文 献 35

致 谢 36