设计简介

摘 要

本文以变速箱壳体镗床组合机床为研究对象,通过对主要结构和运动形式的探究以及对机床的工作过程和控制要求分析,给出了机床动作循环图、液压元件动作表;并采用PLC控制系统的设计方法, 进行了软硬件设计,列出了PLC的I/O地址分配表,绘制了PLC的I/O分配图和单循环自动工作流程图,编写PLC控制程序的梯形图使整个控制系统的操作变得简单,大大提高了系统的自动化程度和实用性。本文首先介绍PLC和组合机床的历史与发展,并着重论述了组合机床的结构和运动形式以及控制方式,接着对PLC的组成和结构进行了分析,并对PLC控制系统的总体设计和程序的表达方式做了概述,接着根据相关内容画出顺序功能图并利用FX-2N画出PLC梯形图。在文章的最后还介绍了PLC控制系统安装维护以及对论文的进一步总结。

关键词: 变速箱壳体,组合机床,可编程控制器(PLC);控制系统

Abstract

In this paper, the shell of the gearbox boring machine tool as the object of study, through to the main structure and motion forms of inquiry and the working process and the control of machine tools for analysis, given the machine cycle diagram, hydraulic element action table; and the design method of PLC control system, the hardware and the software are designed, a list of PLC I/O address allocation table, rendering the I/O distribution in figure PLC and single cycle automatic work flow diagram, write the PLC control program of ladder diagram of the whole control system operation to be simple, greatly improving the degree of automation system and practical.

The history and development of PLC and the combination of machine tool are introduced first, and focuses on the combination of machine tool structure and form of movement and control method, and then the composition and structure of PLC are analyzed, and the overall design and program of PLC control system of expression are summarized, and then according to the related content to draw the sequential function chart and the use of FX-2N to draw the PLC ladder diagram. At the end of the article also introduces the PLC control system installation and maintenance and further summarizes the thesis.

Keywords: shell of the gearbox, combination machine, programmable logic controller (PLC); control system

The history and development of PLC and the combination of machine tool are introduced first, and focuses on the combination of machine tool structure and form of movement and control method, and then the composition and structure of PLC are analyzed, and the overall design and program of PLC control system of expression are summarized, and then according to the related content to draw the sequential function chart and the use of FX-2N to draw the PLC ladder diagram. At the end of the article also introduces the PLC control system installation and maintenance and further summarizes the thesis.

Keywords: shell of the gearbox, combination machine, programmable logic controller (PLC); control system

目 录

摘 要 IIAbstract III

目 录 IV

1 绪论 1

1.1 组合机床的概述 1

1.1.1 组合机床的概念 1

1.1.2 双面组合镗床的介绍 1

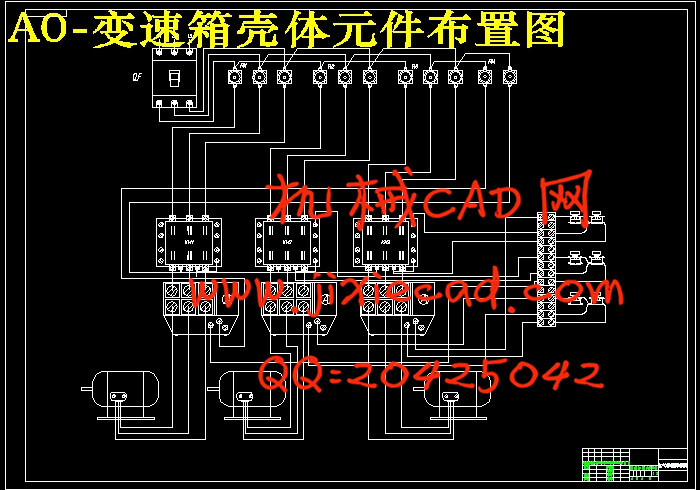

1.2 组合机床装配模型 2

1.3 可编程序控制器及应用 2

1.3.1 可编程序控制器概述 2

1.3.2 可编程控制器的结构和工作方式 3

1.3.3 三菱F2系列PLC及其指令系统 6

1.4 PLC控制系统设计存在的问题 7

1.5 课题内容及其研究目标 8

2 组合机床的电气控制线路设计 10

2.1 选择并确定控制方案 10

2.2 确定机床的工作循环 11

2.3 确定液压动力滑台系统的工作过程 12

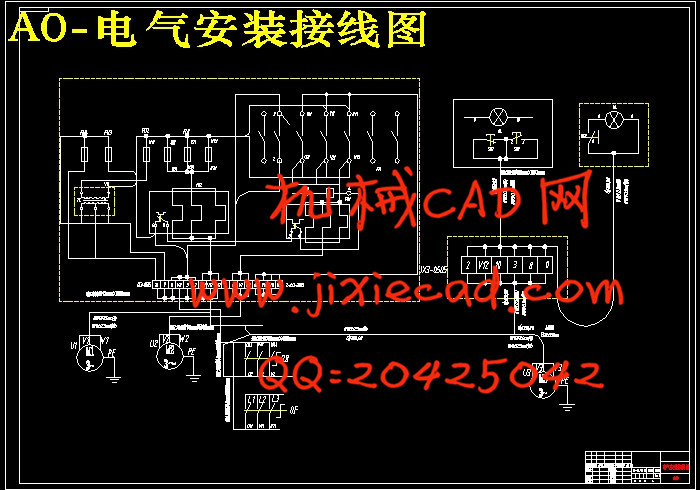

2.4 机床电气控制线路设计 14

2.5 选择电气元件 15

2.5.1 电动机M1、M2、M3的选择 15

2.5.2 电源引入开关的选择 16

2.5.3 热继电器的选择 16

2.5.4 压力继电器KP 16

2.5.5 中间继电器的选择 17

2.5.6 熔断器的选择 17

2.5.7 接触器的选择 17

2.5.8 控制变压器的选择 18

2.5.9 行程开关的选择 18

2.5.10 控制开关的选择 19

2.6 制定电动机和电气元件明细表 19

2.7 电气控制原理图 20

2.8 电气安装接线图 21

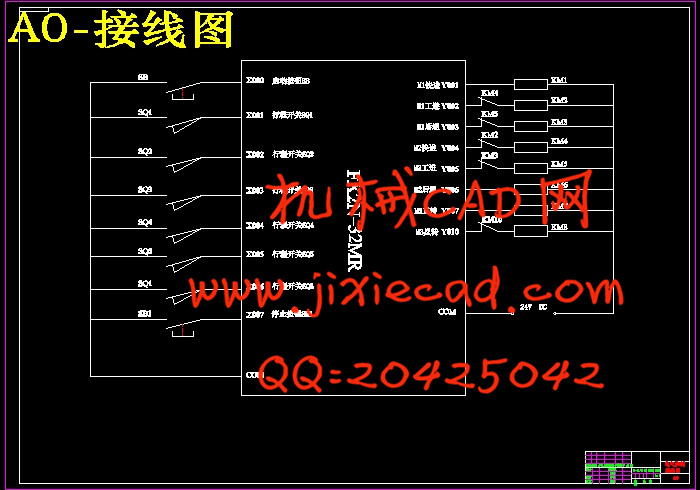

3 可编程控制系统的设计 22

3.1 在设计可编程控制器系统时应遵循的基本原则 22

3.2 工艺要求及动作流程 22

3.3 PLC选型 22

3.4 I/O点地址编号及硬件接线 25

4 PLC的编程 27

4.1 概述 27

4.2 编程语言的形式 27

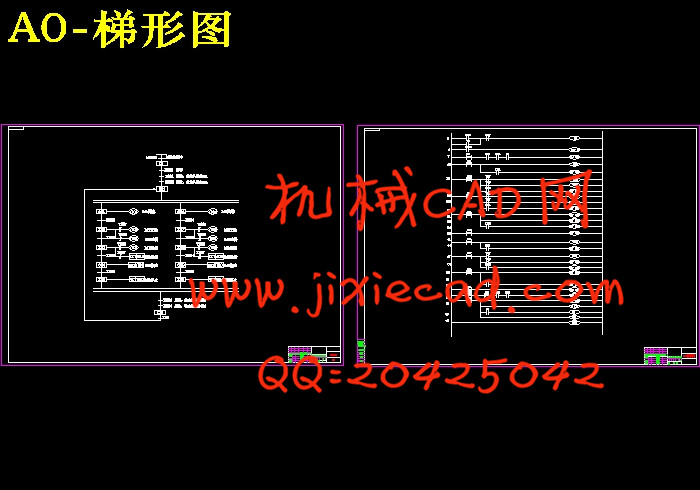

4.3 PLC控制的程序设计 29

4.3.1 顺序功能图的绘制 29

4.3.2 PLC 控制梯形图 30

4.4 本章小结 33

5 PLC注意事项及调试维护 34

结 论 37

致 谢 38

参考文献 39