设计简介

摘 要

国内薄煤层开采在许多矿井中都面临着很多的问题,而朔里矿区也是如此。随着矿井可采储量的日益枯竭,薄煤层的开采问题已越来越突出。 由于开采设备原因,对于1.3~1.5m的较薄煤层开采,机械化程度普遍不高,其生产效率也比较低。薄煤层开采制约了下序其它煤层的开采速度,直接影响着 矿井高产高效生产。较薄煤层使用大架型机械设备进行开采,不仅开采成本增高,而且顶板常会被切割,导致煤炭灰分增高,甚至资源不能得到回收。

目前国内的薄 煤层综采技术,尤其是综采机械化装备配套技术还很不成熟,正处于探索阶段。对于大倾角较薄煤层综采方面的现场技术实践就更少了, 其理论研究工作也相对薄弱。根据我们朔里矿业的自然资源情况,有些就属于大倾角薄煤层。因此,积极探索机械化开采途径就很有必要。

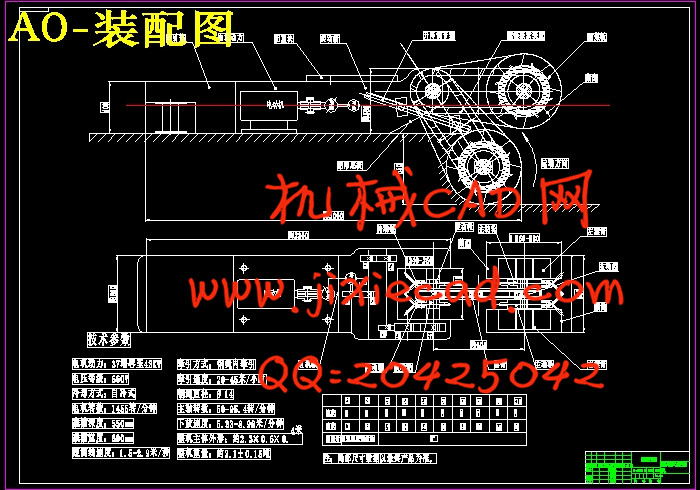

本课题分析的在机械式采煤机基础上改成液压式的采煤机。主要进行了液压式俯采采煤机总体方案设计,液压式俯采采煤机截煤部结构设计,液压式俯采采煤机牵引部结构设计及计算。

关键词:煤层;开采;机械式;液压式

国内薄煤层开采在许多矿井中都面临着很多的问题,而朔里矿区也是如此。随着矿井可采储量的日益枯竭,薄煤层的开采问题已越来越突出。 由于开采设备原因,对于1.3~1.5m的较薄煤层开采,机械化程度普遍不高,其生产效率也比较低。薄煤层开采制约了下序其它煤层的开采速度,直接影响着 矿井高产高效生产。较薄煤层使用大架型机械设备进行开采,不仅开采成本增高,而且顶板常会被切割,导致煤炭灰分增高,甚至资源不能得到回收。

目前国内的薄 煤层综采技术,尤其是综采机械化装备配套技术还很不成熟,正处于探索阶段。对于大倾角较薄煤层综采方面的现场技术实践就更少了, 其理论研究工作也相对薄弱。根据我们朔里矿业的自然资源情况,有些就属于大倾角薄煤层。因此,积极探索机械化开采途径就很有必要。

本课题分析的在机械式采煤机基础上改成液压式的采煤机。主要进行了液压式俯采采煤机总体方案设计,液压式俯采采煤机截煤部结构设计,液压式俯采采煤机牵引部结构设计及计算。

关键词:煤层;开采;机械式;液压式

ABSTRACT

The thin coal seam mining are facing a lot of problems in many mines, and Shuoli kaolin and so. With the increasing depletion of the mine recoverable reserves, mining of thin coal seam has been more and more prominent. Because of mining equipment, for 1.3 ~ 1.5m of thin seam mining, the degree of mechanization is generally not high, the production efficiency is low. Thin coal seam mining restricts the speed of order other coal mining, directly affects the high production and high efficient mine. The thin coal seam with large mechanical equipment for mining, not only the mining cost increased, and the roof is often cut, resulting in coal ash content increased, and even the resources can not be recovered. Thin seam mining technology in China at present, especially the fully mechanized mining equipment technology is not very mature, is in the stage of exploration. For the practical field large inclination of thin seam mining area is less, the theoretical research is relatively weak. According to the mining of natural resources of our moon, some belong to the thin coal seam with large inclined angle. Therefore, it is necessary to explore the positive mechanized mining method.

Analysis on the mechanical coal mining machine based on the change of the coal mining machine hydraulic. Mainly to the overall scheme design of hydraulic shearer underhand, shearer cutting structure design of hydraulic bent mining, hydraulic down coal shearer structure design and calculation.

Keywords: coal seam; mining machinery; hydraulic;

The thin coal seam mining are facing a lot of problems in many mines, and Shuoli kaolin and so. With the increasing depletion of the mine recoverable reserves, mining of thin coal seam has been more and more prominent. Because of mining equipment, for 1.3 ~ 1.5m of thin seam mining, the degree of mechanization is generally not high, the production efficiency is low. Thin coal seam mining restricts the speed of order other coal mining, directly affects the high production and high efficient mine. The thin coal seam with large mechanical equipment for mining, not only the mining cost increased, and the roof is often cut, resulting in coal ash content increased, and even the resources can not be recovered. Thin seam mining technology in China at present, especially the fully mechanized mining equipment technology is not very mature, is in the stage of exploration. For the practical field large inclination of thin seam mining area is less, the theoretical research is relatively weak. According to the mining of natural resources of our moon, some belong to the thin coal seam with large inclined angle. Therefore, it is necessary to explore the positive mechanized mining method.

Analysis on the mechanical coal mining machine based on the change of the coal mining machine hydraulic. Mainly to the overall scheme design of hydraulic shearer underhand, shearer cutting structure design of hydraulic bent mining, hydraulic down coal shearer structure design and calculation.

Keywords: coal seam; mining machinery; hydraulic;

目 录

第1章 绪 论 - 1 -

1.1 采煤机国内外研究现状 - 1 -

1.2大倾角薄煤层开采技术及设备概述 - 2 -

1.2.1 概述 - 2 -

1.2.2 选择合适的综采配套设备 - 2 -

1.2.3 回采技术工艺 - 3 -

1.2.4 支架和运输机防倒滑措施 - 3 -

1.2.5 结束语 - 4 -

第2章 液压式俯采采煤机总体方案设计 - 5 -

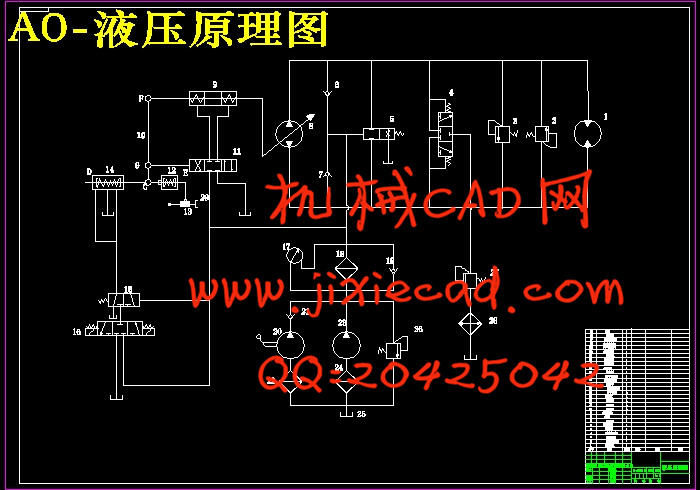

2.1 采煤机牵引部液压系统得特点 - 5 -

2.2 设计参数 - 5 -

2.3 主油路系统 - 5 -

2.4 调速及换向回路 - 7 -

2.5 保护系统 - 8 -

2.5.1 电动机功率过载保护 - 8 -

2.5.2 高压保护 - 9 -

2.5.3 低压欠压保护 - 9 -

2.5.4 停机油泵自动回零保护 - 9 -

2.5.5 闭式系统充油排气 - 9 -

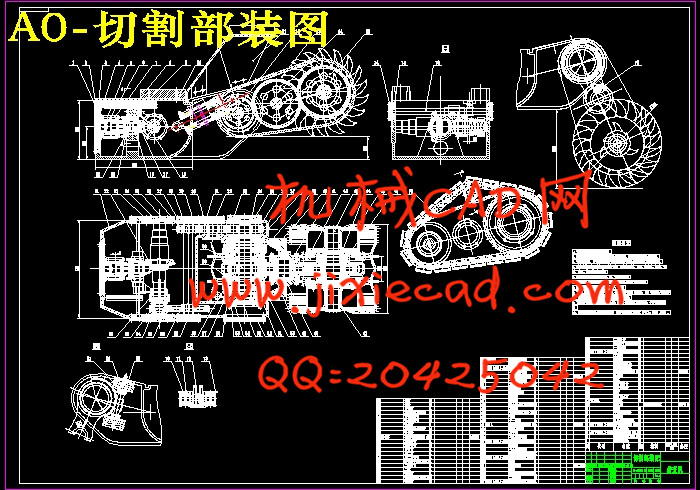

第3章 液压式俯采采煤机截割部结构设计 - 10 -

3.1 截割部概述 - 10 -

3.2 截割部特点 - 10 -

3.3 齿轮传动的设计计算 - 10 -

3.3.1 第一传动组齿轮设计计算 - 10 -

3.3.2 第二传动组齿轮设计计算 - 20 -

3.3.3 第三传动组齿轮设计计算 - 27 -

第4章 液压式俯采采煤机截煤部结构设计 - 36 -

4.1 截一轴及其轴承寿命验算 - 36 -

4.1.1 求轴上的载荷 - 36 -

4.1.2 校核该轴的强度 - 37 -

4.2 截二轴的详细校核 - 37 -

4.2.1 求轴上的载荷 - 37 -

4.2.2 校核该轴的强度 - 39 -

4.3 截三轴的详细校核 - 40 -

4.3.1 求轴上的载荷 - 40 -

4.3.2 校核该轴的强度 - 41 -

4.3.3 轴承寿命的验算 - 42 -

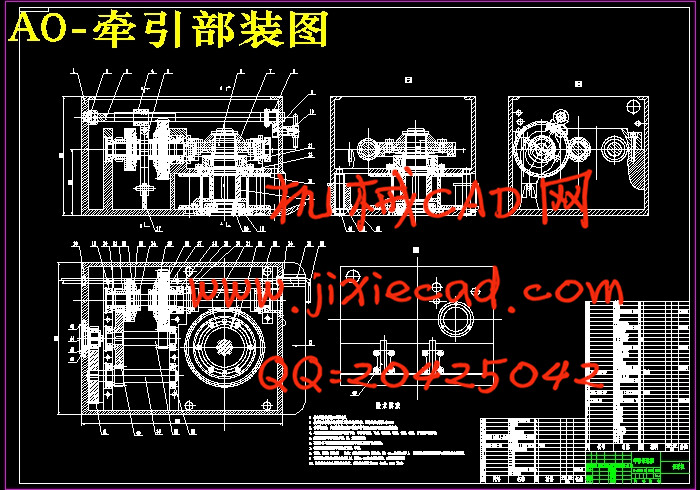

第5章 液压式俯采采煤机牵引部结构设计 - 43 -

5.1 牵引部传动系统的分析 - 43 -

5.2 各级齿轮的传动比的确定 - 43 -

5.3 主油泵和马达的计算 - 43 -

5.4 补油回路中辅助泵5的选择 - 47 -

5.5 采煤机牵引部液压控制元件的选择 - 48 -

5.6 牵引部液压系统的压力损失验算 - 50 -

5.7 牵引部液压系统得温升验算 - 51 -

5.8 牵引部辅助装置液压传动系统 - 52 -

第6章 辅助液压系统的设计计算 - 54 -

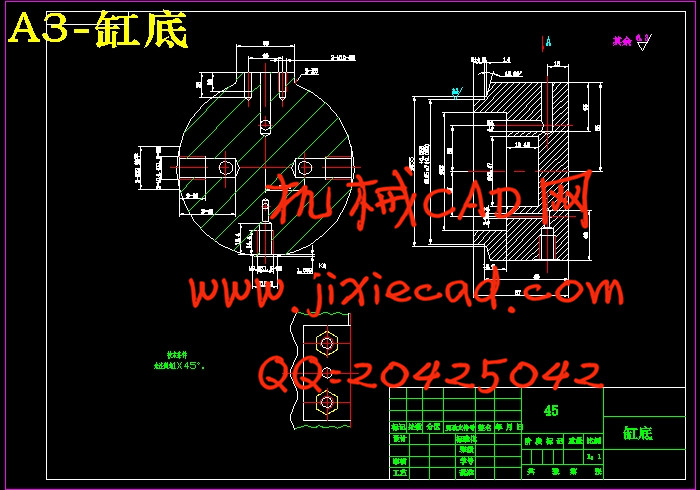

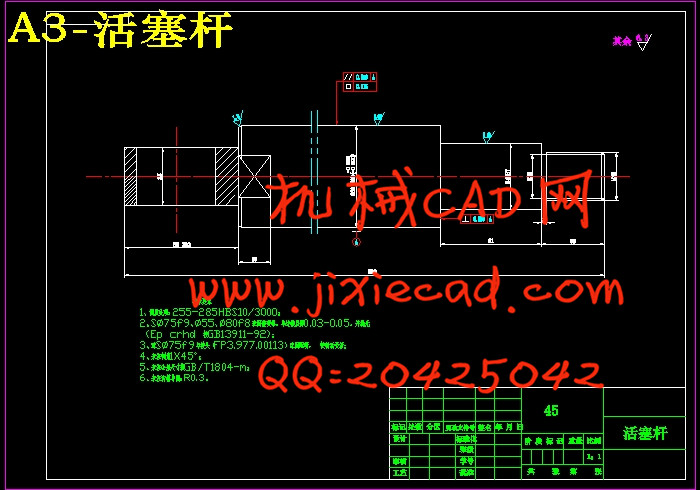

6.1 调高油缸的设计计算 - 54 -

6.2 调斜油缸的计算 - 55 -

6.3 防滑缸的计算 - 57 -

6.4 防转挡煤板油缸计算 - 57 -

6.5 辅助液压系统中元件的选择 - 58 -

总 结 - 59 -

参 考 文 献 - 60 -

致 谢 - 61 -