设计简介

摘 要

为适应我国现代化建设的需要,相信焊接技术必将得到更迅速的发展,并在工业生产中发展发挥出更重要的作用。随着工业生产的发展,对焊接技术提出了多种多样的要求。一方面由于工业生产的发展对焊接技术提出了高要求,另一方面由于科学技术的发展又为焊接技术的进步开拓了新的途径。另外我们也在不断探索新的焊接方法,从以前的几种焊接方法到现在的很多中,从最原始的手工电弧焊到现在的窄间隙埋弧焊、机器人焊接,从以前的焊工保护差到现在的焊工保护好,种种的种种都可以看出,我们国家在发展,我们的焊接技术同样在发展,在不久的将来更高端的焊接技术将被发现,该焊接技术价廉、劳动强度小,焊出来的东西更好更完美。

根据Q235钢选择合适的成型工艺以及焊接方法、编制合理的工艺规程、选择正确的装配方法、对焊接缺陷的预测、危害分析以及找出相关的补救措施。

关键词 焊接工艺,焊接方法,焊接缺,焊接检验

关键词 敞车侧墙;组焊夹具;定位;夹紧

为适应我国现代化建设的需要,相信焊接技术必将得到更迅速的发展,并在工业生产中发展发挥出更重要的作用。随着工业生产的发展,对焊接技术提出了多种多样的要求。一方面由于工业生产的发展对焊接技术提出了高要求,另一方面由于科学技术的发展又为焊接技术的进步开拓了新的途径。另外我们也在不断探索新的焊接方法,从以前的几种焊接方法到现在的很多中,从最原始的手工电弧焊到现在的窄间隙埋弧焊、机器人焊接,从以前的焊工保护差到现在的焊工保护好,种种的种种都可以看出,我们国家在发展,我们的焊接技术同样在发展,在不久的将来更高端的焊接技术将被发现,该焊接技术价廉、劳动强度小,焊出来的东西更好更完美。

根据Q235钢选择合适的成型工艺以及焊接方法、编制合理的工艺规程、选择正确的装配方法、对焊接缺陷的预测、危害分析以及找出相关的补救措施。

关键词 焊接工艺,焊接方法,焊接缺,焊接检验

关键词 敞车侧墙;组焊夹具;定位;夹紧

Abstract

The C70’s Sidewall is one of the main carrying components, it will affect the quality of vehicle’s carrying capacity. Improving manufacturing quality plays a very important role to improve railway freight capacity. Because the sidewall bear the force toward outside, Intensity and accuracy of sidewall become the focus of the work .To avoiding sidewall eviscerate and leaking of the door, I design the new C70’s sidewall welding technology and welding fixture.

In order to meet the need of our country modernization, believe that the welding technology will be more rapid development, and in the industrial production development play a more important role. With the development of industrial production, put forward various requirements on welding technology. On the one hand because of the development of industrial production has put forward high requirements on welding technology, on the other hand, due to the development of science and technology and the improvement of welding technology opens up a new way. We are constantly exploring new welding method, from the previous several welding methods to present a lot of manual electric arc welding, from the most primitive, narrow gap submerged arc welding current to robot welding, welding protection from previous difference to the welder protection now good, various kinds of can see, our country in the development of welding technology, we also in development, in the near future more high-end welding technology will be found, the welding technology is cheap, small labor intensity, welding out of something better and more perfect.

According to Q235 steel suitable forming process and welding method, the preparation of a reasonable process, choose the correct method of assembly, the welding defect prediction, hazard analysis and identify the relevant remedial measures.

key words welding, welding method, welding, welding inspection

The C70’s Sidewall is one of the main carrying components, it will affect the quality of vehicle’s carrying capacity. Improving manufacturing quality plays a very important role to improve railway freight capacity. Because the sidewall bear the force toward outside, Intensity and accuracy of sidewall become the focus of the work .To avoiding sidewall eviscerate and leaking of the door, I design the new C70’s sidewall welding technology and welding fixture.

In order to meet the need of our country modernization, believe that the welding technology will be more rapid development, and in the industrial production development play a more important role. With the development of industrial production, put forward various requirements on welding technology. On the one hand because of the development of industrial production has put forward high requirements on welding technology, on the other hand, due to the development of science and technology and the improvement of welding technology opens up a new way. We are constantly exploring new welding method, from the previous several welding methods to present a lot of manual electric arc welding, from the most primitive, narrow gap submerged arc welding current to robot welding, welding protection from previous difference to the welder protection now good, various kinds of can see, our country in the development of welding technology, we also in development, in the near future more high-end welding technology will be found, the welding technology is cheap, small labor intensity, welding out of something better and more perfect.

According to Q235 steel suitable forming process and welding method, the preparation of a reasonable process, choose the correct method of assembly, the welding defect prediction, hazard analysis and identify the relevant remedial measures.

key words welding, welding method, welding, welding inspection

目 录

目 录 V第1章 绪论 1

1.1 焊接夹具的作用 1

1.2 夹具设计的要求 2

1.2.1焊装夹具的功用 2

1.2.2焊装夹具设计原则 3

1.3 选择与设计焊接夹具类型的依据 4

第2章 转向架的制作工艺 5

2.1 母材的选择 5

2.2各支撑件的制造 6

2.2.1划线 6

2.2.2 号料 6

2.2.3 下料 6

2.3气割 7

2.4 钻孔 7

第3章 转向架的装配工艺 8

3.1坡口形式与焊接技术 8

3.1.1 坡口形式 8

3.1.2 坡口的加工方法 9

3.2 焊接工艺路线单 9

3.3焊接方法与设备 11

3.3.1手工电弧焊 11

3.3.2 CO2气体保护焊 12

3.3.3 MAG焊 14

3.4 焊接接头的常见缺陷与危害和补救措施 15

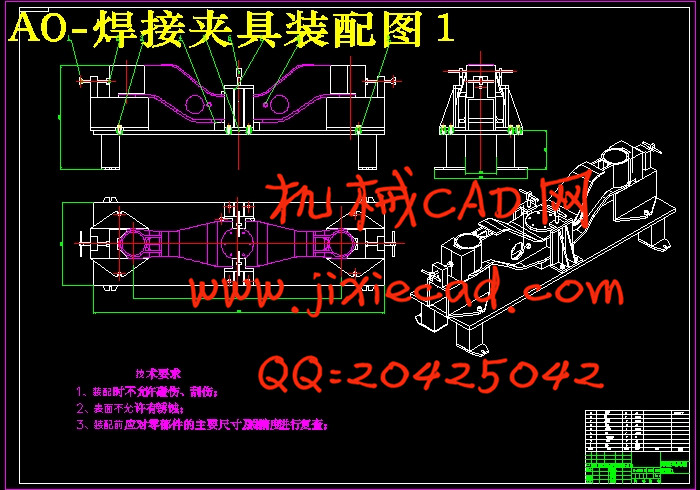

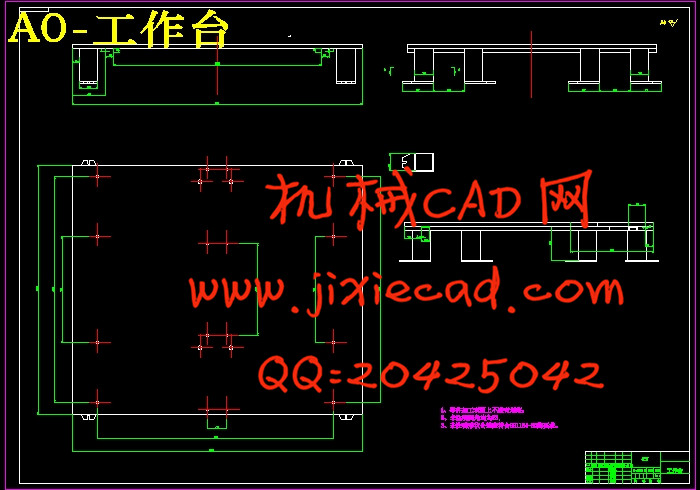

第4章 夹具的设计 17

4.1 焊接夹具的使用 17

4.2 焊接方法的选择 17

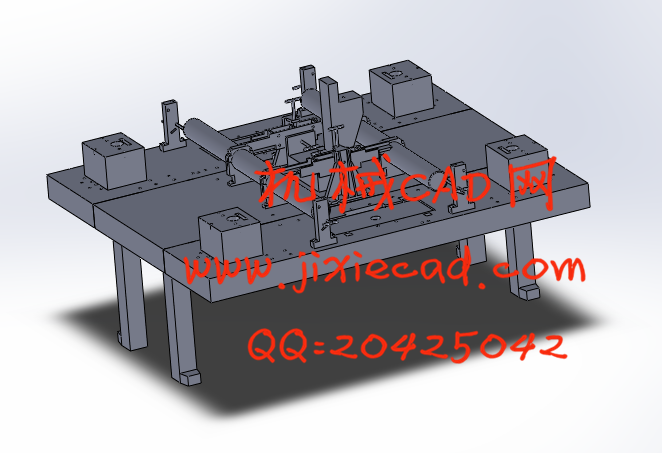

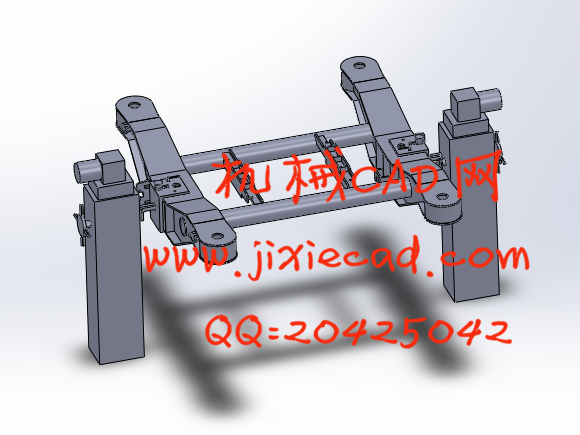

4.3 转向架焊接工位划分 18

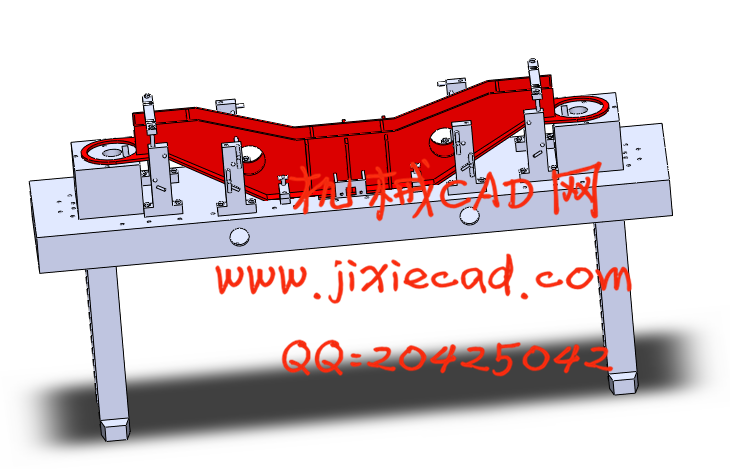

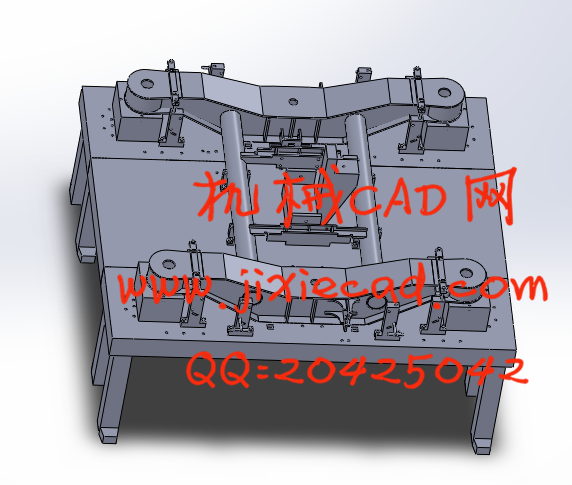

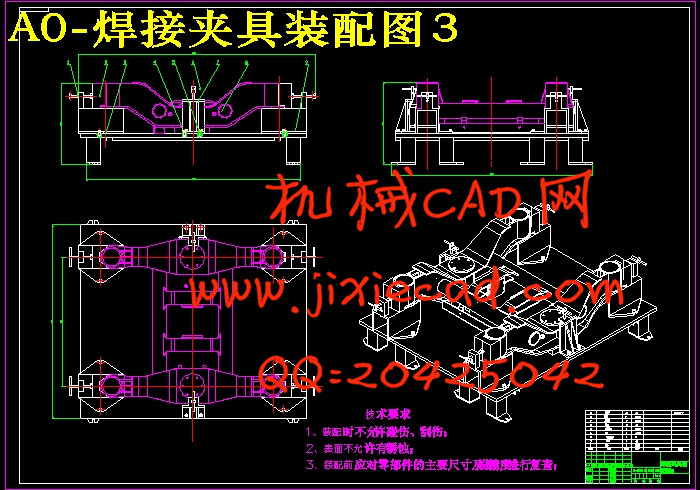

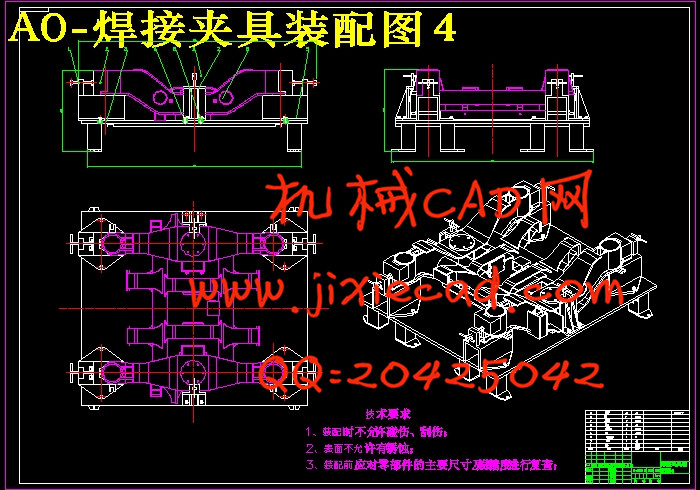

第5章 转向架组焊夹具设计 24

5.1 第一工位夹具设计 24

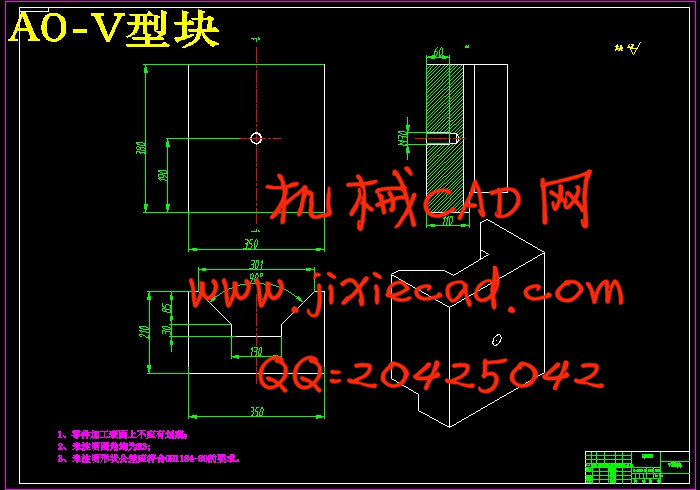

5.1.1 定位方案确定 24

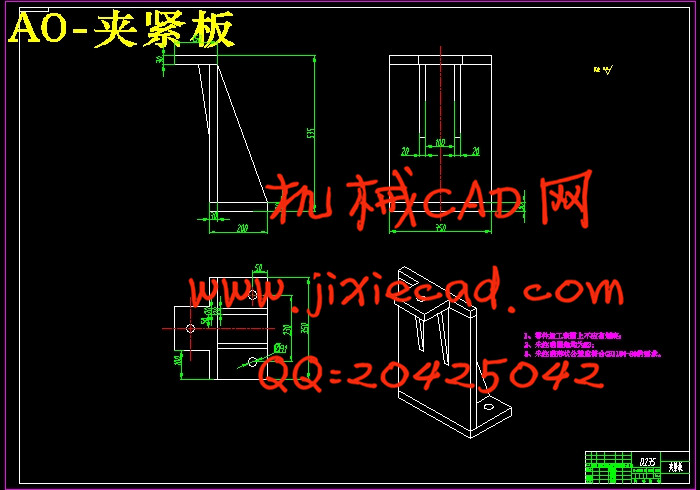

5.1.2 夹紧器设计 26

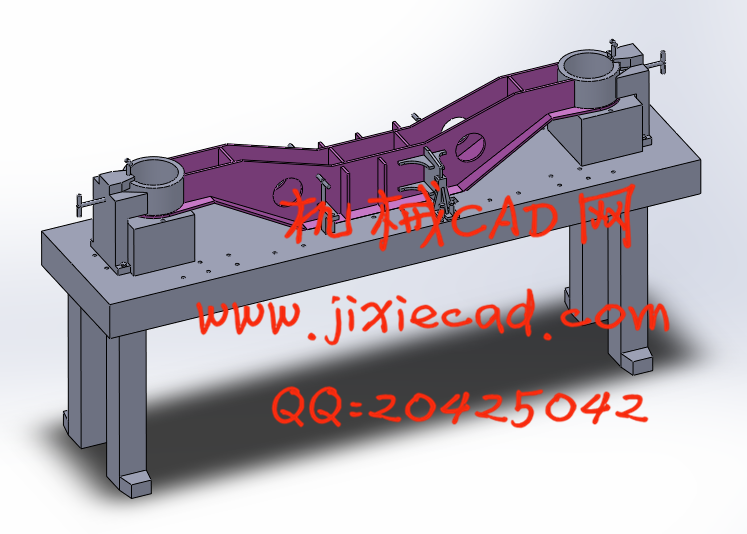

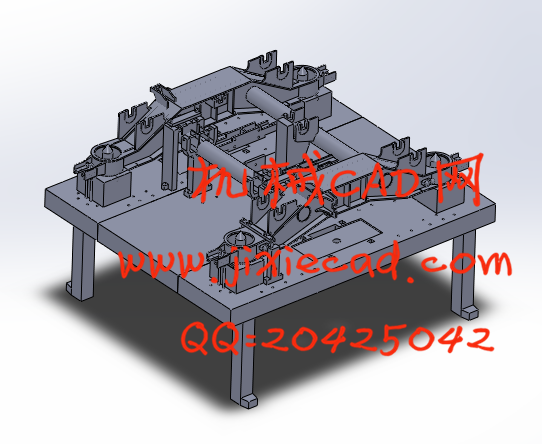

5.2 第二工位组焊夹具设计 27

5.2.1 第二工位总体布局方案 27

5.2.2 定位方案设计 27

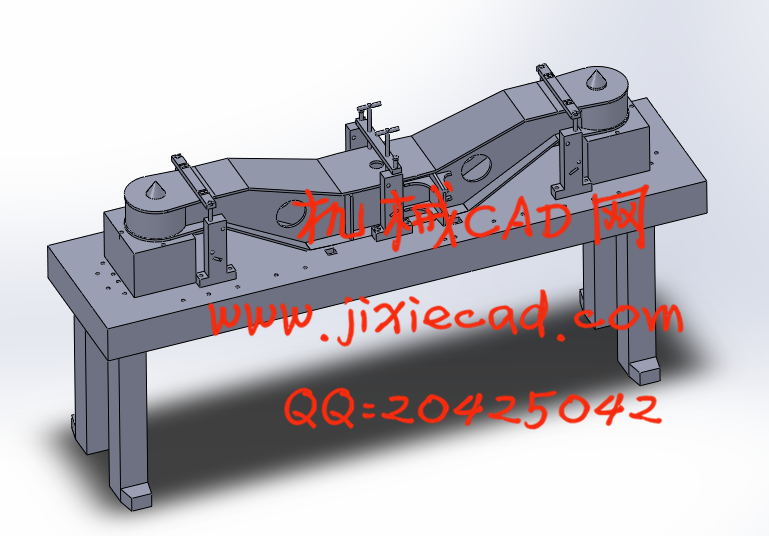

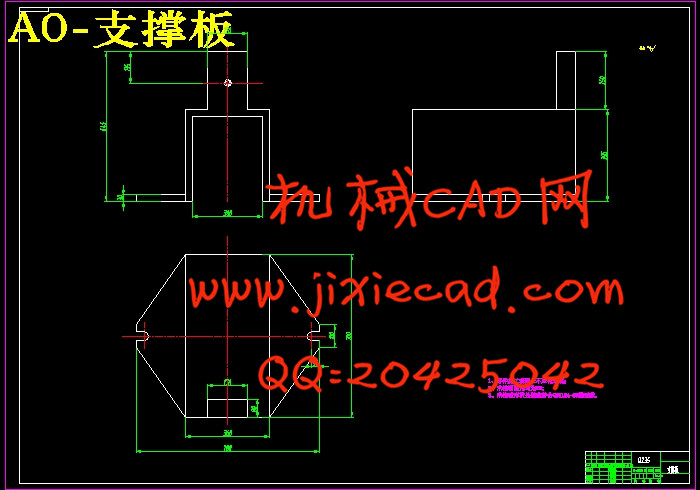

5.3 主要零件设计的说明 28

5.4装焊夹具使用说明 29

第6章 焊接检验 30

6.1 焊接检验的作用 30

6.2 焊接检验方法的确定 30

6.3 超声波检验的优点 30

6.4 采用超声波探伤的方法及设备 30

6.5 超声波探伤的实施步骤 30

结束语 32

致谢 33

参考文献 34