设计简介

本文主要介绍水性干式覆膜机的发展状况,水性干式覆膜机除粉装置结构设计原理,水性干式覆膜机除粉装置总体方案分析及确定,水性干式覆膜机除粉装置结构设计内容所包含的机械图纸的绘制,除粉装置的计算,结构设计结论与建议。

整机结构主要由电动机产生动力通过联轴器将需要的动力传递到带轮上,带轮带动导轨滑靴,提高劳动生产率和生产自动化水平。工业生产中经常出现的笨重工件的搬运和长期、频繁、单调的操作,采用除粉装置是有效的;此外,它能在高温、低温、深水、宇宙、放射性和其它有毒、污染环境条件下进行操作,更显示其优越性,有着广阔的发展前途。

本论文研究内容:

(1) 水性干式覆膜机除粉装置总体结构设计。

(2) 水性干式覆膜机除粉装置工作性能分析。

(3)电动机的选择。

(4) 水性干式覆膜机除粉装置的传动系统、执行部件及机架设计。

(5)对设计零件进行设计计算分析和校核。

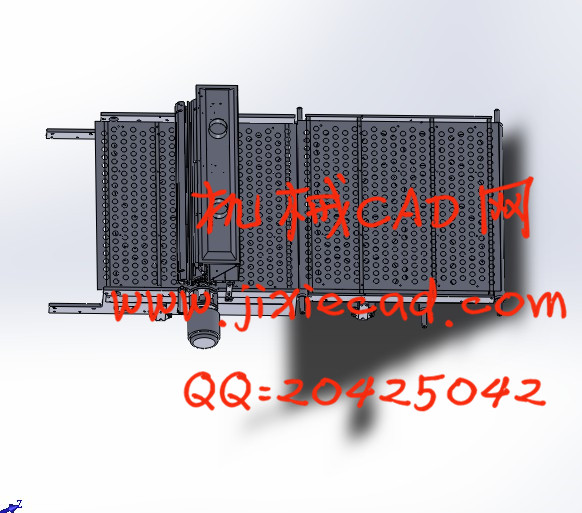

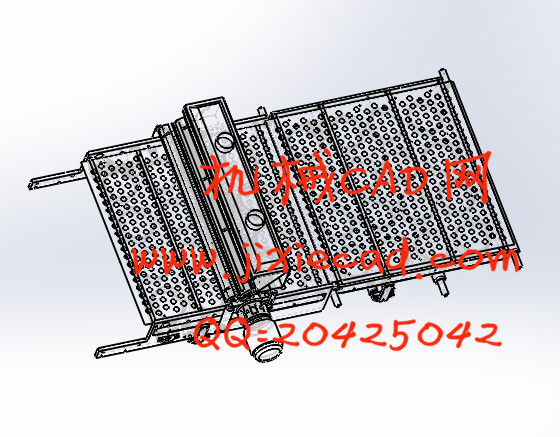

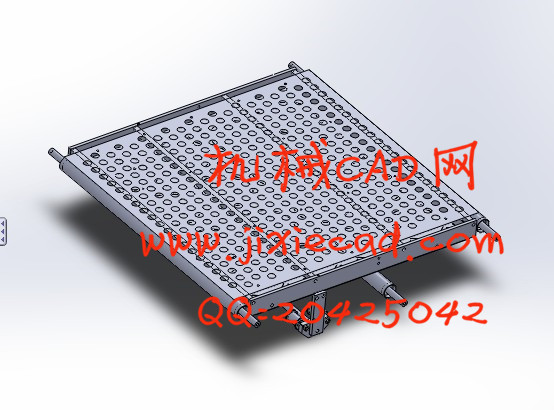

(6)运用计算机辅助设计,对设计的零件进行三维建模。

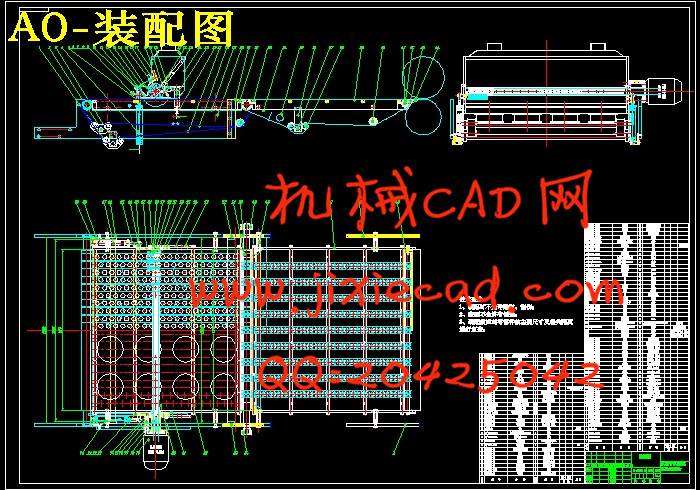

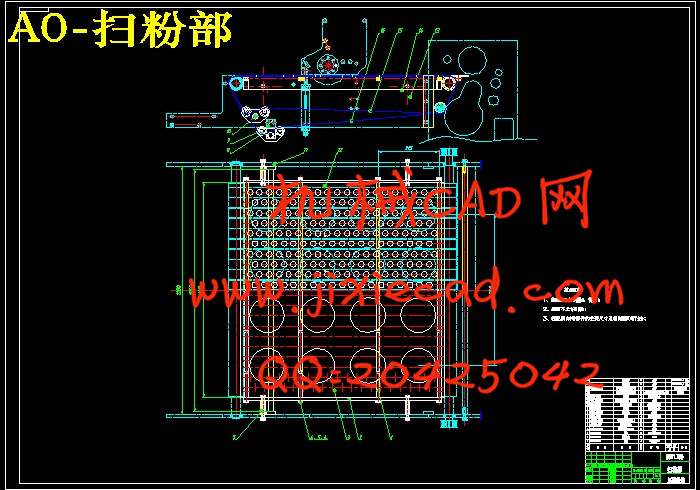

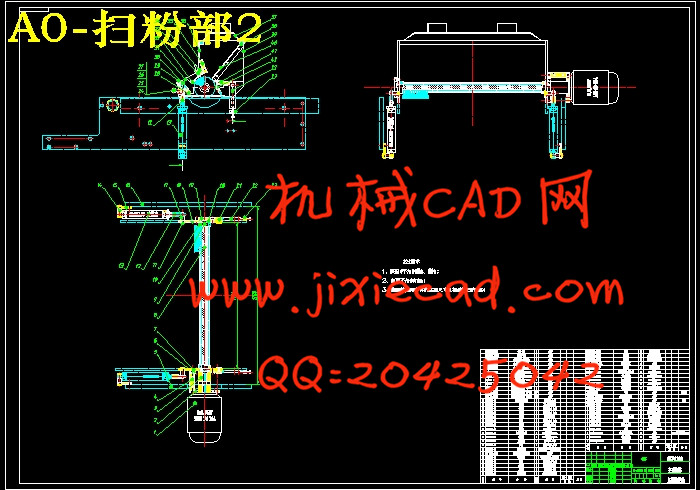

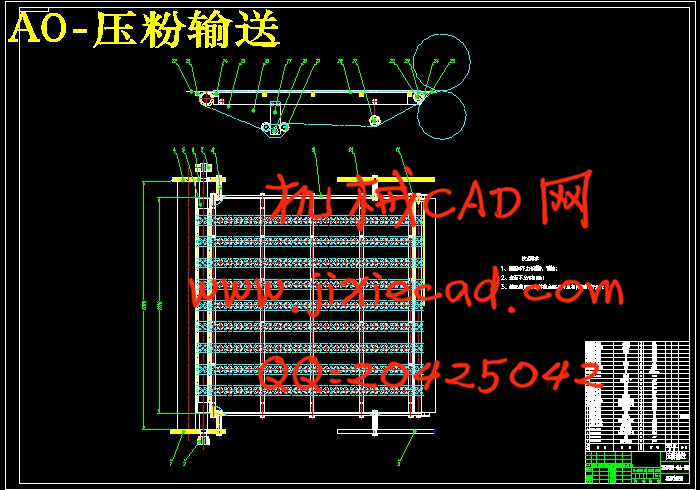

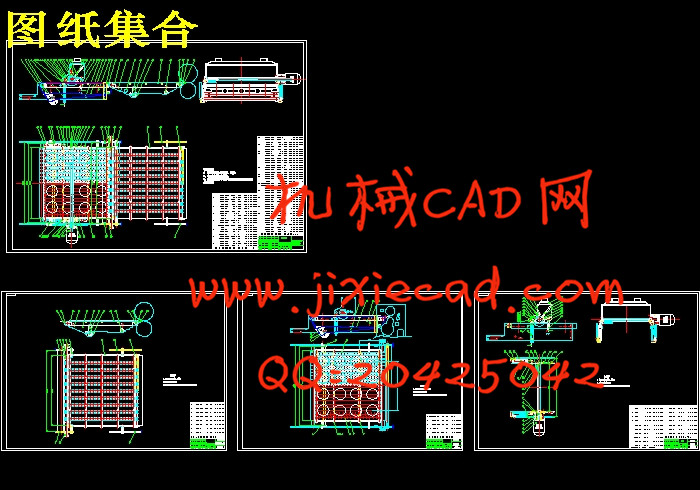

(7)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词:水性干式覆膜机除粉装置,结构设计,三维建模;步进电机

This paper introduces the development situation of waterborne dry-type laminating machine, water dry-type laminated machine in addition to the design principle of powder device structure, water dry-type laminated machine in addition to analysis and determine the overall plan for powder, water dry-type laminated machine powder removing device structure design content includes mechanical drawings drawing, in addition to calculate powder device, conclusion and suggestions for structure design.

The structure is mainly produced by the motor power through the coupling will need to transfer the power to the belt wheel, belt wheel drives the guide slipper, improve labor productivity and automation level of production. Industrial production in the often cumbersome workpiece handling and frequent, the long, monotonous operation, the powder removing device is effective; in addition, it can operate in high temperature, low temperature, water, the universe, radioactive and other toxic, environmental pollution condition, more show its superiority, there are broad development prospects the.

The research of this thesis:

(1) water dry-type laminated machine powder removing device structure design.

(2) water dry-type laminated machine powder removing device performance analysis.

(3) the choice of motor.

(4) water dry-type laminated machine drive system, in addition to powder device executing components and frame design.

(5) the design of components for the design calculation and check.

(6) the use of computer aided design, 3D modeling on Design of parts.

(7) to draw the assembly drawing and parts assembly diagram and parts diagram design.

Keywords: water dry-type laminated machine powder removing device, structure design, 3D modeling; stepping motor

目 录

1 绪 论 6

1.1 覆膜机分类 6

1.2有色金属板覆膜机 7

1.3 覆膜机使用原理 8

2 水性干式覆膜机除粉部分装置总体方案设计 9

2.1水性干式覆膜机的设计要求 9

2.2覆膜工艺流程图 9

2.3 水性干式覆膜机的结构设计示意图 9

2.4 水性干式覆膜机的工作原理 10

3 水性干式覆膜机系统除粉装置的机械计算 11

3.1 同步带的概述 11

3.1.1 同步带介绍 11

3.1.2 同步带的特点 12

3.1.3 同步带传动的主要失效形式 12

3.1.4 同步带传动的设计准则 14

3.1.5 同步带分类 14

3.2 电机的选取 15

3.3 同步带传动计算 16

3.3.1 同步带计算选型 16

3.3.2 同步带的主要参数(结构部分) 19

3.3.3 同步带的设计 21

3.3.4 同步带轮的设计 22

3.4 轴的设计 22

3.5 轴的校核 23

3.6 键的校核 24

3.7 轴承的校核 24

3.8 墙板的强度与刚度的计算 26

3.9 气缸的选择 30

4 除粉部分三维展示 38

总 结 41

致 谢 42

参考文献 43

整机结构主要由电动机产生动力通过联轴器将需要的动力传递到带轮上,带轮带动导轨滑靴,提高劳动生产率和生产自动化水平。工业生产中经常出现的笨重工件的搬运和长期、频繁、单调的操作,采用除粉装置是有效的;此外,它能在高温、低温、深水、宇宙、放射性和其它有毒、污染环境条件下进行操作,更显示其优越性,有着广阔的发展前途。

本论文研究内容:

(1) 水性干式覆膜机除粉装置总体结构设计。

(2) 水性干式覆膜机除粉装置工作性能分析。

(3)电动机的选择。

(4) 水性干式覆膜机除粉装置的传动系统、执行部件及机架设计。

(5)对设计零件进行设计计算分析和校核。

(6)运用计算机辅助设计,对设计的零件进行三维建模。

(7)绘制整机装配图及重要部件装配图和设计零件的零件图。

关键词:水性干式覆膜机除粉装置,结构设计,三维建模;步进电机

This paper introduces the development situation of waterborne dry-type laminating machine, water dry-type laminated machine in addition to the design principle of powder device structure, water dry-type laminated machine in addition to analysis and determine the overall plan for powder, water dry-type laminated machine powder removing device structure design content includes mechanical drawings drawing, in addition to calculate powder device, conclusion and suggestions for structure design.

The structure is mainly produced by the motor power through the coupling will need to transfer the power to the belt wheel, belt wheel drives the guide slipper, improve labor productivity and automation level of production. Industrial production in the often cumbersome workpiece handling and frequent, the long, monotonous operation, the powder removing device is effective; in addition, it can operate in high temperature, low temperature, water, the universe, radioactive and other toxic, environmental pollution condition, more show its superiority, there are broad development prospects the.

The research of this thesis:

(1) water dry-type laminated machine powder removing device structure design.

(2) water dry-type laminated machine powder removing device performance analysis.

(3) the choice of motor.

(4) water dry-type laminated machine drive system, in addition to powder device executing components and frame design.

(5) the design of components for the design calculation and check.

(6) the use of computer aided design, 3D modeling on Design of parts.

(7) to draw the assembly drawing and parts assembly diagram and parts diagram design.

Keywords: water dry-type laminated machine powder removing device, structure design, 3D modeling; stepping motor

目 录

1 绪 论 6

1.1 覆膜机分类 6

1.2有色金属板覆膜机 7

1.3 覆膜机使用原理 8

2 水性干式覆膜机除粉部分装置总体方案设计 9

2.1水性干式覆膜机的设计要求 9

2.2覆膜工艺流程图 9

2.3 水性干式覆膜机的结构设计示意图 9

2.4 水性干式覆膜机的工作原理 10

3 水性干式覆膜机系统除粉装置的机械计算 11

3.1 同步带的概述 11

3.1.1 同步带介绍 11

3.1.2 同步带的特点 12

3.1.3 同步带传动的主要失效形式 12

3.1.4 同步带传动的设计准则 14

3.1.5 同步带分类 14

3.2 电机的选取 15

3.3 同步带传动计算 16

3.3.1 同步带计算选型 16

3.3.2 同步带的主要参数(结构部分) 19

3.3.3 同步带的设计 21

3.3.4 同步带轮的设计 22

3.4 轴的设计 22

3.5 轴的校核 23

3.6 键的校核 24

3.7 轴承的校核 24

3.8 墙板的强度与刚度的计算 26

3.9 气缸的选择 30

4 除粉部分三维展示 38

总 结 41

致 谢 42

参考文献 43