设计简介

OKL-150 OKL-150型螺旋式颗粒肥料成型机器

摘 要植物吸收养分的主要途径为扩散、质流和截获。其中扩散是植物吸收养分的最主要途径。因此在作物根系附近创造一个高营养环境特别重要。大颗粒肥料在土壤中可以形成一个大的养分含量较高的区域,不断扩散供作物吸收利用,而这个区域周围的土壤,则不致因养分浓度过高而影响土壤微生物的活动。

过去的肥料成型用平模成型,平模颗粒机结构简便压力可调,适应不同物料其在何方面有大大的优势。虽然平模颗粒机结构优势,磨损少,但是产量较小,一般在300-3000公斤。因为平模的产量太低故开发螺旋式颗粒成型机。

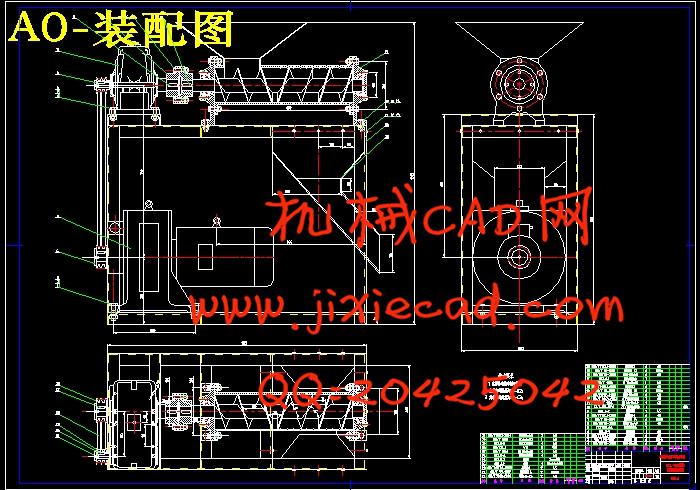

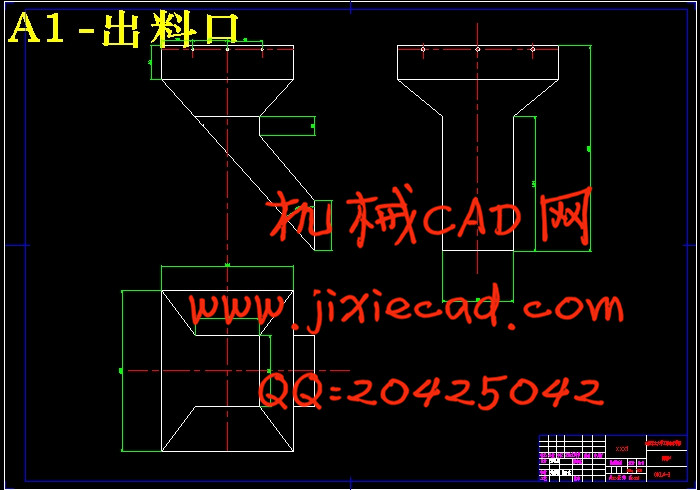

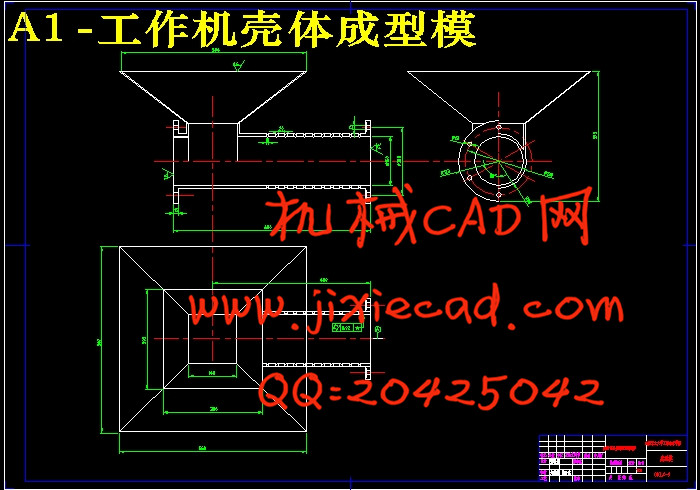

螺旋式颗粒肥料肥料成型机是把粉末状的物料通过机器的加工成型成圆柱状颗粒。成型的过程电机启动通过三角带带动减速器转动减速器通过联轴器带动螺杆转动,物料由进料斗喂入,在螺杆的旋转作用下使得物料受到挤压,挤压的物料通过成型模的小孔成型,经集料装置接收挤出得颗粒肥料排出机外,物料在强大的挤压作用下被挤出小孔。从而得到大颗粒肥料。来提高土壤的肥力问题。本科题就是为了生产大颗粒肥料而设计螺旋式颗粒肥料成型机。

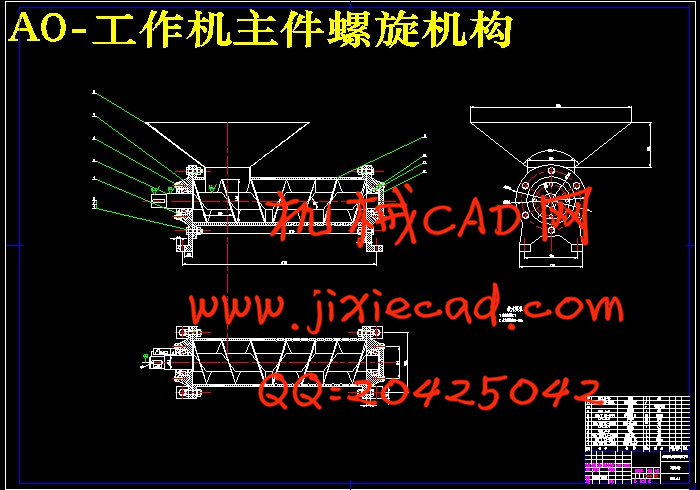

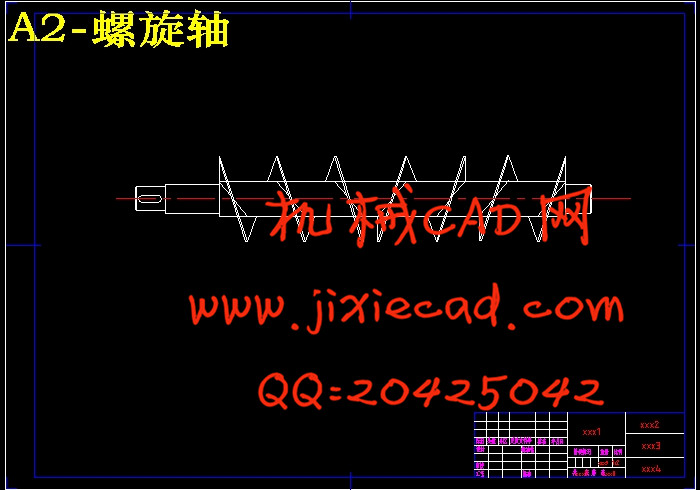

螺旋式颗粒成型机得螺旋轴采用等径、断续、变螺距螺杆。螺杆上的螺旋共分四段,第一段为喂料螺旋,主要作用是输送物料;第二段是预压螺旋主要作用是对物料进行初步挤压;初步使物料压紧,并有物料挤出,第三段、第四段,是压力增加螺旋,主要作用是不断增加对物料的进一步挤压,使物料被强制挤出。特别是第四段具有恒压作用,使得物料的均匀挤出,基本均匀一致,以利于加工的稳定性。

关键词 螺旋式 颗粒 肥料 挤压成型

OKL-150-type granular fertilizer spiral forming machine

Abstract

The plant nutrients as the main way to the proliferation of mass flow and interception. The proliferation of which is the most important plant nutrients ways. Therefore, in the vicinity of crop roots to create a high-nutrient environment is particularly important. Large granular fertilizer in the soil can form a higher nutrient content of the region, the ongoing proliferation of absorption and utilization for crop, and soil around the region, it would not be affected by high nutrient concentrations of soil microbial activity.

Fertilizer was used over the past flat-casting molding, flat-mode particles the structure of simple machines, pressure adjustable to suit different materials in the DR have a significant advantage. Although the flat plane structure mode particles advantages, less wear and tear, but the production of smaller, typically 300-3000 kg. Ping mode of production because it is too low to develop particles spiral machine.

Spiral Forming Machine granular fertilizer is a fertilizer powder materials processed through the machine Start the process of forming through the V-belt driven motor reducer reducer rotating screw driven through the rotating coupling, material from the hopper into the feed, the effect of screw rotation allows materials by extrusion, extrusion molding of the material rotation allows materials by extrusion, extrusion molding of the material through Forming the holes, the aggregate device to receive a granular fertilizer from extrusion machine, the material in the powerful role of being squeezed out of small holes. Undergraduate title to the production of large granular fertilizer designed spiral machine granular fertilizer.

Particles spiral machine using a screw shaft diameter, intermittent, variable pitch screw. The helical screw is divided into four sections, the first paragraph for the feed screw, the main role is to transport materials; the second paragraph is preloading a major role in spiral of preliminary extrusion materials; preliminary compacting of materials and extrusion materials that the third paragraph, the fourth is to increase the pressure screw, the main role is to increase further squeeze on the materials to be forced out of materials. In particular the role of the fourth paragraph with the constant pressure, makes the uniform material extrusion, the basic uniform in order to facilitate the processing stability.

Key words Granular fertilizer Extrusion

目 录

摘 要植物吸收养分的主要途径为扩散、质流和截获。其中扩散是植物吸收养分的最主要途径。因此在作物根系附近创造一个高营养环境特别重要。大颗粒肥料在土壤中可以形成一个大的养分含量较高的区域,不断扩散供作物吸收利用,而这个区域周围的土壤,则不致因养分浓度过高而影响土壤微生物的活动。

过去的肥料成型用平模成型,平模颗粒机结构简便压力可调,适应不同物料其在何方面有大大的优势。虽然平模颗粒机结构优势,磨损少,但是产量较小,一般在300-3000公斤。因为平模的产量太低故开发螺旋式颗粒成型机。

螺旋式颗粒肥料肥料成型机是把粉末状的物料通过机器的加工成型成圆柱状颗粒。成型的过程电机启动通过三角带带动减速器转动减速器通过联轴器带动螺杆转动,物料由进料斗喂入,在螺杆的旋转作用下使得物料受到挤压,挤压的物料通过成型模的小孔成型,经集料装置接收挤出得颗粒肥料排出机外,物料在强大的挤压作用下被挤出小孔。从而得到大颗粒肥料。来提高土壤的肥力问题。本科题就是为了生产大颗粒肥料而设计螺旋式颗粒肥料成型机。

螺旋式颗粒成型机得螺旋轴采用等径、断续、变螺距螺杆。螺杆上的螺旋共分四段,第一段为喂料螺旋,主要作用是输送物料;第二段是预压螺旋主要作用是对物料进行初步挤压;初步使物料压紧,并有物料挤出,第三段、第四段,是压力增加螺旋,主要作用是不断增加对物料的进一步挤压,使物料被强制挤出。特别是第四段具有恒压作用,使得物料的均匀挤出,基本均匀一致,以利于加工的稳定性。

关键词 螺旋式 颗粒 肥料 挤压成型

OKL-150-type granular fertilizer spiral forming machine

Abstract

The plant nutrients as the main way to the proliferation of mass flow and interception. The proliferation of which is the most important plant nutrients ways. Therefore, in the vicinity of crop roots to create a high-nutrient environment is particularly important. Large granular fertilizer in the soil can form a higher nutrient content of the region, the ongoing proliferation of absorption and utilization for crop, and soil around the region, it would not be affected by high nutrient concentrations of soil microbial activity.

Fertilizer was used over the past flat-casting molding, flat-mode particles the structure of simple machines, pressure adjustable to suit different materials in the DR have a significant advantage. Although the flat plane structure mode particles advantages, less wear and tear, but the production of smaller, typically 300-3000 kg. Ping mode of production because it is too low to develop particles spiral machine.

Spiral Forming Machine granular fertilizer is a fertilizer powder materials processed through the machine Start the process of forming through the V-belt driven motor reducer reducer rotating screw driven through the rotating coupling, material from the hopper into the feed, the effect of screw rotation allows materials by extrusion, extrusion molding of the material rotation allows materials by extrusion, extrusion molding of the material through Forming the holes, the aggregate device to receive a granular fertilizer from extrusion machine, the material in the powerful role of being squeezed out of small holes. Undergraduate title to the production of large granular fertilizer designed spiral machine granular fertilizer.

Particles spiral machine using a screw shaft diameter, intermittent, variable pitch screw. The helical screw is divided into four sections, the first paragraph for the feed screw, the main role is to transport materials; the second paragraph is preloading a major role in spiral of preliminary extrusion materials; preliminary compacting of materials and extrusion materials that the third paragraph, the fourth is to increase the pressure screw, the main role is to increase further squeeze on the materials to be forced out of materials. In particular the role of the fourth paragraph with the constant pressure, makes the uniform material extrusion, the basic uniform in order to facilitate the processing stability.

Key words Granular fertilizer Extrusion

目 录

1.前言 1

1.1设计目的和意义 1

1.2国内外技术发展现状 1

1.3主要研究内容 2

2.技术任务书(JR) 3

2.1设计的依据 3

2.2产品的用途和使用范围 3

2.3主要的工作原理 3

2.4已经考虑过的若干方案的比较 3

3.设计计算说明书(SS) 4

3.1机构方案分析 4

3.2总体设计 5

3.2.1结构组成及工作原理 5

3.2.2主要技术参数 6

3.3螺旋挤压装置的设计计算 7

3.3.1生产能力的计算 7

3.3.2功率的计算 8

3.3.3螺旋轴的设计 8

3.3.4成型模孔的设计 9

3.4传动系统的设计 10

3.4.1电动机选型 外形如图3 10

3.4.2减速器的选型 11

3.4.3传动比的计算 11

3.4.4皮带传动的设计 11

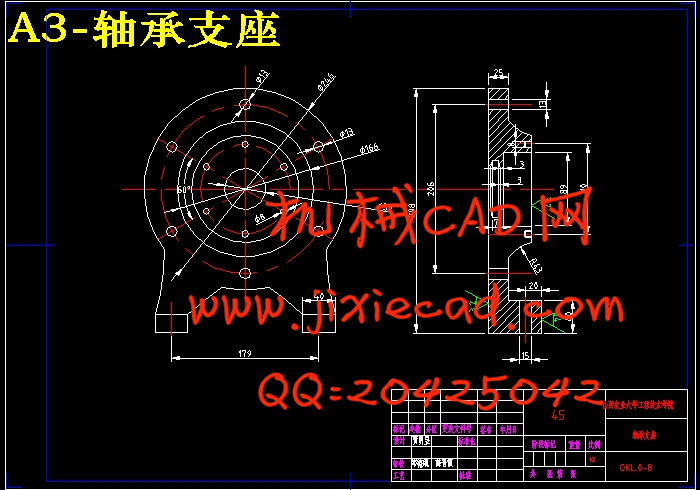

3.5主轴强度的校核 15

3.6主要设计结果 19

4.使用说明书(GM) 19

4.1产品的用途及使用范围 19

4.2操作及维护 19

4.3使用前的准备工作 19

4.4使用方法 20

5.标准化审查报告 20

6.主要研究结论 21

6.1结论 21

6.2进一步改进意见 21

参考文献 23

致谢 24

1.1设计目的和意义 1

1.2国内外技术发展现状 1

1.3主要研究内容 2

2.技术任务书(JR) 3

2.1设计的依据 3

2.2产品的用途和使用范围 3

2.3主要的工作原理 3

2.4已经考虑过的若干方案的比较 3

3.设计计算说明书(SS) 4

3.1机构方案分析 4

3.2总体设计 5

3.2.1结构组成及工作原理 5

3.2.2主要技术参数 6

3.3螺旋挤压装置的设计计算 7

3.3.1生产能力的计算 7

3.3.2功率的计算 8

3.3.3螺旋轴的设计 8

3.3.4成型模孔的设计 9

3.4传动系统的设计 10

3.4.1电动机选型 外形如图3 10

3.4.2减速器的选型 11

3.4.3传动比的计算 11

3.4.4皮带传动的设计 11

3.5主轴强度的校核 15

3.6主要设计结果 19

4.使用说明书(GM) 19

4.1产品的用途及使用范围 19

4.2操作及维护 19

4.3使用前的准备工作 19

4.4使用方法 20

5.标准化审查报告 20

6.主要研究结论 21

6.1结论 21

6.2进一步改进意见 21

参考文献 23

致谢 24