设计简介

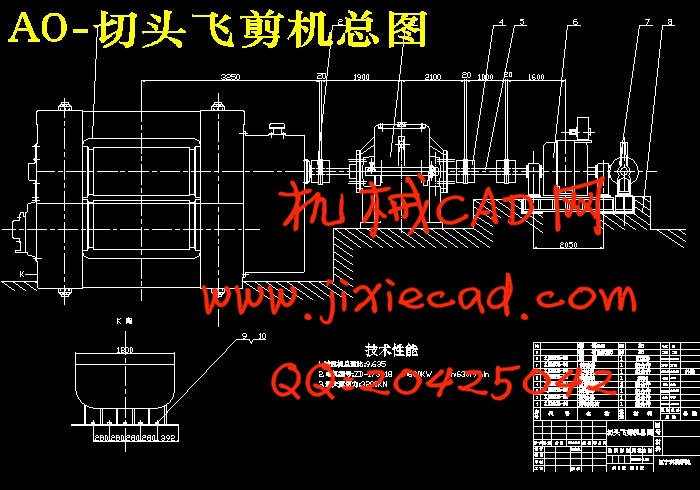

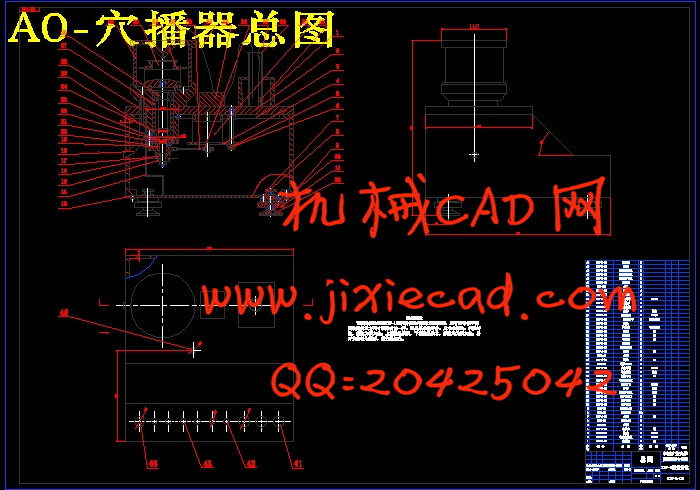

摘要 本文主要讨论的是一种精量穴播器的载插机构,该穴播器主要应用于烟苗、玉米、甜菜、茄子、蕃茄、棉花等作物的田间移栽作业。根据作物育苗移栽的农艺要求,在分析了国内外众多穴播器的基础上,优化设计了适合钵苗移栽的机械的关键部件,分析研究了机械栽苗的一般规律,找出了影响栽苗效果的若干因素,确定了工作部件的主要参数。

该机构的创新点是采用了曲柄连杆机构作为穴播器的投苗机构。由于条件限制,实践方面有待进一步的加强,进行进一步的检验、分析、再设计,使所设计的烟苗穴播器械达到较好的工作性能指标和工作可靠性的要求,但最为重要的是一定要满足农业生产的要求—农艺要求。

移栽部件的运动分析是穴播器设计的基础,在建立钵苗运动数学模型的前提下,运用Inventor建立实体模型,创建组件连接,在Inventor中对移栽部件进行模拟仿真,并对其关键点与建立的数学模型进行比较,对移栽部件参数进行优化。

关键词: 穴播器; 曲柄连杆机构; 投苗机构.

Abstract In the thesis, we discuss the seedling launching mechanism of a planter which are applied in transplanting of baccy、corn、beet、eggplant、tomato、cotton ...etc. According to the requirement for agronomy transplantation to grow seedlings, we have found a good method to the ones that are suitable for the baccy nutrition bowl and grow seedlings and transplant in optimization design on the foundation of analyzing numerous transplanting machines both at home and abroad, and through the investigation of the result of the homework, we have analyzed and researched the universal law of the plant shoots in machinery and found some factors that affect the result of plant shoots.

The crank and rocker mechanisms are applied to the seedling launching mechanism. Because the terms is limited, in practice, the aspect treats to further enhance, examination proceeding further, analyze, then design, make a cotton for designing planter attain the good work function index sign and work dependable and reliability, but the most important must satisfy the agriculture produce of request.

Based on analysis of transplanting parts movement, through development of mathematical model describing seedling moving procedure, the entity of transplanting parts were established with software Inventor, and connections of the parts were created. Simulation of planter working procedure was carried out and moving track was set up for study of planter key points in comparison with mathematical model, so the optimum parameters for transplanting parts were obtained.

Key words: planter; crank and rocker mechanisms; seedling launching mechanism.

目 录

第一章 绪论…………………………………………………………………3

1.1 国内外移栽机的历史和发展状况……………………………………………3

1.1.1国外移栽机的发展状况……………………………………………………3

1.1.2国内移栽机械的发展概况…………………………………………………4

1.1.3国内移栽机械的主要问题…………………………………………………4

1.2发展旱地钵苗移栽机械的必要性……………………………………………5

1.3 移栽机的分类及特点…………………………………………………………7

1.4 机械化移栽目前存在的主要问题…………………………………………10

1.5 选题分析(科学性、可行性论证)和内容……………………………………11

第二章 总体方案…………………………………………………………13

2.1 秧苗移栽的基本农艺要求…………………………………………………13

2.2 主要技术参数………………………………………………………………13

2.3 移栽机作业的技术要求……………………………………………………14

2.3.1 性能评定指标与检测方法………………………………………………14

2.3.2 钵苗栽植状态指标………………………………………………………16

2.3.3 生产率性能指标…………………………………………………………18

2.3.4 移栽机适应性指标………………………………………………………18

2.3.5 自动化程度指标…………………………………………………………19

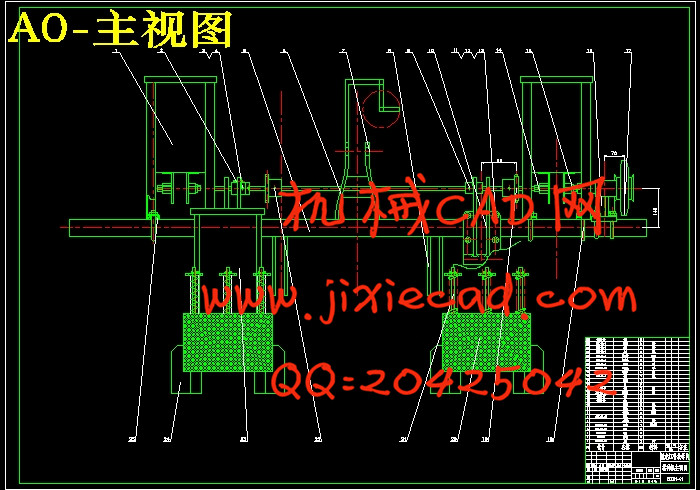

2.4 结构特征与工作原理………………………………………………………19

第三章 关键技术解决办法………………………………………………23

3.1 设计方法选择………………………………………………………………23

3.2 方案选择……………………………………………………………………24

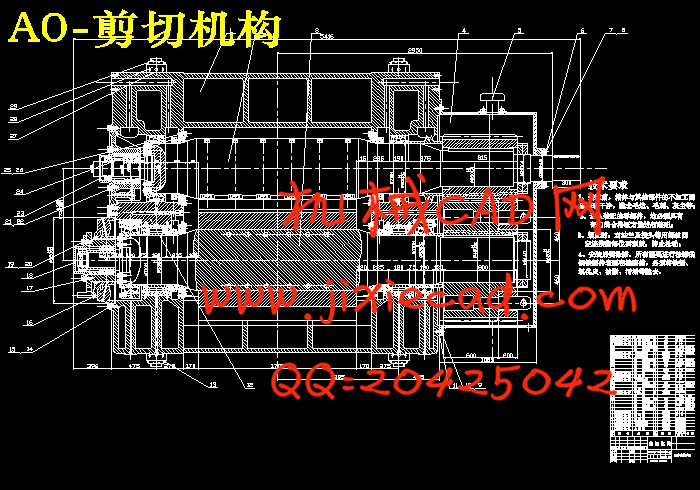

第四章 载插机构的设计及计算…………………………………………25

4.1 移栽机载插机构的设计……………………………………………………25

4.2 具体设计过程………………………………………………………………25

4.2.1 方法学……………………………………………………………………25

4.2.2 种植机械的输出运动需求………………………………………………26

4.2.3 连接参数的设计…………………………………………………………26

4.2.4 连接部件的分析…………………………………………………………27

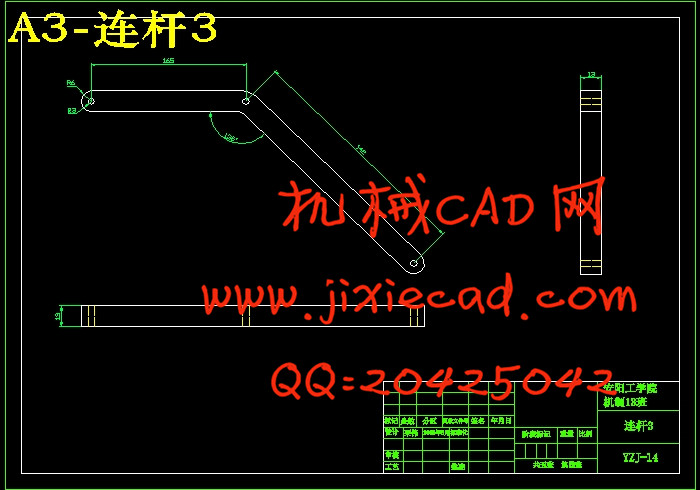

4.2.5 连杆尺寸的确定…………………………………………………………29

4.3 连杆的运动轨迹分析………………………………………………………31

4.3.1 运动分析…………………………………………………………………31

4.3.2 确定最佳运动轨迹………………………………………………………32

4.4 机械设计的初步研究………………………………………………………34

4.5 机构运动的三维仿真………………………………………………………36

4.5.1 计算机分析的基本思想…………………………………………………36

4.5.2 三维设计软件Inventor介绍…………………………………………36

4.5.3 机构的三维图……………………………………………………………37

4.6 主要工作情况………………………………………………………………37

结 论………………………………………………………………………39

致 谢………………………………………………………………………41

参考文献……………………………………………………………………47

该机构的创新点是采用了曲柄连杆机构作为穴播器的投苗机构。由于条件限制,实践方面有待进一步的加强,进行进一步的检验、分析、再设计,使所设计的烟苗穴播器械达到较好的工作性能指标和工作可靠性的要求,但最为重要的是一定要满足农业生产的要求—农艺要求。

移栽部件的运动分析是穴播器设计的基础,在建立钵苗运动数学模型的前提下,运用Inventor建立实体模型,创建组件连接,在Inventor中对移栽部件进行模拟仿真,并对其关键点与建立的数学模型进行比较,对移栽部件参数进行优化。

关键词: 穴播器; 曲柄连杆机构; 投苗机构.

Abstract In the thesis, we discuss the seedling launching mechanism of a planter which are applied in transplanting of baccy、corn、beet、eggplant、tomato、cotton ...etc. According to the requirement for agronomy transplantation to grow seedlings, we have found a good method to the ones that are suitable for the baccy nutrition bowl and grow seedlings and transplant in optimization design on the foundation of analyzing numerous transplanting machines both at home and abroad, and through the investigation of the result of the homework, we have analyzed and researched the universal law of the plant shoots in machinery and found some factors that affect the result of plant shoots.

The crank and rocker mechanisms are applied to the seedling launching mechanism. Because the terms is limited, in practice, the aspect treats to further enhance, examination proceeding further, analyze, then design, make a cotton for designing planter attain the good work function index sign and work dependable and reliability, but the most important must satisfy the agriculture produce of request.

Based on analysis of transplanting parts movement, through development of mathematical model describing seedling moving procedure, the entity of transplanting parts were established with software Inventor, and connections of the parts were created. Simulation of planter working procedure was carried out and moving track was set up for study of planter key points in comparison with mathematical model, so the optimum parameters for transplanting parts were obtained.

Key words: planter; crank and rocker mechanisms; seedling launching mechanism.

目 录

第一章 绪论…………………………………………………………………3

1.1 国内外移栽机的历史和发展状况……………………………………………3

1.1.1国外移栽机的发展状况……………………………………………………3

1.1.2国内移栽机械的发展概况…………………………………………………4

1.1.3国内移栽机械的主要问题…………………………………………………4

1.2发展旱地钵苗移栽机械的必要性……………………………………………5

1.3 移栽机的分类及特点…………………………………………………………7

1.4 机械化移栽目前存在的主要问题…………………………………………10

1.5 选题分析(科学性、可行性论证)和内容……………………………………11

第二章 总体方案…………………………………………………………13

2.1 秧苗移栽的基本农艺要求…………………………………………………13

2.2 主要技术参数………………………………………………………………13

2.3 移栽机作业的技术要求……………………………………………………14

2.3.1 性能评定指标与检测方法………………………………………………14

2.3.2 钵苗栽植状态指标………………………………………………………16

2.3.3 生产率性能指标…………………………………………………………18

2.3.4 移栽机适应性指标………………………………………………………18

2.3.5 自动化程度指标…………………………………………………………19

2.4 结构特征与工作原理………………………………………………………19

第三章 关键技术解决办法………………………………………………23

3.1 设计方法选择………………………………………………………………23

3.2 方案选择……………………………………………………………………24

第四章 载插机构的设计及计算…………………………………………25

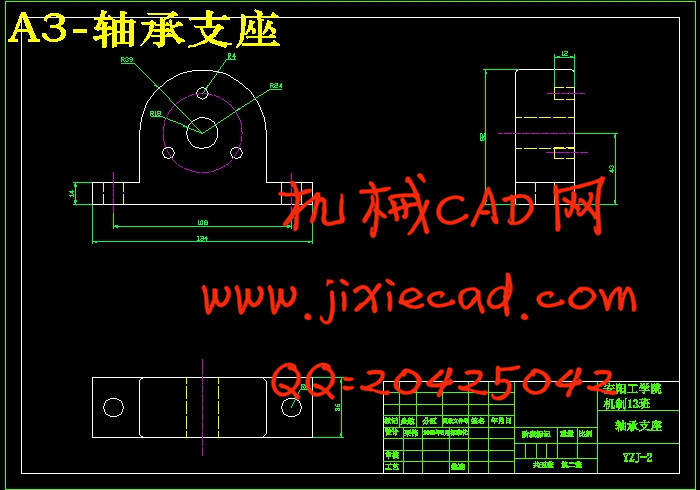

4.1 移栽机载插机构的设计……………………………………………………25

4.2 具体设计过程………………………………………………………………25

4.2.1 方法学……………………………………………………………………25

4.2.2 种植机械的输出运动需求………………………………………………26

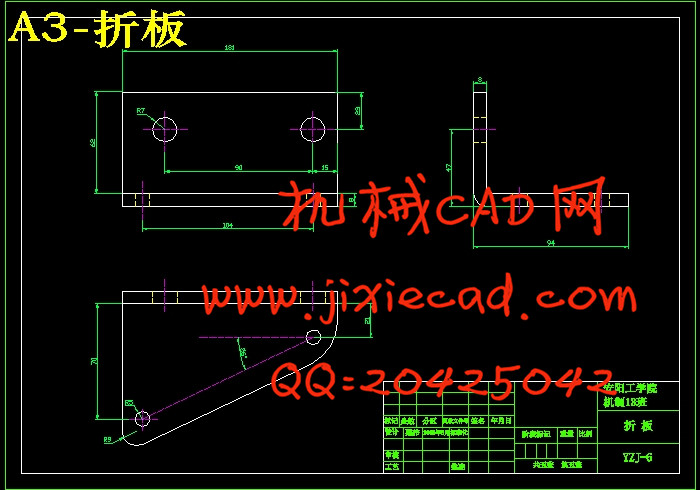

4.2.3 连接参数的设计…………………………………………………………26

4.2.4 连接部件的分析…………………………………………………………27

4.2.5 连杆尺寸的确定…………………………………………………………29

4.3 连杆的运动轨迹分析………………………………………………………31

4.3.1 运动分析…………………………………………………………………31

4.3.2 确定最佳运动轨迹………………………………………………………32

4.4 机械设计的初步研究………………………………………………………34

4.5 机构运动的三维仿真………………………………………………………36

4.5.1 计算机分析的基本思想…………………………………………………36

4.5.2 三维设计软件Inventor介绍…………………………………………36

4.5.3 机构的三维图……………………………………………………………37

4.6 主要工作情况………………………………………………………………37

结 论………………………………………………………………………39

致 谢………………………………………………………………………41

参考文献……………………………………………………………………47