设计简介

MD1200型直线坐标码垛机机械系统设计

摘 要

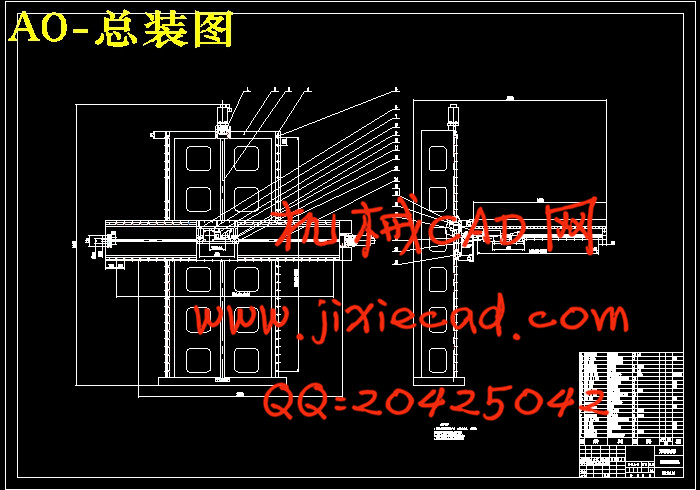

码垛机是立体仓库系统的重要组成部分,它是整个系统的执行部件,存货时将货物从出入货台准确的存放到货位里,取货时将货物从货位中取回到出入货台。无论何种类型的码垛机,一般都由水平行走机构、起升机构、载货台及货叉机构、机架和电气设备等基本部分组成。它是在所谓高层、高速、高密度储藏的概念下的产物。尽管各厂家各有独创,结构形式有些差异,但可以说大同小异,所有的码垛机都不外乎由机架、载货台、伸缩货叉、轨道和控制系统等部分组成。

体现码垛机动态性能优劣的指标主要有:运行速度、提升速度、货叉速度、平稳性、认址精度等。随着科学技术的不断进步,立体仓库的技术水平和仓储机械设备的动态性能也在不断提高。

关键词 :码垛机,滚珠丝杠,导轨滑块

MD1200 Rectilinear coordinate stacker Mechanical System Design

摘 要

码垛机是立体仓库系统的重要组成部分,它是整个系统的执行部件,存货时将货物从出入货台准确的存放到货位里,取货时将货物从货位中取回到出入货台。无论何种类型的码垛机,一般都由水平行走机构、起升机构、载货台及货叉机构、机架和电气设备等基本部分组成。它是在所谓高层、高速、高密度储藏的概念下的产物。尽管各厂家各有独创,结构形式有些差异,但可以说大同小异,所有的码垛机都不外乎由机架、载货台、伸缩货叉、轨道和控制系统等部分组成。

体现码垛机动态性能优劣的指标主要有:运行速度、提升速度、货叉速度、平稳性、认址精度等。随着科学技术的不断进步,立体仓库的技术水平和仓储机械设备的动态性能也在不断提高。

关键词 :码垛机,滚珠丝杠,导轨滑块

MD1200 Rectilinear coordinate stacker Mechanical System Design

The stacker which is the executive parts of the whole system, is an important part of the warehouse system.It can stock goods accurately from dock into cargo space and pick up goods in the opposite way.No matter what type of stacking machine ,is made up of walking mechanism , hoisting mechanism ,cargo and fork body ,rack and electrical equipment,and other basic components. It is the product of the concept of the so-called high-level, high-speed, high-density storage.Although the manufacturers have their own unique products, which is diffferent in structure, but it can be said much the same, all of the stacker are nothing more than the rack, cargo units, telescopic fork, track and control systems and other components.

Indicators which reflect the dynamic performance of the pros and cons of the stacker are: speed, lifting speed, fork speed, stability, and accuracy of recognition site. With the continuous progress of science and technology, the dynamic performance of the technical level of three-dimensional warehouse and warehousing machinery and equipment is also rising.

Keywords: Stacker ,Ball screw ,Rail slider

目 录

1绪论 1

1.1码垛机的分类 1

1.1.1码垛机器人 1

1.1.2桥式码垛机 2

1.1.3直线码垛机 2

1.2给定的条件和要求 3

1.3方案的选取 3

2设备概述 4

2.1 结构原理 4

3设计计算 6

3.1电动机的选择 6

3.2滚珠丝杠的选择 7

3.3导轨的选取 8

3.4传动系统设计 9

3.4.1联轴器的选取 9

3.4.2带传动 11

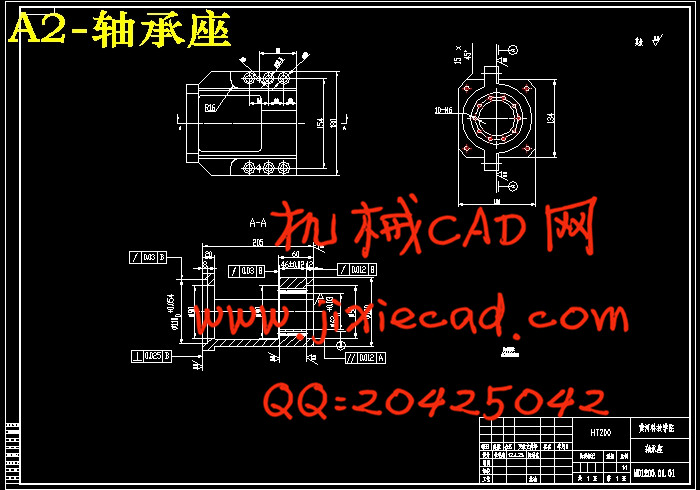

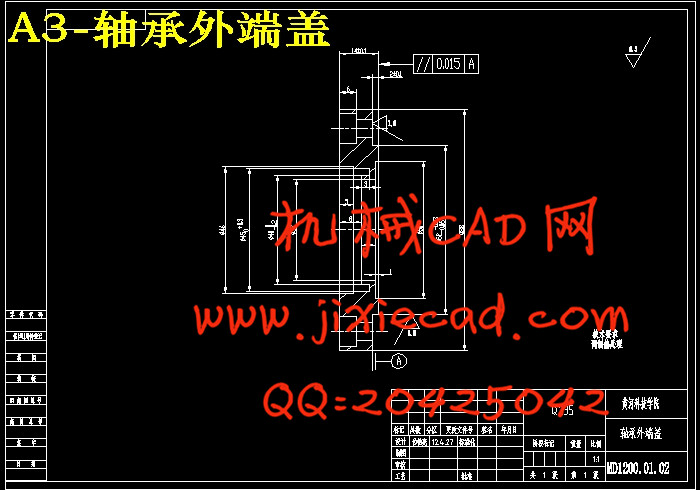

3.5轴承的选取 13

3.6润滑和密封 15

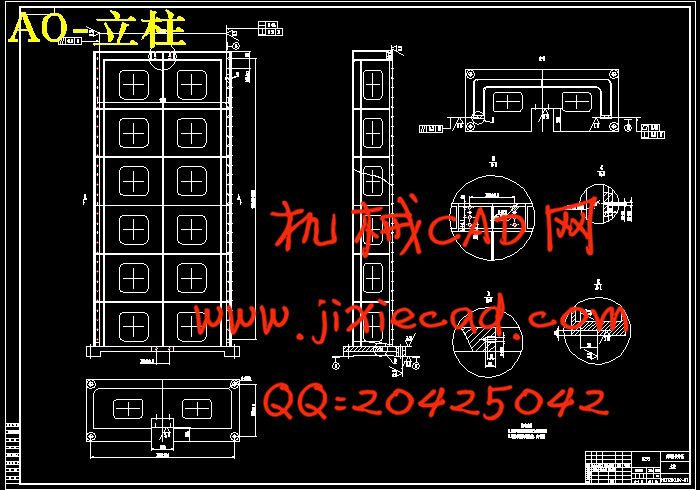

4 机架的设计 17

4.1 设备安装 17

结 论 19

致 谢 20