设计简介

摘 要

驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于载货汽车显得尤为重要。为满足目前当前载货汽车的快速、高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。设计出结构简单、工作可靠、造价低廉的驱动桥,能大大降低整车生产的总成本,推动汽车经济的发展。

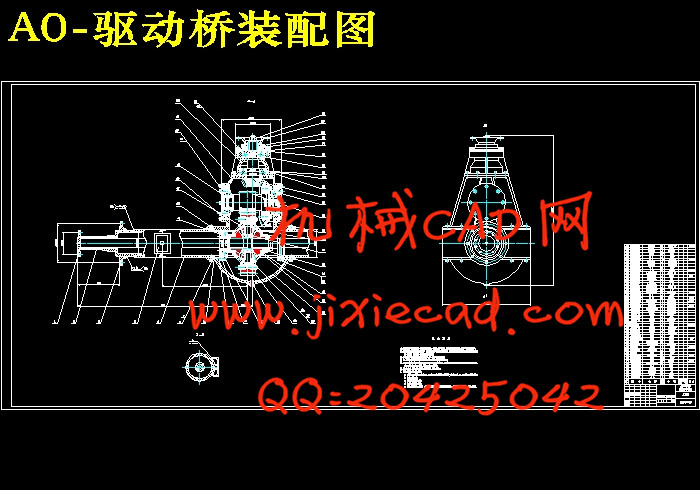

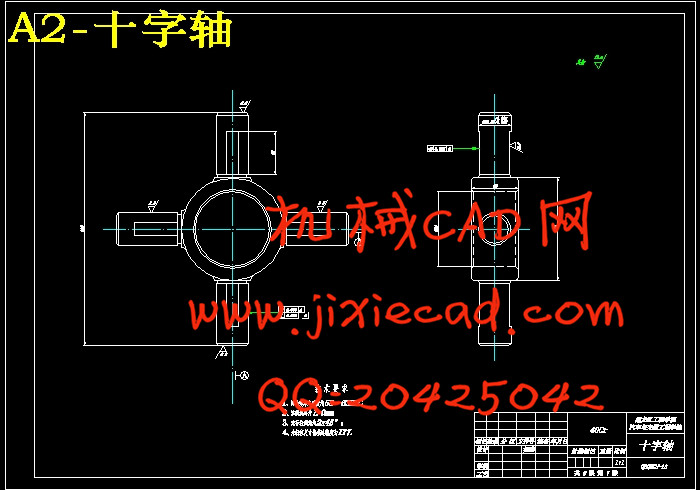

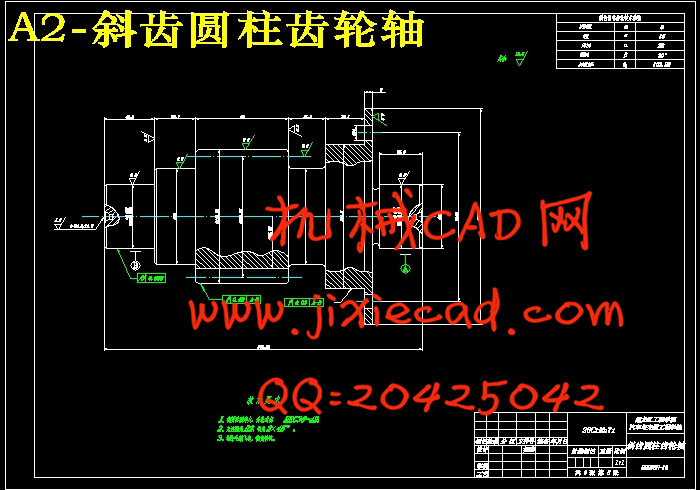

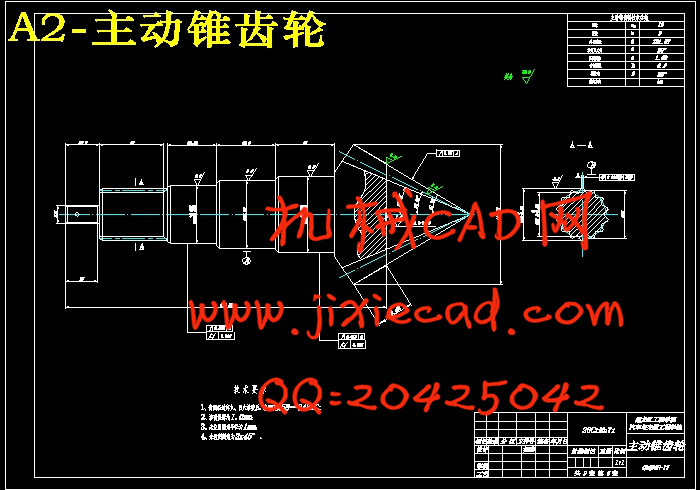

本文首先确定主要部件的结构型式和主要设计参数,在分析驱动桥各部分结构形式、发展过程及其以往形式的优缺点的基础上,确定了总体设计方案,采用传统设计方法对驱动桥各部件主减速器、差速器、半轴、桥壳进行设计计算并完成校核。最后运用AUTOCAD完成装配图和主要零件图的绘制。并且通过对汽车驱动桥的学习和设计实践,可以更好的学习并掌握现代汽车设计与机械设计的全面知识和技能,所以本题设计一款结构优良的中型货车驱动桥具有一定的实际意义。

关键词:驱动桥;主减速器;差速器;半轴;桥壳

ABSTRACT

Drive axle is the one of automobile four important assemblies, its performance directly influence on the entire automobile, especially for the truck .Because using the big power engine with the big driving torque satisfied the need of high speed, heavy-loaded, high efficiency, high benefit todays` truck, must exploiting the high driven efficiency single reduction final drive axle is becoming the trucks’ developing tendency.

In this paper, first of all determine the structure of major components and the main design parameters, the analysis of the various parts of the structure of the bridge drive type, the form of the development process and its advantages and disadvantages of the past, determined on the basis of the design program, using the traditional design method of various parts of the drive axle Main reducer, differential, axle, axle housing was designed to calculate and complete the check. Finally complete the final assembly drawing by using AUTOCAD and mapping the main components. Design a simple, reliable, low cost of the drive axle, can greatly reduce the total cost of vehicle production, and promote the economic development of automobile and automotive drive axle of the study and design practice, can better learn and to master modern automotive design and mechanical design of a comprehensive knowledge and skills, so the title of the fine structure of the design of a pickup vehicle drive axle has a certain practical significance.

Keywords: Drive Axle; Reduction Final Drive; Differential; Axle; Drive Axle Housing

目 录

摘要 I驱动桥作为汽车四大总成之一,它的性能的好坏直接影响整车性能,而对于载货汽车显得尤为重要。为满足目前当前载货汽车的快速、高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。设计出结构简单、工作可靠、造价低廉的驱动桥,能大大降低整车生产的总成本,推动汽车经济的发展。

本文首先确定主要部件的结构型式和主要设计参数,在分析驱动桥各部分结构形式、发展过程及其以往形式的优缺点的基础上,确定了总体设计方案,采用传统设计方法对驱动桥各部件主减速器、差速器、半轴、桥壳进行设计计算并完成校核。最后运用AUTOCAD完成装配图和主要零件图的绘制。并且通过对汽车驱动桥的学习和设计实践,可以更好的学习并掌握现代汽车设计与机械设计的全面知识和技能,所以本题设计一款结构优良的中型货车驱动桥具有一定的实际意义。

关键词:驱动桥;主减速器;差速器;半轴;桥壳

ABSTRACT

Drive axle is the one of automobile four important assemblies, its performance directly influence on the entire automobile, especially for the truck .Because using the big power engine with the big driving torque satisfied the need of high speed, heavy-loaded, high efficiency, high benefit todays` truck, must exploiting the high driven efficiency single reduction final drive axle is becoming the trucks’ developing tendency.

In this paper, first of all determine the structure of major components and the main design parameters, the analysis of the various parts of the structure of the bridge drive type, the form of the development process and its advantages and disadvantages of the past, determined on the basis of the design program, using the traditional design method of various parts of the drive axle Main reducer, differential, axle, axle housing was designed to calculate and complete the check. Finally complete the final assembly drawing by using AUTOCAD and mapping the main components. Design a simple, reliable, low cost of the drive axle, can greatly reduce the total cost of vehicle production, and promote the economic development of automobile and automotive drive axle of the study and design practice, can better learn and to master modern automotive design and mechanical design of a comprehensive knowledge and skills, so the title of the fine structure of the design of a pickup vehicle drive axle has a certain practical significance.

Keywords: Drive Axle; Reduction Final Drive; Differential; Axle; Drive Axle Housing

目 录

Abstract II

第1章 绪论 1

1.1 课题研究的目的意义 1

1.2国内外驱动桥研究现状 2

1.2.1 国外研究现状 2

1.2.2 国内研究现状 4

1.3 设计的主要内容与技术路线 4

第2章 驱动桥的总体方案确定 6

2.1 驱动桥的种类结构和设计要求 6

2.1.1 驱动桥的种类 6

2.1.2 驱动桥的结构组成 6

2.1.3 驱动桥设计要求 7

2.2 设计车型主要参数 7

2.3 主减速器结构方案的确定 7

2.3.1 主减速的齿轮类型 7

2.3.2 主减速器的减速形式 8

2.3.3 主减速器速比的计算 9

2.3.4 主减速器主从动锥齿轮的支承形式及安装方法 10

2.4 差速器结构方案的确定 11

2.5 半轴的形式确定 11

2.6 桥壳形式的确定 12

2.7 本章小结 12

第3章 主减速器设计 13

3.1 概述 13

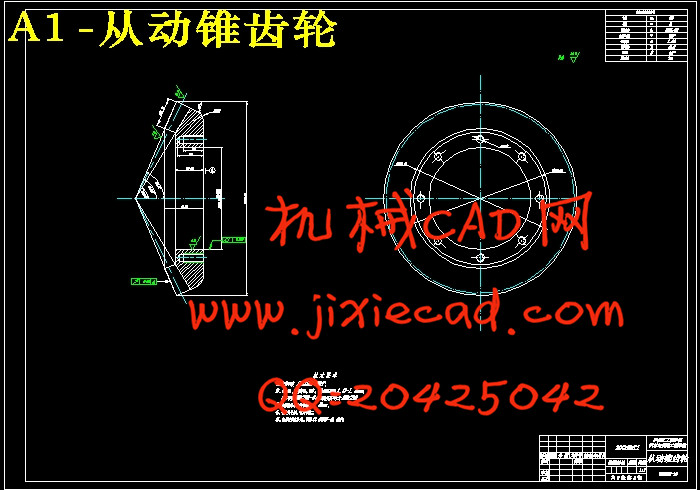

3.2 双级主减速器第一级螺旋锥齿轮参数选择与强度计算 13

3.2.1 13

3.2.2 主减速器螺旋锥齿轮基本参数的选择 14

3.2.3 主减速器螺旋锥齿轮几何尺寸计算 16

3.2.4 主减速器螺旋锥齿轮强度计算 17

3.3 双级主减速器第二级斜齿柱齿轮参数选择与强度计算 21

3.3.1 斜齿柱齿轮传动的几何参数选择 21

3.3.2 斜齿柱齿轮几何尺寸变位 22

3.3.3 斜齿柱齿轮强度计算 23

3.4 主减速器轴承计算 24

3.4.1 作用在主减速器主动齿轮上的力 24

3.4.2 主减速器轴承载荷计算 26

3.5 主减速器材料及热处理 30

3.6 主减速器的润滑 30

3.7 本章小结 31

第4章 差速器设计 32

4.1 概述 32

4.2 对称式圆锥行星齿轮差速器原理 32

4.3 对称式圆锥行星齿轮差速器的结构 33

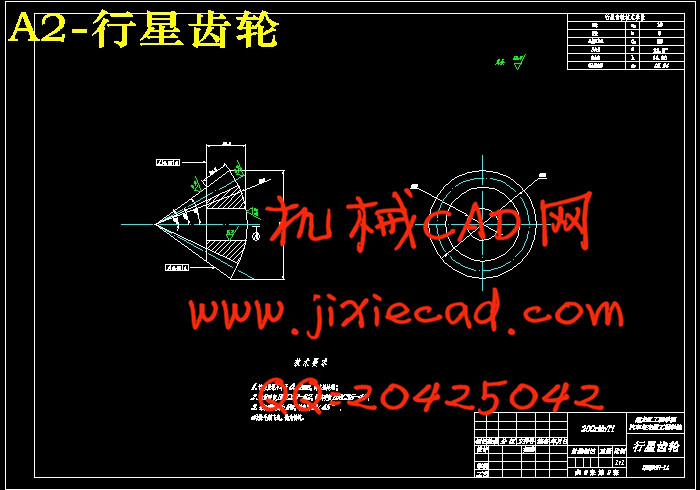

4.4 对称圆锥行星锥齿轮差速器的设计 33

4.4.1 差速器齿轮的基本参数选择 33

4.4.2 差速器齿轮的几何尺寸计算 35

4.4.3 差速器齿轮的强度计算 37

4.5 差速器齿轮的材料 38

4.6 本章小结 38

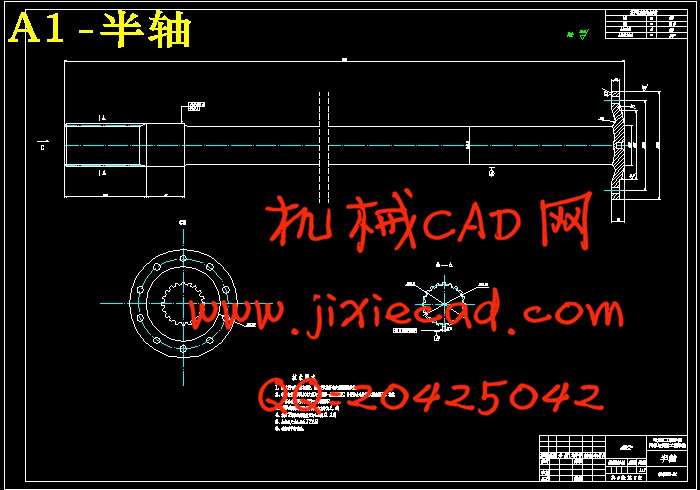

第5章 半轴设计 39

5.1 概述 39

5.2 半轴的设计与计算 39

5.2.1 全浮式半轴的计算载荷的确定 39

5.2.2 半轴杆部直径的初选 41

5.2.3 全浮式半轴强度计算 41

5.2.4 全浮式半轴花键强度计算 42

5.3 半轴材料与热处理 43

5.4 本章小结 43

第6章 驱动桥桥壳的设计 44

6.1 概述 44

6.2 桥壳的受力分析及强度计算 44

6.2.1 桥壳的静弯曲应力计算 44

6.2.2 在不平路面冲击载荷作用下桥壳的强度 46

6.2.3 汽车以最大牵引力行驶时的桥壳的强度计算 46

6.2.4 汽车紧急制动时的桥壳强度计算 48

6.2.5 汽车受最大侧向力时桥壳强度计算 49

6.3 本章小结 52

结论 53

参考文献 54

致谢 55