设计简介

摘 要

载重汽车后桥(驱动桥)作为汽车四大总成之一,它承载着载重汽车的满载荷负重及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;后桥(驱动桥)还传递着传动系中的最大转矩,桥壳还承受着反作用力矩。汽车驱动桥结构型式和设计参数除对汽车的可靠性与耐久性有重要影响外,也对汽车的行驶性能如动力性、经济性、平顺性、通过性、机动性和操动稳定性等有直接影响。为满足目前当前载货汽车的快速、高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。

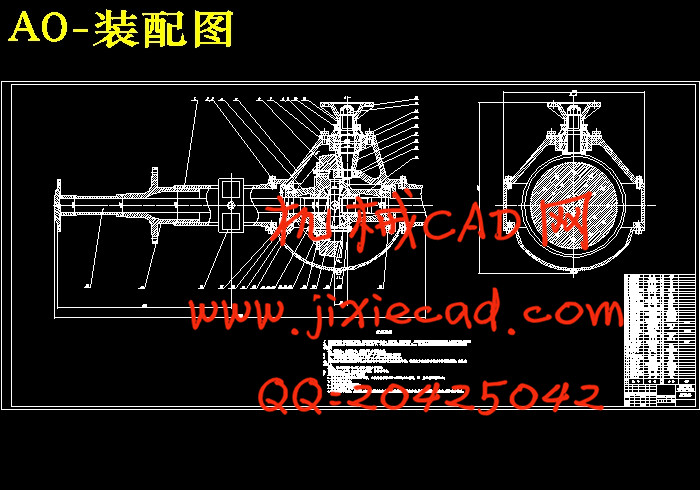

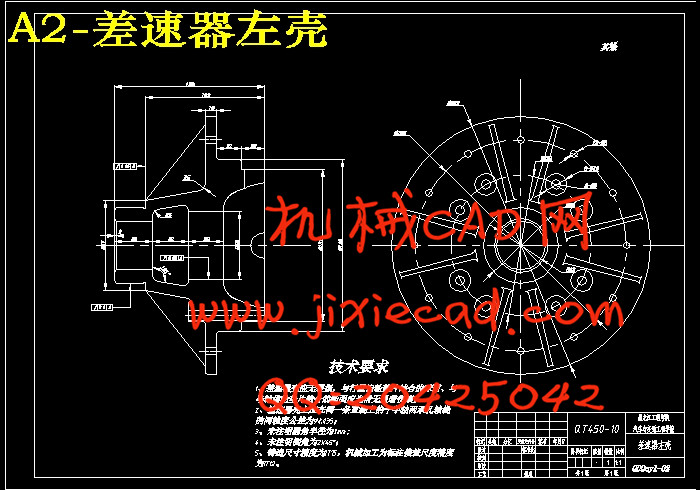

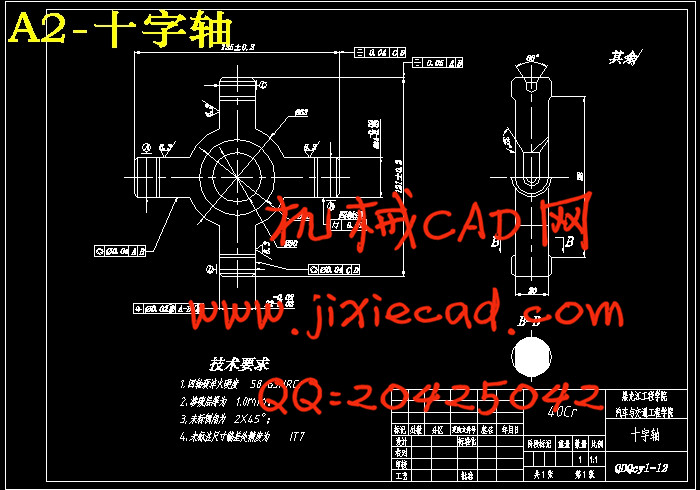

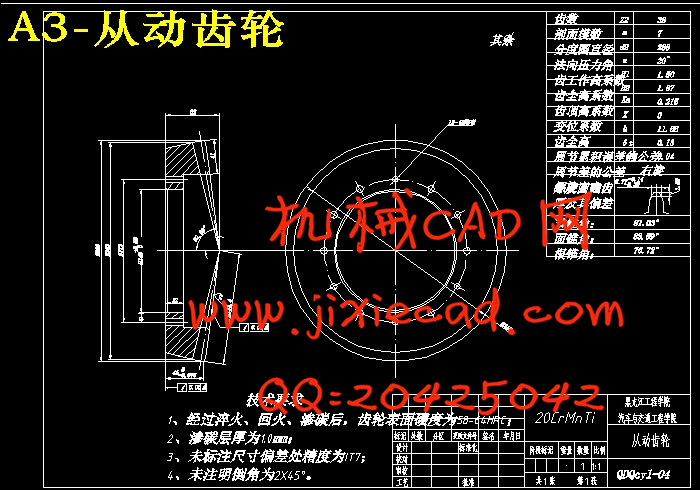

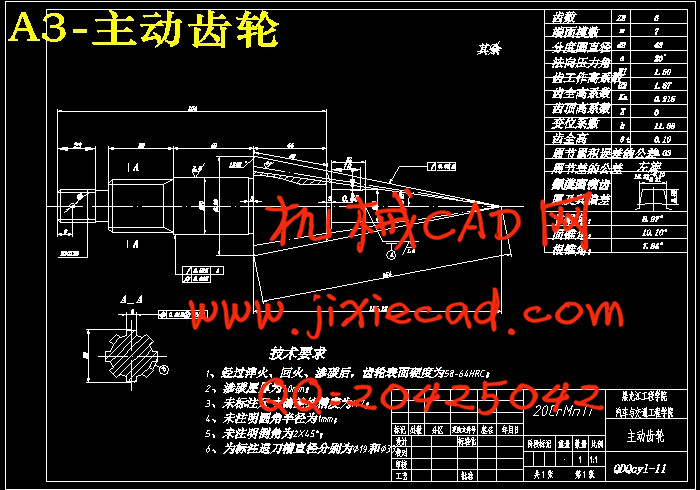

本文参照传统驱动桥的设计方法进行了载重汽车驱动桥的设计。希望做到结构简单、工作可靠、造价低廉的效果。本文首先通过设计参数确定主要部件的结构型式;然后参考类似驱动桥的结构,确定出总体设计方案;如驱动桥的结构型式按工作特性分为两大类,最后选取非断开式驱动桥。主减速器结构形式选取机械传动效率高,易损件减少,可靠性增加的单级主减速器。差速器结构形式选择广泛应用的对称式圆锥行星齿轮差速器。最后对主、从动锥齿轮、半轴齿轮和全浮式半轴强度进行校核以及对支承轴承进行了寿命校核。

关键词:载重汽车;后桥;主减速器;差速器;半轴;齿轮

ABSTRACT

Load truck driving axle (driving axle) as one of the four big car assembly, it carries with heavy trucks full of load weight and ground the wheel, frame, and monocoque body the suspension of the lead to vertical force, longitudinal force, transverse force and torque, and impact load; Driving axle (driving axle) also passed the transmission of the maximum torque, bridge is under adverse effect moment shell. Car driving axle structure and design parameters in addition to the reliability of the automobile and durability has a significant effect on the outside, also for the automobile driving performance such as power, economy, smooth, through the sex, mobility and exercise has a direct impact on the dynamic stability, etc. At present the current commercial vehicles to meet the rapid, high efficiency, high benefit when need, must want to match a more efficient and reliable driving axle.

In this paper the design method of the traditional reference to drive the car driving axle load of the design. Hope to do simple structure, reliable operation, low in cost effect. This paper first through the design parameter determination of the main parts of structural type; Then the structure of the reference similar thing, to determine the overall design project; Such as the structural type thing according to work characteristics into two categories, the last thing the broken off selection. The Lord reducer structure form selection machine of high transmission efficiency, reduce the increase reliability, vulnerable single stage Lord reducer. Differential structure choose widely used symmetric cone of planetary gear differential. Finally, driven to the bevel gear and half axle gear and all the serving the half shaft test of strength and the supporting bearing life respectively.

Key words: Truck;Rear axle;The Lord reducer;Differential;Half shaft;gear

目 录

摘要 I载重汽车后桥(驱动桥)作为汽车四大总成之一,它承载着载重汽车的满载荷负重及地面经车轮、车架及承载式车身经悬架给予的铅垂力、纵向力、横向力及其力矩,以及冲击载荷;后桥(驱动桥)还传递着传动系中的最大转矩,桥壳还承受着反作用力矩。汽车驱动桥结构型式和设计参数除对汽车的可靠性与耐久性有重要影响外,也对汽车的行驶性能如动力性、经济性、平顺性、通过性、机动性和操动稳定性等有直接影响。为满足目前当前载货汽车的快速、高效率、高效益的需要时,必须要搭配一个高效、可靠的驱动桥。

本文参照传统驱动桥的设计方法进行了载重汽车驱动桥的设计。希望做到结构简单、工作可靠、造价低廉的效果。本文首先通过设计参数确定主要部件的结构型式;然后参考类似驱动桥的结构,确定出总体设计方案;如驱动桥的结构型式按工作特性分为两大类,最后选取非断开式驱动桥。主减速器结构形式选取机械传动效率高,易损件减少,可靠性增加的单级主减速器。差速器结构形式选择广泛应用的对称式圆锥行星齿轮差速器。最后对主、从动锥齿轮、半轴齿轮和全浮式半轴强度进行校核以及对支承轴承进行了寿命校核。

关键词:载重汽车;后桥;主减速器;差速器;半轴;齿轮

ABSTRACT

Load truck driving axle (driving axle) as one of the four big car assembly, it carries with heavy trucks full of load weight and ground the wheel, frame, and monocoque body the suspension of the lead to vertical force, longitudinal force, transverse force and torque, and impact load; Driving axle (driving axle) also passed the transmission of the maximum torque, bridge is under adverse effect moment shell. Car driving axle structure and design parameters in addition to the reliability of the automobile and durability has a significant effect on the outside, also for the automobile driving performance such as power, economy, smooth, through the sex, mobility and exercise has a direct impact on the dynamic stability, etc. At present the current commercial vehicles to meet the rapid, high efficiency, high benefit when need, must want to match a more efficient and reliable driving axle.

In this paper the design method of the traditional reference to drive the car driving axle load of the design. Hope to do simple structure, reliable operation, low in cost effect. This paper first through the design parameter determination of the main parts of structural type; Then the structure of the reference similar thing, to determine the overall design project; Such as the structural type thing according to work characteristics into two categories, the last thing the broken off selection. The Lord reducer structure form selection machine of high transmission efficiency, reduce the increase reliability, vulnerable single stage Lord reducer. Differential structure choose widely used symmetric cone of planetary gear differential. Finally, driven to the bevel gear and half axle gear and all the serving the half shaft test of strength and the supporting bearing life respectively.

Key words: Truck;Rear axle;The Lord reducer;Differential;Half shaft;gear

目 录

Abstract II

第1章 绪论 1

1.1 课题研究的目的与意义 1

1.2 课题的国内外驱动桥研究状况和发展趋势 2

1.3 设计的主要内容与技术路线 5

第2章 驱动桥的总体方案确定 7

2.1 非断开式驱动桥 7

2.2 断开式驱动桥 8

2.3 多桥驱动的布置 8

2.4 本章小结 9

第3章 主减速器设计 10

3.1 主减速器结构方案分析 10

3.1.1 主减速器的齿轮类型 10

3.1.2 结构形式 11

3.2 主减速器主从动锥齿轮的支承方案 12

3.2.1 主动锥齿轮的支承 13

3.2.2 从动锥齿轮的支承 13

3.3 主减速器的基本参数的选择与设计计算 13

3.3.1 主减速器计算载荷的确定 13

3.3.2 主减速器齿轮参数的选择 15

3.4 主减速器圆弧锥齿轮的强度计算 19

3.4.1 损坏形式及寿命 19

3.4.2 主减速器螺旋锥齿轮的强度计算 21

3.5 主减速器齿轮的材料及热处理 24

3.6 主减速器轴承计算 25

3.6.1 作用在主减速器主动齿轮上的力 25

3.6.2 主减速器轴承载荷的计算 28

3.7 主减速器的润滑 31

3.8 本章小结 31

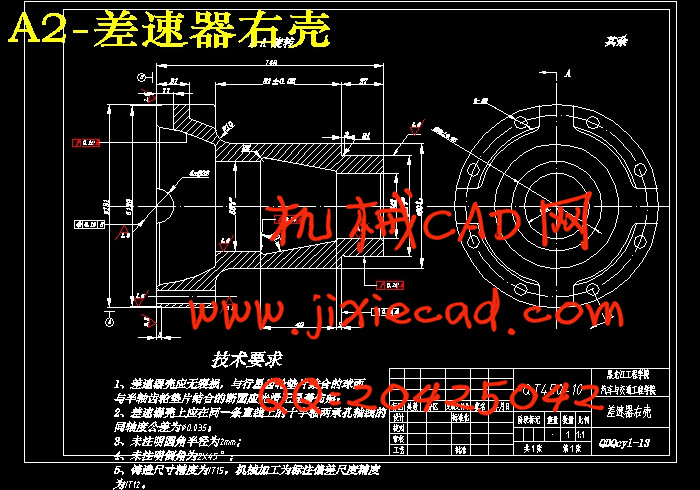

第4章 差速器设计 32

4.1 差速器结构形式选择 32

4.2 对称式圆锥行星齿轮差速器原理 33

4.3差速器齿轮的基本参数选择 34

4.3.1 差速器齿轮的基本参数选择 34

4.3.2 差速器齿轮的几何尺寸计算 36

4.4差速器齿轮的强度计算 38

4.5差速器齿轮材料 39

4.6 本章小结 39

第5章 半轴设计 40

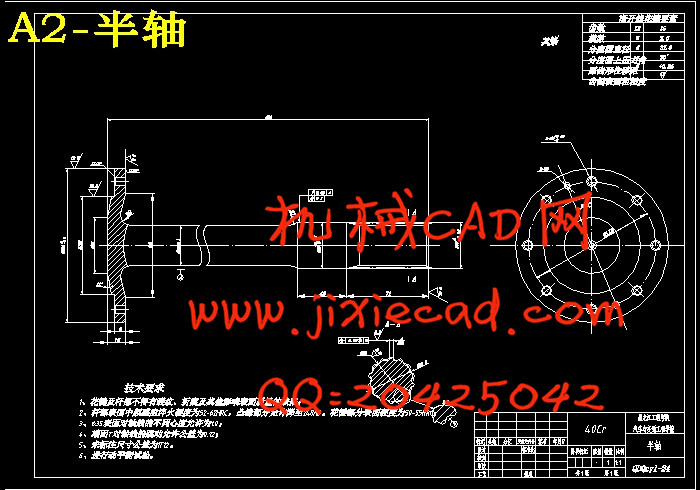

5.1 半轴的设计与计算 40

5.1.1 全浮式半轴的计算载荷的确定 40

5.1.2 全浮式半轴杆部直径的初选 42

5.1.3 全浮式半轴强度计算 42

5.1.4 全浮式半轴花键强度计算 43

5.2 半轴材料与热处理 44

5.3 本章小结 44

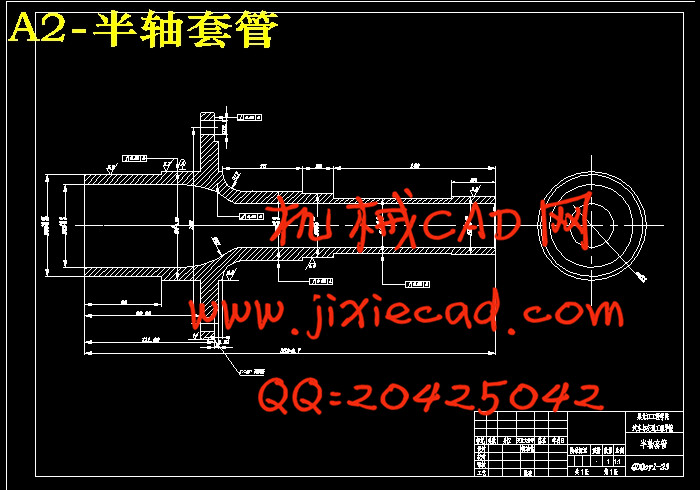

第6章 驱动桥桥壳设计 46

6.1 概述 46

6.2 桥壳的受力分析及强度计算 46

6.2.1 桥壳的静弯曲应力计算 46

6.2.2 在不平路面冲击载荷作用下桥壳的强度 48

6.2.3 汽车以最大牵引力行驶时的桥壳的强度计算 48

6.2.4 汽车紧急制动时的桥壳强度计算 50

6.2.5 汽车受最大侧向力时桥壳强度计算 51

6.3 本章小结 54

结论 55

参考文献 56

致谢 57