设计简介

变速器用来改变发动机传到驱动轮上的转矩和转速,是汽车总成部件中的重要组成部分,是主要的传动系统。变速器的结构要求对汽车的动力性、燃料经济性、换档操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响。

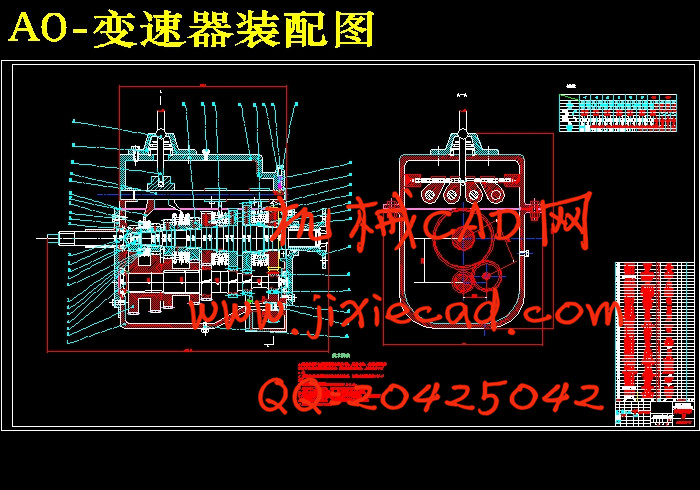

三轴式变速器由于具有体积小、原理简单、工作可靠、操纵方便等优点,故在大多数汽车中广泛应用。本文设计研究了三轴式五档手动变速器,其目的主要是基于对机械原理、机械设计、AutoCAD等知识的熟练运用和掌握,同时运用汽车构造、汽车设计、材料力学、互换性测量等学科知识,对三轴式变速器的各部件进行设计,并利用AutoCAD软件绘制装配图和零件图等六项内容。首先,本文将概述变速器的现状和发展趋势,介绍变速器领域的最新发展状况。其次,对工作原理做了阐述,对不同的变速器传动方案进行比较,选择合理的结构方案进行设计。再次,对变速器的各档齿轮和轴以及轴承做了详细的设计计算,并进行了受力分析、强度和刚度校核计算,并为为这些元件选择合适的工程材料及热处理方法。对一些标准件进行了选型以及变速器的传动方案设计。简单讲述了变速器中各部件材料的选择。最后,本文将对变速器换档过程中的重要部件—同步器以及操纵机构进行阐述,讲述同步器的类型、工作原理、选择方法以及重要参数。

关键词:变速器;传动比;轴;齿轮;设计计算;校核

ABSTRACT

Transmission to change the engine reached on the driving wheel torque and speed, Automotive transmission parts in the automobile assembly of an important part of the main drive system. Transmission of the power structure of the vehicle, economy, manipulation of the reliability and portability, the smooth drive and have a direct impact on efficiency.

Three-shaft transmission is widely used most vehicle for its particular advantages ,such as small dimension ,simply theory ,good stability, conveniently operation .This design study of the three-axis 5-speed manual transmission, the purpose is based on the skillful of using mechanic theory ,mechanic design, AutoCAD. Meanwhile, my paper is incorporated structure of vehicle, design of vehicle, mechanic of materials, and survey of interchangeability. I will design the parts of three-shaft transmission, and using Auto CAD software, drawing assembly drawings and parts diagrams of five elements. At the same time the use of vehicle construction, automotive design, material mechanics, interchangeability of measurement knowledge of the subjects on the three-axis gearbox design file 12.At first, I will give a summary of the current situation and the tendency of development of the vehicle transmission, and introduce the latest development state in the field of the transmission.The second, I will compare the transmitting scheme of different transmission, and choose a better structure scheme.Next, I will do some mechanic analyses, strength, stiffness check of the shafts and gears, which are the important parts of the transmission, and choose appropriate materials and heat treatment.At last, I will introduce the operation mechanism and the synchronizer, which plays an important role in changing gear. I will give an account of the type, operation, design procedure and major parameter of the synchronizer.

Key words: Transmission;Transmission Ratio;Shaft;Gear;Design and Calculation;Checking

目 录

三轴式变速器由于具有体积小、原理简单、工作可靠、操纵方便等优点,故在大多数汽车中广泛应用。本文设计研究了三轴式五档手动变速器,其目的主要是基于对机械原理、机械设计、AutoCAD等知识的熟练运用和掌握,同时运用汽车构造、汽车设计、材料力学、互换性测量等学科知识,对三轴式变速器的各部件进行设计,并利用AutoCAD软件绘制装配图和零件图等六项内容。首先,本文将概述变速器的现状和发展趋势,介绍变速器领域的最新发展状况。其次,对工作原理做了阐述,对不同的变速器传动方案进行比较,选择合理的结构方案进行设计。再次,对变速器的各档齿轮和轴以及轴承做了详细的设计计算,并进行了受力分析、强度和刚度校核计算,并为为这些元件选择合适的工程材料及热处理方法。对一些标准件进行了选型以及变速器的传动方案设计。简单讲述了变速器中各部件材料的选择。最后,本文将对变速器换档过程中的重要部件—同步器以及操纵机构进行阐述,讲述同步器的类型、工作原理、选择方法以及重要参数。

关键词:变速器;传动比;轴;齿轮;设计计算;校核

ABSTRACT

Transmission to change the engine reached on the driving wheel torque and speed, Automotive transmission parts in the automobile assembly of an important part of the main drive system. Transmission of the power structure of the vehicle, economy, manipulation of the reliability and portability, the smooth drive and have a direct impact on efficiency.

Three-shaft transmission is widely used most vehicle for its particular advantages ,such as small dimension ,simply theory ,good stability, conveniently operation .This design study of the three-axis 5-speed manual transmission, the purpose is based on the skillful of using mechanic theory ,mechanic design, AutoCAD. Meanwhile, my paper is incorporated structure of vehicle, design of vehicle, mechanic of materials, and survey of interchangeability. I will design the parts of three-shaft transmission, and using Auto CAD software, drawing assembly drawings and parts diagrams of five elements. At the same time the use of vehicle construction, automotive design, material mechanics, interchangeability of measurement knowledge of the subjects on the three-axis gearbox design file 12.At first, I will give a summary of the current situation and the tendency of development of the vehicle transmission, and introduce the latest development state in the field of the transmission.The second, I will compare the transmitting scheme of different transmission, and choose a better structure scheme.Next, I will do some mechanic analyses, strength, stiffness check of the shafts and gears, which are the important parts of the transmission, and choose appropriate materials and heat treatment.At last, I will introduce the operation mechanism and the synchronizer, which plays an important role in changing gear. I will give an account of the type, operation, design procedure and major parameter of the synchronizer.

Key words: Transmission;Transmission Ratio;Shaft;Gear;Design and Calculation;Checking

目 录

摘要 I

Abstract II

第1章 绪论 1

1.1汽车变速器的概述 1

1.2汽车变速器研究状况、发展趋势及成果 1

1.2.1研究现状 1

1.2.2设计目的意义 2

1.2.3汽车变速器发展趋势 2

1.3汽车变速器的设计方法和研究内容 3

1.3.1变速器设计的主要内容 3

第2章 变速器传动机构布置方案 5

2.1变速器的选择 5

2.1.1结构工艺性 5

2.1.2变速器的径向尺寸 5

2.1.3变速器齿轮的寿命 5

2.1.4变速器的传动效率 5

2.2 倒挡布置方案 5

2.3 零、部件结构方案分析 6

2.3.1齿轮形式 6

2.3.2换挡机构形式 7

2.3.3自动脱挡 7

2.4本章小结 8

第3章 变速器主要参数的选择 9

3.1概述 9

3.2挡数 9

3.3传动比范围 9

3.4变速器各档传动比的确定 9

3.5中心距A 11

3.6变速器的齿轮参数的确定 12

3.6.1齿轮模数 12

3.6.2压力角 12

3.6.3螺旋角 13

3.6.4齿宽 13

3.6.5齿顶高系数 13

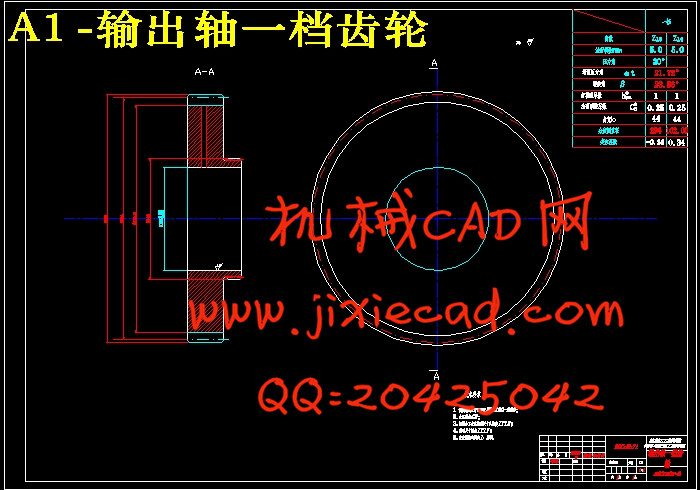

3.7变速器各档齿轮齿数的分配 14

3.7.1确定一挡齿轮的齿数 14

3.7.2确定常啮合挡齿轮的齿数 16

3.7.3确定其他各档的齿数 19

3.8本章小结 32

第4章 齿轮校核 45

4.1 齿轮材料的选择原则 45

4.2计算各轴的转矩 33

4.3齿轮的强度计算 34

4.3.1轮齿的弯曲应力计算 34

4.3.2轮齿接触应力计算 39

4.4本章小结 44

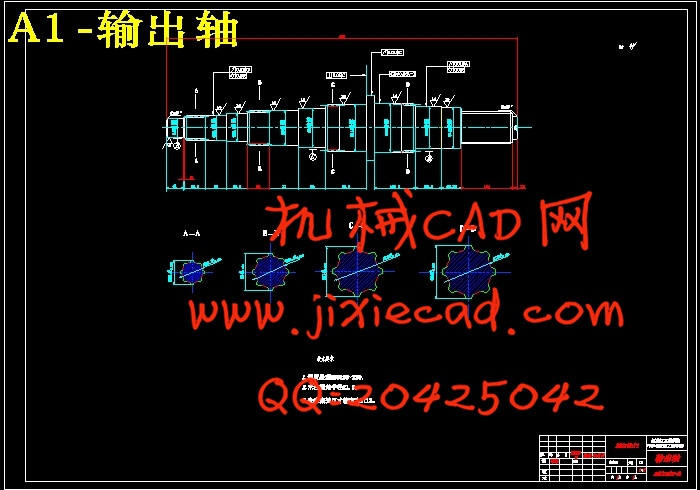

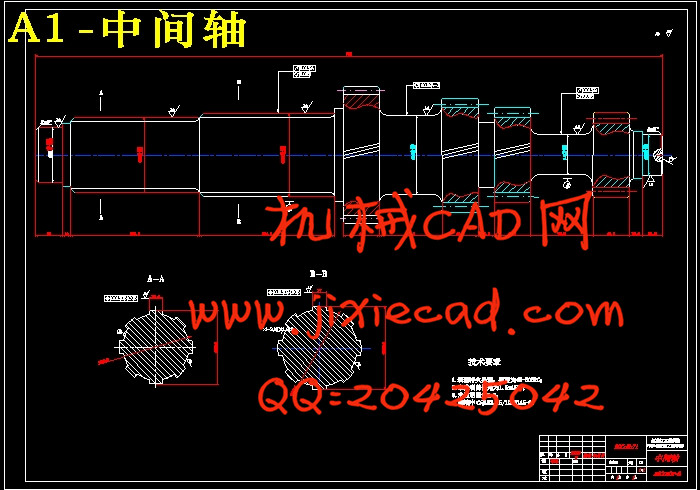

第5章 变速器轴和轴承的设计及校核 45

5.1变速器的轴径和轴长设计计算 45

5.2变速器轴的强度计算 46

5.2.1齿轮上的受力计算 46

5.2.2轴的强度计算 49

5.2.3轴的刚度计算 51

5.3轴承的选择和校核 53

5.3.1输出轴轴承的选择和校核 53

5.3.2中间轴轴承的选择和校核 54

5.4本章小结 55

第6章 同步器和操纵机构的设计及选用 56

6.1同步器的设计 56

6.1.1锁销式同步器 56

6.1.2锁环式同步器 57

6.1.3同步器主要尺寸的确定 58

6.1.4同步器主要参数的确定 61

6.2变速器操纵机构的设计 63

6.2.1变速器操纵机构的要求及分类 63

6.2.2变速器操纵机构分析 64

6.3变速器箱体的设计 65

6.4本章小结 66

第7章 输出轴的有限元静力学分析 67

7.1 ANSYS软件简介 67

7.2 Pro/E和ANSYS接口的创建 67

7.3利用ANSYS对输出轴进行有限元受力分析 69

7.4输出轴有限元受力分析 69

7.4.1第一档、倒挡花键有限元受力分析 71

7.4.2第二档、三档花键有限元受力分析 73

7.4.3第四档、五档花键有限元受力分析 75

7.4.4第六档、常啮合档花键有限元受力分析 77

7.5本章小结 80

结论 81

致谢 83

参考文献 82