设计简介

摘 要

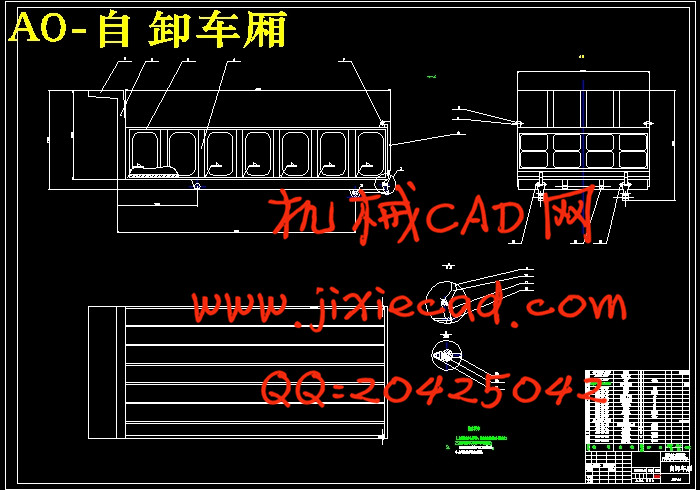

本次设计的题目是HGC3110自卸车设计。该自卸汽车是以CA1123P9K2L4E型货车底盘改装,自卸车近几十年来它在国内外获得迅速的发展与普及,它最大的优点是实现了卸货的机械化,从而提高卸货效率。不仅可以减轻工人劳动强度,还可以促进国家的经济建设速度,关系到国家重点建设项目的建设和发展。同时在自卸车研究和生产过程中,也带动了钢铁,化工等其它很多行业,又提供了大量的工作岗位,减轻就业压力,并日趋完善,成为系列化多品种的产品。因此,自卸车的发展是很有必要的。

所以本文以HGC3110型自卸车为设计题目,设计的主要内容有以下几个方面:确定HGC3110型自卸车的总体设计方案、对举升机构结构进行设计及其力学分析、对液压系统的设计、对车厢的结构及副车架的设计、对HGC3110型自卸车进行整车性能分析。最后所设计出来的自卸车能够承载5.5吨的货物,举升时间为15s的一款自卸车。

关键词:系统;车厢;液压;设计;分析;机械化;自卸车;举升;

ABSTRACT

The design is the subject of the design modifications and HGC3110-type dump truck. CA1123P9K2L4E Dump Truck is the truck-based chassis modification, HGC3110-type dump truck at home and abroad in recent decades it was the rapid development and popularity of its greatest strengths is to achieve a discharge of mechanization, thereby enhancing the discharge efficiency. Not only can reduce the labor intensity of workers, but also to promote the country's economic construction speed, related to the key national construction projects, building and development. At the same time, research and production in the dump truck has also led the iron and steel, chemical, and other many industries, but also provide a large number of jobs and reduce the employment pressure, and gradually maturing as a series of product variety. Therefore, the development of dump truck is necessary.

Therefore, this paper HGC3110-Type dump truck for the design of the subject, the main elements of design are as follows: HGC3110-type dump truck to determine the overall design program. On the lifting body structure design and mechanical analysis. The design of the hydraulic system. The structure of the compartments and sub-frame design. HGC3110 type of dump truck for vehicle performance analysis. The last designed by the dump truck can carry5.5 tons of goods, lifting time of a dump truck for the 15s.

Keywords: System;Carriage;Hydraulic;Desig;Analyse;Mechanization;Type tipper;Lifting

目 录

摘要......................................................................................................................................I

Abstract................................................................................................................................II

第1章 绪论.......................................................................................................................1

1.1课题的提出................................................................................................................1

1.2课题来源及研究意义................................................................................................1

1.3 自卸车国内外研究概况...........................................................................................2

1.3. 1国外研究发展概况 2

1.3.2国内研究发展概况 4

1.4研究的内容 5

第2章 整车参数的确定及车厢的设计 6

2.1质量参数的确定 6

2.2总体方案设计 6

2.3举升车厢形式的选择 7

2.4车厢的选材 9

2.5车厢的设计规范及尺寸确定 9

2.6车厢锁止机构的选择与设计 11

2.7本章小结 12

第3章 液压举升机构的设计 13

3.1液压举升机构应满足的性能 13

3.2举升系统性能主要评价参数 14

3.3液压举升机构参数的选择与确定 15

3.3.1液压举升机构简述 15

3.3.2液压举升机构方案的选择 17

3.4举升机构几何尺寸的确定 18

3.4.1车厢与副梁铰支点O的确定 19

3.4.2车厢放平时举升机构与车厢前铰支点A0的确定 19

3.4.3液压油缸与副梁铰支点的确定 19

3.4.4车厢放平时三角臂中支点C0座标和A0C0长度的确定 20

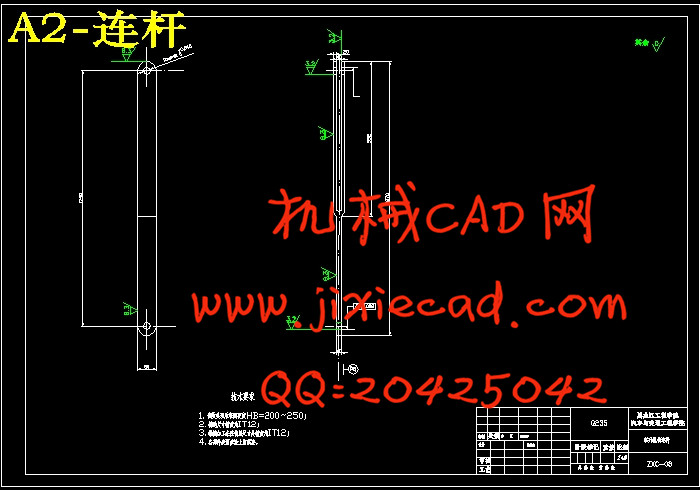

3.4.5车厢放平时拉杆与三角臂铰接点B0的确定 20

3.4.6拉杆与副梁铰接点D及拉杆长度的确定 20

3.5 举升机构力学分析 20

3.5.1举升机构参数的计算及校核 21

3.5.2拉杆截面尺寸的确定 22

3.6液压系统设计与计算 23

3.6.1液压油缸性能参数计算 23

3.6.2液压泵性能参数计算 23

3.6.3油箱容积与油管内径计算 25

3.6.4系统压力校核 26

3.6.5车厢升降时间的校核 26

3.6.6方向控制阀的选型 27

3.6.7操纵方式的选择 27

3.6.8液压系统原理 27

3.6.9取力器的选择 28

3.6.10本章小结 29

第4章 副车架的设计 30

4.1选用的底盘主车架的主要尺寸 30

4.2副车架的结构设计 30

4.2.1副车架的外形 30

4.2.2副车架的选材 31

4.2.3副车架的截面形状 31

4.2.4加强板的布置 32

4.2.5副车架的前端形状及安装位置 32

4.2.6纵梁与横梁的连接设计 34

4.3 副车架与主车架的连接设计 35

4.4 副车架尺寸的确定 36

4.5 副车架的强度刚度弯曲适应性校核 36

4.6 本章小结 42

第5章 整车性能分析...................................................................................................43

5.1 概述.......................................................................................................................43

5.2 汽车动力性能分析...............................................................................................43

5.2.1 基本参数确定..............................................................................................43

5.2.2汽车的行驶方程式.......................................................................................44

5.2.3汽车最高车速确定.......................................................................................47

5.3 燃油经济性计算...................................................................................................49

5.4 整车稳定性分析...................................................................................................50

5.4.1稳定性分析内容...........................................................................................50

5.4.2空载质心高度计算.......................................................................................50

5.4.3空载侧倾角计算...........................................................................................50

5.4.4最小转弯直径计算.......................................................................................51

5.5 本章小结...............................................................................................................52

结论 53

参考文献 54

致谢 55