设计简介

摘

万向传动装置是汽车传动系统中的重要组成部分,万向传动装置位于变速箱和驱动桥之间,一般由万向节、传动轴和中间支承组成。万向节能实现变角度动力传递;传动轴把变速器的转矩传递到驱动桥上;中间支承能补偿传动轴轴向和角度方向的安装误差和车辆行驶过程中由于发动机窜动或车架等变形所引起的位移。万向传动装置的功用是在汽车行驶过程中,在轴间夹角及相互位置经常发生变化的两个转轴之间传递动力。本文主要是对汽车的十字轴式万向传动装置进行设计。根据车辆使用条件和车辆参数,按照传动系统的设计步骤和要求,主要进行了以下工作:选择相关设计参数主要为:十字轴、万向节、传动轴、中间支承的参数确定,并进行了总成设计主要为:十字轴的设计,万向节的设计、传动轴的设计以及中间支承的设计等。并通过Pro/E建模和有限元ANSYS软件对设计万向传动装置进行结构分析,根据分析结果对万向传动装置进行改进设计得出合理的设计方案。

关键词:万向传动装置;十字轴;万向节;传动轴;有限元分析

Abstract

The automobile universal transmission device is in the automobile transmission system important constituent,is located between the gear box and the driving axle . Generally by the universal joint, the drive shaft and the middle supporting is composed. The universal joint energy conservation realization changes the angle power transmission;Transmit the torque of the gear box to the transaxle with drive shaft;The middle supporting can compensate the drive shaft axial and the angle direction in the wiring error and the vehicles travel process because the engine flees moves the displacement which or distortions and so on frame causes. The rotary transmission device function is in the automobile travel process, the included angle and the mutual position changes between the revolution axis in the axis between to transmit the power frequently.

This article mainly is carries on the design to the automobile cross shaft type rotary transmission device. According to vehicles exploitation conditions and vehicles parameter, according to transmission system design procedure and request, Mainly has carried on following work: Mainly has carried on following work choice correlation design variable mainly is: Cross axle, universal joint, drive shaft, middle supporting parameter determination, and has carried on the unit design mainly is: Cross axle design, universal joint design, drive shaft design as well as middle supporting design and so on. And to designs the rotary transmission device through the finite element Pro/E and ANSYS software to carry on the structure analysis, Carries on the improvement design according to the analysis result to the rotary transmission device to obtain the reasonable design proposal.

Keywords: Universal Transmission Device; Cross Axle; Universal Joint; Transmission shaft; Finite Element Analysis

目 录

摘要 I

Abstract II

第1章 绪 论 1

1.1 概 述 1

1.2汽车传动轴的国内外研究现状 2

1.3研究汽车万向传动轴的目的和意义 3

1.3.1研究汽车万向传动轴的目的 3

1.3.2研究汽车传动轴的意义 3

1.4 万向传动轴的结构特点及基本要求 4

1.5本课题研究的主要内容 5

第2章 汽车传动轴的结构方案分析与选择 7

2.1汽车传动轴的结构方案概述 7

2.1.1万向节与传动轴的结构型式 7

2.1.2传动轴管、伸缩花键及中间支承结构型式 7

2.1.3万向节类型 10

2.2传动轴设计方案 12

2.3本章小结 13

第3章 万向传动轴的设计 14

3.1HGC1050汽车的主要技术参数 14

3.2传动轴总成设计计算及校核 15

3.2.1传动轴计算载荷的确定 15

3.2.2传动轴轴管的选择及校核 16

3.2.3中间支承的结构设计 21

3.3十字轴总成的设计计算及校核 24

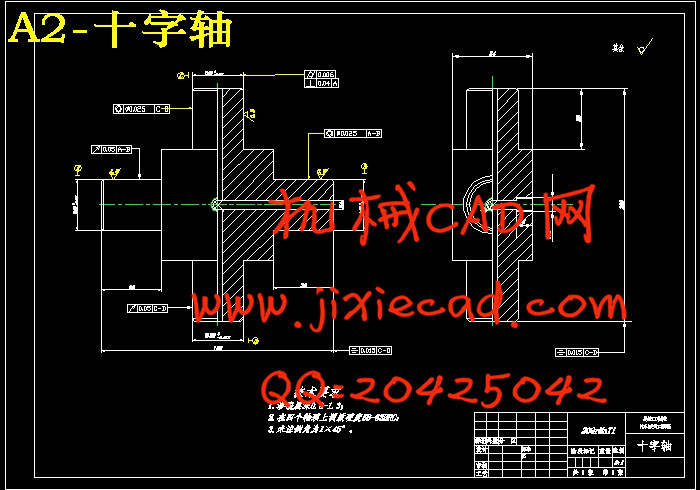

3.3.1万向节的受力分析 24

3.3.2十字轴万向节的设计及校核 26

3.3.3十字轴滚针轴承的校核 27

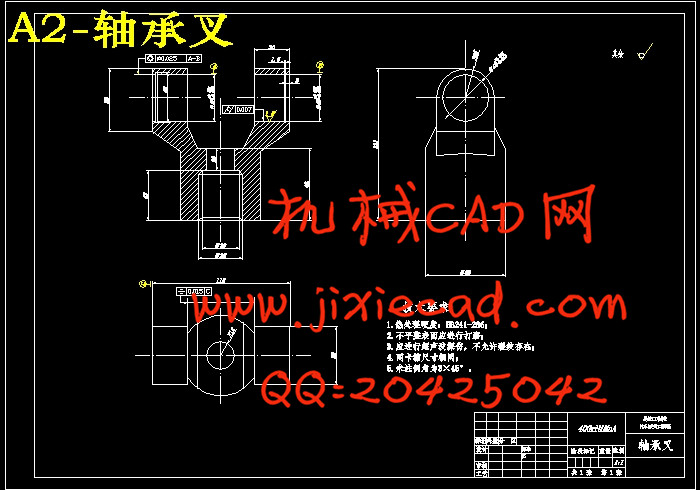

3.3.4万向节叉的设计及校核 28

第4章 传动轴总成建模与装配 30

4.1 Pro/ENGINEER软件简介 30

4.2利用Pro/ENGINEER软件进行三维实体建模 31

4.2.1十字轴的创建 31

4.2.2凸缘叉的创建 31

4.2.3轴承差的创建 32

4.2.4传动轴管的创建 32

4.2.5带花键的传动轴管的创建 33

第5章 万向传动装置的有限元静力学分析 34

5.1 ANSYS软件简介 34

5.2Pro/E与ANSYS接口的创建 34

5.3利用ANSYS对望向传动装置进行有限元受力分析 36

5.3.1十字轴有限元受力分析 36

5.3.2凸缘叉有限元受力分析 40

5.3.3传动轴有限元受力分析 41

5.4本章小结 42

结 论 43

参考文献 44

致 谢 45